WMG News - Latest news from WMG

Criminal convicted of making 3D printed guns thanks to WMG expert

Analysis of homemade 3D printed assault rifles at WMG at The University of Warwick has helped convict a criminal in a ground-breaking case.

Analysis of homemade 3D printed assault rifles at WMG at The University of Warwick has helped convict a criminal in a ground-breaking case.

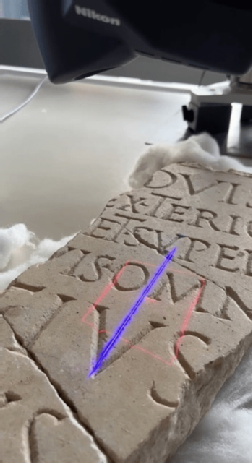

Several homemade 3D printed guns were seized by West Midlands PoliceLink opens in a new window at the home of David Biddell-Portman in December 2020 as part of Operation Captiva, a Police response designed to reduce firearm deaths across greater Birmingham.

Professor Mark WilliamsLink opens in a new window, an expert in 3D printing and scanning at WMG was called in by West Midlands Police. His 3D scanning machines are 100 times more powerful than a hospital CAT scanner and can view images in detail smaller than a human hair.

By using his cutting-edge technology to scan the weapons, Mark was able to discover the amounts of metal and plastic in each of the weapons. This is achieved by analysing the different densities of the materials.

This crucial evidence helped prove that these homemade guns would be working and potentially deadly weapons. It also showed the levels of sophistication, effort and premeditation that went into the construction of the guns.

This evidence was crucial in securing a conviction, with the defendant receiving a five-year sentence.

Professor Mark Williams said: “It’s satisfying to see justice served, and I’m glad to use our technology in any way we can to help the efforts of West Midlands Police.

“By making this sort of technology available to the public sector, we’re ensuring it’s not just big companies that have access to cutting edge techniques.

“A dangerous criminal is now off the streets thanks to the efforts of West Midlands Police, and I look forward to our continuing work with them.”

By scanning the guns, police ensured that the judge and jury were aware of the extensive use of metal in the weapons – a sure sign that, when completed, they would have been working and potentially deadly weapons.

It also meant that the state of the guns was recorded if they deteriorated during test firing of the weapons by police, something that often occurs with 3D printed guns. The scanning also ensured that the police, judge and jury could understand the evidence surrounding the weapons.

For many, 3D printed weapons have never been encountered before, and are often irregular and defy categorisation due to their black market, homemade construction. With the scans, police could identify the closest professionally made weapons and make comparisons.

Michelle Painter, Deputy Head of Forensics at West Midlands Police commented: “This partnership is invaluable to West Midlands Police, the strength and commitment is truly unique and the boundaries are limitless.

“The application of the use of Micro CT scanning in criminal cases continues to be innovative and ground-breaking and progresses investigations and brings justice for victims.”

The conviction is the latest success in the decade long partnership between Professor Williams, WMG, Warwick and West Midlands Police. They recently marked a milestone, with the scanning technology having been used in over 300 casesLink opens in a new window since 2014.

The full paper on the case can be read hereLink opens in a new window.

Read more about WMG’s Centre for Imaging, Metrology, and Additive Technologies (CIMAT) here: Metrology and 3D Imaging (warwick.ac.uk)Link opens in a new window

WMG Professors become Fellows of the Royal Academy of Engineering

Two Professors at WMG at the University of Warwick have been elected as Fellows of the prestigious Royal Academy of EngineeringLink opens in a new window.

Professor Claire DavisLink opens in a new window, Head of Advanced Steel Research Centre; and Professor Mark WilliamsLink opens in a new window, Head of the Metrology and Visualisation Research Group, at WMG, have been elected as part of a group of 71 leading figures in the field of engineering and technology.

WMG, have been elected as part of a group of 71 leading figures in the field of engineering and technology.

The group consists of 60 Fellows, six International Fellows and five Honorary Fellows, each of whom has made exceptional contributions to their own sector.

Each Fellow has been involved in pioneering new innovations, leading progress in business or academia, providing high level advice to government, or promoting wider understanding of engineering and technology.

The new Fellows will be formally admitted to the Academy at a special ceremony in London on 27 November, when each Fellow will sign the roll book.

In joining the Fellowship, they will lend their unique capabilities to achieving the Academy’s overarching strategic goal to harness the power of engineering to create a sustainable society and an inclusive economy for all.

Professor Davis said: “I am very honoured to have been elected a Fellow of the Royal Academy of Engineering. It is an exciting and dynamic time for the global steel industry and I look forward to working with the Royal Academy in promoting clean technologies for the future.”

Professor Davis said: “I am very honoured to have been elected a Fellow of the Royal Academy of Engineering. It is an exciting and dynamic time for the global steel industry and I look forward to working with the Royal Academy in promoting clean technologies for the future.”

Professor Mark Williams said: “I’m honoured to be elected as a Fellow of the Royal Academy of Engineering and am extremely grateful to colleagues across the country who have seen fit to elect me.

“It’s a long way from my time as an apprentice to the Royal Academy. I’d like to thank my colleagues at Warwick who have supported me over my career here and look forward to working with the other Fellows.”

Dr John Lazar CBE FREng, President of the Royal Academy of Engineering, says: “Our new Fellows represent some of the most talented people in the world of engineering and are taken from the ranks of those who are aiming to address some of our most critical problems.

“We are proud to say that many of our newly elected Fellows have come from underrepresented groups in engineering and related sectors and we hope this helps to tackle some of the issues around a lack of diversity within the profession.

“There is ample evidence that a wider pool of ideas and experiences helps to improve decision-making and develop novel solutions to global challenges.”

See the complete list of Fellows elected here: Royal Academy of Engineering Fellows 2024 (raeng.org.uk)Link opens in a new window

Advanced technology could give us ‘personalised’ hip replacements

‘Personalised’ hip replacement surgery might be just what the doctor ordered for people with hip arthritis – according to new research. Using advanced technology from other industries such as automotive and manufacturing, researchers are driving medical advancement.

The result is tailored hip replacements, as each person moves their hips in slightly different ways. At the moment, replacements are based on a ‘normal’ hip rather than being specifically designed for the patient.

In the study by WMG at The University of Warwick, in collaboration with University Hospitals Coventry and Warwickshire (UHCW) NHS Trust and Corin Group, researchers revealed this pioneering approach to hip replacements could improve patient outcomes and surgery success rates.

More than 100,000 people in the UK undergo hip replacements each year, according to the NHS – commonly due to arthritis, a disease of the joints which causes significant pain.

The new study analysed longstanding problems in hip replacement surgery: on the specific range of motion needed in a replacement and how the value of the personalised surgery could be calculated before any operation.

In the study, Lead Researcher Dr Arnab Palit, Assistant Professor at WMG at The University of Warwick, and his team combined real-life and computer models to compare simulated and real hip motions.

This demonstrated that certain hip motions can be easily and accurately calculated using state-of-the-art computer simulations based on CT scans of the patient’s hip joint, closely mirroring real hip motions.

This advancement could enable surgeons to plan hip surgeries based on patient-specific target hip motions, rather than relying on population norms or arbitrary 'normal' values. This personalised approach is particularly valuable for patients who do not fall within these average values, ensuring that pre-surgical planning is truly individualised and likely to be more effective.

Using these tailor-made hip replacements could improve the success of operations, making them ‘right at the first time’. Surgeons may be able to put the artificial hip in just the right spot based on the pre-operatively calculated personified target hip motion.

This could reduce the chances of any clinical problems later on, minimising the risk of revision surgery. This will also help to improve the recovery time of patients, while also reducing additional costs and labour to the NHS.

Dr Palit said: “This research shows a big step forward in hip replacement planning. By using computer simulations based on a patient's hip shape from CT scans, we can predict certain hip movements accurately. During surgery, these predicted movements can guide them to place implants in the best positions for each patient.

“So, instead of using average measurements, we're customising the surgery to fit each person perfectly, leading better surgery. Further research will be necessary to fully explore its potential to utilise it for NHS patients.”

Professor Richard King, Clinical Orthopaedic Surgeon at UHCW and the clinical lead of the project, commented: “The hip replacement has been called ‘the operation of the century’.

“As surgeons, we are constantly looking to make it better and more reliable. This work we have done with WMG could help us to do exactly this, by showing us how to tailor the operation precisely for each individual patient.”

Dr Christopher Plaskos, Vice President, Global Clinical Innovation at Corin Group added: “Corin is proud to support this research aimed at predicting the true range of clinical motion of a hip joint from pre-operative CT and hip motion simulation. It’s research like this that will shape the future of hip planning, leading to truly personalised hip replacement.”

Find out more about WMG’s scanning capabilities here: Metrology and 3D Imaging (warwick.ac.uk)

How the cookie crumbles: University of Warwick X- ray tech used to reveal the secrets of baking the perfect biscuit

WMG at the University of Warwick and Cadbury have used powerful X-ray scanning equipment to uncover the secrets of how the structure of biscuits, which is essential for the perfect ‘crunch’, forms.

The discoveries have been released to mark National Biscuit Day this Wednesday, 29th May. Biscuits are the UK’s favourite sweet treat, with the average person in the UK eating around six a week.

WMG researchers scanned biscuits in a bespoke oven as they baked, imaging the inside of the biscuit to reveal how the porous structure, essential for the perfect ‘crunch’, forms during the baking process.

WMG researchers scanned biscuits in a bespoke oven as they baked, imaging the inside of the biscuit to reveal how the porous structure, essential for the perfect ‘crunch’, forms during the baking process.

Associate Professor at WMG’s Centre for Imaging, Metrology and Additive Technologies, Jay Warnett, said that this was just the beginning for the technology:

“Joining forces with Cadbury, we're cracking the code to the perfect biscuit. Through our X-rays, we're helping uncover the ideal baking time, thickness, and recipe for the ultimate eating experience”.

“But our research doesn't stop there; we're diving deeper into the world of biscuits and baked food and hope to continue working with Cadbury for a long time to come”.

Researchers at WMG, who were approached by Cadbury, constructed an oven from scratch inside an X-ray CT scanner – a similar machine to what you might find in a hospital.

Using the latest algorithms, the imaging process was sped up to scan the biscuit every 20 seconds throughout the baking process. When put together, the WMG and Cadbury teams could observe the biscuit baking over time.

Principal Scientist at Cadbury, Thomas Curwen, is excited for the future of biscuit development:

“The latest algorithms have allowed us to watch and quantify the baking process inside the biscuit in greater detail than ever before. This capability will help us determine the function of different ingredients in more detail and how the structure that forms controls the eating experience. I am excited by what we can learn and how this will help us deliver the great tasting biscuits of the future.”

The research process, which was led by Dr Warnett and Research Fellow Dr Evelien Zwanenburg, has proved the concept possible, and is therefore likely to be the first step before a larger project later this year.

This future work aims to extend the work across other biscuit varieties and baked goods.

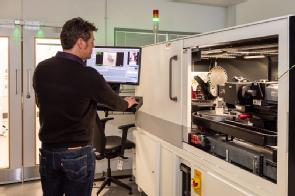

Pioneering CT scanning tech facility opens at WMG

A new CT scanning facility has been unveiled at WMG at the University of Warwick’s Centre for Imaging, Metrology and Additive Technologies (CiMAT).

The facility was officially opened by Dean of WMG, Professor Robin Clark; and Lady Bhattacharyya, the wife of the late Professor Lord Bhattacharyya who founded WMG in 1980.

The facility was officially opened by Dean of WMG, Professor Robin Clark; and Lady Bhattacharyya, the wife of the late Professor Lord Bhattacharyya who founded WMG in 1980.

CT is becoming increasingly important within industry, assisting new manufacturing processes and supporting work on complex products and materials.

Within CiMAT, researchers and engineers use advanced technology, tools and techniques, to deliver impact in a range of sectors including archaeology, healthcare and forensics.

Since first opening in 2021, over 300 projects from 46 different companies have passed through the facility.

An additional £1m has now been invested by WMG, the EPSRC and the National X-ray Computed Tomography (NXCT) research facility to expand research capabilities and to create a dedicated teaching and learning space for PhD students.

Professor Mark Williams, who heads up the CiMAT at WMG, explains: “ The scanning technologies, such as high-resolution laser scanning and microfocus CT, enable 3D characterisation of internal and external structures. With a total of five different CT systems, the group is capable of supporting a wide range of applications, from small scale to large scale, high resolution to high powered penetration for dense materials.”

High profile work includes forensic partnerships with 30 police forces across the UK whereby the use of cutting-edge 3D imaging tech has been used to view injuries in incredibly high detail providing crucial evidence in over 300 murder cases.

Professor Williams add: “The use of CT in a variety of engineering areas is growing rapidly, and we are leading the way in fast scanning technologies. Through iterative reconstruction methods we can bring scan times down from hours/minutes down to minutes/seconds.”

Find out more about CiMAT here: Metrology and 3D Imaging (warwick.ac.uk)

University of Warwick technology helps solve over 300 murder cases

Over 300 murder cases have been solved over the last decade using cutting edge 3D imaging technology from WMG at the University of Warwick.

The technology, which can produce images with resolutions 1000 times more detailed than a hospital CT scan, has been used in murder cases by 30 police forces across the UK to view injuries in incredibly high detail.

This has helped to convict the guilty, as well as prove innocence. The technology is so advanced that it can show the difference between a wound inflicted with force, versus the typical profile of one delivered by natural causes. Cases have included strangulation, stabbing, blunt force trauma and bone fractures.

This has helped to convict the guilty, as well as prove innocence. The technology is so advanced that it can show the difference between a wound inflicted with force, versus the typical profile of one delivered by natural causes. Cases have included strangulation, stabbing, blunt force trauma and bone fractures.

The technology was first used in 2014 when West Midlands Police approached WMG’s Professor Mark Williams. They asked him to help with their investigation into the grisly Birmingham canal murder, where a body was discovered in a suitcase in a Birmingham canal.

Professor Williams comments: “We were able to help the Police by examining a charred piece of evidence thought to contain human bone.

“We discovered that it was a perfect jigsaw fit to another piece of bone in the suitcase, and, using the very high-resolution scanning technology, we were able to show the tool marks on both pieces in micro scale (one 50th of a millimetre).

“These matched the characteristics expected for the type of saw the offender had disposed of, alongside the victim.”

This microscopic level of detail led to the conviction of murderer Lorenzo Simon, who was jailed for 19 years.

This marked the start of a productive research partnership for WMG with West Midlands Police, who have now used the technology in dozens of murder cases. Now, 30 police forces in the country have used the cutting-edge technology.

The technology has also been used in other high-profile cases, including to rule out foul play. In one case where a 64-year-old had fallen, 3D model printing of the skull of the deceased showed exact matches with the geometry of the doorhandle, suggesting a fall. This resulted in the cause of death being ruled as accidental.

The high-resolution scans were also used to help convict Tipton murderers Nathan Maynard-Ellis and David Leesley, who dismembered their victim. The scans helped prove the deliberate nature of their behaviour after their crime, including the direction and variation of their cuts. Both were convicted and will serve a life sentence.

Read more about WMG’s Metrology and 3D Imaging research here: Metrology and 3D Imaging (warwick.ac.uk)

University of Warwick teams up with Ca’ Foscari University in Venice to create museum exhibitions of the future

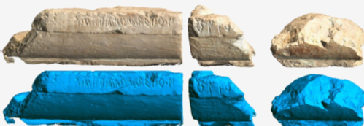

The University of Warwick is collaborating with Ca' Foscari University of Venice to analyse Roman artefacts in a history project which could change the face of museums for the 21st century.

Warwick is working with historians at Ca’ Foscari to scan and analyse artefacts from ancient Roman and pre-Roman Venice, including in 3D and VR forms.

Researchers hope that these artefacts, scanned into 3D and virtual reality (VR), could revolutionise how people experience historical items, including in museums.

Rather than studying items in glass cases, artefacts could instead be scanned and produced using 3D printing or VR technology so visitors can hold and experience history in a whole new way.

This is especially vital when the items themselves are fragile or extremely old, meaning the originals can’t be held or examined by the public.

The collaboration between Warwick and Ca’ Foscari is focused on over 30 items related to religion from the Roman settlement of Altinum – the ancestor of the city of Venice.

Altinum is larger than Pompeii but remains mostly unexcavated, with researchers suggesting a trove of artefacts may be there waiting to be discovered.

The items themselves are from the Roman period and before, including from the Venetii natives who were assimilated into the Roman Empire over centuries.

The artefacts are being analysed by historians at Ca’ Foscari, with engineers at Warwick using cutting edge imaging technology to scan the items in incredibly high definition.

This helps historians read writing from the period and is especially vital when some artefacts have been damaged or are fragmented.

Academics at Warwick and Ca’ Foscari presented their findings at a conference in Venice on Friday (24th November), highlighting the potential of the combined arts knowledge of Ca ‘Foscari and the technology of WMG.

Professor Mark Williams, Head of the Centre for Imaging, Metrology and Additive Technology (CiMAT) at WMG commented: “This is an excellent example of universities working together, including across the arts and sciences. This scanning technology has truly exciting possibilities, including for the future of historical learning and we were delighted to be able to assist our Venetian colleagues in bringing a small section of their history to life”.

Professor Mark Williams, Head of the Centre for Imaging, Metrology and Additive Technology (CiMAT) at WMG commented: “This is an excellent example of universities working together, including across the arts and sciences. This scanning technology has truly exciting possibilities, including for the future of historical learning and we were delighted to be able to assist our Venetian colleagues in bringing a small section of their history to life”.

Associate Professor Lorenzo Calvelli, a historian at Ca’ Foscari University, said: “These artefacts represent the very beginnings of Venice from over two millennia ago, and we are very pleased to be able to bring this history to a wider audience, both here in Italy and in the UK.

“It has been excellent to meet and collaborate with colleagues from Warwick, and I am very excited about our future plans to dive deeper into the treasure trove of artefacts that is waiting for us in Altinum”.

Altinum developed over the course of the Roman Empire into a booming trading hub, particularly know for valuable amber and horses which were prized across Europe. Eventually, refugees from Altinum are believed to have contributed to the founding of Venice in the wake of the fall of the Roman Empire.

Professor Rachel Moseley, Chair of the Faculty of Arts at Warwick, commented: “This is an excellent example of science and the arts working together to create exciting new possibilities.

“Every day, we see scientific advances allowing us to delve deeper into history in a way which recently we would have thought was impossible. Equally, the arts give science that grounding and philosophy to make these advances tangible to the public.

“I’m delighted that our new base of Warwick Venice Centre has brought all these excellent researchers together and is already encouraging collaboration in a hugely positive way.”

AI triaging of shrapnel wounds developed through UK and Ukraine partnership

Researchers in the UK and Ukraine are teaming up to develop artificial intelligence (AI) that will help treat those wounded by shrapnel.

Scientists at WMG at the University of Warwick and the Kharkiv National University of Radio Electronics (NURE) in Ukraine are developing AI software that will help medics understand which patients require immediate treatment, due to life-threatening wounds that might not be obvious with the naked eye. The state-of-the-art technology enables users to feed data from a CT scan to a computer programme, which will help medics make quick decisions on which of the injured require most immediate treatment.

will help medics understand which patients require immediate treatment, due to life-threatening wounds that might not be obvious with the naked eye. The state-of-the-art technology enables users to feed data from a CT scan to a computer programme, which will help medics make quick decisions on which of the injured require most immediate treatment.

The project is one of 33 being discussed at the House of Lords this evening, to mark the one-year anniversary of the Twinning initiative – an institution-to-institution collaboration model which allows universities around the world to support their Ukrainian counterparts in real, concrete ways. It is funded by a £5m grant from Research England, administered by Universities UK International (UUKi).

Professor Mark Williams, WMG at the University of Warwick, said: “A huge problem for medics dealing with many severely injured people at the same time is the rapid identification of life-threatening injuries so they can prioritise who needs emergency surgery soonest. This is why we’re developing software with the team in Kharkiv to help address this issue. As well as being useful in other emergency situations such as earthquakes, the research is also applicable to doctors in trauma wards – already stretched by pressures experienced by the NHS – who need to triage patients quickly.

“For WMG’s part of the project, we will be creating phantom models using 3D imaging – replicas of human anatomy and shrapnel wounds. These will act as ‘test objects’, which experts in computer science can use to calibrate their technology and AI programme.

‘test objects’, which experts in computer science can use to calibrate their technology and AI programme.

“It is very exciting to be able to bring our expertise in Additive Manufacture at WMG to deliver a rapid solution to such an important humane need, allowing us to truly exploit the incredible advantages in speed of response and material complexity offered by this technology.”

Anastasiya Chupryna, coordinator of Radio Electronics-Warwick Allied Research and Development (REWARD) project at NURE said: “We would like to thank our partner Warwick University for supporting us in joint research activities. Within this project NURE and Warwick University will be able to solve extremely important problems. We believe that practical results of these projects will demonstrate significant impact and innovation solutions for society.”

WMG is considered the leading international role model for successful collaboration between academia and the public and private sectors by successive UK Governments. The WMG specific research is funded by a £179k grant from UUKi.

More here https://www.ukri.org/news/research-england-invests-in-uk-ukraine-university-twinning-scheme/

Ends

University of Warwick press office contact:

Annie Slinn

Communications Officer | Press & Media Relations |

Email: annie.slinn@warwick.ac.uk

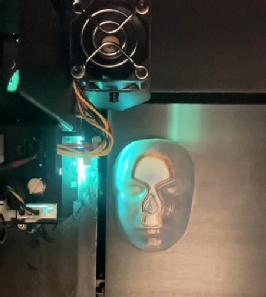

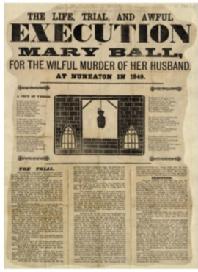

Ground-breaking science will help illustrate Coventry’s last hanging story in pop-up museum

· On International Museum Day (18 May) we’re revealing an inspiring partnership between WMG at the University of Warwick and West Midlands Police

· Experts from WMG, University of Warwick have created a 3D copy of the death mask of Mary Ball, the last woman to be hung in Coventry.

· It’ll go on display in the pop-up museum opening as part of Coventry UK City of Culture

The ‘Forensic Centre for Digital Scanning and 3D printing’, an innovative partnership between West Midlands Police and world-leading researchers at WMG, University of Warwick, is helping to make history more accessible to museum-goers in Coventry.

Having already established a long term relationship with WMP through ground-breaking forensic work, in which researchers from WMG apply cutting edge 3D Scanning and Additive Manufacturing technology normally used in Automotive and Aerospace industries to support Homicide investigations, researchers can use the same technology to help illustrate one of Coventry’s most famous criminal cases, that of Nuneaton housewife Mary Ball who was the last women to be publicly hung in the city, on 9 August 1849.

3D Scanning and Additive Manufacturing technology normally used in Automotive and Aerospace industries to support Homicide investigations, researchers can use the same technology to help illustrate one of Coventry’s most famous criminal cases, that of Nuneaton housewife Mary Ball who was the last women to be publicly hung in the city, on 9 August 1849.

The WMG researchers have created a digitally-scanned 3D replica of Mary’s death mask which will go on display in a pop-up museum West Midlands Police are opening in Coventry city centre as part of the city’s year as UK City of Culture.

Professor Mark Williams, from WMG, University of Warwick says projects like this help provide digital archives and preserve important history:

“It is a real privilege to support West Midlands Police. The opportunity to apply state-of-the technology to support murder investigations, and secure justice for victims and their families, is very exciting.

“It is a real privilege to support West Midlands Police. The opportunity to apply state-of-the technology to support murder investigations, and secure justice for victims and their families, is very exciting.

“But projects like the Mary Ball death mask are incredibly rewarding too. We’re delighted to play our part in preserving Coventry’s history and making it accessible to everyone in support of the city of culture celebrations.”

Michelle Painter, assistant director of our forensics team, approached the team at WMG to help produce the copy:

“We’ve worked with the team on many high-profile criminal cases but I knew the science could be used for other things too.

“During a visit I saw a replica the team had created of the Queen’s favourite wedding cake which had been vandalised with red paint while on display in a museum. It was incredible.

“I knew they’d be able to do justice to Mary Ball’s death mask so I asked them to help us bring her story to life for the museum.”

The replica is an exact copy of the death mask and by putting the 3D version on display, it means museum visitors will be able to touch and hold the mask, making it more accessible, especially to those who are blind or partially-sighted.

Mary Ball’s story is a sad one. She was in a violent marriage and five of her six children had died. One day when her husband Thomas came home from fishing he ate a bowl of stew and bread. He later fell ill with stomach pains and died the next day. The doctor ruled he’d died of natural causes as a result of inflammation of the bowels. However, gossip spread about his death. Mary was said to have suffered enough at the hands of her violent husband and was accused of buying arsenic which she mixed with salt for the stew. A post mortem later found arsenic in Thomas’ stomach and Mary was charged with murder. She was convicted by a sympathetic jury who recommended mercy. However, they could offer no legal reason for leniency because at the time, having a violent husband was no defence. The judge sentenced her to death by hanging.

Awaiting her punishment, Mary was visited by the prison chaplain. Frustrated with Mary’s refusal to confess he held a lit candle to her arm causing blisters and burns. The governor of Coventry prison heard about the torture and dismissed the chaplain. The following day, Mary reportedly confessed. She put the change of heart down to having suffered enough already.

Mary was buried within the grounds of Coventry prison.

Corinne Brazier, West Midlands Police’s heritage manager said:

“The death mask is an incredibly emotive object telling the story of Mary Ball, a story that would have had a very different ending if it had taken place today.

“The 3D scanning process has allowed us to capture finer details of Mary’s face and might give us more of an idea of what she would have looked like.

“Whilst it might seem a bit macabre to have such an object on display, it’s an important story that needs to be told and no photographs exist of Mary to bring the very personal side of her story to life.”

The pop-up museum is due to open to the public in June.

ENDS

18 MAY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mary_ball_1_.jpg

Caption: Images of the scans conducted by researchers at WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mary_ball_3.jpg

Caption: 3D printing the death mask

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mary_ball_2.jpg

Caption: Left is the 3D print, right is the original death mask

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mary_ball_5_.jpg

Caption: The newspaper article about Mary Ball’s execution

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mary_ball_4.jpg

Caption: The plaque were Mary Ball’s execution took place

Credit: WMG, University of Warwick

To see the progress of the museum follow @WMPHistory on Twitter or ‘The Lock Up’ on Facebook.

To find out more about WMG’s work, visit https://warwick.ac.uk/fac/sci/wmg/ and https://warwick.ac.uk/fac/sci/wmg/about/facilities/forensic/

To find out more about Coventry City of Culture visit their website.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Online museum exhibitions will be more prominent post COVID-19

- During the COVID-19 lockdowns in England, many shops and services shut their doors, including museums

- Museums still had to keep their audience interested despite being closed, and therefore moved into the digital world

- The success of online museum exhibitions have been analysed by researchers from WMG, University of Warwick, highlighting how museums have maintained engagement with audiences

- Researchers have however highlighted online exhibition successes, that should be maintained post-COVID, therefore changing the way museums traditionally work

When museums closed their doors in March 2020 for the first COVID-19 lockdown in the UK a majority moved their activities online to keep their audiences interested. Researchers from WMG, University of Warwick have worked with OUMNH, to analyse the success of the exhibitions, and say the way museums operate will change forever.

The cultural impact of the COVID-19 pandemic has been analysed by researchers from WMG, University of Warwick in collaboration with OUMNH (Oxford University Museum of Natural History) who in the paper, ‘Digital Responses of UK Museum Exhibition to the COVID-19 Crisis March-June 2020’ published in the journal Curator: The Museum Journal, have analysed the success of online museum exhibitions, and investigated what the future of Museums holds.

Researchers analysed 21 museums who had temporary exhibitions due to open between March and June 2020, and decided to go ahead with the exhibition virtually. The analysis included noting how COVID was considered, how content was presented, and discussing themes of access, embodiment, and human connection.

The research team found that in May-June museums had more online content for their exhibitions, suggesting there was time to prepare the transfer of exhibition online. All exhibitions were different, with some hosting podcasts, some doing filmed walk-arounds and some hosting a virtual room where you click on exhibits.

Although digital exhibitions were a success, researchers concluded online exhibitions do not provide the same social and embodied experience as the physical museum, as you miss the travelling there, welcome from staff, chatting with other visitors and the gift shop or coffee shop after.

They did however highlight that extra material was provided for online content which isn’t traditionally presented in the museum, this included behind the scenes videos for example. Researchers say this suggests museums were trying to give their audiences some exclusives that they would not receive from a normal visit.

Lead Author, PhD Student Ellie King from WMG, University of Warwick comments:

“The COVID-19 lockdowns have created a crucial turning point in the Museum sector, as they now see themselves working in a physical-digital overlap. It is interesting to note how in being forced to shut, museums focused their online provisions around existing physical exhibitions.

“Museums and galleries will continue to adapt in light of a post‐COVID world where practices, both digital and physical, will undoubtedly shift. It is important to see the digital exhibition world as an opportunity to provide unseen materials and attract audiences who may not be able to visit in person.”

Although it’s likely there will be more online material generated by museums and galleries from now on due to the pandemic, there is the issue of staff having the digital skills to manage a new arena of engagement.

Professor Mark Williams, from WMG, University of Warwick explains:

“One of the major tasks of converting to online is the financial implications, 30% of museums have changed staff tasks to provide services online. Despite this, there are concerns that staff teams are not fully equipped to handle such monumental changes.

“This highlights the practical challenge of enabling the rise of digital content for museums, which will be difficult for the sector in such a stretched resource environment.”

Professor Paul Smith, Director at the Oxford Museum of Natural History adds:

“The first COVID-19 lockdown imposed a real-time stress test on museums, and their ability to respond in an agile way to events. The paper highlights the creative ways in which some museums were able to adapt to the unique and unprecedented circumstances they faced.”

This research is part of a wider interest of the CiMAT team in WMG to engage with subject areas beyond engineering. Based on previous research into User Experience, the research group is seeking to apply concepts into areas of the arts and humanities. The research has blossomed with the collaboration between WMG and Oxford University Museum of Natural History. This research, which analyses how visitors experience museums online, is a welcome starting point. The researchers stress to museums that with this rising atmosphere of change on the horizon, it is important they consider such conceptual issues and evaluate audience needs rigorously when developing online offerings to maintain such cultural importance.

ENDS

12 MAY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/compton_verney_screenshot_.jpg

Caption: Compton Verney’s homepage for the Cranach exhibition which opened in March 2020

Credit: Compton Verney

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk