New Council established to protect steelmaking in the UK

Professor David GreenwoodLink opens in a new window, CEO of the High Value Manufacturing Catapult at WMG, comments on the newly established UK Steel Council.

Professor David GreenwoodLink opens in a new window, CEO of the High Value Manufacturing Catapult at WMG, comments on the newly established UK Steel Council.

“The establishment of the Steel Council marks a turning point in the narrative of the UK steel industry as it transitions to a clean, green, digitalised future.

“To succeed, government, industry, trade unions and research bodies must work together to deliver a long-term strategy encompassing policy; technology; skills; supply chains, and regions.

“WMG, as a centre of the High Value Manufacturing Catapult, is delighted to contribute to the success of the Council and help to secure the future of the UK steel industry.”

WMG Professors become Fellows of the Royal Academy of Engineering

Two Professors at WMG at the University of Warwick have been elected as Fellows of the prestigious Royal Academy of EngineeringLink opens in a new window.

Professor Claire DavisLink opens in a new window, Head of Advanced Steel Research Centre; and Professor Mark WilliamsLink opens in a new window, Head of the Metrology and Visualisation Research Group, at WMG, have been elected as part of a group of 71 leading figures in the field of engineering and technology.

WMG, have been elected as part of a group of 71 leading figures in the field of engineering and technology.

The group consists of 60 Fellows, six International Fellows and five Honorary Fellows, each of whom has made exceptional contributions to their own sector.

Each Fellow has been involved in pioneering new innovations, leading progress in business or academia, providing high level advice to government, or promoting wider understanding of engineering and technology.

The new Fellows will be formally admitted to the Academy at a special ceremony in London on 27 November, when each Fellow will sign the roll book.

In joining the Fellowship, they will lend their unique capabilities to achieving the Academy’s overarching strategic goal to harness the power of engineering to create a sustainable society and an inclusive economy for all.

Professor Davis said: “I am very honoured to have been elected a Fellow of the Royal Academy of Engineering. It is an exciting and dynamic time for the global steel industry and I look forward to working with the Royal Academy in promoting clean technologies for the future.”

Professor Davis said: “I am very honoured to have been elected a Fellow of the Royal Academy of Engineering. It is an exciting and dynamic time for the global steel industry and I look forward to working with the Royal Academy in promoting clean technologies for the future.”

Professor Mark Williams said: “I’m honoured to be elected as a Fellow of the Royal Academy of Engineering and am extremely grateful to colleagues across the country who have seen fit to elect me.

“It’s a long way from my time as an apprentice to the Royal Academy. I’d like to thank my colleagues at Warwick who have supported me over my career here and look forward to working with the other Fellows.”

Dr John Lazar CBE FREng, President of the Royal Academy of Engineering, says: “Our new Fellows represent some of the most talented people in the world of engineering and are taken from the ranks of those who are aiming to address some of our most critical problems.

“We are proud to say that many of our newly elected Fellows have come from underrepresented groups in engineering and related sectors and we hope this helps to tackle some of the issues around a lack of diversity within the profession.

“There is ample evidence that a wider pool of ideas and experiences helps to improve decision-making and develop novel solutions to global challenges.”

See the complete list of Fellows elected here: Royal Academy of Engineering Fellows 2024 (raeng.org.uk)Link opens in a new window

WMG welcomes representatives from the Steel All-Party Parliamentary Group

It was an honour to welcome Stephen Kinnock MP and Jessica Morden MP, Chair and Vice Chair respectively, of the Steel All-Party Parliamentary Group (APPG), to WMG at the University of Warwick this week.

of Warwick this week.

The guests were met by Professor Claire Davis and Dr Russell Hall from the Advanced Steel Research Centre, and Dean of WMG, Professor Robin Clark.

They enjoyed a tour of the Advanced Materials and Manufacturing Centre (AMMC), home to WMG’s world-class steels research facilities, where they heard more about WMG’s work to support the steel industry including the importance of green steel production for a sustainable future.

Stephen Kinnock MP Chair of the Steel APPG and Jessica Morden MPVice Chair of the Steel APPG commented: “It was great to visit Claire Davis and her team at WMG's Advanced Materials Manufacturing Centre to see for ourselves the industrial research and development they're working on with the UK Steel sector, including cutting the cost of developing new steel alloys, deploying alternative fuels for green steel production or converting scrap steel to high value products.

“Innovation has a crucial role in improving the quality of UK steel production, reducing energy costs and making UK steel sustainable and it was heartening to see academics and industry working together on these critical issues for the future of UK steel, which is so important for our country."

Professor Claire Davis said: “Stephen and Jess were really interested in hearing about the work we do in the Advanced Steel Research Centre. It was great to show them examples of our fundamental and applied research supporting the development of new steel processing and alloys, and the impact it has for the UK steel industry. It is a very exciting, and challenging time to be working on steel due to the pace of change as we move to green steel production.”

Find out more about WMG’s Steels Processing research here: Steels processing (warwick.ac.uk)

UK closer to net-zero steel thanks to new WMG and Tata Steel partnership

More sustainable, low-carbon steel and electric vehicle batteries are the target of a new two-year technology development programme between WMG at the University of Warwick and Tata Steel, as part of the High Value Manufacturing Catapult.

University of Warwick and Tata Steel, as part of the High Value Manufacturing Catapult.

The two major partners will come together to focus on developing new environmentally-friendly steel grades, coatings, films, and battery structures – enabling the growth of steel application across key industrial sectors as the UK advances towards a net-zero future.

This partnership builds on the long-standing relationship between both parties and will see them collaborate to make steel cleaner, greener and more responsive to the fast-changing needs of customers across a variety of sectors.

Researchers, led by Professor Claire Davis, at WMG, University of Warwick, will be working alongside experts at Tata Steel in the UK to translate and apply outputs from the early-stage research across key UK manufacturing priority areas including advanced materials and light-weighting, electrified propulsion system applications, digital manufacturing and net-zero manufacturing including circular supply chains.

The initial research activity will be focused across five core themes: Product metallurgy; Surface state optimisation; Non-metallic coatings; Future material applications and Material forming/joining and associated characterisation.

Professor David Greenwood, CEO of the High Value Manufacturing Catapult at WMG, University of Warwick, explained, “WMG has worked with Tata Steel on projects for many years, and this partnership will see the collaboration grow across key research themes, including decarbonising the supply chain and enabling future applications of steel across zero carbon propulsion systems and transport vehicles. This activity will include identifying new collaborative relationships and developing world-class technology for the future of the UK steel industry.”

on projects for many years, and this partnership will see the collaboration grow across key research themes, including decarbonising the supply chain and enabling future applications of steel across zero carbon propulsion systems and transport vehicles. This activity will include identifying new collaborative relationships and developing world-class technology for the future of the UK steel industry.”

Dr. Sumitesh Das, Director of R&D, Tata Steel, explained: “This is a critical partnership for us to help support new product development with low carbon footprints across various market segments. It also strengthens our ongoing work including building technology capability and expertise in the UK in manufacturing.”

-ENDS-

Notes to Editors

Press Contacts:

Simmie Korotane. Media Relations, University of Warwick, Email: mailto: Simmie.korotane@warwick.ac.uk

Tim Rutter, Head of Public Relations, Tata Steel UK, M: +44 (0)7850 990755, E: mailto: tim.rutter@tatasteeleurope.com

UK aims to be the first Country in the world to circulate steel and aluminium fully, supported by the CircularMetal programme

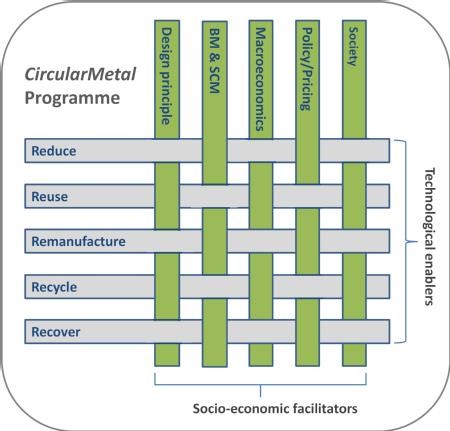

§ The UKRI National Interdisciplinary Circular Economy Research Programme aims to create a sustainable circular economy for lots of different industries, including metals

§ Metals and metal products create 10-20% of all the world’s harmful impacts, such as greenhouse gas emissions and pollution and energy consumption; we cannot do without goods made from metals; so we must learn how to make their use circular, i.e. extend their lifetimes and increase their repair, re-use and recycling

§ The Interdisciplinary Centre for Circular Metals aims to accelerate the transition from the current largely take-make-waste linear economy to full metal circulation by conducting high quality research and innovation through a systems approach. Its ambition is to make the UK the first country to realise full metal circulation (at least for the high-volume metals – steel and aluminium) by 2050. This will form an integral part of the government’s efforts to achieve Net Zero by 2050

§ To deliver the CircularMetal research programme, WMG at the University of Warwick will conduct inter-disciplinary research on steel production, recycling technologies, remanufacturing of steel components, and artificial intelligence in scrap separation

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The UKRI has established five Interdisciplinary Circular Economy Centres in the UK, coordinated by the Circular Economy Hub (CE-Hub), which together form the NICER Programme, a £30 million investment on research aimed at developing a circular economy in the UK, One of these CECs is CircularMetal, the Interdisciplinary Centre for Circular Metals, led by Brunel University London, with partners from WMG, University of Warwick, University College London and Loughborough University.

The ultimate aim of the group is to make the UK fully circulate all their steel and aluminium, thereby minimising or eliminating the extraction of raw materials and the production of waste.

WMG, at the University of Warwick, will specifically research steel, including opportunities for reuse and the technologies for scrap sorting to increase recyclability, working with partners in the project on business model supply chains and the economy and policy surrounding them.

The Interdisciplinary Centre for Circular Metals is a four-year project, which started in January 2021 thanks to £4.2m funding from UKRI. Discussions within the team on strategies to reuse / recycling / reduce / remanufacture / recovery and the technological barriers are on-going with input being provided to government groups.

Professor Claire Davis, from WMG, University of Warwick comments:

“To be part of the Interdisciplinary Centre for Circular Metals is incredibly exciting, especially in light of COP26, as the potential that a circular economy for metals could have towards meeting goals of sustainability and furthermore preventing climate change.

“At WMG, University of Warwick we hope to research how technology can help us to reuse and recycle steels, for example, understanding the end of life condition of steel components to determine whether and how they can be used, and using artificial intelligence to increase scrap recyclability.

“If metals can be fully recycled and reused the need to extract raw materials to make them in the first place could be eliminated, and the current workforce in the metals industry could be reskilled to work in recycling and repurposing metals.”

Professor Brian Cantor, Deputy Director, The UKRI Interdisciplinary Centre for Circular Metals BCAST, from Brunel University comments:

“Metallic materials are the backbone of manufacturing and the fuel for economic growth. They underpin the competitive position of almost every industrial sector and, including metal manufacture and downstream product processing, they collectively contribute 15-20% of all greenhouse gas emissions, pollution and energy consumption. Transformation of the metals industries from the current largely linear economy to a circular economy will, therefore, play a critical role in delivering the government’s industrial strategy for clean growth, doubling of resource productivity and reaching net zero carbon emissions in 2050.

“CircularMetal is focused on helping the UK become the first country to realise full metal circulation, concentrating on the two main bulk metals aluminium and steel, and the three main industrial sectors of transport, construction and packaging.”

ENDS

22 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture1.jpg

Caption: A graphic of the factors considered in the CircularMetal programme

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture2.jpg

Caption: The building the Warwick arm of the CircularMetal project are based in at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Scottish steel industry needs to be revived to thrive

- · The Scottish steel using sectors currently employ just under 1/3 of the Scottish working population, and accounts for 31.2% of Scotland’s turnover

- · With an ever-growing population the need for steel is increasing, meaning an opportunity is there for the Scottish steel sector

- · If investment in the sector happens it could result in making new types of steel such as crude, which is the most in demand but is currently the least manufactured in Scotland

The value of the Scottish steel using sectors in relation to the rest of the world and also the UK specifically has been analysed by researchers from WMG, University of Warwick, who have found investment could be the key to reviving the industry into a thriving industry.

Steel has played an important part of Scotland’s economy since 1751. The nation’s industrial heritage has relied upon steel, which has been a key part of shipbuilding, energy, rail and civil engineering industries. There have been 12 iron and steel works in Scotland with the last major one to close being Ravenscraig in 1992.

shipbuilding, energy, rail and civil engineering industries. There have been 12 iron and steel works in Scotland with the last major one to close being Ravenscraig in 1992.

There are currently 266,500 people employed in Scottish steel using industries, while indirect employees in the supply chains can be estimated at around 800,000, making a total of 1.06 million people – around a third of Scotland’s working population. The steel markets account for 31.2% of Scotland’s turnover, essentially meaning just under 1/3 of the population rely on Steel for income.

Between 2015 and 2030 the steel market across the UK is set to increase by 1.5 million tonnes, worth a total of £3.8billion to the UK economy, with the demand expected to increase in construction, machinery and engineering, and yellow goods (earth moving equipment).

However whilst the demand for steel is increasing, it is predominantly increasing for crude steel, which Scotland does not produce a significant amount of, in fact the largest steel plant in Scotland is Liberty Steel Dalzell in Motherwell, which doesn’t produce any crude steel.

In 2018 a total of 1.816 billion tons of crude steel was produced globally using blast furnace (BF) + basic oxygen furnace (BOF) and electric arc furnace (EAF) techniques. The United Kingdom produced 7.3 million tons of crude steel in 2018, 0.004% of global production. Scotland has produced less than 6000 tons of crude steel per year in the last three years. Global crude steel production is dominated by Asia, in particular China, which produced 928 million tons of crude steel alone in 2018.

In fact in 2018 there was £371.4m of imports of iron and steel into Scotland whereas their total iron and steel product exports stood at £313m, with £159m of that being exported to the EU.

Dr Russell Hall, from WMG, University of Warwick comments:

“The world’s population is set to increase from 7.7bn people in 2020 to 9.7bn in 2050, therefore the demand for steel will continue to increase, this provides an opportunity for Scotland to revive their steel industry and boost their income, however this will require coordinated government intervention and leadership into steel making capability, this could be in the form of direct investment, indirect support such as the reduction of energy costs or increase in skills provision for steelmaking.

“This could mean that Scotland could manufacture new steel types, expand current steel making capabilities, and reduce the operating costs for steel makers.

"If investment were to happen it could mean lower CO2 emissions, as it enables lower energy steel processing, it also enables the sector to work with existing supply chain and customer demands, and put state of the art equipment into Scottish steel manufacturing. In combination with Scotland’s renewable energy agenda it could see green steel production at the heart of Scotland’s manufacturing industry”.

ENDS

25 OCTOBER 2021

NOTES TO EDITORS

High-res images available at: https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/9652258404_7a8c8e9679_b.jpg

Caption: Forth Rail Bridge over the Firth of Forth in Scotland

Report available to view at: https://warwick.ac.uk/fac/sci/wmg/research/materials/wmg_scottish_steel_sector_report_final.pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7902 531 211

E-mail: alice.j.scott@warwick.ac.uk

WMG Professor recognised by UK engineering institution

Congratulations to WMG Professor Claire Davis who has been awarded the prestigious Hadfield (Sir Robert Hadfield) Medal and Prize by The Institute of Materials, Minerals and Mining (IoM3).

Congratulations to WMG Professor Claire Davis who has been awarded the prestigious Hadfield (Sir Robert Hadfield) Medal and Prize by The Institute of Materials, Minerals and Mining (IoM3).

Professor Davis was presented with the award in recognition of her exceptional contribution to the steel industry and its value chain.

The Hadfield Medal is widely recognised as a distinguished achievement in relation to metallurgical practice, process development, product development, metallurgical understanding or design engineering connected with iron and steel or associated industries.

Professor Davis holds the Royal Academy of Engineering / Tata Steel Chain in Low Energy Steel Processing at WMG. Her research focuses on the development of microstructure during processing and the relationships between microstructure and properties (both physical and mechanical) in steels.

Find out more about Professor Davis’s research here.

Smarter, greener, cleaner steel: £35 million boost for research to transform UK steel industry

A smart, green and clean steel industry will come a giant step closer thanks to a new £35 million research network, announced today, which will see steelmakers and University experts work together on a seven-year research programme to transform the UK steel sector.

A smart, green and clean steel industry will come a giant step closer thanks to a new £35 million research network, announced today, which will see steelmakers and University experts work together on a seven-year research programme to transform the UK steel sector.

The network, called SUSTAIN, is to transform the whole steel supply chain, making it cleaner, greener and smarter, and more responsive to the fast-changing needs of customers. Its work will be concentrated on two areas:

· Zero waste iron and steelmaking, with the aim of making the industry carbon-neutral by 2040: Steel is already the world’s most recycled material, but the network will investigate new ways of making the industry’s processes and products even greener, such as harvesting untapped energy sources, capturing carbon emissions and re-processing societal and industrial waste streams.

· Smart steel processing: like any 21st century industry, steelmaking involves masses of data. SUSTAIN will develop new ways of acquiring and using this data to improve the steels produced as well as in new metallurgical processes, which can deliver bespoke high tech products.

Steel is the most widely-used structural material in the world. If a product isn’t made of steel it’s made using steel. Steel is at the heart of UK manufacturing sectors such as the car industry, construction, packaging and defence. It is an indispensable component of the UK’s future national infrastructure such as transport, communications and energy, and for high-tech 21st century industries, from energy-positive buildings to wind turbines and electric vehicles.

The work of SUSTAIN is projected to:

- Double UK steel manufacturers’ gross value added (GVA) by 2030

- Boost jobs in the industry to 35,000

- Increase productivity by 15%

SUSTAIN involves more than twenty partners across the UK steel industry: companies, trade bodies, research organisations and academic experts including WMG, University of Warwick. The network is being supported by £12.5M investment from the Engineering and Physical Sciences Research Council, as one of their Future Manufacturing Research Hubs, along with significant investment from the steel companies within the UK.

The announcement is a landmark as it is the first time that UK steel producers and representatives from the manufacturing sector have lined up behind a co-ordinated programme of research. It is also the largest ever single investment in steel research by a UK research council.

The plan is that SUSTAIN will be a seed from which much wider research and innovation will grow, drawing on expertise across UK academia and beyond.

Professor Claire Davis, from WMG, University of Warwick comments: “The UK has a rich tradition of research excellence and innovation in steel metallurgy. SUSTAIN will bring together leading research groups in this area, as well as introducing new expertise in big data and supply chain innovation, to work collaboratively with the UK industry.

The network will be able to tackle the large issues facing the steel industry, particularly in becoming low energy, carbon neutral, dynamic and responsive to customer needs. It is an exciting time to be working on steel as there are opportunities to contribute to making the planet a greener place.”

Dr Cameron Pleydell-Pearce, steel expert at Swansea University and SUSTAIN’s deputy director, said: “This news is a massive vote of confidence in the steel industry. It will support the industry’s vision for a responsible, innovative and creative future. We are already on the road to clean, green and smart steelmaking, but this is another giant step forward.

Research and innovation are the bedrock of a modern steel industry. This network represents almost the whole UK steel sector, with researchers and companies working together on an unprecedented scale. Here in Swansea we’re proud to lead it.”

Gareth Stace, UK Steel Director General, said: "This new boost of innovation funding into the sector is a vital piece of the puzzle to help deliver our vision of a cutting-edge, vibrant, and sustainable steel industry in the UK.

The future success of our sector rests on our ability to remain at the forefront of product and process innovation, delivering the new steel products demanded by our customers and society. This new hub will enable us to do just that.”

The virtual factory – boost for steel innovation with £7 million to speed up new alloy development

A new method of testing alloys - Rapid Alloy Prototyping, is 100 times faster than current methods, allowing new products to reach the market more quickly, thanks to £7 million of funding announced today for a new “virtual factory” designed by the Prosperity Partnership, including WMG at the University of Warwick.

A new method of testing alloys - Rapid Alloy Prototyping, is 100 times faster than current methods, allowing new products to reach the market more quickly, thanks to £7 million of funding announced today for a new “virtual factory” designed by the Prosperity Partnership, including WMG at the University of Warwick.

This Prosperity Partnership – led by Swansea University and involving WMG at the University of Warwick, will implement a Rapid Alloy Prototyping (RAP) process, thanks to £7 million of funding announced today from the Engineering and Physical Sciences Research Council (EPSRC)

Rapid Alloy Prototyping effectively means that much of the testing can be carried out in research labs and imaging suites - a virtual factory – rather than in an actual steel plant.

Supporting the steel industry at WMG

Businesses of all sizes in Coventry and Warwickshire can take advantage of a state-of-the-art facility to develop the next generation of lightweight steel products.

Businesses of all sizes in Coventry and Warwickshire can take advantage of a state-of-the-art facility to develop the next generation of lightweight steel products.

WMG (Warwick Manufacturing Group) at the University of Warwick has created a cutting-edge research, design and skills infrastructure zone in its Advanced Manufacturing and Materials CentreLink opens in a new window.

Its work is focused on supporting the development of new lightweight steel products as well as building an environment to develop the next generation of experts in this specialist field and can be accessed by SMEs as well as global businesses.

The three-year project has received £1 million of funding from the Government’s Local Growth Fund through the Coventry and Warwickshire Local Enterprise Partnership (CWLEPLink opens in a new window) to buy key R&D equipment and a further £1 million from WMG which includes industry funding.