WMG Insights

Smart Communication within a Smart Cell – Power Line Communication (PLC)

Electrifying transportation is key to reducing the contribution of carbon dioxide emissions from the haulage and travel industries (including road, air and marine). Smart cells, with integrated sensing and control hardware, underpin the next generation of battery packs and battery management systems (BMS). For the first time, these cells could permit the life expectancy, energy density and reliability needed for all-electric aircraft, longer range electric vehicles and safer electric heavy-duty transportation.

The Cell Instrumentation Team at WMG, University of Warwick, have extensively explored and reported on a new understanding of cell operation possible through internal temperature and pressure sensing. Analysing individual cell performance is a vital building block, but further battery pack innovations will come from understanding how a cell interacts with its neighbours in a cluster of cells. Rigorous instrumentation processes, developed within WMG, enable repeatable sensor installation within a cell. In terms of manufacturing this introduces further challenges, when adding more cabling to the already complex wiring harnesses in the vehicle. This also increases the risk of failure, through needing relatively delicate communication cabling throughout the battery pack.

Complex, delicate and cumbersome cabling, even in a laboratory environment, prevents instrumented cells from being arranged in a format similar to a final application. In an end-application, the cabling needed to link basic sensors to the central BMS is prone to damage, where packs must be discarded if reliable communication cannot be established. Communication over the existing cell bus-bars (positive and negative connections) is a unique solution – removing the need for communication cabling – saving cost, weight and physical volume. Termed power line communication (PLC), this technology is often associated with larger AC grids, or broadband sharing via power plugs in a domestic home. By transmitting and receiving data at high frequency (MHz and higher), the existing DC link between batteries and the central BMS serves dual purpose as a power and communication carrier.

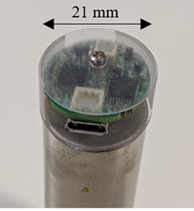

We envisage a communication, namely integration of a PLC modem, as an essential component of a smart cell. As the cell terminals are connected internally, integrated PLC and interface circuitry within a cell along with sensors will allow the manufacture of sealed smart cells, with sensors included from cell manufacture. This will provide valuable data during the complete lifetime of a cell, for example, from an insight into the critical first cycles performed on a cell at the start of its life, to grading a cell when entering its second or third life application. A smart cell PCB integrated on the top of cylindrical cell is shown in Figure 1. At this stage of the work at WMG, the smart cell circuitry is mounted externally to the cell. Further developments are focused on integrating this control hardware directly within the cell, to avoid changing the cell form-factor – maintaining high energy density and permitting easier integration within existing pack layouts.

Figure 1: Smart cell PCB installed on top of a cylindrical cell.

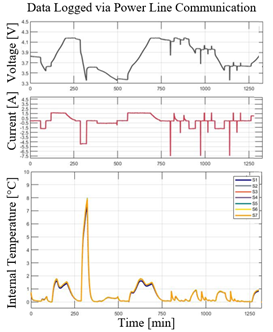

Dr Timothy Vincent and the Cell Instrumentation Team have recently published their novel research developing cells instrumented with arrays of thermistor sensors installed in cylindrical 21700 format cells. Voltage and current sensing completed the fundamental sensing elements needed to model and understand cell operation, shown in Figure 2.

Figure 2: Data collected from an instrumented cell. Wire-free communication with data transferred by the existing cell bus-bars. Voltage, current and internal temperature data (relative to ambient 25 °C) collected at 10 Hz.

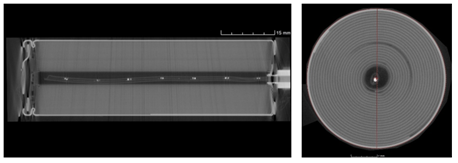

The sensor and PLC circuitry are powered from the individual cells, with focus on low-power consumption components and software; with data transfer over the same cell bus-bars (PLC), there is minimal impact on the cell’s useful energy and lifespan. The array of 7 sensors (Figure 3) can provide unique insights into cell performance without the traditional cabling required for each point sensor. PLC is a scalable technology; low-bandwidth (lower frequency, capable of lower bytes-per-second data transfer) is best suited to individual smart cells requiring less data to be transfer to the BMS. This offers comparable data transfer rates to traditional vehicular CAN (500 kbps), with excellent reliability achieved in small modules tested at WMG. High-bandwidth PLC, requiring greater power consumption, is capable of at around 500 mbps data transfer rates, suitable for smart modules or larger format smart cells.

Figure 3: Successful instrumentation along the core of a cylindrical cell – array of 7 thermistor sensors installed internally within the cell.

Innovative technology such as PLC will form a key step towards smart cells for future energy storage applications. The need to improve current transportation infrastructure, moving to all-electric aircraft, developing micro transportation solutions in an economically viable and environmentally sustainable manner leads the drive to optimise battery construction, performance and safety. Smart cell developments at WMG are chemistry agnostic, scalable, reliable and proven ready to power future energy storage applications.