Assistive Technology

Assistive Technology

Engaging young people with assistive technologies using 3D printing technologies and computer aided design (CAD) software.

Click here for our resources page which includes CAD tutorials Link opens in a new window- AT products featured in Action Duchenne workshop |

Students with learning difficulties and disabilities at Hereward College in Coventry have expert knowledge of disability and what assistance is needed by young people living with disability. This project is about enabling them to tailor the design of tools and accessories to their own requirements and to investigate how they can share their designs and expertise with the wider community. By providing this opportunity we aim to raise aspirations of Hereward students, as they are currently unlikely to go into STEM areas.

Initial WMG research & design work with Hereward College

Over the summer months, WMG worked with Hereward College to design and 3D print an iphone mount with a bespoke attachment for a student's wheelchair. There are numerous different wheelchair designs and different users require items such as iphones to be attached in different positions, so this work provided an excellent example of how 3D design and print can help to produce bespoke user solutions. The design and 3D print process can be seen below:

|

|

|

| Assessing user needs | Producing 3D CAD drawing | Printed iphone mount in use |

The wheelchair user was consulted regarding required poistion, angle and anchoring point for the iphone mount. Photographs and measurements were taken and used to produce the 3D computer aided design of the iphone mount ready for it to be 3D printed at WMG.

The finished printed iphone mount was delivered to Hereward College and installed on the student's wheelchair. The position and angle were correct and the product was left with the user for evaluation.

Over the summer months further project work with Hereward College was completed by James Atkinson, WMG Student Intern - click here to see the Academic Poster produced by James.

Project Team

| WMG | Computer Science | Hereward College | Student Tutors |

| Margaret Low Research Page linkLink opens in a new window |

Dr Claire Rocks | Paul Doyle | Isobel Ferguson |

| Diane Burton |

Dr Alexandra Cristea |

Howard Knight | James Atkinson |

| Dr Greg Gibbons Research page linkLink opens in a new window |

Dr Jonathan Foss |

Russell Smith | |

| Evaluation: Sarah Jenkins, Jenesys Associates | |||

News

October 2014

Assistive Tech Project features at TCT 3D Printing Show at the NEC, Birmingham

Project Officer, Diane Burton, was invited to speak about the project at this International 3D Printing Show. A number of the products designed and produced during the project were featured on a display for the duration of the show.

June 2014

Students from Hereward College who have taken part in the Assistive Technology Project spent the day at the University of Warwick showcasing their work on the project. There were displays about what they had learned and achieved and examples of the assistive tech products they have developed. Hereward students did a great job of telling guests about the products they had created. Hereward students Joel Morrison and Sally Walton demonstrated the use of the 3D CAD software used on the project and invited guests to try it out. The Cubex Trio 3D printer used on the project was set up and running for guests to see and some of the students explained how the printer works.

Some of the products designed and produced by the Hereward 3D printing group

Stand for a communication aid

Below left is a communication aid used to help a student with severely impaired speech to hold a conversation. The device has a simple U-shaped metal bracket on the back as shown. The problem is that it tends to slide away from the user when the device buttons are pressed or when it is knocked accidentally by the user as can easily happen.The group designed a simple 3D printed stand which the metal bracket clips into – as seen in the picture to the right. The stand stabilises the communication aid making it easier to use and holds it at the correct angle for the student. With 3D printing, it is quick and simple to make adjustments to the design to suit the user, e.g. to enable the communication aid to sit at a slightly different angle or the user may simply prefer a different colour stand. For extra stability some double-sided velcro or simply a couple of rubber pads can be placed on the bottom of the stand before it is put onto the wheelchair tray.

Holder for an environmental control

Wheelchair users often have an environmental remote control which can be programmed to do tasks such as open doors, open curtains, switch lights on and off, etc. The control tends to sits on the wheelchair tray and users have to pick it up and get it at the correct angle to use - it must point to the infra red sensor which is part of the control system and is generally located above the door.These controls often slip off the wheelchair tray onto the floor and get damaged - they are very expensive! We designed a holder which the control fits snuggly into. It places the control at the correct angle and the base of the holder can simply be velcroed to the wheelchair tray.

A straw support for use with a range of bottle sizes

Just before Christmas, Hereward student Ollie Baskaran made the important step of using his new-found skills to think of a product idea which he could design and 3D print to solve a problem he encounters. Ollie’s condition means he has to drink from a straw, but the straw bobs around in the bottle and often falls out. With some help from student tutor Russell, Ollie designed a straw support which fits neatly in the top of a bottle. The design has a series of rings to allow the straw support to fit a variety of bottles.

Straw supports for different types of drinking glass

Ollie was so pleased with his new creation that he put a post on Facebook to tell people about his new 3D printed creation. This led to requests from other students at Hereward for straw supports to be used with different types of glasses. Below are the 2 products the group designed and printed - the one on the left works with a straight-sided glass and the longer one on the right works with a curved sided glass.

Spring 2014

See the range of assistive technology products developed during the project

January 2014

Hereward student designs assistive technology straw support.

November 2013

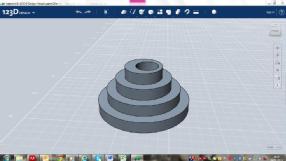

Hereward students involved in the project were introduced to 123D Design 3D CAD software in October and have made very good progress using the range of screenshot and screencast tutorials compiled for this project. Initially they learned to use the software to draw a variety of small items such as a badge with their name on and a keyring, a safe handle, a security cardholder. These items were 3D printed and the students were able to take them home to show family and friends.

As the students’ skills increased, they drew their first assistive technology product for a fellow Hereward student. This was a new bespoke handle for a mini safe. The safe is used for storing medication by a Hereward student who has limited hand function, so is unable to use the small dial on the safe and needs a carer to operate the safe. A large handle he could just tap up and down was required. A tutorial was produced to enable the students to see the process of taking the measurements needed for the finished item, then drawing the design in the CAD software ready to be 3D printed. The design was 3D printed and has since been in daily use by the student.

Mini safe with unsuitable dial handle and the CAD drawing of safe handle completed by Hereward students.

New handle being 3D printed and the finished safe with a new handle attached.

October 2013

Professor Les Ebdon, Director of the Office for Fair Access visited Hereward College to find out about this Project.

September 2013

A launch event was held for Hereward students taking part in the project, to be held at the University. Fourteen students taking part in the project spent the day at the University and were hosted by staff and student tutors from WMG and Computer Science. They enjoyed a tour of WMG, including the 3D Powerwall, Rescue Robot, Formula Student car and they saw the excellent 3D printing technologies available at the University. They spent the afternoon working with staff and student tutors to develop their ideas for new bespoke assistive technology products.

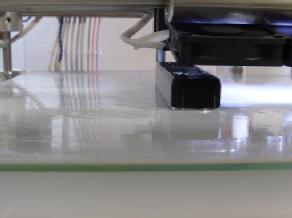

The first project workshop was held at Hereward College. Students learned how 3D printers work and printed their first product on the new Hereward 3D printer.

Take a look at our Project Video

Link opens in a new window

Project presentation at TCT ShowLink opens in a new window

BBC News Website project coverage

Wall Street Journal online project article

Link to new project Engaging Young Learners

in CAD and 3D PrintingLink opens in a new window

The project was led by The University of Warwick Computer Science Department and Warwick Manufacturing Group working in partnership with Hereward College.

The Cubex Trio 3D printer for this project was kindly donated by 3D Systems Ltd

For further information contact:

Margaret Low M.J.Low@warwick.ac.uk,