WMG News

WMG in landmark partnership to develop UK electric motorcycle capability

Researchers at WMG are part of a unique four-way partnership with Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division, focusing on developing specialist electric motorcycle technology and innovative integrated solutions.

Phase 2 of Project TE-1, a landmark four phase collaboration in British design and engineering, is now complete with the exciting reveal of the innovative advanced electric powertrain and battery, and the very first styling sketches for the final prototype.

Phase 2 of Project TE-1, a landmark four phase collaboration in British design and engineering, is now complete with the exciting reveal of the innovative advanced electric powertrain and battery, and the very first styling sketches for the final prototype.

Including innovation in battery and powertrain design, initial test performance results that far exceed the current benchmarks and industry targets and development in efficiency and range technology, Project TE-1 is well on track to fully deliver on the partnership’s objectives to enhance the credibility and profile of British industry and design, and provide substantial input into future electric motorcycle strategy from Triumph.

Nick Bloor, Triumph CEO said: “The completion of Phase 2, and the promising results achieved to date, provide an exciting glimpse of the potential electric future and showcase the talent and innovation of this unique British collaboration. Without doubt the outcome of this project will play a significant part in our future efforts to meet our customer’s ambition and desire to reduce their environmental impact and for more sustainable transportation.

“This important project will provide one of the foundations for our future electric motorcycle strategy, which is ultimately focussed on delivering what riders want from their Triumph; the perfect balance of performance, handling and real world usability, with genuine Triumph character.”

Truong Quang Dinh, WMG’s Assistant Professor of Energy Management and Control Systems explained: “Our creation of initial computer-based simulation models at the start of Phase 1 has been instrumental in ensuring that the component selection was appropriate to achieve the performance targets defined by the partners for the TE-1 Prototype. We have continued with this work across Phase 2 of the project, refining the models to a much more complex level to allow us and the partners to imitate further components on the bike such as braking, throttle, lighting and other systems and mimic real-world riding to provide development opportunities before components were fully designed. Additionally we have created a physical rig wired with all of the control units, in order to implement a design validation test programme to ensure the function of each section was within the allowable range.”

Truong Quang Dinh explains more here: Project TE-1 - WMG cut on Vimeo

WMG has also been providing guidance to Triumph relating to future legislation, charging infrastructure and recycling strategies.

Project TE-1, a two year project, is supported and co-funded by the UK Government’s Department for Business, Energy & Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), via Innovate UK.

Read more about the Project here: Project Triumph TE-1 | For the Ride (triumphmotorcycles.co.uk)

Read more about WMG’s energy research here: Energy (warwick.ac.uk)

WMG commends the advances to UK innovation, skills and industrial growth made by the Industrial Strategy Challenge Fund and supports NAO recommendations to further improve impact

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- NAO right to support streamlining start-up and approvals processes of up to 72 weeks, which can deter bids, especially among smaller businesses

- Longer term visibility of funding will be needed to give investment confidence to businesses and academia

- Mechanisms to engage private sector finance should be considered – especially as innovations become ready for market

- As industry faces challenges of the pandemic, flexibility in financing bids, especially to support smaller businesses, should be considered

- Regional and Skills strategies should be a key part of innovation funding approach

- The Catapult network provides an established and successful platform for innovation, and its geographic locations also suggest it could play a big role in regional levelling-up

- Skills must be developed alongside innovation to give the UK the ability to exploit our ISFC investments. WMG, at the University of Warwick, have been pioneers in developing skills programmes alongside innovation and industrialisation

WMG at the University of Warwick has welcomed today’s National Audit Office report on the Industrial Strategy Challenge Fund, supporting their positive assessment of the fund, and backed their calls for a more streamlined approach to innovation funding, alongside a greater emphasis on the importance of innovation for regional development and skills growth.

Professor Dave Greenwood, Director of Industrial Engagement at WMG, University of Warwick and Chief Executive of the WMG High Value Manufacturing Catapult said:

“The Industrial Strategy Challenge Fund (ISCF) has been a powerful tool to support innovation that meets the most pressing national challenges.

“The ISCF has bought government, business and researchers together at scale, and at pace, to help our transport industry decarbonise through the Faraday Battery Challenge, and is delivering vital vaccine capacity through the Vaccine Manufacturing and Innovation Centre. It has supported over 1,600 projects, including the new UK Battery Industrialisation Centre in Coventry, with over forty per cent of support in the first two waves going to small and Micro companies.

“These projects are making a difference to UK innovation, skills and industrial growth, and these successes should be celebrated.

“As the report says, however, there are always opportunities to improve how the Fund operates.

“First, we need to make the funding process faster and more agile – especially given rapid changes in the external Business and social environment, from Brexit to the Pandemic. Lengthy Approvals processes of up to 72 weeks for selecting challenges and awarding projects can deter bids, especially among smaller businesses.

“Alongside this, with much of industry dealing with financial pressures from the pandemic, government should consider relaxing some of the funding constraints on the programmes – especially where they fall significantly short of what state aid would allow, such as in the co-investment requirement from Industry, which was increased in Wave 3 of the Fund.

“Together, these steps would help position the UK for clean growth post-COVID and deliver on opportunities created for the UK supply chain by the UK/EU trade agreement.

“Looking forward, it’s essential that there is a long-term funding package in place to support the Industrial Strategy Challenges. As the report notes “The Fund was part of a one-year settlement in the spending review in November 2020.” Short term spending decisions will ultimately be detrimental to large scale industrial and academic investments – a 5 year rolling funding horizon is needed for full confidence from Industry partners. To help deliver this, we should consider the role of private finance in these programmes, and what mechanisms might de-risk industry investments to support clean growth.

“It’s also crucial that the ISCF supports regional development as part of the Government’s ‘levelling up’ agenda. Currently, almost half of funding has gone to projects in London and the South East, and while we in the West Midlands have secured significant investment, the ISCF should reflect the regional profile of Industrial R&D more closely. It is notable that government funding relative to private sector investment is much lower in the Midlands than in the South East for instance.

The Catapult network, with centres of excellence across the country, strong links to regional industries, and good networking between them, is an exemplar of how levelling up should be delivered. This established and successful platform could provide an efficient and effective means to boost R&D in under-represented regions in accordance with the recommendations of this report.

“We also need to link innovation spending to the education and skills agenda. The UK needs not just the best technologies but also the people to develop, manufacture and support them. These cannot be developed in isolation. Here, WMGs approach of delivering innovation and skills programmes together and in partnership with industry is an established model, allowing degree apprenticeships, re-training, lifelong learning to support industry innovation programmes. As the Government considers responses to the skills white paper, it should consider how future industry skills needs will be shaped by the innovations being delivered by the challenge fund, from transport electrification to digital skills.

Immersion Cooled EV battery initiative, project i-CoBat, wins The Engineer’s Collaborate to Innovate Automotive Award

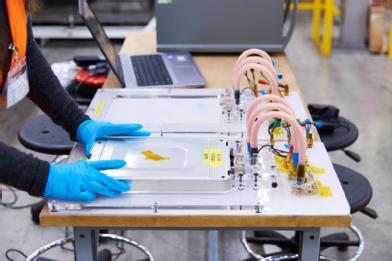

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

The project, led by M&I Materials, is a consortium involving battery systems developer Ricardo and WMG, at the University of Warwick which works to commercially and technically validate new technologies for industry.

Funded by Innovate UK, project i-CoBat uses a novel thermal management system for EV batteries using a novel, biodegradable dielectric fluid called MIVOLT, which allows for faster charging than conventional systems and a higher performance battery.

On receiving the news of the award for i-CoBat, Project Lead, M&I Materials Technical Director, Mark Lashbrook commented:

“We’re thrilled for project i-CoBat to have been recognised with this award, particularly since we were up against some incredibly exciting and forward thinking companies. This award is a testament not only to this type of initiative and what its implications are for the wider EV market, but to both Ricardo and Warwick Manufacturing Group for their extensive knowledge, expertise and leadership. Innovate UK have also been incredibly supportive throughout, so this award is also in recognition of the pioneering research projects, like i-CoBat, which they initiate.”

WMG's Principal Engineer, Stene Charmer, added: “I am thrilled and delighted that the ICO-BAT team have won this award. It has been wonderful to work with M&I materials and Ricardo, supporting the research of our advanced battery cell, module testing and advanced simulation techniques. At WMG we are leading innovative battery research and development, and innovative battery thermal management systems, the technology researched within ICO-BAT, are key to realising cost effective electrical energy storage systems for passenger vehicles.”

ENDS

WMG's Professor David Greenwood responds to the Government’s new climate target plan that was announced today

Professor Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement, comments:

Professor Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement, comments:

"Today’s announcement, alongside the previously announced Ten Point Plan for a green industrial revolution, shows that the UK intends to take a leading role in decarbonisation, and to reinvigorate our economy in doing so. Delivering this will not be easy, but this clear and consistent policy is an essential first step.

“The decarbonisation of the transport sector will be a major contributor to delivering on this challenge. The current generation of EV technology performs well in passenger cars but remains too expensive for many people, and the cost of the battery is the biggest factor in this. To reduce costs, two things must happen – significant investment in fast charging infrastructure, meaning that battery sizes can be reduced, and sustained investment in R&D into the technology of batteries and their manufacturing processes.

“Beyond passenger cars there are great opportunities for the UK in micro-mobility (e-bikes, scooters, motorcycles and small vehicles), low carbon freight, rail, maritime and aviation. To ensure sustainability of the products we roll out today, we must also be investing in the technologies of recycling and re-use of their component parts – and these too will present industrial opportunities for the UK to secure material supply chains and minimise environmental impact.

“To ensure our innovation investment benefits Britain’s economy, we need a clear action plan to expand and strengthen our transport supply chain. This includes supporting skills and retraining, widening access to finance, improving the industrialisation of innovation and attracting manufacturing investment to the UK.

"Investment in the industries and people striving to make transport zero carbon is the only way that we will achieve a green transport future that is convenient for its users and achieves long term sustainability."

WMG partners with Pashley Cycles and a team of UK SMEs to bring a novel e-assisted cargo trike to market

WMG is collaborating with Pashley Cycles and three other SMEs across the Midlands to develop an electrically assisted, last mile delivery trike. The trike features an innovative tilting suspension system which will provide greater stability on corners (and therefore speed and manoeuvrability) than a conventional tricycle configuration of the same size.

Supported and part-funded by the Niche Vehicle Network, through a “Production Readiness” funding call, the Articulating Lightweight Electrically-assisted Cargo Solution (ALECS) project, will form the platform for a new generation of configurable products to meet the rapidly growing market for zero-emission last mile cargo vehicles.

Project Manager, Dr Alex Attridge, explained: “This project provides a fantastic opportunity for WMG to apply its knowledge and expertise in vehicle electrification, and in product testing and evaluation, to a real-world product development process, helping a consortium of UK SMEs bring a new, zero-emission delivery vehicle to a rapidly growing market.”

ALECS is designed to carry cargo on a versatile and customer configurable, multi-functional rear platform. It is particularly suited to parcel and package deliveries in an urban environment where fast and efficient multiple deliveries are the key to success.

The consortium brings together the engineering and simulation capabilities of Simpact Engineering, with the high strength, lightweight tubing expertise of Reynolds Technologies, and the composite panelling and cargo structures expertise of Foresight Innovations. Coupled with Pashley’s heritage and capability in the personal mobility, mobility as a service, and cargo cycles markets, and WMG’s knowledge and experience in progressing innovation through the TRL levels into finish products, the project is set to be completed in April 2021.

One of the seven High Value Manufacturing Catapult centres, WMG brings a number of key technical capabilities to the project. These specifically include the development of photorealistic visualisations (in the form of still renders and interactive digital models) of the concept, and the delivery of digital design review content for both desktop and virtual reality environments. WMG is also responsible for the modelling and optimisation of the production facilities in an immersive, digital environment, utilising large scale laser scanning technology and the latest game engine software. Finally, as the consortium begins the physical testing stage, we will be responsible for the instrumentation of prototype and pre-production vehicles, and the subsequent data acquisition and analysis.

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

It’s electrifying!

WMG Centre High Value Manufacturing Catapult, with support from Advanced Propulsion Centre (APC) Electrical Energy Storage Spoke, has created a series of short educational videos to help explain the process of transport electrification.

WMG Centre High Value Manufacturing Catapult, with support from Advanced Propulsion Centre (APC) Electrical Energy Storage Spoke, has created a series of short educational videos to help explain the process of transport electrification.

There are a total of three episodes featuring WMG’s Electric Vehicle experts Professor David Greenwood, Research Fellow Faduma Maddar, and Dr Mel Loveridge.

In each episode, the experts explain more about the research carried out at WMG’s Energy Innovation Centre and address the key issues surrounding an electric future.

The videos will now be shared with policy makers, and schools across Coventry and Warwickshire to help support STEM learning.

The three episodes can be found in WMG’s Electric Vehicle playlist here.

WMG joins the Electric Revolution challenge

WMG is proud to be playing its part in the government’s Driving the Electric Revolution challenge.

WMG is proud to be playing its part in the government’s Driving the Electric Revolution challenge.

Fourteen winning projects, announced by the Business Secretary in March, will share a total of £6.7 million. These projects will help boost supply chain efficiencies in industries affected by electrification, from aerospace to automotive, to energy and rail.

Transport Minister Rachel Maclean said:

“Funding and increased support for state-of-the-art electric manufacturing centres will help people, goods and services move across the nation, in a greener, safer and more reliable way than ever before.

By investing in world-leading science and engineering institutions, we are creating a modern transport system, bringing communities closer together while reducing the UK’s contribution to climate change.”

Co-ordinated by WMG Centre High Value Manufacturing Catapult, WMG at the University of Warwick, will be part of the project consortiums for High Volume E-Machine Stack Manufacture and Lightweight Aluminium Winding (LAW).

High Volume E-Machine Stack Manufacture

This project brings WMG together with Brandauer, and Jaguar Land Rover to improve the production methods, tooling design, processes and material selection used in the creation of rotor and stator components to pave the way to a high volume production of thinner laminations in the UK.

Given the rise of electric vehicles and more electrified systems it is strategically desirable for the UK to develop its own supply chain for the production and distribution of high-performance electric machines at volume. This project seeks to close the gap in UK-based supply of rotor and stator lamination stacks.

Brandauer is already established as a market leader in high precision stampings and pressings in multiple sectors but does not currently have the capability to meet the demand of the automotive sector. This will create the opportunity for Brandauer to not just enter the automotive supply chain, but to do so as best-in-class.

Lightweight Aluminium Winding (LAW)

A consortium, led by Aspire Engineering, with WMG, Voltalogic, Ashwoods Automotive, Hydro Aluminium Rolled Products will develop a winding machine for aluminium wires. The winding machine will provide the first UK supply chain solution for manufacturing aluminium coils. Coil winding is a critical component of eMachine manufacture and is not provided by any UK manufacturer. UK based companies of eMachines have to purchase winding machines from overseas suppliers or have wound coils shipped to them.

Ashwoods and Voltalogic will provide copper coil designs that will be redesigned to use aluminium wire. Hydro Aluminium Rolled Products will provide coated aluminium wire with the preferred electrical conductivity and mechanical properties. Aspire will build their work on winding machines to provide a volume manufacturing solution, and WMG will leverage their development work on volume e-Machine manufacture to guide the partners to the provision of a volume manufacturing solution.

The successful completion of the project will provide a UK supply chain for the manufacture of e-Machine coil winding. Through this, it will enhance the UK's competitiveness to deliver e-Machine manufacturing technology. It will embed the design and manufacturing expertise for coil winding into the UK supply chain.

The project will develop the reduction in weight of e-Machines by 15% without compromising performance by developing manufacturing processes for winding coils from alternative material.

It will also deliver, for the first time, to the off-highway market a single source drive system incorporating advanced IPM motor technology, radically lighter BUT equally as efficient as current IPM technology.

Find out more about WMG’s Transport Electrification and Energy research here.

Electric superbike designed by students to race this summer

In a race to be clean and green the motor industry is changing, which has inspired 40 Warwick students to make an electric superbike to race this summer, 2020.

In a race to be clean and green the motor industry is changing, which has inspired 40 Warwick students to make an electric superbike to race this summer, 2020.

As the government has announced proposals to ban the sale of petrol, diesel and hybrid cars by 2035 the race to electrify the motor industry is on, and motorbikes aren’t to be overlooked.

The 40 students from a range of departments including: WMG, School of Engineering, Computer Science, Physics and Maths will work together to make the electric superbike possible with thanks to support from Rajputana Custom Motorcycles and Mupo Race Suspension.

School of Engineering student Aman Surana is managing the Warwick Moto team, he comments:

“The reason why I’m doing engineering is because of my interest in motorsports, be it four wheels or two. More than theory and the principles behind engineering concepts, it’s about the practical experience and finding real solutions rather than just what works on paper.

“My work experience at one of Asia’s biggest custom motorcycle shops Rajputana Custom Motorcycles helped reinforce my passion for motorcycles and is the reason Warwick Moto exists.

“It’s great to have the support from our sponsors Rajputana Custom Motorcycles and Mupo Race Suspension, and further support from WMG centre High Value Manufacturing Catapult, leading  academics in the industry are helping us to make this possible.”

academics in the industry are helping us to make this possible.”

The students will work in sub-teams focussing on:

1. Battery and Drivetrain

2. Chassis

3. Design and Aerodynamics

4. Finance

5. Marketing

6. On-Board Auxiliary systems

Superbike rider Tom Weeden has agreed to ride the electric superbike for them, and will be involved in all the testing and trials ready for a self-organised technological demonstration event in July 2020, he comments:

“I’m over the moon to be signing to ride the Warwick Moto electric bike in 2020 and hopefully beyond. The electric class is something I’ve been interested in and keen to be involved in for some time now.

“I’m looking forward to working with the students to develop a package that we can build for the future. Hopefully one day we can go to the TT and take it to the big budget teams.

“The passion these guys have is truly inspiring and I’m looking forward to learning more about how the technology works and adapting my riding to suit the different characteristics of the electric motor.

“I’ve ridden my brothers electric trials bike for the past few years and I know just how much torque and instant linear power these bikes can produce. The bike is based on the Honda Fireblade which has a brilliant handling chassis so should be an awesome platform to build from. Fingers crossed we can bring the budget that this team deserve to put together and develop the technology of the future!”

The students will have the motor and invertor delivered and tested in the next month, and will test the battery at the same time. They hope to have the prototype module testing in March.

The bike will then race at events over summer, but the long-term objective is to compete with a podium qualifying time at the Isle of Man TT 2022.

The team are looking for more supporters to make their first electric bike, you can sponsor them or donate to them here: https://www.justgiving.com/crowdfunding/warwickmoto

Follow their journey:

Instagram: https://www.instagram.com/warwick.moto/

Facebook: https://www.facebook.com/warwickmotoracing/

LinkedIn: https://www.linkedin.com/company/warwick-moto/

ENDS

DATE

NOTES TO EDITORS

High-res images available credit to WMG, University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_20.jpg

Caption: The full team of students and academics with the driver, Tom Weeden

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_04.jpg

Caption: The students and some academics working on the Warwick Moto team with the bike

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_08.jpg

Caption: Tom Weeden, left with students and the bike

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_18.jpg

Caption: Tom Weeden, on the electric superbike

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920531221

E-mail: alice.j.scott@warwick.ac.uk

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920531221

E-mail: alice.j.scott@warwick.ac.uk

Used Nissan LEAF batteries given “second life” thanks to WMG, University of Warwick

The ability to reuse high numbers of Electric Vehicle Lithium Ion batteries for domestic and industrial use is becoming a reality for Nissan thanks to a new grading system developed by researchers at WMG, University of Warwick.

The ability to reuse high numbers of Electric Vehicle Lithium Ion batteries for domestic and industrial use is becoming a reality for Nissan thanks to a new grading system developed by researchers at WMG, University of Warwick.

Once EV batteries have fulfilled their life-span for automotive applications, they are usually recycled by the manufacturer. However many automotive Lithium-ion (Li-ion) batteries have enough life left in them after the car is scrapped for ‘second-life’ uses both domestically and industrially.

To do this, it is necessary to “grade” the used batteries – identifying those suitable for use as spare parts, those suitable for “second life”, and those suitable for recycling of materials. This grading process is traditionally a long and expensive process.

Car company Nissan were keen to explore ways to make a much faster grading process for their used Li-ion batteries from the Nissan LEAF – allowing re-use of old battery packs or modules instead of disposing or recycling them.

They were challenged to demonstrate 1MWh of energy storage by the end of 2019.

Part-funded by BEIS (Business, Energy and Industrial Strategy) the ‘UK Energy Storage Laboratory’ project was launched, where 50 Nissan LEAF batteries were used to develop the existing grading process led by Nissan, WMG at the University of Warwick, AMETEK and Element Energy.

WMG’s battery technology experts in the Energy Innovation Centre developed a safe, robust and fast methodology for used automotive Lithium-ion batteries, at pack level. This methodology, which was initially developed in WMG, was successfully transferred to a pilot second-life facility, where the target of 1MWh of second-life energy storage was achieved.

In addition, the team at WMG developed ways of grading modules – the sub-components of battery packs in as little as 3 minutes – a process which previously took over 3 hours.

Graded second-life battery packs can provide reliable and convenient energy storage options to a range of customers: from electric roaming products – providing electricity for customers on the move, to home storage products – enabling customers with solar panels to store their energy generated. More crucially, the packs can be used for storage allowing increased intermittent renewable energy sources on the grid, without putting security of supply at risk.

Professor David Greenwood from WMG, University of Warwick comments:

“Automotive batteries deliver some great environmental benefits, but they consume a lot of resources in doing so. Opening up a second life for batteries improves both the environmental and the economic value we draw from those resources before they need recycling. I’m delighted that by working with the partners in this project, we’ve been able to make it much easier to access those second life applications.”

Business and Climate Change Minister, Lord Ian Duncan, said:

Business and Climate Change Minister, Lord Ian Duncan, said:

“It’s great to hear that the University of Warwick and Nissan are collaborating in pursuit of a greener, cleaner future. Reusing the batteries from electric cars could provide a valuable contribution to the UK’s green revolution - helping us lead more efficient and smarter lives as we end our contribution to climate change by 2050.

“We’ve part-funded this project to help give manufacturers more options than recycling – meaning a battery that helped a driver get from A to B could then be used to help store energy used to power a home.”

Ametek developed specialist equipment, and worked with WMG to embed the algorithms developed into a robust and industrialised machine that can be used by Nissan and other companies to grade second life batteries.

Andrew Williams, AMETEK Advanced Measurement Technology Business Unit Manager comments:

“The algorithm was developed with assistance from AMETEK EIS analyzers. We are currently implementing the algorithm in our new family of Solartron Analytical Battery Analyzer products, including our flagship SI-9300R model, which we expect will reduce market barriers for second life applications.”

The novel process is now being trialled for grading of battery modules at the second-life pilot facility, through these two processes, Nissan hopes to be able to re-use the vast majority of packs currently assembled in EVs in Europe.

Francisco Carranza, Managing Director from Nissan Energy comments:

“The number of electric vehicle batteries reaching end-of-service is set to increase from thousands to tens of thousands per annum by 2025. These batteries typically retain significant capacity and power delivery capability, and their re-use in so-called ‘second-life’ applications has been proposed as a mean to extend the battery value chain and minimise waste by deferring recycling.”

Project managers Element Energy commented:

“Reconditioning car batteries has to become business as usual - it makes sense environmentally and commercially. This project has proven a scalable process to deploy reconditioning and represents a significant milestone in the UK pathway to net zero emissions.”

For more information on this project, please see the UKESL Public Report at: http://www.element-energy.co.uk/wordpress/wp-content/uploads/2020/01/UKESL-Non-technical-Public-Report_2020.pdf

ENDS

21 JANUARY 2020

NOTES TO EDITORS

High-res images available credit to the University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/january2020/university_of_warwick_and_nissan_011.jpg

Caption: Two engineers with a battery pack at WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/january2020/university_of_warwick_and_nissan_029.jpg

Caption: A battery pack in the lab

https://warwick.ac.uk/services/communications/medialibrary/images/january2020/university_of_warwick_and_nissan_033.jpg

Caption: From left to right: Dr John Harper Senior Development Manager – Ametek, Priya Raju Project Support Officer – WMG University of Warwick, Djovana Dantas Manzi Head Of Operations at Nissan Energy Service (Europe), Dr Maria Tsiamtsouri Research Fellow at WMG Univeristy of Warwick, and Dr Jonathan Sansom Lead Engineer WMG University of Warwick.

https://warwick.ac.uk/services/communications/medialibrary/images/january2020/university_of_warwick_and_nissan_055.jpg

Caption: From left to right: Dr Maria Tsiamtsouri Research Fellow at WMG Univeristy of Warwick, Djovana Dantas Manzi Head Of Operations at Nissan Energy Service (Europe), Dr Jonathan Sansom Lead Engineer WMG University of Warwick and Priya Raju Project Support Officer – WMG University of Warwick.

https://warwick.ac.uk/services/communications/medialibrary/images/january2020/university_of_warwick_and_nissan_058.jpg

Caption: From left to right: Dr John Harper Senior Development Manager – Ametek, Djovana Dantas Manzi Head Of Operations at Nissan Energy Service (Europe) and Dr Jonathan Sansom Lead Engineer WMG University of Warwick.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

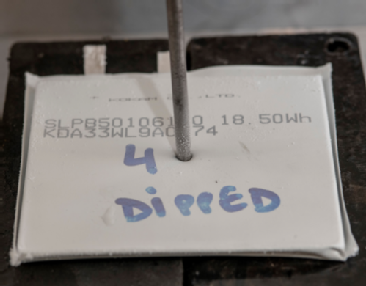

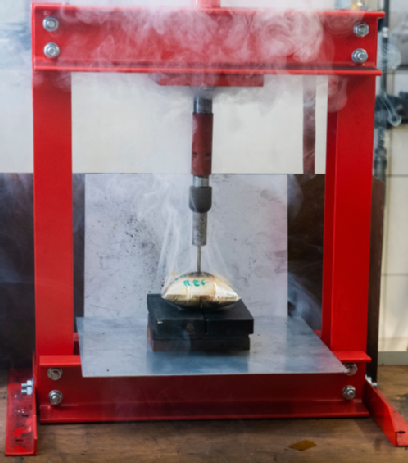

Car batteries can be frozen for safer transportation

Currently transporting damaged and defective car batteries is an expensive process as they need to be placed in an explosion proof box which costs thousands of pounds, however researchers from WMG at the University of Warwick in collaboration with Jaguar Land Rover engineers have been able to freeze batteries with Liquid Nitrogen.

An explosion proof box to transport a typical Tesla sized battery costs €10,000 and a further €10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

€10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

In the paper, ‘Cycle life of lithium ion batteries after flash cryogenic freezing’ published in the Journal of Energy Storage, researchers highlight that cryogenic freezing does not reduce lithium ion battery’s energy capacity or affect cycle or service life, and could be transported in a safer way.

As the sales of electric vehicles increases, there is more concern for the transportation of damaged and defective lithium ion battery packs. Currently, it is an expensive process, as they are put in an explosion proof box that costs €10,000 and a further €10,000 for the UN accreditation, which EV manufacturers are picking up the bill for.

Explosion boxes are used to contain the battery in case it goes into thermal runway, an overheating condition which can lead to violent explosions and toxic gases being released. However being able to cryogenically flash freeze the batteries completely removes the risk of an explosion, and could therefore mean they can be transported safely in a plastic box.

Researchers who were part of the ELEVATE project funded by EPSRC, WMG Centre High Value Manufacturing Catapult, and  supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

When being transported batteries will have to be kept in a lorry at -35 degrees, however the amount of packaging is significantly less than explosion proof boxes, making the process more sustainable.

Dr Thomas Grandjean from WMG, at the University of Warwick comments:

“Transporting damaged and defective batteries is an expensive and unsustainable process, however being able to freeze them with liquid nitrogen could save thousands of pounds and help electric vehicle manufacturers be more sustainable.

“We tested the batteries in the most extreme abuse conditions, such as driving nails through the cells and inducing external short circuits, proving that the freezing process is effective and safe.”

ENDS

2 DECEMBER 2019

NOTES TO EDITORS

High-res images available credit to WMG University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_3_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_5_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_7_.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_6.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_2_.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/untitled.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or + 44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk