WMG Insights

Laser beam welding for transport applications

Laser beam welding is a key tool for manufacturing e-vehicles and accelerating adoption of lightweight structures and recycled materials. Typical applications include doors and closure panels, sides frame, seats, battery tabs, sealing individual cells and modules, and fabrication of structural battery enclosures which must adhere to strict engineering requirements (i.e.water/gas tightness, strength, weight distribution and cooling of high-voltage circuits); as well as manufacturing e-motors (hairpin welding). Understanding laser-to-material interaction, and developing novel welding strategies for similar and dissimilar materials is therefore vital. In addition, having intelligent decision-making systems for autonomous selection of the welding process and real-time feedback control allows maximisation of productivity, whilst reducing down-time, scrap and waste.

The studies outlined here emphasise the need for innovative research in laser beam shaping for tailored functional performance, advanced process simulation for better understanding of the physical phenomena, and machine learning/artificial intelligence for weld quality control.

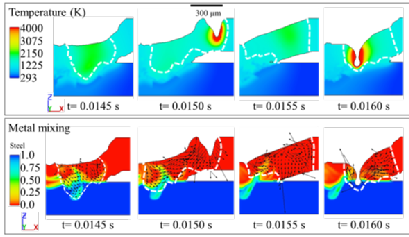

Multi-physical CFD simulation of metal mixing behaviour during remote laser welding of copper to steel

Simulated thermal field and metal mixing during remote laser welding of copper to steel

Remote Laser Welding (RLW) of dissimilar metallic thin foils has fundamental importance in battery pack manufacturing where high repeatability is a strict requirement. WMG researchers implemented a combination of CFD (Computational Fluid Dynamics) multi-physics modelling and experiments to study the metal mixing behaviour during lap welding of 300 µm copper to 300 µm nickel-plated steel, with circular beam wobbling. The CFD model provided information about temperature fields, fluid flow and metal mixing, all of which are difficult to measure directly via physical experiments. The study highlighted that the part-to-part gap leads to uncontrolled metal mixing. Researchers then concluded that laser beam shaping is a viable approach for controlling the metal mixing and hence for improving weld quality.

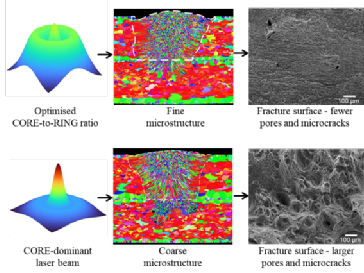

Grain refinement using laser beam shaping of 6xxx aluminium alloys

Impact of laser beam shaping on refinement of weld microstructure

The automotive industry is increasingly pursuing 6xxx series aluminium alloys because of the high strength-to-weight ratio, excellent formability and good corrosion resistance. This is particularly crucial for battery electric vehicles (BEVs) which demands lightweight structures to maximimise the driving range and reduce costs. However, the notorious crack sensitivity of 6xxx series aluminium has prevented the wide-spread application in welded structures. Current practice in industry is to modify the chemical composition of the molten pool using filler wires (either 4xxx or 5xxx aluminium wires). Nonetheless, this is limited to specific joint geometries and adds complexity and costs. WMG researchers studied the impact of an adjustable-ring-mode (ARM) laser beam to optimise the microstructure and mechanical performance of laser welded 6xxx high-strength aluminium alloy, without filler wires. Findings showed that both core-dominant beam and ring-dominant beam lead to low thermal gradient and cooling rate at the solidification front. Researchers noticed that only a proper selection of core/ring ratio can restrict the formation of columnar grains near the interface boundary and allow wider formation of equiaxed dendrites and better grain refinement. The study showed that the joint strength was improved by approximately 40 %. This research is a first step towards fully autogenous laser welding (no filler wires) of 6xxx high-strength aluminium alloy.

The effects of the adjustable ring-mode laser on intermetallics during steel to aluminium welding

Impact of laser beam shaping on intermetallics

Dissimilar joining of steel-to-aluminium is undoubtedly one of the most challenging combinations that has attracted interest from researchers and practitioners for decades. However, the notorious low miscibility of aluminium alloys and steel, caused by very large differences in their thermophysical properties, and the formation of brittle intermetallic compounds (IMCs), have prevented the wide-spread application. WMG researchers implemented the adjustable-ring-mode (ARM) laser beam and explored the influence on the weld pool and metallurgical properties during remote laser welding of IF steel to 1050 aluminium alloy. Researchers found that the use of a ring-dominant beam significantly reduces the amount of the brittle Fe2Al5 IMC, in contrast to a core-dominant beam. The findings are significant to accelerate adoption of dissimilar material structures, across a wide range of applications, from structural parts in automotive bodies to tabs and connectors in battery systems.

Supervised machine learning for automatic classification of defects in laser weldments

Photodiodes data streams used to train ML/AI algorithms. Application in battery tabs welding

There is undoubtedly a gradual transition towards autonomous and intelligent decision-making systems brought on by tools from Industry 4.0 such as Machine Learning (ML) / Artificial Intelligence (AI). These tools hold promises of improving productivity and quality, optimising energy consumption and reducing scrap. Rather than relying entirely on the open-loop nature of traditional welding process development – meaning robust design optimisation and then “reactive” adjustment of the process parameters on the production line to satisfy the quality targets - autonomous systems leverage a number of digital twin assets which gather in-process data and in real-time, and provide continuous feedback information for predictive decision making. Sensor technologies play a pivotal role since they serve as the “surveillant” of the process. The need for sensor technologies is very timely indeed for the explosive growth of e-mobility where a large number of joints (up to 20,000 joints per single battery pack!) are generated for each vehicle. WMG researchers studied whether photodiodes and supervised ML algorithms are sufficient to automatically classify weld defects caused by simultaneous variation of part-to-part gap and laser power during remote laser welding of thin foils, with applications in battery tabs assembly. Researchers obtained up to 97% classification accuracy. The study highlighted the importance of further investments in ML/AI and sensor fusion, along with real-time multi-physical simulation, to enable trustable and intelligent decision-making systems.

Conclusion

By working across the entire research and innovation cycle, from fundamental research, through applied research, to technology development, the Laser Beam Welding team at WMG are enhancing understanding of laser-to-material interaction, creating new welding strategies, and delivering in-process closed-loop control. This is vital for e-vehicle manufacture and for lightweight structures for the automotive and aerospace sectors.

To discuss how WMG can work with your business contact: wmgbusiness@warwick.ac.uk

Reach out to the research team:

Dr Pasquale Franciosa (Head of Laser Beam Welding)

Dr Tianzhu Sun (Material Characterisation Lead)

Prof Darek Ceglarek (Director)

Acknowledgement

Thanks is given to the funding bodies that have supported the research: EPSRC, Innovate UK, Advanced Propulsion Centre, High Value Manufacturing Catapult.

Article originally featured in the AILU magazine Issue 106 Autumn 2022 (https://www.ailu.org.uk/wp-content/uploads/2022/11/Issue-106-p1-4.pdf).