WMG News

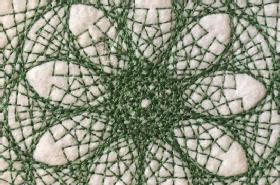

Join WMG for a Stitch In Time this half term

Join the WMG Outreach Team on Tuesday 1st June for a free science based workshop, inspired by Coventry’s textiles history, at The Herbert Art Gallery and Museum.

Stitch In Time is a collaborative project between WMG and local primary schools for Coventry UK City of Culture 2021.

Taking inspiration from Coventry’s textiles history, children will create patterns using TurtleStitch, and these designs will then be stitched onto fabric by a digital embroidery machine.

Taking inspiration from Coventry’s textiles history, children will create patterns using TurtleStitch, and these designs will then be stitched onto fabric by a digital embroidery machine.

The educational workshop will introduce the children to fun science activities while building their maths and computing skills.

Director of Outreach and Widening Participation for WMG, Professor Margaret Low, explains: This project aims to give children an insight into how technology can be used creatively to design and make physical objects.”

The event is aimed at 9+ year olds . Book your child’s free place here: Stitch In Time - The Herbert Art Gallery & Museum

Charging ahead with battery research

WMG has been named as a partner in five key battery research projects funded by the Faraday Institution.

WMG has been named as a partner in five key battery research projects funded by the Faraday Institution.

The Faraday Institution has committed £22.6m to battery research projects involving a consortium of universities around the UK.

Research will progress over the next two years to 31 March 2023. The projects, involving WMG, are:

· SOLBAT. The solid-state battery (SSB) is one of the most important challenges in battery R&D. As well as increasing energy density, lifetime and transforming safety, SSBs will enable step changes in the safety, driving range and longevity of electric vehicles. Read more here: SOLBAT – Solid state metal anode batteries – The Faraday Institution

· SafeBatt – the science of battery safety. Safety control and countermeasures are built into the design of today's Li-ion batteries (LiB) systems, but this adds complexity, cost and weight. As the use of LiBs expands further into automotive, stationary storage, aerospace and other sectors, there is a need to decrease the risk associated with battery usage further and to enable the simplification of safety systems. This can only be achieved through enhanced understanding of the “science of battery safety.” Read more here: SafeBatt – Science of Battery Safety – The Faraday Institution

· Battery Degradation. Although mass manufacture has made lithium-ion batteries cheaper, cost and durability remain obstacles to the widespread adoption of battery electrical vehicles. The lifetime of the batteries falls well below the consumer expectation for long-term applications such as transport. The automotive industry wants to better understand the causes and mechanisms of degradation to enable improved control and prediction of the state of health of battery systems. Read more here: Battery Degradation – The Faraday Institution

· Multi-scale modelling. The performance and lifetime of a battery depends on how the cells are combined into a pack large enough to power an electric vehicle (EV), an aeroplane or even an electricity grid. The mechanism controlling the local environment of each cell within that pack also influences lifetime and performance. The first challenges to be tackled include fast charging of batteries, low temperature operation and thermal management of cells within battery packs. Read more here: Multi-scale Modelling – The Faraday Institution

· Nextrode Electrode Manufacturing. Nextrode focuses principally on manufacturing research into how to engineer a new generation of battery electrode structures. Novel developments in electrode structuring will be drawn from basic science understanding of the current slurry casting manufacture of Li-ion electrodes along with predictive modelling to suggest how control of electrode microstructure can deliver improved energy storage characteristics. Nextrode will support UK manufacturers and supply chain companies, draw on cutting edge scientific and technological knowledge to produce increased cell performance, add value in electrode processing, and improve safety and sustainability. Read more here: Nextrode – electrode manufacturing – The Faraday Institution

Meet the team and read more about WMG’s Energy research here.

Fully electric masterclass created for the next generation of engineers

WMG High Value Manufacturing Catapult Centre is working with the Smallpeice Trust and the Faraday Institution to create and deliver a Fully Electric Challenge for year 11 students.

The online course has been created by a team of four WMG graduate trainee engineers, including Ben Hunt; Lauren Cooper; Irma Houmadi and Joshua Wallis, with support from the WMG Outreach team.

It aims to deliver key insights into the battery industry, provide an overview of transport electrification and explain how this translates to wider areas of society.

It aims to deliver key insights into the battery industry, provide an overview of transport electrification and explain how this translates to wider areas of society.

Students will have the opportunity to design and build an automotive product using engineering concepts and processes, before presenting their designs and ideas to their peers.

The course will also provide details on a variety of STEM career paths that can help contribute to a more sustainable future.

sustainable future.

Ben Hunt explained: “This is another great event to be involved in which highlights the exciting range of careers in STEM. I hope we manage to capture the multi-disciplinary nature of electrification during the four-day course, it really is a one-stop-workshop!

“It has been great to work alongside some fantastic professionals in designing the event and I’m looking forward to listening to their lectures myself. The event content is derived from their real-world experience across various industries so I am confident students will be as informed as they could be, certainly more than I was in my final school years!”

Lauren Cooper added: One of my favourite parts of my job at WMG is inspiring the engineers of the future by designing and delivering events like the Fully Electric Challenge. I think it is important to give students a taste of how exciting a career in engineering can be, and demonstrate the importance of STEM in the future world. Through the Fully Electric challenge, we aim to show how broad the subject of electrification is including aspects of battery technology, economics and policy for sustainability in transport as well as wider society. STEM careers provide so many opportunities to learn and make impact in society through the development of technology for electrification. Having studied chemistry and started my career as a graduate at WMG, I have really enjoyed learning how underlying battery chemistries are developed manufactured and implemented utilising knowledge and skills from other areas of STEM.”

Each year 124,000 new engineers and technicians are needed to meet current and future demands. The Smallpeice Trust is an educational charity that inspires young people to pursue careers in science and engineering through events and workshops.

It takes place from 9-13th August (except on 12th August - GCSE results day) from 9.30am to 1.30pm. Once registered each student is sent instructions, a guide to the activities and a kit enabling them to build a battery powered vehicle.

To register your place visit: https://www.smallpeicetrust.org.uk/course-page/8cbb5b40-ae76-eb11-a812-0022481a98e1

University of Warwick’s WMG and Engineering wins £5 million and key coordinating role in Government’s Driving the Electric Revolution programme

WMG and the School of Engineering at the University of Warwick have been awarded just over £5 million funding and a key coordinating role in the Government’s Driving the Electric Revolution Industrialisation Centre programme.

Government’s Driving the Electric Revolution Industrialisation Centre programme.

Driving the Electric Revolution is a UKRI (UK Research and Innovation) funded Industrial Strategy Challenge Fund (ISCF) technology programme to help achieve the UK’s net zero ambitions working across cars, aircraft, rail, marine, renewables, industrial digital technology, industrial power electronics, and machines & drives. It is investing £28.5 million into cutting edge equipment across the country.

WMG and the School of Engineering at the University of Warwick have been awarded the following equipment funding:

• Almost £4 million from UKRI and the High Value Manufacturing Catapult for a new Winding Centre of Excellence led by Dr David Simkin in WMG at the University of Warwick. The facility will help UK supply chain companies to manufacture discrete hairpin machines.

• An award in order of £1.3 million from UKRI and High Value Manufacturing Catapult for the University of Warwick’s School of Engineering for a facility led by Professor Phil Mawby and focusing on power electronics reliability and failure analysis.

WMG at the University of Warwick has also been selected to provide leadership to the Midland’s region Driving the Electric Revolution Centre, which is one of four across the UK. These centres will coordinate and build on the UK’s national capability to deliver long-term sustainable growth on the road to net zero. Together they will help businesses scale up the use of electric-powered vehicles and machines across a range of industries and transport systems to grow the UK supply chain.

Margot James, Executive Chair at WMG, University of Warwick said: “We are delighted that Warwick is leading such an important project in the UK’s effort to build a net zero future. The green agenda will contribute significantly to our economic recovery and growth, with zero carbon transport crucial to protecting our planet. It’s encouraging to see an opportunity for UK businesses to work together, through the Centres, to deliver on the sustainable transport challenge.

Professor Will Drury, Driving the Electric Revolution Challenge Director said: “This investment represents a vital step forward in making the UK a world leader in Power Electronics, Machines and Drives (PEMD). With access to the Centres and network open to all, we aim to give all UK businesses and researchers the ability to develop and scale new PEMD technologies and manufacturing processes. Only by investing now in developing PEMD will the UK achieve its net zero ambitions.”

Dr. Andreas Docter, Director Electric Powertrain, Jaguar Land Rover said: “This is a great opportunity to support the most advanced projects in the development and testing of Power Electronics, Machines & Drive (PEMD) systems. Jaguar Land Rover has a specific interest in projects which improve manufacturing processes, accelerate the PEMD manufacturing innovation to production and an important one is flexible eDrive prototyping. These all contribute to the company’s mission of achieving Destination Zero.”

David Bock MIET, @FutureBEV Technical Lead BMW AG said: “@FutureBEV is pleased to be working with University of Warwick as a strong partner in the development of next generation powertrain development and core component development within the APC15 @FutureBEV programme. University of Warwick’s place in the Government’s Driving the Electric Revolution programme will provide value in the @FutureBEV reinforcing the knowledge transfer to real products that will influence the concept to product delivery within the program and in steering the next generations of engineers into the industry. The UK supply chain needs this capability, and this provides a strong path to delivering best in class power electronics to market as well as the needed skill base for future delivery into the value chain.

ENDS

23 MARCH 2021

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

UKRI

To arrange an interview Professor Will Drury please contact: press@ukri.org.

Notes for Editors:

Any business or researcher interested in using a Driving the Electric Revolution Industrialisation Centre should visit www.der-ic.org.uk.

Funding

The funding comes from Driving the Electric Revolution. Part of the Industrial Strategy Challenge Fund (ISCF) delivered by UK Research and Innovation (UKRI). Driving the Electric Revolution started in August 2019 as part of the ISCF programme. The programme is funded by £80 million from the government’s ISCF Future of Mobility grand challenge and aims to secure £154m private investment. It aims to make the UK a global leader in the manufacture of core technologies which support electrification: Power Electronics, Machines and Drives (PEMD). It seeks to accelerate the journey into the growth of PEMD supply chain in the UK.

The ISCF

ISCF aims to bring together the UK’s world leading research with business to meet the major industrial and societal challenges of our time. The fund was created to provide funding and support to UK businesses and researchers, part of the government’s £4.7 billion increase in research and development over the next 4 years. It was designed to ensure that research and innovation takes centre stage in the Government’s modern Industrial Strategy. It is run by UK Research and Innovation.

UKRI

UKRI is the largest public funder of research and innovation in the UK, with a budget of over £8bn. It is composed of seven disciplinary research councils, Innovate UK and Research England.

We operate across the whole country and work with our many partners in higher education, research organisations businesses, government, and charities.

Our vision is for an outstanding research and innovation system in the UK that gives everyone the opportunity to contribute and to benefit, enriching lives locally, nationally and internationally.

Our mission is to convene, catalyse and invest in close collaboration with others to build a thriving, inclusive research and innovation system that connects discovery to prosperity and public good.

UKRI continues to support the research and innovation community to navigate the transitions associated with the exit of the UK from the EU. To keep up to date please visit our dedicated pages. https://www.ukri.org/research/international/ukri-eu-exit/

WMG in landmark partnership to develop UK electric motorcycle capability

Researchers at WMG are part of a unique four-way partnership with Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division, focusing on developing specialist electric motorcycle technology and innovative integrated solutions.

Phase 2 of Project TE-1, a landmark four phase collaboration in British design and engineering, is now complete with the exciting reveal of the innovative advanced electric powertrain and battery, and the very first styling sketches for the final prototype.

Phase 2 of Project TE-1, a landmark four phase collaboration in British design and engineering, is now complete with the exciting reveal of the innovative advanced electric powertrain and battery, and the very first styling sketches for the final prototype.

Including innovation in battery and powertrain design, initial test performance results that far exceed the current benchmarks and industry targets and development in efficiency and range technology, Project TE-1 is well on track to fully deliver on the partnership’s objectives to enhance the credibility and profile of British industry and design, and provide substantial input into future electric motorcycle strategy from Triumph.

Nick Bloor, Triumph CEO said: “The completion of Phase 2, and the promising results achieved to date, provide an exciting glimpse of the potential electric future and showcase the talent and innovation of this unique British collaboration. Without doubt the outcome of this project will play a significant part in our future efforts to meet our customer’s ambition and desire to reduce their environmental impact and for more sustainable transportation.

“This important project will provide one of the foundations for our future electric motorcycle strategy, which is ultimately focussed on delivering what riders want from their Triumph; the perfect balance of performance, handling and real world usability, with genuine Triumph character.”

Truong Quang Dinh, WMG’s Assistant Professor of Energy Management and Control Systems explained: “Our creation of initial computer-based simulation models at the start of Phase 1 has been instrumental in ensuring that the component selection was appropriate to achieve the performance targets defined by the partners for the TE-1 Prototype. We have continued with this work across Phase 2 of the project, refining the models to a much more complex level to allow us and the partners to imitate further components on the bike such as braking, throttle, lighting and other systems and mimic real-world riding to provide development opportunities before components were fully designed. Additionally we have created a physical rig wired with all of the control units, in order to implement a design validation test programme to ensure the function of each section was within the allowable range.”

Truong Quang Dinh explains more here: Project TE-1 - WMG cut on Vimeo

WMG has also been providing guidance to Triumph relating to future legislation, charging infrastructure and recycling strategies.

Project TE-1, a two year project, is supported and co-funded by the UK Government’s Department for Business, Energy & Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), via Innovate UK.

Read more about the Project here: Project Triumph TE-1 | For the Ride (triumphmotorcycles.co.uk)

Read more about WMG’s energy research here: Energy (warwick.ac.uk)

New insight into how lithium-rich cathode materials for high energy EV batteries store charge at high voltages

- By 2030 only EV’s will be in production, meaning manufacturers are racing to create a high-energy battery that’s affordable and charges efficiently, but conventional battery cathodes cannot reach the targets of 500Wh/Kg

- Lithium-excess cathodes offer the ability to reach 500Wh/Kg but unlocking their full capacity means understanding how they can store charge at high voltages

- A new X-ray study lead by WMG, University of Warwick has resolved how the metals and oxygen facilitate the charge storage at high voltages

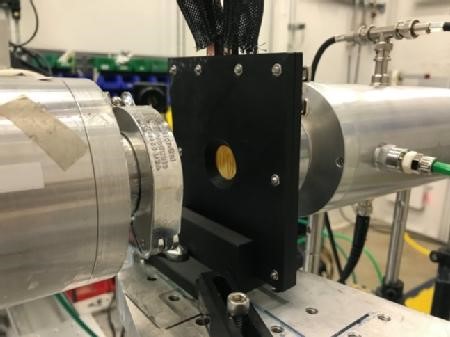

High energy storage batteries for EVs need high capacity battery cathodes. New lithium-excess magnesium-rich cathodes are expected to replace existing nickel-rich cathodes but understanding how the magnesium and oxygen accommodate charge storage at high voltages is critical for their successful adaption. Research led by WMG, University of Warwick in collaboration with U.S. researchers employed a range of X-ray studies to determine that the oxygen ions are facilitating the charge storage rather than the magnesium ions.

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Although progress has continued over the last 10 years to push the performance of state-of-the-art nickel-rich cathodes for EV, the material is unable to provide the energy density needed. To increase the capacity more lithium needs to be used, which means going beyond the ability of nickel to store electron charge.

Lithium-excess magnesium-rich cathodes offer sufficient energy density but to reach ultimately reach energy storage targets of 500Wh/Kg we need to understand how the electron charge is stored in the material. Simply put, is the electron charge stored on the magnesium or oxygen sites.

In the paper, ‘Whither Mn Oxidation in Mn-Rich Alkali-Excess Cathodes?’, published in the Journal ACS Energy Letters today the 17th of February, researchers from WMG, University of Warwick have overcome a significant milestone in understanding of charge storage in lithium-excess magnesium-rich cathodes.

Li-excess compounds that involve conventional and non-conventional redox, conventional refers to metal ions changing their electron density. Reversibly changing the electron density on the oxygen (or oxygen redox) without it forming O2 gas is unconventional redox. Various computational models exist in the literature describing different mechanisms involving both, but careful x-ray studies performed while the battery is cycling (operando) are ultimately required to validate these models.

Researchers between the UK and US, led by WMG at the University of Warwick, performed operando x-ray studies to precisely quantify magnesium and oxygen species at high voltages. They demonstrated how x-ray beams could irreversibly drive highly oxidized magnesium (Mn7+) to trapped O2 gas irreversibly in other materials.

However, by performing careful operando x-ray studies that circumvented beam damage and observe only trace amounts of Mn7+ forming upon charging in Li-excess cathodes during battery cycling.

Professor Louis Piper, from WMG, University of Warwick explains:

“We have ultimately resolved that oxygen rather than metal redox is driving the higher capacity, which means we can now design better strategies to improve cycling and performance for this class of materials.”

ENDS

17 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/operando_x-ray_louis_piper.jpg

Caption: Photo of the operando x-ray studies being performed at a Synchrotron facility.

Credit: WMG, University of Warwick

Paper available to view at: https://pubs.acs.org/doi/10.1021/acsenergylett.0c02418

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG commends the advances to UK innovation, skills and industrial growth made by the Industrial Strategy Challenge Fund and supports NAO recommendations to further improve impact

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- NAO right to support streamlining start-up and approvals processes of up to 72 weeks, which can deter bids, especially among smaller businesses

- Longer term visibility of funding will be needed to give investment confidence to businesses and academia

- Mechanisms to engage private sector finance should be considered – especially as innovations become ready for market

- As industry faces challenges of the pandemic, flexibility in financing bids, especially to support smaller businesses, should be considered

- Regional and Skills strategies should be a key part of innovation funding approach

- The Catapult network provides an established and successful platform for innovation, and its geographic locations also suggest it could play a big role in regional levelling-up

- Skills must be developed alongside innovation to give the UK the ability to exploit our ISFC investments. WMG, at the University of Warwick, have been pioneers in developing skills programmes alongside innovation and industrialisation

WMG at the University of Warwick has welcomed today’s National Audit Office report on the Industrial Strategy Challenge Fund, supporting their positive assessment of the fund, and backed their calls for a more streamlined approach to innovation funding, alongside a greater emphasis on the importance of innovation for regional development and skills growth.

Professor Dave Greenwood, Director of Industrial Engagement at WMG, University of Warwick and Chief Executive of the WMG High Value Manufacturing Catapult said:

“The Industrial Strategy Challenge Fund (ISCF) has been a powerful tool to support innovation that meets the most pressing national challenges.

“The ISCF has bought government, business and researchers together at scale, and at pace, to help our transport industry decarbonise through the Faraday Battery Challenge, and is delivering vital vaccine capacity through the Vaccine Manufacturing and Innovation Centre. It has supported over 1,600 projects, including the new UK Battery Industrialisation Centre in Coventry, with over forty per cent of support in the first two waves going to small and Micro companies.

“These projects are making a difference to UK innovation, skills and industrial growth, and these successes should be celebrated.

“As the report says, however, there are always opportunities to improve how the Fund operates.

“First, we need to make the funding process faster and more agile – especially given rapid changes in the external Business and social environment, from Brexit to the Pandemic. Lengthy Approvals processes of up to 72 weeks for selecting challenges and awarding projects can deter bids, especially among smaller businesses.

“Alongside this, with much of industry dealing with financial pressures from the pandemic, government should consider relaxing some of the funding constraints on the programmes – especially where they fall significantly short of what state aid would allow, such as in the co-investment requirement from Industry, which was increased in Wave 3 of the Fund.

“Together, these steps would help position the UK for clean growth post-COVID and deliver on opportunities created for the UK supply chain by the UK/EU trade agreement.

“Looking forward, it’s essential that there is a long-term funding package in place to support the Industrial Strategy Challenges. As the report notes “The Fund was part of a one-year settlement in the spending review in November 2020.” Short term spending decisions will ultimately be detrimental to large scale industrial and academic investments – a 5 year rolling funding horizon is needed for full confidence from Industry partners. To help deliver this, we should consider the role of private finance in these programmes, and what mechanisms might de-risk industry investments to support clean growth.

“It’s also crucial that the ISCF supports regional development as part of the Government’s ‘levelling up’ agenda. Currently, almost half of funding has gone to projects in London and the South East, and while we in the West Midlands have secured significant investment, the ISCF should reflect the regional profile of Industrial R&D more closely. It is notable that government funding relative to private sector investment is much lower in the Midlands than in the South East for instance.

The Catapult network, with centres of excellence across the country, strong links to regional industries, and good networking between them, is an exemplar of how levelling up should be delivered. This established and successful platform could provide an efficient and effective means to boost R&D in under-represented regions in accordance with the recommendations of this report.

“We also need to link innovation spending to the education and skills agenda. The UK needs not just the best technologies but also the people to develop, manufacture and support them. These cannot be developed in isolation. Here, WMGs approach of delivering innovation and skills programmes together and in partnership with industry is an established model, allowing degree apprenticeships, re-training, lifelong learning to support industry innovation programmes. As the Government considers responses to the skills white paper, it should consider how future industry skills needs will be shaped by the innovations being delivered by the challenge fund, from transport electrification to digital skills.

Student recruited by West Midlands SME following success of WMG Internship Programme

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

The Programme is designed to allow companies and students to work together to overcome a business challenge or investigate ways of improving business performance. Interns, placed at companies, are supervised by an expert member of the WMG team to ensure objectives are met and to provide access to world-renown facilities. This means participating companies get the benefit of both the resources and industry-leading knowledge.

Tom Lockhart, WMG SME Project Officer, explains: “Over the past 10 years, we have supported more than 300 internship projects. We work with businesses to identify their challenges, scope out a project and set clear objectives for a short, but focused piece of work.”

One particular highlight of this year’s programme was an internship placement at Alucast, an aluminium casting foundry that supply the automotive industry.

Through a collaborative approach, the student intern, Farhan, was, within just 12 weeks, able to help boost productivity by an impressive 30% and has now been offered a full time position. This is a particularly positive outcome in such challenging times and a real testament to Farhan’s hard work.

John Swift, Managing Director at Alucast, commented: “We have long been an advocate of promoting engineering as a career choice and, with this in mind, it was great to work with Farhan. It reinforced our belief that young students and graduates make excellent employees, combining a great work ethic with technical knowledge and insight. The project really exceeded expectations and we’re pleased to be able to offer Farhan a full-time role with us.”

Read more about the SME Team’s project with Alucast, an aluminium casting company based in the Black Country and more success stories here: warwick.ac.uk/smesuccessstories

To find out more about working with the WMG SME Internship Team email wmgsme@warwick.ac.uk

Immersion Cooled EV battery initiative, project i-CoBat, wins The Engineer’s Collaborate to Innovate Automotive Award

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

The project, led by M&I Materials, is a consortium involving battery systems developer Ricardo and WMG, at the University of Warwick which works to commercially and technically validate new technologies for industry.

Funded by Innovate UK, project i-CoBat uses a novel thermal management system for EV batteries using a novel, biodegradable dielectric fluid called MIVOLT, which allows for faster charging than conventional systems and a higher performance battery.

On receiving the news of the award for i-CoBat, Project Lead, M&I Materials Technical Director, Mark Lashbrook commented:

“We’re thrilled for project i-CoBat to have been recognised with this award, particularly since we were up against some incredibly exciting and forward thinking companies. This award is a testament not only to this type of initiative and what its implications are for the wider EV market, but to both Ricardo and Warwick Manufacturing Group for their extensive knowledge, expertise and leadership. Innovate UK have also been incredibly supportive throughout, so this award is also in recognition of the pioneering research projects, like i-CoBat, which they initiate.”

WMG's Principal Engineer, Stene Charmer, added: “I am thrilled and delighted that the ICO-BAT team have won this award. It has been wonderful to work with M&I materials and Ricardo, supporting the research of our advanced battery cell, module testing and advanced simulation techniques. At WMG we are leading innovative battery research and development, and innovative battery thermal management systems, the technology researched within ICO-BAT, are key to realising cost effective electrical energy storage systems for passenger vehicles.”

ENDS

WMG High Value Manufacturing Catapult helps British taskforce develop UK negative pressure ventilator to assist recovery of COVID-19 patients

As the UK feels the impact of the current wave of coronavirus, the exovent task force today unveils its UK negative pressure ventilator designed to assist the recovery of COVID-19 patients and for the treatment of Pneumonia and COPD.

As the UK feels the impact of the current wave of coronavirus, the exovent task force today unveils its UK negative pressure ventilator designed to assist the recovery of COVID-19 patients and for the treatment of Pneumonia and COPD.

The exovent task force formed in March 2020 in response to the COVID-19 crisis, inspired by calls from the UK Government for rapid innovation to combat the challenge presented by this highly contagious and aggressive disease. The team is composed of anaesthetists, critical care consultants, nurses, medical clinicians, engineers, academics, scientists and manufacturers.

exovent was not part of the UK Ventilator Challenge as this was conceived for positive pressure devices. Instead, the exovent team focused on exploring the benefits of negative pressure ventilation, founded upon lessons learned from nearly 100 years of Negative Pressure utilisation.

Thanks to the investment of over £1m of volunteer time, rapid engineering development and prototyping by Marshall ADG (the UK’s leading privately owned Aerospace and Defence business) and partnership with WMG High Value Manufacturing Catapult, a highly professional system is now available for approval.

The latest and most advanced iteration, the exovent-19, is ready to progress to approval by the Medicines and Healthcare products Regulatory Agency. Once approved, several leading intensive and respiratory care units stand ready to trial the system, including the Critical Care Research Team, Southampton NIHR Biomedical Research Centre (University Hospital Southampton & University of Southampton) and the Queen Elizabeth Hospital, King’s Lynn NHS Trust.

Recognising the applicability of the technology to developing countries, the team has also been partnering internationally with pioneer groups in Ghana, Bangladesh, and Ethiopia to help them develop local versions that can be approved and manufactured by them using locally sourced materials where possible. Marshall has shipped two of its protoype exovent machines designed and manufactured at its Cambridge headquarters, direct to Indian ventilator manufacturer, Skanray, who plan to use them, along with the supporting design information, to develop a relatively low cost production model that can be rapidly approved and developed for mass distribution in their local markets as quickly as possible.

exovent are hoping to come to an agreement with a UK based manufacturer in the coming weeks. In addition, the team plan to develop both a global low cost system and a paediatric low cost system working with UK engineering partners.

Speaking about the new system, exovent CEO, Ian Joesbury, stated:

“We are really excited to be unveiling this life saving system which is a cutting-edge reinvention of pre-existing technology. In the UK I believe this can form part of a longer-term plan to treat COVID-19. As the patient does not need to be anaesthetised it opens up alternative treatment options that may allow more patients to be treated outside of intensive care.”

Dr Malcolm Coulthard, from the exovent team, said:

“From research and findings to date, we firmly believe that the use of negative pressure devices can transform the patient journey for COVID-19 patients and those with pneumonia and other diseases that affect breathing. The technology is safe, simple to use and systems could be built and deployed rapidly, in both the UK and overseas. Our recent paper published in the medical journal Anaesthesia demonstrates that the exovent-19 is twice as efficient as other negative pressure systems.”

Patrick Wood, Chief Technical Officer at Marshall ADG, shared:

“Our engineering team have designed a robust and reliable system using rapid prototyping methodology that enabled the first systems to be functionally tested within a few weeks of our first discussions. We look forward to seeing the system help patients across the globe once it is approved.”

David Rawlins, Chief Technology Officer for WMG High Value Manufacturing Catapult Centre explained: “When exovent initially contacted WMG back in March 2020, the opportunities to support the UK and international pandemic efforts with a lower cost alternative treatment route were clear. Minimising time to deliver the first prototype was key, and WMG supported exovent in engaging organisations to support the effort. Marshalls ADG responded to the request and significant efforts from the engineering and manufacturing teams delivered the initial prototypes in a few weeks with support from the wider UK industry supply chain. I would like to congratulate all the engineers and medics who have achieved this milestone, and I look forward to seeing the project progress on a global scale once approvals are in place and trials have completed.”

Margot James, Executive Chair at WMG added: “I am very proud of WMG’s involvement in the development of exovent, the negative pressure ventilator promises to help more Covid patients be treated effectively as with established ventilator technology, whilst needing less oxygen and nursing resource. I congratulate the team of engineers and medics who have brought forward this innovation.”

How exovent works as an alternative treatment for COVID-19

One of the key features of COVID-19 is that it can cause pneumonia and acute respiratory failure, with over 2 million recorded deaths across the world by mid January 2021. Many countries, including the UK, took substantial action to mitigate the impact including putting in place support for ventilator production. However, whilst ventilators and high flow oxygen devices are clearly lifesaving, they are not without their challenges and may not be suitable for all patients, particularly the elderly.

In contrast, the exovent-19 has key benefits that make it particularly suitable to support COVID-19 patients. Use of negative pressure is far less intrusive and much more like normal breathing than either intubation or continuous positive airway pressure (CPAP). exovent-19 is non-invasive, which means that patients do not need to have their windpipes intubated, so they don’t need to be anaesthetised and oxygen can be delivered in the form of a normal oxygen mask or nasal prongs rather than through a high flow oxygen device that puts hospital oxygen supplies under pressure. Patients remain conscious, and can take medication and nutrition by mouth, and talk to loved ones on the phone.

exovent-19 works by being fitted over the patient’s torso and can operate in two modes, continuous negative extrathoracic pressure (CNEP), the negative pressure equivalent of CPAP, increases the volume of air in the lungs while the patient continues to breath for themselves by applying negative pressure to the outside of the patient’s chest and abdomen. Negative pressure ventilation (NPV) cycles that negative pressure and reduces the effort required for a patient to breath. The level of support can be increased or reduced progressively to help in the patient’s recovery. It also increases the heart’s efficiency compared to conventional ventilators which squeeze the chest and put pressure on the heart. The simple design concept for the exovent system makes it widely accessible with highly cost effective, reliable units able to be readily manufactured and approved around the world.

Longer term vision

The vision of the team is a world where everyone has access to non invasive breathing support when they need it. Recognising the important contribution that exovent systems can make in achieving this in the longer as well as the short term, the task force decided to register as a UK Charity. The team is very grateful to law firm Bates Wells who generously donated their time and expertise and to many other companies who have provided support.

The response of the Charity Commission was also enormously impressive - understanding the urgency, they registered the charity in just one working day. Charity Commission CEO, Helen Stephenson, later explained that like Bates Wells, her team was determined to do what they could to help the COVID effort and prioritised all COVID related applications.

ENDS

For more information see https://www.exovent.info/

Note to Editors

Medical benefits

· exovent-19 can provide an alternative choice to using continuous positive airway pressure (CPAP) by delivering continuous negative extrathoracic pressure (CNEP). This device does not require to be driven by pressurised air or oxygen. Additional oxygen that the patient needs can be provided with tubing or a face mask as required

· exovent-19 should give excellent oxygen and carbon-dioxide transfer because replacing PPV+PEEP (positive pressure ventilation + positive end expiratory pressure) with NPV+NEEP (negative pressure ventilation + negative end expiratory pressure) has been shown to give equal or improved gas transfer when treating ARDS

· exovent-19 should increase the heart’s efficiency by up to 25% compared to conventional PPV which squeezes the heart and veins in the chest and may actually reduce cardiac function. This is especially important because COVID-19 can make heart function worse

· exovent-19 is non-invasive, which means that patients do not need to have their windpipes intubated, so they don’t need to be sedated or paralysed. Instead, they can remain conscious, take medication and nutrition by mouth, and talk to loved ones on the phone

· Being non-invasive and simple to use, exovent-19 could be used in intensive care or potentially on an ordinary ward

· exovent-19 only covers the torso so monitoring is still possible, and patients can be easily treated while prone (lying on their front) which is more effective in treating pneumonia. Oxygen can be delivered direct to the patient by mask or tubing as required

· exovent-19 is less likely to cause a pneumothorax (burst lung) as negative pressure ventilation produces less micro-trauma to the lung

Manufacturing benefits:

· Can be rapidly mass produced

· Uses parts currently available in the UK

· Has a small number of moving parts

· Does not compete for the same resources required by the commissioned manufacturers of PPVs

· Unlike PPVs or CPAPs, exovent does not require medical-grade compressed gases, which are at risk of shortage in the NHS due to heavy levels of demand for oxygen (although Covid-19 patients will need to be treated with oxygen)

· Is less expensive than other forms of ventilation

· Can be assembled at speed