WMG News

Members of the Worshipful Company of Engineers visit WMG

WMG, University of Warwick welcomed members of the Worshipful Company of Engineers to the department to discuss the importance of industry working with academia on research and education. The Company comprises leading engineers, and works to promote and develop all aspects of the science, art and practice of engineering.

Professor Mark Williams, Head of Metrology and Visualisation gave a tour of WMG facilities which focused on the important role of CT scanning in battery technology, criminal forensics, and medicine.

Current winner of the Leete Premium Award, Will Naylor presented his PHD work to the group. Will’s research which has been recognised due to its potential to introduce significant change in manufacturing, investigates methods of capturing, transmitting, and delivering high quality, multisensory, 3D data between remote locations.

Professor Paul Jennings ,Director of Research at WMG who led the visit said: “It was a pleasure to welcome members of the Worshipful Company of Engineers to WMG and give them a real insight into our pioneering research and innovation. The importance of collaboration was a key discussion point throughout the day and Will’s work is a true testament to that – his research is helping engineers to seamlessly work together and share ideas around the world.”

Find out more about WMG’s research here: https://warwick.ac.uk/fac/sci/wmg/research/

Members of the Slovakia government visit WMG

Delegates from the Slovakian government visited WMG, University of Warwick for an introduction into the department’s ground-breaking battery R&D and a discussion on the importance of industry and academia collaboration.

A total of eight delegates led by State Secretary, Ministry of Economy, Ján Oravec enjoyed a tour of the Energy Innovation Centre (EIC) by Chief Engineer, Mark Amor-Segan who demonstrated EIC’s facilities to research, develop and test the latest technologies at the forefront of energy storage.

Professor Paul Jennings, Director of Research at WMG, University of Warwick who hosted the visit said: “It was great to be able to meet the delegation and showcase the power of academia and industry working together, demonstrating how we are helping to drive the sector forward through impactful research and new education and skills offerings.”

Find out more about WMG’s energy research here: https://warwick.ac.uk/fac/sci/wmg/research/energy/

UK-based consortium established to develop prototype solid-state batteries

MOU signed between Johnson Matthey, Faraday Institution, Britishvolt, Oxford University, UK Battery Industrialisation Centre, Emerson & Renwick and University of Warwick

HARWELL, UK (19 August 2021) A consortium of seven UK-based organisations has signed a memorandum of understanding to combine ambitions to develop world-leading prototype solid-state battery technology, targeting automotive applications.

develop world-leading prototype solid-state battery technology, targeting automotive applications.

Solid-state batteries offer significant potential advantages over conventional lithium-ion batteries and could be transformational in meeting the UK’s net zero commitments through the electrification of transport. The successful outcome of the collaboration would be to harness and industrialise UK academic capability to produce cells using highly scalable manufacturing techniques that leapfrog the cost-effectiveness and performance achieved elsewhere.

The consortium comprises the following world-leading organisations in battery research, development and manufacturing:

· Faraday Institution – the UK’s independent institute for electrochemical energy storage research, which has led the consortium’s formation and will lead its development.

· Britishvolt – the UK-based Gigaplant developer, with a site in NE England.

· E+R (Emerson & Renwick) – a world leading designer of manufacturing equipment.

· Johnson Matthey – a global leader in sustainable technologies and the UK’s leading battery materials business.

· Oxford University – that leads the Faraday Institution’s solid-state battery project (SOLBAT) and provides the necessary scientific understanding to the consortium.

· UK Battery Industrialisation Centre – the pioneering battery manufacturing development facility to enable UK battery manufacturing scale-up and facilitate upskilling in the battery sector.

· WMG, University of Warwick – leaders in battery R&D and initial scale-up capability, as well as academic and apprenticeship skills development.

The preliminary design for a prototyping facility has been developed. Sources of funding are currently being sought.

Minister for Investment Lord Grimstone said: “Collaboration between industry, government and our world-leading academic institutions is putting the UK at the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

“It is the work of our internationally-renowned research and development base, like those brought together by this consortium, that will give us the tools needed to forge a strong and sustainable future for the automotive sector and increase our contribution to combatting climate change.”

“I am delighted to be able to announce the formation of this unique consortium for the advancement of solid-state battery prototyping that includes leading UK-based organisations at many stages in the value chain,” said Professor Pam Thomas, CEO of Faraday Institution. “Our leadership in this venture signals a move towards a role that the Faraday Institution will increasingly play as a trusted convener of significant partnerships between UK industry and academia as a route to commercialise breakthrough science emerging from our research programmes to maximise UK economic value.”

Solid-state batteries (SSBs) offer significant potential advantages over existing lithium-ion battery technologies, including the ability to hold more charge for a given volume (leading to increased electric vehicle (EV) range) and reduced costs of safety-management. Early deployment of SSBs is likely to be in consumer electronics, niche automotive applications and unmanned aerospace, before being used in broader EV markets. The Faraday Institution forecasts that, in 2030, SSBs are likely to take a 7% share of the global consumer electronics battery market and a 4% share of the EV battery market[1]. Global SSB revenues from sales to EV manufacturers are expected to reach $8 billion by 2030[2] and then grow rapidly to 2040 and 2050 when the market is expected to become extensive.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

The construction of the one-of-a-kind facility being developed by the collaboration will enable SSB technology to emerge from UK university laboratories. It will allow larger cells to be produced using scalable manufacturing techniques that will be improved iteratively through deep investigation of the causes of problems that emerge during manufacture and testing of prototype batteries. This will leverage the collective knowledge of Faraday Institution SSB researchers and the industrial partners.

Christian Gunther, CEO, Battery Materials at Johnson Matthey comments, “The realisation of a prototype solid-state battery cell will be a great achievement for the UK battery industry, and this consortium will be a critical enabler for delivering this milestone. Delivering enhanced range and safety over traditional lithium-ion battery technologies will be a key driver for battery electric vehicle adoption, supporting the transition to a net zero future.”

Dr Allan Paterson, Chief Technology Officer, Britishvolt comments, “Solid-state is the holy grail of battery solutions. Solid-state batteries have the potential to increase energy density significantly over battery technology available today and could dramatically, and positively, change the world of electric vehicles. Britishvolt will be at the forefront of commercialising this step change over the coming years. This collaboration, which includes major global industrial leaders such as Johnson Matthey and academic leadership from University of Oxford, underscores another key objective in our technology roadmap – home grown intellectual property.”

Professor Peter Bruce, Principal Investigator of SOLBAT, comments: “It’s fantastic to see the culmination of combined UK academic strength in solid-state battery research come to fruition. I’m proud that the work of the Faraday Institution SOLBAT project, led by Oxford University, will make a significant contribution to the UK’s green energy revolution.”

Ian Whiting, Commercial Director at UKBIC added: “Our newly opened national battery manufacturing scale up facility is already contracted to scale new cells and battery packs by companies basing their manufacturing centres in the UK. It’s a really exciting time for this fast-growing industry. We’re scaling technologies that will be the core products of the UK’s emergent Gigafactories. But we need to think even further ahead and solid-state battery technology is going to be a big part of that. This collaboration is what is needed to give the UK the edge it needs in creating a centre of excellence for solid-state batteries and we’re excited to be part of it. The bringing together of academic and industrial know how in this space is key to unlocking Britain’s electrified potential.”

David Greenwood, Professor of Advanced Propulsion Systems, and CEO of WMG High Value Manufacturing Catapult comments: “Early forms of solid-state battery are already around us, but we have yet to see solutions which are both mass-manufacturable and meet the performance and cost targets for future transport applications. There remains huge opportunity for innovation in this space, and this initiative will provide the route for the UK to fast-track candidate technologies to industrialisation.”

Andrew C Jack, Sales Director, E&R Group comments, “E&R Group are delighted to be contributing our world renowned engineering expertise working in partnership Faraday and the wider consortium on this exciting development for next generation battery production for the UK.

For more information on the Faraday Institution, visit www.faraday.ac.uk and follow @FaradayInst on twitter.

Charging ahead at Battery School

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG battery experts will facilitate a mix of lectures and practical hands-on-sessions, with the intention of inspiring the next generation of engineers into battery related careers, crucial for the UK’s electrification sector.

The lectures will cover areas including manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical lab sessions will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find out more and book your place here.

Used electric vehicle batteries could be used for rickshaws in Bangladesh

Used EV batteries could be used to power rickshaws in Bangladesh, as researchers from WMG, University of Warwick, seek to find out how they can be repurposed for the rickshaws and lower peoples’ carbon footprint.

Motorised rickshaws, also known as easy-bikes, have gained popularity in Bangladesh due to their cost-effectiveness with one million of them all over the country.

However, the easy-bike currently uses a lead-acid battery for power, which has a lifetime of 6-12 months and therefore increases the operating cost as well as the carbon footprint.

In order to reduce the carbon footprint, researchers at WMG are exploring the possibility of repurposing used EV Li-ion batteries thanks to a £25,000 grant from Global Challenges Research Fund (GCRF), an award from the UKRI aimed to deliver scalable solutions to issues faced by low and middle-income countries.

Currently, Li-ion batteries retire from EVs after reaching 70-80% of their state of health (SoH). At 70% SoH, the lithium-ion battery still have 3 times higher energy density than a new lead-acid battery, and potentially can have a lifetime of 3-5 years in easy-bike application.

The researchers hope to repurpose the batteries to improve the energy storage life from 6-12 months to 3-5 years, which in turn will reduce the number of batteries being recycled and improve the ecosystem.

The new application of Li-ion batteries will be better environmentally without an additional cost in transport. As easy-bike replaces manual driving, the quality of life will improve significantly and bring a socio-economic change to a large community in Bangladesh. Furthermore, this development could reduce the consumption of grid-connected electricity which could be used to develop industries and infrastructure.

In fact, there are currently one million rickshaw pullers in Bangladesh who earn $4.8 billion every year. The new development in easy-bikes will directly improve their economic status. A few million people involved in vehicle support such as mechanics and manufacturing industries will also be benefited.

This project eventually could lead to mass production of second-life Li-ion batteries in Bangladesh, in conjunction with UK automobile industries, which will create job opportunities for thousands of people.

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

“To prevent climate change, all cars in the future will need to be electric. However, the batteries in EVs once they have reached their end of life, for car purposes, is something that can be explored more, as there is still energy left in them to be used.”

“If we can re-purpose them to be used for easy-bikes in Bangladesh it will help lower their carbon footprint and provide the country with a new economy. Thousands of jobs opportunities could be created both in Bangladesh and the UK.”

ENDS

13 NOVEMBER 2019

NOTES TO EDITORS

High-res images available at: https://warwick.ac.uk/services/communications/medialibrary/images/october2019/mohammad_photograph.jpg

About GCRF - https://www.ukri.org/research/global-challenges-research-fund/

UK Research and Innovation works in partnership with universities, research organisations, businesses, charities, and government to create the best possible environment for research and innovation to flourish. We aim to maximise the contribution of each of our component parts, working individually and collectively. We work with our many partners to benefit everyone through knowledge, talent and ideas.

Operating across the whole of the UK with a combined budget of more than £7 billion, UK Research and Innovation brings together the seven research councils, Innovate UK and Research England.

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The future of mobility: Times are changing

Times are changing

If we are to seize electrification and autonomy opportunities, it’s essential that the UK develops an environment suitable for breakthrough technologies. From domestic charging solutions to developing repeatable testing environments, the UK faces big challenges and we are addressing these through our lead centre for Vehicle Electrification and Connected and Autonomous Vehicles at WMG, University of Warwick.

Electrification shaping a low carbon future

David Greenwood – Professor, Advanced Propulsion Systems at WMG, University of Warwick

Demand for electric vehicles (EVs) is surging in the UK and registrations of plug-in cars increased by more than 160,000 between 2013 and 2018. With the electrification industry estimated to be worth over £6billion by 2025, the next decade presents a massive opportunity.

As our society continues to grow, transformation in energy and mobility is required to create sustainable environments. The electrification of transport is shaping that low carbon future. Our vision at WMG is to enable the development of cleaner, safer and smarter vehicles and help drive sustainable mobility across the UK, which aligns with the Government’s ‘Road to Zero’ strategy, aiming to make road transport emission-free by 2050. Our research focuses on establishing advanced hybrid and electrical vehicles, including commercial, rail and marine, battery technology, supply chain, manufacturing and automation.

At WMG, we’re working with the UK Battery Industrialisation Centre to deliver on the UK’s Industrial Strategy ‘Future of Mobility’ Grand Challenge to transform the UK into a world leading battery manufacturer for vehicle electrification.

Connected and Autonomous Vehicles

Siddartha Khastgir – Head of Verification and Validation, Intelligent Vehicles at WMG, University of Warwick

The global Connected and Autonomous Vehicles (CAV) industry is estimated to be worth over £50billion by 2035, with the UK CAV industry comprising over £3billion of this. The UK Government's Industrial Strategy aims to bring fully autonomous cars without a human operator on UK roads by 2021, which will make us one of the first countries to achieve this.

The CAV vision is motivated by the potential societal benefits the technology offers – increasing safety, decreasing traffic congestion and driving lower emissions. At WMG, we’re striving to deliver these through Intelligent Vehicles research exploring Verification and Validation, Communications (i.e. 5G), Experiential Engineering, Supply Chains, Cyber Security and Cooperative Autonomy.

Our involvement in research programmes like the £35m Midlands Future Mobility focuses on “smart miles”, proving concepts and getting products to market. Led by WMG, Midlands Future Mobility is an “on-road ecosystem” comprising nine partners with a shared objective – To launch the first service offering of public road testing by mid-2020.

Times are changing.

The British Science Festival is coming to Coventry and Warwickshire

One of Europe’s largest science festivals is coming to town between September 10th and 13th.

With a schedule comprising more than 100 free events, activities and performances, the British Science Festival will “transform the region into a celebration of science and culture”.

The festival will feature talks from a selection of WMG experts, including Erik Kampert - Senior Research Fellow, Dave Greenwood – Professor of Advanced Propulsion Systems, Mark Williams – Professor of Metrology and Alan Chalmers – Professor of Visualisation.

Held in partnership with the University of Warwick, the programme highlights local strength in digital technologies, smart cities and the future of energy and healthcare.

There’s a special emphasis on the fun, thought-provoking, and societal aspects of science to show how it’s not just confined to laboratories, but something that’s all around us.

Plus, there will be a special filming of The Sky at Night: Question Time with Dr Maggie Aderin-Pocock and Professor Chris Lintott.

Other highlights include interactive experiences like a live 3-D psychedelic show and festival carpool in a driverless pod, discussions on how ‘gaming becomes gambling’, how AI could revolutionise cancer treatment, and how to tackle food poverty with food writer Jack Monroe.

Not to mention, a mud kitchen and tea-blending for adults and a takeover of Coventry’s FarGo Village with comedy, artistic workshops and an escape room.

Book here.

Researchers convert car batteries into units that could power farms in the developing world

As part of a Circular Economy for electric vehicle battery systems, as the number of such vehicles increases rapidly, the need to find the best way to reuse and recycle vehicle batteries becomes just as intense.

In partnership with Jaguar Land Rover, Connected Energy and Videre Global, researchers at WMG, University of Warwick, have found a way not just to recycle those used batteries, but repurpose them as small energy storage systems (ESS) for off grid locations in developing countries or isolated communities.

The repurposed units, each containing approximately 2kWh of energy capacity, will be able to power a small shop, a farm holding, or multiple residential homes.

WMG’s Professor James Marco who was lead researcher on the project said:

“When an electric vehicle’s battery reaches the end of its useful life it is by no means massively depleted. It has simply reached the end of its useful life in a vehicle.

"It is generally accepted that an EV battery has reached end of life when its capacity drops to 80% of a fresh battery. While this is no longer enough to satisfy drivers, it remains immensely useful for anyone who seeks to use the battery in a static situation.”

While such partially depleted batteries remain potentially very useful to other users there are still challenges to overcome, particularly to ensure that they can be used reliably, sustainably, and cheaply in remote locations. These challenges include:

· How to protect the lithium-ion cells from over-charge and discharge

· Can the ESS be made compatible with a variety of other used battery cells and modules from other manufacturers

· How to keep it low cost and easy maintenance, while providing an interface that is easy to use and understand

The WMG team, at the University of Warwick, set about overcoming these challenges with the help of the WMG HVM Catapult and Jaguar Land Rover who supplied batteries and components from the Jaguar I-PACE, their first all-electric performance SUV. The team designed a new Battery Management System (BMS) and packaging that allowed them to create a working and easily portable prototype ESS which included:

• The use of standard low cost components for control, communication and safety functions. All parts were either sourced from the JLR service department or were low cost components purchased from any electrical retailer.

• The ability to use different modules that could be interchanged within the 2nd-life system without having to recalibrate the whole BMS

• Enough energy for a small shop, farm holding or multiple residential homes

• Multiple 12V DC sockets and 5V USB charge ports

• The ability to have the 2nd –life module charged via reclaimed laptop chargers

• Simplified control system for easy integration and deployment

Professor James Marco continues:

“This is a great result that not only provides a highly efficient repurposing solution for automotive batteries but which could also change lives in remote communities. We are now looking for support to allow these new units to be further developed and tested in remote or off grid locations.”

The research project was part of the Innovate UK funded Project: 2nd hEVen (2nd-Life Energy Storage Systems) and is supported by the WMG High Value Manufacturing (HVM) Catapult.

Charging ahead!

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

In its role as the Electrical Energy Storage APC Spoke, WMG’s battery experts together with guest lecturers facilitate a mix of presentations and practical hands-on lab sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

The new collaborative Battery School was officially opened by Neil Morris, CEO of the Faraday Institution, with the first session held for 25 PhD students and future battery engineers, in June.

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is situated at WMG’s Energy Innovation Centre – the largest facility of its kind in the UK. Find out more about the Energy Innovation Centre here.

How you charge your mobile phone could compromise its battery lifespan

Researchers at WMG at the University of Warwick have found that use of inductive charging, whilst highly convenient, risks depleting the life of mobile phones using typical LIBs (Lithium-ion batteries)

Consumers and manufacturers have ramped up their interest in this convenient charging technology, abandoning fiddling with plugs and cables in a favour of just setting the phone directly on a charging base.

Standardisation of charging stations, and inclusion of inductive charging coils in many new smartphones has led to rapidly increasing adoption of the technology. In 2017, 15 automobile models announced the inclusion of consoles within vehicles for inductively charging consumer electronic devices, such as smartphones – and at a much larger scale, many are considering it for charging electric vehicle batteries.

Inductive charging enables a power source to transmit energy across an air gap, without the use of connecting wire but one of the main issues with this mode of charging is the amount of unwanted and potentially damaging heat that can be generated. There are several sources of heat generation associated with any inductive charging system – in both the charger and the device being charged. This additional heating is made worse by the fact that the device and the charging base are in close physical contact, any heat generated in one device may be transferred to the other by simple thermal conduction and convection.

In a smartphone, the power receiving coil is close to the back cover of the phone (which is usually electrically non-conductive) and packaging constraints necessitate placement of the phone’s battery and power electronics in close proximity, with limited opportunities to dissipate heat generated in the phone, or shield the phone from heat generated by the charger. It has been well-documented that batteries age more quickly when stored at elevated temperatures and that exposure to higher temperatures can thus significantly influence the state-of-health (SoH) of batteries over their useful lifetime.

The rule of thumb (or more technically the Arrhenuis equation) is that for most chemical reactions, the reaction rate doubles with each 10 °C rise in temperature. In a battery, the reactions which can occur include the accelerated growth rate of passivating films (a thin inert coating making the surface underneath unreactive) on the cell’s electrodes. This occurs by way of cell redox reactions, which irreversibly increase the internal resistance of the cell, ultimately resulting in performance degradation and failure. A lithium ion battery dwelling above 30 °C is typically considered to be at elevated temperature exposing the battery to risk of a shortened useful life.

Guidelines issued by battery manufacturers also specify that the upper operational temperature range of their products should not surpass the 50−60 °C range to avoid gas generation and catastrophic failure.

These facts led WMG researchers to carry out experiments comparing the temperature rises in normal battery charging by wire with inductive charging. However the WMG were even more interested in inductive charging when the consumer misaligns the phone on the charging base. To compensate for poor alignment of the phone and the charger, inductive charging systems typically increase the transmitter power and/or adjust their operating frequency, which incurs further efficiency losses and increases heat generation.

This misalignment can be a very common occurrence as the actual position of the receiving antenna in the phone is not always intuitive or obvious to the consumer using the phone. The WMG research team therefore also tested phone charging with deliberate misalignment of transmitter and receiver coils.

All three charging methods (wire, aligned inductive and misaligned inductive) were tested with simultaneous charging and thermal imaging over time to generate temperature maps to help quantify the heating effects. The results of those experiments have been published in the journal ACS Energy Letters in an article entitled “Temperature Considerations for Charging Li-Ion Batteries: Inductive versus Mains Charging Modes for Portable Electronic Devices.”

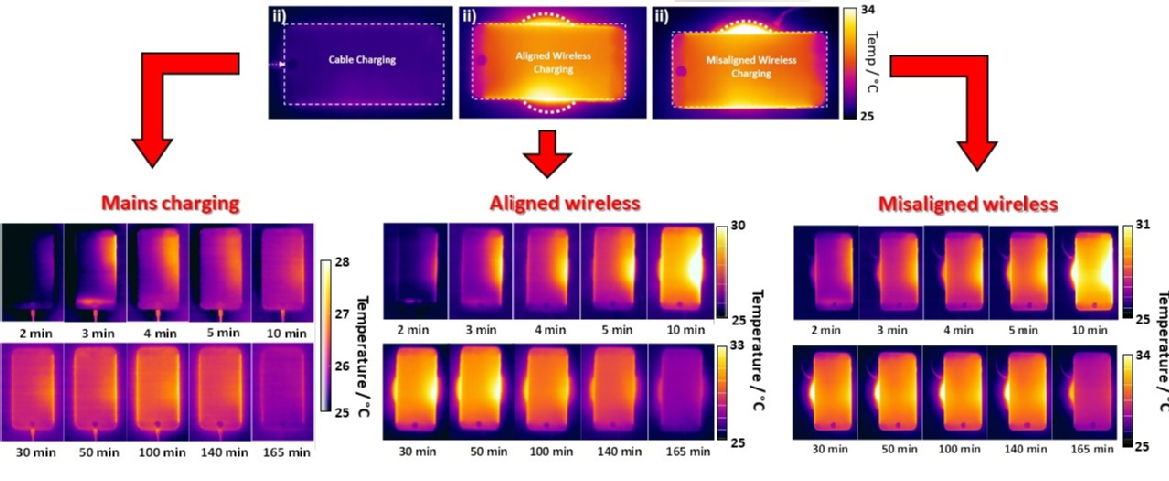

The graphics with this press release illustrates three modes of charging, based on (a) AC mains charging (cable charging) and inductive charging when coils are (b) aligned and (c) misaligned. Panels i and ii show a realistic view of the charging modes with a snapshot of the thermal maps of the phone after 50 min of charging. Regardless of the mode of charging, the right edge of the phone showed a higher rate of increase in temperature than other areas of the phone and remained higher throughout the charging process. A CT scan of the phone showed that this hotspot is where the motherboard is located In the case of the phone charged with conventional mains power, the maximum average temperature reached within 3 hours of charging did not exceed 27 °C.

The graphics with this press release illustrates three modes of charging, based on (a) AC mains charging (cable charging) and inductive charging when coils are (b) aligned and (c) misaligned. Panels i and ii show a realistic view of the charging modes with a snapshot of the thermal maps of the phone after 50 min of charging. Regardless of the mode of charging, the right edge of the phone showed a higher rate of increase in temperature than other areas of the phone and remained higher throughout the charging process. A CT scan of the phone showed that this hotspot is where the motherboard is located In the case of the phone charged with conventional mains power, the maximum average temperature reached within 3 hours of charging did not exceed 27 °C.

In contrast this for the phone charged by aligned inductive charging, the temperature peaked at 30.5 °C but gradually reduced for the latter half of the charging period. This is similar to the maximum average temperature observed during misaligned inductive charging.

In the case of misaligned inductive charging, the peak temperature was of similar magnitude (30.5 °C) but this temperature was reached sooner and persisted for much longer at this level (125 minutes versus 55 minutes for properly aligned charging).

Also noteworthy was the fact that the maximum input power to the charging base was greater in the test where the phone was misaligned (11W) than the well-aligned phone (9.5 W). This is due to the charging system increasing the transmitter power under misalignment in order to maintain target input power to the device. The maximum average temperature of the charging base while charging under misalignment reached 35.3 °C, two degrees higher than the temperature detected when the phone was aligned, which achieved 33 °C. This is symptomatic of deterioration in system efficiency, with additional heat generation attributable to power electronics losses and eddy currents.

The researchers do note that future approaches to inductive charging design can diminish these transfer losses, and thus reduce heating, by using ultrathin coils, higher frequencies, and optimized drive electronics to provide chargers and receivers that are compact and more efficient and can be integrated into mobile devices or batteries with minimal change.

In conclusion, the research team found that inductive charging, whilst convenient, will likely lead to a reduction in the life of the mobile phone battery. For many users, this degradation may be an acceptable price for the convenience of charging, but for those wishing to eke out the longest life from their phone, cable charging is still recommended.

ENDS

26 JUNE 2019

NOTES FOR EDITORS

While one specific model of mobile phone was used to conduct the tests the issues raised obviously apply to all phones or portable devices now or in the future that seek to use inductive charging.

High-res image available at: https://warwick.ac.uk/services/communications/medialibrary/images/june2019/iphone_charging_mode_2.jpg

Credit: WMG, University of Warwick

Paper available to view at: https://pubs.acs.org/doi/10.1021/acsenergylett.9b00663

List of Authors (all WMG) include:

Melanie. J. Loveridge

Chaou C. Tan

Faduma M. Maddar

Guillame Remy

Mike Abbott

Shaun Dixon

Richard McMahon

Ollie Curnick

Mark Ellis

Mike Lain

Anup Barai

Mark Amor-Segan

Rohit Bhagat

Dave Greenwood