Success Story Assetbank

WMG creates novel open innovation vehicle platform to support the development and testing of Connected and Autonomous Vehicles products and services

Challenge and Opportunity

By 2035, the Connected and Autonomous Vehicles (CAV) and CAV technologies markets are projected to be worth £650bn globally and £41.7bn in the UK. Developing high capabilities and competitiveness in the production of CAV technologies will give the UK the opportunity to both decrease import shares and increase export shares within relevant markets by up to 50% (against baseline assumptions) – leading to an increase in gross output, GVA and jobs.[1]

To maintain momentum in this area, it is critical that UK industry has access to specialist equipment and people to easily develop, test, and demonstrate products and services, as well as bring them to market.

Solution

With support from the High Value Manufacturing Catapult (HVMC), WMG has developed a vehicle test and evaluation platform to do just this. The Open Innovation Vehicle Platform (OIVP) is an open, modular, and autonomous capable solution complimented by two Mobile Roadside Units (MRSU). It provides an ideal opportunity to accelerate the commercialisation of Connected, Cooperative and Automated Mobility (CCAM) products and services. Both the OIVP and MRSUs are designed to work together during operation, with the MRSU able to act as a temporary roadside infrastructure node to collect and share local perception data in real time to nearby connected vehicles. They provide a highly flexible and open testing platform for the rapid development of novel ideas for UK businesses, particularly SMEs, as well as research organisations and transport authorities.

Impact

A range of industrial and research partners have now started to make use of the platform and roadside units securing >£3.4m in collaborative R&D (CR&D) funding and >£400k in direct contract research (DCR). Highlights have included three recent projects, all focusing on the use of additional information from roadside infrastructure to support driving more safely and efficiently:

- EU L3Pilot (34 partners across 10 countries, including automotive manufacturers such as Volkswagen AG, SMEs, research bodies and government authorities): The MRSU was used to support the OIVP to drive autonomously through a T-Junction even when the view from the ego vehicle was blocked by a parked vehicle.

- EPSRC CARMA (WMG, Jaguar Land Rover, TRL and the University of Surrey): The OIVP was used to demonstrate the benefits provided by the novel three-tier processing CARMA platform. The OIVP was able to optimise its route through a connected roundabout by making use of perception data shared by the infrastructure.

- Innovate UK Autoplex (WMG, Jaguar Land Rover, Highways England, Yunex Traffic, Transport for West Midlands): The OIVP was used to demonstrate how a connected vehicle can make use of infrastructure RADAR sensor data to merge safely and comfortably on a UK public motorway.

Catapult funding has also supported the training and development of five graduate engineers, three of whom have now progressed into WMG Project Engineer roles as core members of the team that operate the OIVP and MRSUs. The project has also supported several PhD / EngD, MSc and undergraduate projects. There is currently an EngD project sponsored by MOLE to develop an automated park function to integrate with a robotic autonomous wired charger.

The platforms and the knowledge developed by the team will also be applied to other sectors such as very light rail, as well as automated guided vehicles used in manufacturing.

What’s Next?

WMG’s applied research is accelerating the development and commercialisation of CCAM solutions, helping to realise its promise of safer, faster, more efficient, and lower carbon transport.

Dr Graham Lee, Principal Engineer at WMG, University of Warwick, commented: “The team has created a highly capable vehicle platform that has already been used in several projects to tackle a variety of complex problems currently being faced by the industry. The MRSU is a unique piece of hardware that allows developers to rapidly test and evaluate novel technologies designed for roadside infrastructure. Both platforms and the knowledge and expertise of the team will enable industry partners to realise and bring to market innovative CCAM products and services.”

Professor Mehrdad Dianati, Head of Intelligent Vehicles Research at WMG, University of Warwick added: “As the transformation of future mobility systems accelerates, there are huge opportunities for the UK’s thriving SMEs, as well as more established businesses. The UK economy is well placed to flourish in knowledge-based sectors in emerging areas such as connected, automated, shared, and electrified future mobility systems and collaborative robotic systems. These facilities are powerful tools for collecting data, training Artificial Intelligence (AI)/Machine Learning (ML) models and testing emerging concepts in Cooperative Autonomy and Multi-Agent Systems, which are becoming increasingly promising technologies across multiple application sectors."

Key features of the OIVP and MRSU currently include:

Open Innovation Vehicle Platform (OIVP)

- Modular / plug-and-play hardware, enabling components to be integrated and positioned easily

- Sensor Suite: 360° camera, LiDAR and ultrasonic as well as forward and rear facing RADAR

- Connectivity: 4G/5G, WiFi, ITS-G5/DSRC and in-vehicle communication (CAN & ethernet)

- GNSS with Real-Time-Kinematic (RTK), providing centimetre level positioning accuracy

- Custom auxiliary battery power system, which can power the additional equipment for all day testing

- Drive-by-wire (DBW) system, which allows the vehicle’s speed, acceleration, steering angle and other parameters to be controlled via software

- Custom Autonomous Control System (ACS) with perception, localisation, planning and control functions

- On-board computing

Mobile Road Side Unit (MRSU)

- Modular / plug-and-play hardware

- Sensor Suite: LiDAR, RADAR, camera and weather sensors

- Connectivity: 4G/5G, WiFi and ITS-G5/DSRC

- Extendable poles up to 8m, to mount equipment at height

- Weatherproof with internal cooling and heating

- Custom battery power system

- On-board/Edge computing

For more information about working with these platforms and the team, email wmgbusiness@warwick.co.uk

[1] Connected Places Catapult (2020). Market Forecast for Connected and Autonomous Vehicles, pp 56.

Journeying to a Wireless Future

Challenge

Wireless charging means being able to charge an electric vehicle without having to plug it in, which can be easier than wired charging, and negates the need for cables. This means there are no trailing cables or heavy connectors which reduces clutter and trip hazards. It’s accessible for people with disabilities, more convenient for fleet charging, and can even enable autonomous vehicles to charge themselves. Charging could be completed at taxi ranks and short-stay car parks like when visiting a supermarket.

In wireless inductive charging systems, high frequency electricity is supplied to a ground pad giving rise to a pulsating magnetic field. This allows power to be transmitted contactlessly via the electromagnetic link to the receiver pad embedded in the base of the vehicle and following rectification it is fed to the DC terminals in the vehicle. A sophisticated control system manages the flow of power to the battery.

Currently, there is no UK supply chain for this technology. High Value Manufacturing Catapult at WMG set out to address this. WMG took on the challenge to design, build and retrofit to an electric vehicle a fully UK-made 20kW wireless charging system. Along with honing expertise as part of this process, engaging with potential UK supply chain partners was a key priority, recognising that many elements of wireless charging systems would be new to potential UK suppliers. WMG was able to work with a range of companies in fabricating and assembling parts for the system (pad-makers, potters, etc.), mechanical integration (retrofitters), electrical integration (EV charger specialists) and back-office (communications, app interface, metering and billing specialists).

Solution

WMG designed, assembled, tested and delivered a working prototype of a 20kW rated wireless charging system, retrofitted and electrically integrated on a BMW i3. Supply chain partners were engaged to construct various parts of the system according to WMG’s specification. WMG contributed expertise in wireless charging, use of a high-performance computing cluster, along with purpose-built analytical design scripts to explore the large potential design space and find an electromagnetic and resonant circuit configuration that would meet requirements. WMG’s laboratory facilities were used to assemble and test the overall system.

The project was a significant step up from previous work, taking a wireless system beyond the laboratory bench and integrating it with a vehicle.

The physical delivery of the wireless charging system was performed under the MK GUL (Milton Keynes Go-Ultra-Low) project, where WMG was contracted through eFIS (an ARUP subsidiary) by Milton Keynes Council for delivering electric vehicle charging or charging support technology. The resulting wireless charging system was publicly demonstrated in three events in Milton Keynes in a central car park location. The demonstration system is mobile (with no permanent ground works on site) so can be used in various locations.

During the demonstration events, members of the public and representatives of the project’s organisations drove the electric vehicle around the car park and aligned it in its parking space containing the charging ground pad. Then they initiated, monitored and terminated the charging process through a mobile app developed by WMG.

Impact

The prototype wireless charging system demonstrated is thought to be the first UK-designed and built wireless charging system to have been retrofitted to an electric vehicle.

As part of follow-on work relating to the Innovate UK OSRIC project, a second copy of the wireless charging system is being constructed for which further UK companies are being engaged and knowledge transfer occurring so that they can understand the assembly activities that were carried out at WMG.

WMG has a notable track record and experience in delivering a number of wireless charging projects, although this is the first one which has been taken out of the lab setting and into a fully functional practical application. WMG took a leading role in the design, development and knowledge transfer regarding wireless charging technology.

Future research will explore further aspects of systems to make them more commercially acceptable and easier to adopt. Also extending research capabilities into the high and very high frequency wireless charging systems, alongside continued engagement with industry partners for the development of a UK supply chain. WMG is not seeking to manufacture systems directly, so working alongside UK-based SMEs will be critical to getting the technology applied in “real life” and commercialised. WMG therefore invites more commercial partnerships in this sector.

Pictured: Members of the project team from WMG (University of Warwick), eFIS (ARUP), and Milton Keynes Go-Ultra-Low.

Uni-WARP project supports companies in a shift to transport electrification

Transport is now the highest emitting sector of the UK economy, accounting for 22% of total green-house gas emissions. The Government has announced plans to make every mode of transport net zero emissions by 2050 and has set ambitious decarbonisation targets. Electric vehicles (EVs) are seeing a surge in demand, with sales of battery electric and plug-in hybrid vehicles accounting for over 13% of sales in January 2021 compared with 6% in 2020 (Society of Motor Manufacturers and Traders, SMMT). But market opportunities in other transport sectors, such as two-wheeled vehicles, aerospace and marine, are growing significantly.

Challenge

While automotive battery technology is relatively well established, other transport sectors are at an earlier stage in their electrification journey. This led to new partners from sectors such as aerospace and off-highway approaching WMG with questions like “what size of battery do I need?” and “what is its mass and volume?”

Engineers in our Energy Innovation Centre (EIC) set out to create a set of easy-to-use modelling tools to provide simple answers to these questions. These tools would support OEMs in non-automotive sectors to better understand battery capacity and sizing as well as analysing the cost-benefit ratio over the lifetime of a single vehicle or fleet.

The Uni-WARP project was funded by WMG Centre High Value Manufacturing (HVM) Catapult and aimed to create tools to help companies to make the right choices early, saving time and cost, ultimately enabling the shift to transport electrification.

Solution

Our team of technical experts created a unique database using real-world battery data compiled from over ten years’ of cell characterisation data from WMG’s own labs, as well as publicly available data on energy and power requirements for electric and hybrid vehicles.

Several models and tools were created to help businesses select the right approach to suit their needs, in terms of system architecture, configuration, cells, subsystems and control.

Two of the key tools of use to industry, trade bodies and Government agencies are:

- Ready reckoner: a high-level sizing tool for wheel-based, aircraft, rail, marine, off-highway and public service vehicles. It calculates the battery size, weight and cost to support decision making.

- Cost-Benefit Analysis (CBA) tool: uses high-level battery pack cost estimates to determine the potential costs and benefits over different timescales and for different technologies. The CBA tool provides a £/kgCO2 saved, and a payback period for the savings compared with a conventional product.

Impact

The tools have already been a critical enabler in electrification decisions for several businesses. In particular, the tools have received positive feedback from firms in the aerospace industry including operators and airports who are working with WMG to help them meet their sustainability targets

The Uni-WARP toolchain was utilised within the Innovate UK funded “Triumph TE-1” project, which aims to create an electric motorcycle technology demonstrator, in collaboration with Triumph Motorcycles Ltd, Williams Advanced Engineering, Integral Powertrain and WMG.

Uni-WARP formed the basis of a study investigating the CO2 savings, cost benefit, energy usage and vehicle payback period for electric motorcycles, for different user groups within the UK. Outputs from study are supporting Triumph with respect to their future product plans and business strategy. Defined CO2 savings and energy usage from this study are directly supporting a government strategy document for electric two wheeled vehicles.

Natalie Fern-Lyons, Special Engineering Programme Lead, Triumph Motorcycles Limited commented, “The battery sizing and cost-benefit analysis tools were a vital input in the Triumph TE-1 project. Understanding the CO2 and energy savings will help us develop a business case for Triumph’s future electric motorcycle offer.”

The tools generated through this project will continue to be used to underpin other collaborative projects across multiple sectors, as well as helping companies to enhance their understanding of battery technology. Further to this, we are supporting trade bodies such as the Aerospace Technology Institute (ATI) to understand the CO2 savings and energy usage in aerospace and aviation.

Digital solutions leave seat manufacturer sitting pretty

Car manufacturing in the UK is changing radically, as the electrification is forcing innovation and design change of almost all parts of cars. Industry leaders are challenged to change design radically, launch new products more quickly, while maintaining quality levels and costs. To keep up with this, many manufacturers in the supply chain are already embracing digital technologies to connect their factories, improve processes and reduce costs. By embracing digitalisation, the electrification of the automotive sector could unlock growth of up to £75bn by 2035, benefitting the entire supply chain.

Using digital to develop manufacturing

Lear Corporation are a leading supplier of automotive seats and electrical systems, and their customers include major OEMs such as Jaguar Land Rover. With a long history in luxury and performance seating, they are one of the world’s largest providers of premium automotive leather seats, operating over 250 facilities across 38 countries, including 3 Just in Time final assembly plants here in the UK.

With safety and performance paramount, Lear must ensure that every seat is of the highest quality but working with comfort materials, such as foam, and natural materials, such as leather, brings with it a number of challenges. Not least, the natural defects that occur in these materials, such as wrinkles and discolouration, which must be rectified before products are ready for the customer.

Back in 2017, Andrew Williams, Director, Process Innovation at Lear Corporation was looking for ways to deploy digital technology to improve their seat inspection process, reducing waste and rework. “Seat inspection takes place at the end of the production line, and it’s a manual process which relies on the judgement of experienced operatives,” Andrew said. “But ultimately, it is subjective, we set our standards very high to protect our customer but human judgement will always have an element of variation.”

Lear wanted to innovate and deploy smart manufacturing solutions that would automate the inspection process, providing increased consistency and generating quantitative product data to the engineers in our relentless pursuit of perfect quality. Lear approached WMG as a market study showed a lack of readily available commercial and deployable solution that suited Lear’s needs at that time.

“We already had a relationship with WMG with apprentice, undergraduate and post graduate training programs. Lear’s philosophy is to constantly look for ways to use new technology to improve manufacturing processes and knowing WMG were all about industry-focused research, we knew they would be a good fit for this challenge.”

Andrew teamed up with our Automation Systems Group on the Lear Seat Manufacturing (LSM) project, supported by funding from WMG Centre HVM Catapult.

Exploring the possibilities

After scoping the project carefully, WMG set about building and testing machine learning-based object detection systems as an inspection tool; Using image capture systems mounted on a seat inspection station, the solution would be capable of detecting and classifying defects, and of assessing whether the seat would be acceptable against the customer standards, or whether additional rework is needed.

Developing the solution and training the AI, involved manually labelling a large data set. To facilitate this process, the team developed a “digital marker” that allows an in-line, in-process labelling workflow.

Dr Dan Vera, Associate Professor at WMG, said: “To train the AI inspection system, you need to tell it what defects are and what they look like. You have to label defects so it learns. Typically, labelling is done offline, after images are captured. With the labelling system developed at WMG, operators can digitally label defects on the real seat, and directly on the production line – we call it the magic wand!”

In order to test how the different elements would work together in a real manufacturing environment, we installed a prototype inspection station in the National Automotive Innovation Centre (NAIC) at WMG before taking the station into Lear’s plants for evaluation in production.

Looking to the future

The machine-learning seat inspection software was trialled at two of their factory sites, allowing it to collect data from different types of seat and improve its ability to recognise and categorise all types of defect. It is now on track to deploy across our plants worldwide.

Andrew said that without the help of the team at WMG, supported by funding from HVM Catapult and Innovate UK, they might have missed this opportunity. “This was unchartered territory,” he reflects. “Because this technology was so new, and there were no commercially available solutions at the time, we would not have had the bandwidth to develop this in house. The cumulative effect of these projects has the potential to significantly increase the consistency of our inspection processes and provide our customer with even higher quality products.”

Lear has showcased the test bed in NAIC to some of their key customers, who have been impressed with the outcomes of their work. There is a continued appetite within Lear to develop new ways to use digital technology to improve their manufacturing processes.

For more information about this project, or working with us, please email wmgbusiness@warwick.ac.uk.

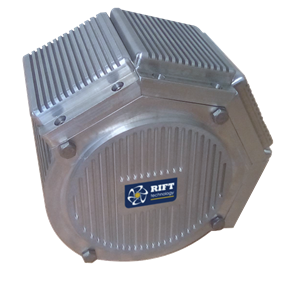

WMG supports RIFT Technology with a greener cost-effective electric motor

A cheaper and more environmentally friendly electric motor for electric vehicles is a step closer to market with the support of WMG at the University of Warwick.

WMG has provided valuable knowledge and expertise in developing a UK focused, cost-effective production and supply chain for RIFT (Reduced Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

The aim of the project was to help RIFT Technology; an R&D company bringing a product to market for the first time, advance RIFT-10 to a higher manufacturing readiness level (MRL 7), to get the motor closer to production, by rooting the supply chain in the UK, rather than abroad (given the disruption to supply caused by the pandemic) and supporting production of trial units.

WMG, is committed to delivering UK economic impact and achieving net-zero by supporting industry in accelerating new concepts to commercial reality. This supports the University of Warwick’s approach to sustainability - the Way to Sustainable – which focuses on the real-life implications of creating a sustainable future and the practical challenges of getting there - prioritising research expertise, sustainability in the curriculum, and developing solutions for the benefit of industry and society.

The team of experts at the University has facilitated the RIFT-10 project to deliver on creating revenue, jobs, CO2 reduction, and supply chain growth in the UK.

RIFT Technology has developed the RIFT 10-30 kW motor (RIFT-10) by taking an exciting innovation from their sister business (RIFT Actuators) and working with APC and the Niche Vehicle Network to get the motor to working prototype stage (installed on a G-Whiz). The novel electric motor configuration is proven to generate 10-30kW of power, torque from 0-400Nm and up to 10,000RPM as demonstrated with a prototype vehicle.

The RIFT 10 motor demonstrated unique advantages over conventional EV motors:

Environmental benefits of the project:

· The low sales cost and attractive features of RIFT-10 enable greater/earlier market adoption of EUV’s, resulting in a reduction of CO2 production over ICE vehicles.

· A RIFT-10 weight saving and efficiency over competing EV motor designs increase vehicle range, resulting in less energy usage over alternatives.

· With RIFT-10, equivalent power output is achieved using fewer raw materials (i.e., 85% reduced copper weight and ~85% reduced magnet volume), resulting in less earth material usage as well as fewer material costs.

· Less materials usage results in an estimated 75% reduction in CO2 produced during manufacture. Planned production efficiencies also lead to further CO2 reductions. An estimated 612,000 Tonnes of CO2 would be saved by year 5.

· Development of an EV motors supply chain in the UK for a UK and EU market reduces international shipping of components thus reduces related CO2 production.

Social benefits of the project:

· RIFT-10 creates/safe-guards 50+ much needed and good-quality manufacturing, sales, administration and R&D jobs in the Malvern area with an estimated X14 more UK jobs across the supply chain (over 5-years).

· Growth of RIFT-10 addresses the government’s priority area of ‘Smart Cities’ by allowing smart monitoring of vehicle fleets efficiency performance, usage and other data points. The use of the Internet of Things and resulting analysis can only be as strong as the data input. Traditional alternatives offer no smart functionality.

James Black, WMG Innovation Manager at the University of Warwick said, “The Covid-19 pandemic has been particularly difficult for SMEs and R&D-focused organisations that have previously relied on face-to-face networking events to find new partners, investors, and customers.

“WMG’s network means we’re in a great position to connect UK companies together to help them accelerate their product to the market, and we’re delighted that RIFT Technology has benefited from our extensive background for practical supply chain solutions that have delivered economic and societal value to the project.”

James O’Donnell, Technical Manager from RIFT Technology said, “As a research and development company bringing a product to market for the first time, RIFT Technology needed to bridge the gap between prototype and small-scale production. We had to answer difficult questions such as what to make and what to buy, high level questions such as how to develop a supply chain strategy and practical questions such as how best to select suppliers.

“With a unique blend of academic expertise and industrial experience from the University of Warwick, WMG’s Supply Chain and Operations Group were able to support us in our journey.”

The project took place during the pandemic, meaning several online workshops were carried out targeting topics such as strategic management, supplier selection and decision-making, and end-of-life strategies.

For further stories, click here.

For more information about this project, or working with us, please email wmgbusiness@warwick.ac.uk.

Students race Embracing sustainability and electrification through motorcycle racing

The UK has formalised its ambitions to accelerate the shift to zero emission vehicles over the last year, which has been illustrated through policy commitments such as the government’s Ten Point Plan for a Green Industrial Revolution.

To reinforce this commitment, the transition to Electric Vehicles (EVs) of all types is being encouraged, with manufacturers doing all they can to make electrified mobility as convenient and cost effective as possible.

Aiming to embrace sustainability and electrification through motorcycle racing, a group of 15 undergraduate and EngD students from WMG, Engineering, Mathematics, Law, Computer Science and Physics departments across the University of Warwick set out ambitions to research the future of electric motorcycle racing in the summer of 2019. The goal was to overcome the challenge of designing, building and racing the University’s first fully electric race-spec superbike.

The Warwick Moto project was supported by WMG Centre High Value Manufacturing Catapult, alongside a selection of leading academics, engineers and researchers, all aiming to help create an electrically powered racing bike. The aim is to promote sustainability through electrification without compromising the characteristics seen in standard race-spec bikes. The project provided an opportunity for students from across the University to expand their knowledge and understanding of an industrial project.

Frontier: An innovative electric superbike solution

Impressed by the students’ ability to design a superbike demonstrated through the preceding ‘Aurora’ project, OEM manufacturer Norton Motorcycles decided to establish a collaboration with students from Warwick University, donating a high-performance sports bike frame and data to support the project and help nurture the skills of the students.

Culminating in the racing bike coined ‘Frontier’, the group produced a solution in just seven months, designing an electric powertrain to accompany the frame, which produces a power output of 160kW and 400Nm torque. This has been coupled with an immersion-cooled battery pack, which is a first of its kind for application in an electric motorcycle, with benefits including extended range and faster charging speed. A tailored control system has also been developed, demonstrating the in-house capability across the group.

The acceleration and speed characteristics of the electric bike in motion translate into a combustion-engine equivalent of around 900cc to 1,000cc.

In order to further the technology, the team also decided to utilise standard charging protocols on the vehicle, allowing not only fast charging capability but also the ability to charge at electric vehicle spots across the country. The vehicle uses the ChAdeMo protocol, and combined with immersion cooling, the team can charge to 80% in just 30 minutes.

These impressive figures have supported the testing and development of the electric bike prototype, with riding time on the track maximised thanks to reduced charging times.

Aman Surana, former Chief Engineer of the Warwick Moto team, said:

“The efforts of the whole Warwick Moto team during my time leading the project resulted in an innovative superbike in Frontier, which has now been widely showcased. Having now graduated, and since achieving a position at Norton Motorcycles, I can see how the learning and experience garnered throughout the project, both in terms of engineering and real-world management, were directly relevant and complementary to the requirements of modern industry. I look forward to seeing what the new cohort of students in the team have planned for the next instalment of the Warwick Moto project.”

Nesta Ferguson, new Chief Engineer of the Warwick Moto team added: “The collaboration between Norton and WMG at The University of Warwick to create the Frontier amounted to a fantastic example of sustainable EV innovation. The team hopes to set a precedent to its competitors and technological demonstrators and highlight how innovative projects like the Frontier are crucial if we are to help create a sustainable future. My role now is to build on the momentum established throughout the project. To do this, we have created a vision, which includes a four-year plan to ensure the longevity and continued development of the project.”

On-campus research has been reinforced with input, support, mentoring, and technical guidance from Norton’s own designers and engineers, further to the supply of the frame.

Making race debuts

Having undergone significant testing including much computer-based validation and modelling around thermal management, along with physical testing of cells and modules, Frontier has made several appearances outside of the workshop in recent weeks. This includes testing at Bicester Heritage where rider, Tom Weeden, summarised his first experiences:

“The first test aboard Frontier and working with the Warwick University team absolutely surpassed all my prior expectations. The professionalism of all the students was superb throughout and I had no issues trusting in the electric bike ‘Frontier’ that they had tirelessly created in such a short space of time.

“We eased into the test slowly, with an initial low power run at approx. 25% power output. Despite this, my initial feeling was hugely positive. The throttle connection and delivery of the power weren’t too dissimilar to a conventional internal combustion powered bike which was a pleasant surprise! As we upped the power the potential of the Norton framed Frontier bike was clearly evident! She handled beautifully from the off and with a little further testing time to dial in the suspension we can further enhance this. In fact, I found the bike really easy to ride - no gears, just twist and go and lots of fun! Despite the slight weight increase to a conventional bike the team have balanced it perfectly - plus there is plenty of potential for future suspension/geometry tweaks to further enhance the overall handling. All in all, a positive test showing plenty of potential for much more in the future! It’s an absolute pleasure and honour to be involved with the Frontier project!”

Having taken the bike to its first conference at the world’s number one festival of electric vehicles and clean energy, Fully Charged Live 2021, the team impressed the public once more by showcasing the bike alongside some of the largest EV manufacturers in the world at LCV Cenex 2021.

Dr Robert Hentschel, CEO of Norton Motorcycles, said:

“We are thrilled to be able to support the engineers of the future, who are developing tomorrow’s technology today on the basis of a Norton frame. Our support by means of donation of the frame is just the beginning. Norton’s team of designers and engineers have been very interested to observe how this project is taking shape, supporting the student team wherever possible with advice and guidance.”

Significant support from industrial partners such as the High Value Manufacturing (HVM) Catapult team at WMG, University of Warwick, Norton Motorcycles, Michelin Motorcycle PLC, MIVOLT by M&I Materials, PWR Advanced Cooling Technology, DYMAG Performance Wheels, Laserlines, Wraptastic, Rock West Composites, Xometry, Renthal, Pro-Bolt, embed, R&G Racing, R&G Gleam, HEL, and RS Components have immensely helped the team.

WMG helps rising automotive security company prove its technology

Mitigating the risks associated with autonomous vehicles

Mitigating the risks associated with autonomous vehicles

According to recent information published by the UK Government’s Centre for Connected and Autonomous Vehicles (CCAV), the CAV market in the UK could be worth between £52 billion and £62 billion by 2035.

Although the scope and potential within the sector is huge, public trust, perceptions, and the prospect of changing daily travel routines and ideologies pose significant challenges. Such challenges are being addressed to successfully implement CAVs, particularly in the context of proving that the new technology is safe.

CAV safety can be considered in the context of an automated vehicle’s physical attributes, or the physical interaction between such vehicles and the real world (e.g., roads, traffic lights, lampposts, and pedestrians). However, as automation technology advances, vehicles are becoming less about getting from “A to B” and more about the convenience of travel and the transfer of data between the vehicle and the road infrastructure. For example, gauging changeable conditions such as congestion, weather severity, lane closures and hazards in the road in real-time are all elements that depend on the effective transmission of data.

Given the complexities around this data transmission and storage, data and technology transfer for in-vehicle and extravehicular communications needs to be robust in terms of cyber security to mitigate risk. Solutions used to strengthen security mitigate threats to systems in several ways, helping make hacking unattractive. Such solutions also mitigate against data spoofing, replay attacks (an attack on networks to delay or repeat data transmission), eavesdropping (theft of information as data is being transferred), and impersonation. It helps maintain the privacy of data and increases difficultly to track a vehicle via its signals.

Maintaining safety through data encryption

Specialist SME Angoka provides embedded hardware-based solutions to mitigate cyber security risks, particularly in the Intelligent Vehicles sector. To test its new Device Authentication Unit (DAU) technology to authenticate and safeguard the identity and communication integrity within the vehicle, and from the vehicle to external sources, the company had to embark on developing a real-word demonstrator.

The SCAV project was launched in October 2019 and provided an opportunity for Angoka to collaborate with WMG. Having recently been completed, the testing phase made up a major part of the project. Carsten Maple, Professor of Cyber Systems Engineering at WMG, University of Warwick, and Principal Investigator for SCAV said:

“SCAV provided an opportunity for WMG to support a promising young company with the development of a unique piece of data encryption technology that could not only accelerate the company’s growth but also prove pivotal to the safety and security of CAVs in the UK. Through our facilities, expertise and experience we were able to successfully collaborate with Angoka, and I look forward to continuing the momentum built within SCAV to help apply academic and theoretical research within an industry context.”

Dr Dan Fowler, Research Fellow at WMG for SCAV said:

“The real-world testing was important to validate Angoka’s device authentication and communication security technology. Not only for the in-vehicle data communications but also Vehicle-to-Infrastructure (V2I) communications.

“To that extent, WMG’s Secure Cyber Systems (SCS) research group was able to support Angoka with a loan of V2I communications equipment to help further develop the IP and provide support towards the real-world testing phase.”

Support from WMG’s Intelligent Vehicles (IV) research group also enabled Angoka to retrofit its Device Authentication Units (DAUs) to the Catapult Open Innovation Platform vehicle and use it to replace the normal unencrypted vehicle control signals with encrypted ones, whilst allowing the vehicle to operate as normal.

The testing during October 2020 allowed the vehicle to operate autonomously with authenticated and encrypted control signals and V2I authenticated and encrypted control signals. This allowed completion of robust field testing, which would be the first real-world demonstration of the SME’s Device Authentication Unit (DAU) technology for in-vehicle and extravehicular communications.

Angoka’s solution uses embedded hardware-based fingerprinting technology, used to generate dynamic, unforgeable identities for the connected devices and encryption keys to encrypt or decrypt data. These look like typical vehicle Electronic Control Units (ECUs) but can replace a normal ECU to provide device authentication and data encryption at the main point of control in a vehicle.

The real-world testing revolved around the usage of the High Value Manufacturing (HVM) Catapult funded autonomous capable vehicle with a Drive-by-Wire (DbW) system, and SCAV prompted the first usage of this facility by an organisation outside of the University of Warwick.

The test vehicle is used to develop and test CAV hardware and software technologies and services. In addition to the DbW system, the vehicle is fitted with a sensor suite (cameras, LIDAR, RADAR, ultrasonics), GNSS, computing hardware, DSRC and 4G. With the support from the IV team, it enabled Angoka to trial its technology in the real world. Dr Graham Lee, Lead Engineer and Technical lead for the Catapult Open Innovation Platform vehicle said:

“The HVM Catapult Open Innovation Platform vehicle was pivotal in supporting the testing phases within the project, and SCAV provided the perfect opportunity to use this technology with industry for the first time. The test vehicle enabled Angoka to physically test their DAU technology on a vehicle to observe and validate the behaviour of their technology in a more realistic operating environment”

In addition to implementing technology to aid testing, the WMG Intelligent Vehicles Research Group provided the expertise to facilitate the testing and analyse the results. When reflecting on the research project, Tim Harrison, Engineering Lead at Angoka said:

“WMG gave Angoka access to top-rated researchers and experts in cyber security and Smart Mobility who provided us with an unbiased and independent assessment of our technology both from a security and practical perspective. This has enabled us to further develop and enhance our technology ensuring its resilience and interoperability within the rapidly evolving Connected and Autonomous Vehicle world.

“Furthermore, access to facilities and resources, such as the WMG test vehicle and open test areas for mobile testing, were essential to demonstrating the practical implementation of our DAU technology.”

Each DAU within a vehicle will generate a unique identity for the device, as well as multiple communication encryption keys. The identities and encryption keys will be stored in a secure chip within the DAU that cannot be copied or tampered with.

The hardware solution utilises the physical characteristic of the device to create an unforgeable fingerprint for the device, and uses Angoka’s S-CAN protocol to generate unique and dynamic identities and encryption keys to authenticate connected devices and data messages (for example, messages to control vehicle braking and vehicle signalling were used during testing).

If that data is manipulated in some way, then the DAU’s fingerprint ensures it becomes invalid. This hardware digital signature is the key to the authentication of the communication and ensures that the contents of a data message have not been altered or changed. Dr Dan Fowler added:

“An autonomous vehicle could be controlled remotely via a V2I message. For example, to slow it if traffic jams are detected. However, if control messages can be spoofed, the vehicle could be made to perform unintended, and potentially unsafe, operations.”

Tim Harrison added:

“Our technology is built around decentralising the authentication and encryption process, meaning we require no central authority to generate and distribute keys. Our approach eliminates the single point of failure and a single point of attack of a central authority.

“Any public key infrastructure (PKI) based system uses asymmetric encryption which has a significantly associated overhead to generate, distribute and manage certificates. Our encryption technology is based on symmetric encryption protocols which with our decentralised mechanism to generate and manage identity and encryption keys eliminates these overheads.”

Bringing Angoka’s technology to market

As well as helping Angoka to establish as a start-up, the collaboration with WMG through SCAV has resulted in several follow-on collaborations to allow the expansion of the team and activities in real-world testing. Angoka has recruited two new staff to broaden its expertise as a result of the project. Shadi Razak, CTO & Co-Founder from Angoka said:

“Testing on the vehicle has helped Angoka commit to further developments, whilst also generating client interest. The testing that was conducted at WMG as part of the project has directly led to several follow-on projects.

“The first is with the Zenzic Testbeds, which will allow Angoka to further expand our real-world testing into multiple autonomous vehicles and urban environments. We have also secured another Innovate UK project in partnership with WMG, BT and other partners to deliver a quantum key distributed autonomous vehicle network.”

The SCAV report, due for completion end of December, will contain the full findings from the testing.

---------------------------------------------------------------------

Find out more about WMG's Transport research here.