WMG News

WMG Professor named as one of the ‘Top 100 Women in Supply Chain’

WMG Professor of Operations and Supply Chain Strategy, Jan Godsell, has been ranked 54th in the ‘Top 100 Women in Supply Chain’ report.

WMG Professor of Operations and Supply Chain Strategy, Jan Godsell, has been ranked 54th in the ‘Top 100 Women in Supply Chain’ report.

The list collated by Supply Chain Digital, in association with IBM, recognises exceptional female figures who are driving global innovation across the world.

Professor Godsell comments: “This last year, and the challenges of COVID, has highlighted the importance of supply chains. They are critical to life and the economy, but have often been overlooked. It is great to recognise the achievements of 100 women, leading the way in the use of digital technology in supply chains.”

Professor Godsell, who joined WMG in 2013, is highly influential within the engineering and manufacturing sectors. She is a Chartered Engineer and Member of the IMechE. She has advised government and industry on supply chain strategy, and its relationship to industrial and business strategy, and is currently a member of the Department for Business Energy and Industrial Strategy (BEIS) supply chain resilience advisory group. She is also a member of the Industrial Strategy Challenge Fund (ISCF) advisory groups for Manufacturing Made Smarter and Driving the Electric Revolution.

In addition, earlier this week Professor Godsell also began a new role as Co-Director of the Manufacturing Made Smarter Network+.

Read more about Professor Godsell’s career here: Jan Godsell (warwick.ac.uk)

You can see the official Top 100 Women in Supply Chain report here: https://issuu.com/supplychaindigital/docs/supplychain-top100-women-suppliment-2021-final/12

Solid-state batteries could be made more cleanly by scaling-up flash sintering

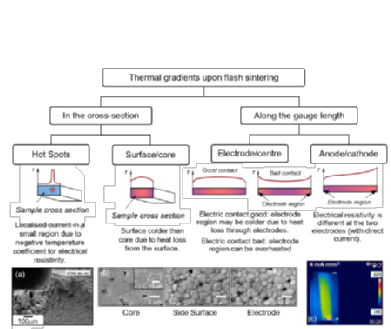

· Flash sintering is a ceramic processing technique which uses electric current to intensively heat the ceramic sample internally rather than using only external furnace heating. The process can lower ceramic processing temperatures and durations significantly, enabling ceramics to be co-processed with metals or other materials, and reducing energy use.

· However, the process can result in low quality ceramics due to weaknesses caused by inhomogeneities in the microstructure.

· The origins of these inhomogeneities caused by thermal gradients in the material during flash sintering have been studied by researchers based at WMG, University of Warwick and academic and industrial collaborators, and routes to mitigate the effects of these gradients are outlined.

· Adopting these modified flash sintering routes will enable the wider use of flash sintering in ceramic processing, enabling lower energy production of many useful ceramic products including solid-state batteries.

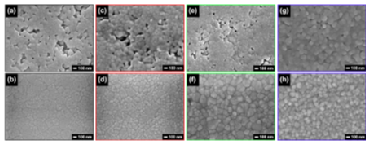

Densifying ceramics using flash sintering reduces energy use and may be used to improve the viability of manufacturing complex ceramic structures such as those required for solid state batteries by lowering the temperatures and shortening the duration of the heat treatment.

Working in collaboration with academic and industrial partners, researchers from WMG, University of Warwick have published a review of the state of the art of flash sintering focusing on the formation of inhomogeneous regions within the ceramics which currently limit the scale-up potential of flash sintering. The review finds that thermal gradients are responsible for microstructural inhomogeneities and suggests of routes to eliminate or reduce these effects.

of flash sintering focusing on the formation of inhomogeneous regions within the ceramics which currently limit the scale-up potential of flash sintering. The review finds that thermal gradients are responsible for microstructural inhomogeneities and suggests of routes to eliminate or reduce these effects.

The reduction of energy use in the ceramic manufacturing industry is a key step in meeting global emissions reduction targets, as conventional processes require long firing treatments at very high temperatures. Several low-energy processes have been developed over the past decade, with flash sintering emerging as a particularly promising route for densification of materials for use in applications including solid state batteries, thermal barrier coatings, and ceramic joints.

In the paper, ‘Promoting microstructural homogeneity during flash sintering of ceramics through thermal management’ published as part of a special issue of the MRS Bulletin, Gareth Jones and Dr Claire Dancer from WMG, University of Warwick worked with collaborators from the University of Trento, Wuhan University of Technology, Normandie Université, and Lucideon Ltd to review the origins of microstructural variations in different regions of ceramic materials undergoing flash sintering.

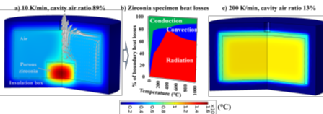

Differences in microstructural development originate from thermal gradients within the material during processing, and these can be reduced by careful thermal management during the flash sintering process. These include:

Differences in microstructural development originate from thermal gradients within the material during processing, and these can be reduced by careful thermal management during the flash sintering process. These include:

· Altering the method for applying electrodes

· Improving thermal homogeneity through insulation

· Tailoring the frequency of the AC current

· Developing contactless methods for applying the electric current - which are currently limited to consolidation of thermal barrier coatings.

The findings of this review provide a roadmap for further research on thermal management in flash sintering, which will accelerate the development of the process for industrial implementation.

Dr Claire Dancer, leader of the Ceramics Group within the Materials and Sustainability Directorate at WMG, University of Warwick comments:

“Lowering ceramic processing temperatures by using techniques such as flash sintering is an essential step for manufacturing complex multi-material structures such as those needed for solid-state batteries, and for lowering overall energy use in the ceramic industry.

“However, the process must produce robust homogenous ceramic materials to be of widespread use. Our paper explains why flash sintering can result in inhomogeneous properties in ceramics and suggests a number of routes to mitigate these effects.”

ENDS

9 MARCH 2021

NOTES TO EDITORS

The work has been funded by an EPSRC New Investigator Award, a PhD studentship from ERDF and Lucideon, the Royal Society, and the High Value Manufacturing Catapult.

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure1.png

Caption: Causes and Effects of thermal and microstructural gradients in flash sintered ceramics.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure2.png

Caption: Microstructural development changes with different sintering approaches. Flash sintering produces fine microstructures with very high density with lower energy use than conventional approaches.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure3_png.png

Caption: Simulation of heat distribution during flash sintering.

Credit: WMG, University of Warwick

Paper available to view at: https://link.springer.com/article/10.1557/s43577-020-00010-2

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Celebrating International Women Day

Today (Monday 8th March), WMG will be celebrating International Women’s Day and supporting the ‘Choose to Challenge’ initiative.

Staff from across the department have pledged their support which has been used to create this short animation: Choose To Challenge | WMG supports International Women's Day 2021 - YouTube

Staff from across the department have pledged their support which has been used to create this short animation: Choose To Challenge | WMG supports International Women's Day 2021 - YouTube

WMG Executive Chair, Margot James, has also been sharing her personal thoughts about those who have inspired her, and explains why she is passionate about supporting change for other females. You can hear more from Margot in this short video: https://www.youtube.com/watch?v=Le4XRezK1GU&t=4s

The Day is also a perfect opportunity to celebrate the achievements of the WMG Women in STEM, including Bethany Haynes, Connie Qian and Freeha Azmat. You can read their inspiring stories and more about how they’ve been smashing stereotypes on the: Athena SWAN (warwick.ac.uk) pages.

Innovating the Future: British Science Week at WMG

Between 5-14 March, WMG will be supporting British Science Week 2021 - a ten-day celebration of science, technology, maths and engineering. The theme for this year’s event is ‘Innovating the Future.’

WMG has a programme of activities that will showcase the work of its scientists and engineers. You can see more here: WMG - The University of Warwick

MozFest

On 8th March, Professor Margaret Low, WMG’s Director of Outreach and Widening Participation, will be taking part, virtually, in MozFest. The Mozilla Festival, affectionately known as MozFest, is hosted by the Mozilla Foundation, with themed ‘spaces’ akin to mini-festivals.

Professor Low will join other experts to present “Exploring Coding, Stitching Culture,” through a series of tutorials and workshops in the Global Culture and  Heritage Space. Participants will have the opportunity to create designs with Turtlestitch coding. The designs will them be exhibited in the Mozfest gallery.

Heritage Space. Participants will have the opportunity to create designs with Turtlestitch coding. The designs will them be exhibited in the Mozfest gallery.

Turtlestitch is freely available software that enables the generation and stitching of patterns using a digital embroidery machine. WMG has a series of free tutorials and lesson plans for Turtlestitch available online.

You can register for MozFest here: Mozilla Festival - Tickets

WMG Talks Science

On Friday 12th March, WMG’s Outreach Project Officer, Dr Phil Jemmett will be hosting a live ‘WMG Talks’ event aimed at Year 9 and 10 pupils.

The youngsters will have the chance to hear from four WMG scientists – Amar Gohil, Ben Hunt, Katerina Gonos and Kevin Couling, who will share their expertise on driverless vehicles, transport electrification, battery chemistry and 3D printing, respectively.

Dr Phil Jemmett explains: “British Science Week takes cutting-edge, awe-inspiring work, usually hidden in university buildings, and shares it with the people who will end up using that technology.

Dr Phil Jemmett explains: “British Science Week takes cutting-edge, awe-inspiring work, usually hidden in university buildings, and shares it with the people who will end up using that technology.

“Futuristic concepts belong in the classroom because those students will be the people who end up designing, making, and improving the technology we are talking about today. Our Outreach activity links the school curriculum to our leading research.

“Amar is teaching cars to drive themselves to make transport accessible and safe; Katerina and Ben are making it possible to generate and store energy in a 'green' way, and Kevin is 3D printing body parts for surgeons to train on. These topics will have huge impacts on all of us and they need future STEM experts to turn these concepts into real products. The next leader in STEM is probably in school somewhere right now - could it be you?”

To find out more or to register a place for your child visit: https://warwick.ac.uk/fac/sci/wmg/about/outreach/opportunities/wmgtalks

Digital supply chain visibility needed to rebuild after COVID-19

Manufacturers must unlock supply chain visibility to rebuild after the COVID-19 pandemic, WMG and Blue Yonder are warning.

The pandemic has disrupted supply and demand in many ways, from factory and border closures to swings in consumer needs, and those without supply chain visibility have been struggling to adapt and keep up. Digital supply chain technologies perform a vital role across all stages of manufacturing, from sourcing materials and quality control to warehouses and shipping. Now the industry is being warned any talk of ‘building back stronger’ won’t come to fruition if manufacturers don’t have the visibility over demand and supply that digital supply chains can bring.

The warning comes as a result of WMG research conducted in with almost 250 manufacturing companies revealing that lack of visibility and workforce issues are creating the biggest supply chain bottlenecks:

- 47% cited lack of visibility of capacity at suppliers and 37% cited lack of visibility of demand from customers as major supply chain constraints.

- More than half (55%) used inventory as the major buffer against disruption. This ties up cash and can leave organisations exposed if demand falls.

- Less than a third (32%) used visibility in their supply network to react to disruption. This is potentially a more effective strategy in the longer term.

To help manufacturers assess their supply chain needs, WMG at the University of Warwick and Blue Yonder worked together to design a freely accessible digital readiness tool. The digital readiness tool gives manufacturers the ability to assess their current supply chain to see where they are now and where they need to be. Manufacturers can also enquire about a further consultation to understand what they need to do to get to their goal and survive in the post COVID-19 world.Professor Jan Godsell, WMG, University of Warwick

Professor Jan Godsell, from WMG, University of Warwick, comments: “As we continue to deal with the disruptions of COVID-19, demand and supply visibility has never been more critical. It enables manufacturers to better plan their manufacturing operations, to minimise costly inventory buffers. We hope that the supply chain digital readiness tool can assist manufacturers with identifying opportunities to use digitisation to help their businesses to survive and thrive amidst the challenges of COVID-19. We are also offering manufacturers further advice.”

has never been more critical. It enables manufacturers to better plan their manufacturing operations, to minimise costly inventory buffers. We hope that the supply chain digital readiness tool can assist manufacturers with identifying opportunities to use digitisation to help their businesses to survive and thrive amidst the challenges of COVID-19. We are also offering manufacturers further advice.”

Alan Duncan, Senior Director of Manufacturing Strategy at Blue Yonder, adds: “They say ‘the wise man built his house on the rock,’ and when they’re rebuilding after COVID-19, manufacturers must put resilient digital supply chains at the centre of operations. Manufacturers have been investing more in the move to digital supply chains in recent years, but it’s crucial that their plans are pushed through to fruition. A digital supply chain will give them the end-to-end visibility, resilience and agility required to emerge from pandemic disruption in the strongest manner possible.”

ENDS

4 MARCH 2021

NOTES TO EDITORS

The data comes from a WMG survey of 248 manufacturers in September 2020.

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january2019/jangodsell250.jpg

Caption: Professor Jan Godsell, WMG, University of Warwick

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Royal Academy of Engineering announces new Lord Bhattacharyya bursary winners for students in the West Midlands

Students across the West Midlands have been awarded a series of bursaries as part of the Royal Academy of Engineering’s Lord Bhattacharyya Engineering Education Programme.

Students across the West Midlands have been awarded a series of bursaries as part of the Royal Academy of Engineering’s Lord Bhattacharyya Engineering Education Programme.

The Winners have been announced on the second anniversary of the death of Lord Bhattacharyya, and the programme is named in his honour. He was Britain's first ever Professor of Manufacturing he founded WMG at the University of Warwick in 1980 - today WMG is one of the world’s top applied research centres, with a reputation for academic excellence and business results spanning the globe. He died on March 1st 2019.

The programme recognises the outstanding achievements and continues the legacy of the late Professor Lord Bhattacharyya KT CBE FREng FRS, in tribute to his work championing manufacturing and industrially engaged education. The West Midlands has a long history of engineering and manufacturing, with strong roots in bicycles, cars, textiles and watches, and this project builds on that heritage, supporting the untapped engineering potential within local students to build a skills base for engineering companies in the area.

Four higher education bursaries have been awarded to students studying engineering at university this year, along with 18 post-16 technical education bursaries to support students studying at Level 3. This ambitious programme will also deliver science, technology, engineering and mathematics (STEM) education support for students and teachers and has allocated over £44,000 of funding to 20 secondary schools and a number of further education colleges in the region this academic year. It has been made possible by government funding from the Department for Business, Energy and Industrial Strategy.

Higher education bursaries for the 2020-2021 academic year have been awarded to:

- Abdulhakim Fundikira, studying Civil Engineering at Coventry University

- Farid Moulaye, studying Electrical and Electronic Engineering at Coventry University

- Jessica Oliver, studying Civil Engineering at Coventry University

- Saman Salih, studying Engineering (inc. integrated Foundation Year) at Coventry University

Read more about all of the recipients here: Meet the recipients - Royal Academy of Engineering (raeng.org.uk)

Post-16 technical education bursaries for this academic year have been awarded to students studying at:

- WMG Academy for Young Engineers, Coventry

- WMG Academy for Young Engineers, Solihull

- Warwickshire College, Rugby

Read more about the Lord Bhattacharyya Engineering Education Programme here: https://www.raeng.org.uk/education/schools/education-programmes/the-lord-bhattacharyya-engineering-education-

The programme recognises the outstanding achievements and continues the legacy of the late Professor Lord Bhattacharyya KT CBE FREng FRS, in tribute to his work championing manufacturing and industrially engaged education. The West Midlands has a long history of engineering and manufacturing, with strong roots in bicycles, cars, textiles and watches, and this project builds on that heritage, supporting the untapped engineering potential within local students to build a skills base for engineering companies in the area.

The Academy is leading this programme in partnership with WMG at the University of Warwick. The programme draws together secondary schools, further education colleges, universities, local employers and other key stakeholders to inspire and encourage more young people to study STEM subjects in post-16 education and beyond. The programme will enrich the curriculum, stimulate interest and improve student attainment outcomes by bringing real-world engineering practice into the student experience. The aim of the project is to encourage a diverse range of young people to progress towards the engineering roles of the future in local industry.

Applications for higher education bursaries for academic year 2021/2022 will open in Spring 2021 to students planning to study engineering at degree-level. For more information please see: https://www.raeng.org.uk/grants-prizes/grants/schemes-for-students/lord-bhattacharyya-bursary-scheme

The Lord Bhattacharyya Engineering Education Programme has established networks of secondary school STEM teachers and engineering lecturers in further education capable of supporting each other and sharing good practice. Funding supports involvement in national and regional engineering programmes as well as the purchase of kit and equipment to enhance and enrich the delivery of the STEM curriculum in schools and colleges. It will provide up to 6,000 STEM learning opportunities for young people each year. Students will also be able to apply for up to 90 bursaries each year to support progression on to full-time engineering technical education or degree courses.

The programme is based on a template of successful Academy engineering education projects in the Welsh Valleys, Barrow-in-Furness, Stoke-on-Trent and Lowestoft, Suffolk, which have together delivered more than 120,000 STEM learning opportunities for young people since their launch. The Lord Bhattacharyya Engineering Education Programme builds on this model and includes fully funded industrial placements for college lecturers and STEM teachers at local engineering companies.

An aligned longitudinal research study led by WMG at the University of Warwick will assess the impact of the good practices pioneered or identified through the programme.

Dr Hayaatun Sillem CBE, Chief Executive of the Royal Academy of Engineering, said:

“We want more young people from all backgrounds to have the opportunity to make a difference through a career in engineering. This programme is supporting young people in the West Midlands to discover how they could make an impact by studying engineering as well as removing some of the barriers that might prevent them going into technical education. I am sure Professor Lord Bhattacharyya would approve of the positive contribution of this initiative in a region that is synonymous with his passion and commitment to engineering innovation.”

Science Minister Amanda Solloway said:

"As we build back better, I am determined that we invest in our young people and eliminate the barriers that exist for those looking to pursue a career in STEM – ensuring that our best and brightest can excel no matter what their background.

“Through this bursary programme, inspired by the legacy of Lord Bhattacharyya, I am delighted we are able to provide a launchpad for the UK’s next generation of highly skilled engineers right in the heart of the West Midlands, building on the region’s proud tradition of engineering and manufacturing.”

Professor Robin Clark, Dean of WMG, University of Warwick, commented:

“We are delighted to be working with the Royal Academy of Engineering to deliver the Lord Bhattacharyya Engineering Education Programme. We are looking forward to helping enable the opportunities this will provide for the students involved, as well as the advantages it will bring for their schools and colleges. This is a great opportunity for us to deliver on the Government’s ambitions for developing the next generation of engineers to fill the skills gaps in engineering.”

Rebecca Archer, Student Destinations Manager at WMG Academy Solihull, said:

“The Lord Bhattacharyya HE Bursary Scheme has been pivotal in breaking down the barriers to Higher Education for some of our students who may not have otherwise continued on their journey to university. One of our successful candidates was overwhelmed in being chosen for this award; it has made a crucial difference between having to be selective to being fully prepared for their studies from a financial perspective. WMG Academy recognises the lifeline the Lord Bhattacharyya HE Bursary Scheme can offer our students. It has ensured that those who are motivated to pursue engineering at university have the chance to take their first steps into this industry.”

Marie Fletcher of Colmers School and Sixth Form College said:

"We have set up our first Engineering qualification using the grant money to purchase equipment to inspire pupils in an area where uptake to careers in the engineering sector is low."

Heavy rain affects object detection by autonomous vehicle LiDAR sensors

High level autonomous vehicles (AVs) are promised by Original Equipment Manufacturers (OEMs) and technology companies to improve road safety as well as bringing economical and societal benefits to us all.

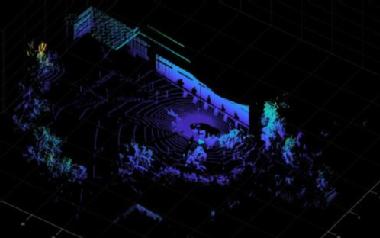

All high-level AVs rely heavily on sensors, and in the paper, ‘Realistic LiDAR with Noise Model for Real-Tim Testing of Automated Vehicles in a Virtual Environment’, published in the IEEE Sensors Journal, researchers from the Intelligent Vehicles Group at WMG, University of Warwick have specifically simulated and evaluated the performance of LiDAR sensors in rain.

Using the WMG 3xD simulator, researchers tested an autonomous vehicle’s LiDAR sensors in different intensities of rain, driving around a simulation of real roads in and around Coventry. The simulator is a key part of testing autonomous vehicles, as they have to have been on several million miles of road, this therefore means that they can be tested in a safe environment that is the same as a real road.

Using the WMG 3xD simulator, researchers tested an autonomous vehicle’s LiDAR sensors in different intensities of rain, driving around a simulation of real roads in and around Coventry. The simulator is a key part of testing autonomous vehicles, as they have to have been on several million miles of road, this therefore means that they can be tested in a safe environment that is the same as a real road.

LiDAR sensors work by emitting numerous narrow beams of near-infrared light with circular/elliptical cross sections, these can reflect off objects in their trajectories and return to the detector of the LiDAR sensor.

One of the issues of LiDAR sensors is the degradation of its performance in rain. If a LiDAR beam intersects with a raindrop at a short distance from the transmitter, the raindrop can reflect enough of the beam back to the receiver, therefore detecting the raindrop as an object. The droplets can also absorb some of the emitted light, degrading the range of performance for the sensors.

Using different probabilistic rain models (none, to different intensities) researchers made it ‘rain’ the WMG 3XD simulator, and measured the LiDAR sensor’s responses to the rain, making a record of false positive and false negative detections.

They found that as the rain intensity increased it became more difficult for the sensors to detect objects. In a short range from the vehicle (up to 50m),  several rain drops were erroneously detected. However in a medium range, (50m-100m) this had decreased, but as rainfall increased to up to 50mm per hour, the sensors detection of objects decreased in conjunction with a longer range in distance.

several rain drops were erroneously detected. However in a medium range, (50m-100m) this had decreased, but as rainfall increased to up to 50mm per hour, the sensors detection of objects decreased in conjunction with a longer range in distance.

Dr Valentina Donzella, from WMG, University of Warwick comments:

“Ultimately we have confirmed that the detection of objects is hindered to LiDAR sensors the heavier the rain and the further away they are, this means that future research will have to investigate how to ensure LiDAR sensors can still detect objects sufficiently in noisy environment.

“The developed real-time sensor and noise models will help to further investigate these aspects, and may also inform autonomous vehicles manufacturers’ design choices, as more than one type of sensor will be needed to ensure the vehicle can detect objects in heavy rain.”

ENDS

25 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/pic_1.jpg

Caption: The WMG 3xD simulator, used to test the LiDAR sensors

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/pic_2_.jpg

Caption: A virtual scan of the NAIC building generated with Intelligent Vehicle Group’s LiDAR model

Credit: WMG, University of Warwick

Paper available to view at: https://ieeexplore.ieee.org/document/9354172

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

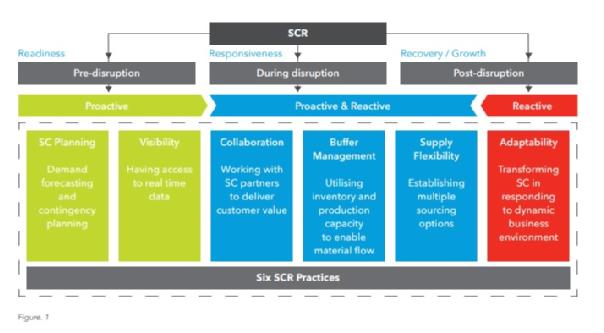

The three key actions to secure supply chain resilience after Brexit and COVID

Brexit and COVID were two major disruptions to manufacturers’ supply chains, however, a consortium of academic and industry partners including WMG, University of Warwick has identified key ways to build supply chain resilience.

A report by researchers from WMG, University of Warwick in conjunction with Argon & Co, Tata Consumer Products Ltd and Pinsent Masons has highlighted three practical solutions for supply chain resilience:

1. Risk management – Identifying risks throughout the supply chain to make wise decisions

2. Buffer management – Utilising inventory and capacity in the supply chain to react in a timely manner

3. Contract management – Increasing contracting agility to build a close tie with business partners

Supply chains have been under a significant amount of stress over the last year with Brexit and COVID-19, with three in four organisations likely to experience disruptions. Therefore, their resilience is key to recovery.

The complexity of supply chains means that disruptions can happen at any time. When COVID-19 hit the world in early 2020 firms had little time to prepare, but the report found that those that were able to adapt, supply flexibility and buffer manage were able to deal with the disruption more effectively.

but the report found that those that were able to adapt, supply flexibility and buffer manage were able to deal with the disruption more effectively.

Huge uncertainties lie ahead when it comes to Brexit, however with time to prepare, the industries can be ready for a number of different scenarios. Research has found the use of proactive practices such as planning and visibility and collaboration were effective in initial Brexit preparation.

In order to improve supply chain resilience it’s essential that there is an understanding of what exactly supply chain resilience is and planning ahead for it. Assessing just how resilient a manufacturer is by identifying vulnerable areas is the first step in preventing disruption.

This then leads onto managing buffers, for example optimising inventory stocks and production capacity, and with that being cooperative. A coordinated approach to supply chain planning enables great visibility and mitigates risks.

Professor Jan Godsell, from WMG, University of Warwick comments:

“Supply chain risks will always be unavoidable, however the quick succession of Brexit and COVID has rung a bell for suppliers to be prepared for any situation that may arise. Areas of preparation include identifying risk throughout the supply chain to inform better decisions, managing buffers to respond faster and adopting flexible contracting enables greater collaboration.

“We encourage all firms to consider these solutions, so their supply chain is more resilient and that ultimately they’ll be more sustainable in the long term.”

Clare Francis, partner at Pinsent Masons LLP adds:

“The last year has seen supply chains disrupted on an unparalleled scale. As businesses have moved from the initial challenges of ensuring supplies in the short-term they now need to focus on rebuilding resilient supply chains for the future. There are a number of areas that businesses must consider when doing this but they have an opportunity to learn from the lessons of Covid-19 and implement more resilient and better supply chains for the future.”

ENDS

23 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/jan_godsell_supply_chain_resilience_figure_1.jpg

Caption: Types of supply chain resilient strategies pre-disruption, during disruption and post-disruption.

Credit: WMG, University of Warwick

Report available to view at: https://warwick.ac.uk/fac/sci/wmg/business/supply_chain_resilience_hub_report_-_final.pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

New insight into how lithium-rich cathode materials for high energy EV batteries store charge at high voltages

- By 2030 only EV’s will be in production, meaning manufacturers are racing to create a high-energy battery that’s affordable and charges efficiently, but conventional battery cathodes cannot reach the targets of 500Wh/Kg

- Lithium-excess cathodes offer the ability to reach 500Wh/Kg but unlocking their full capacity means understanding how they can store charge at high voltages

- A new X-ray study lead by WMG, University of Warwick has resolved how the metals and oxygen facilitate the charge storage at high voltages

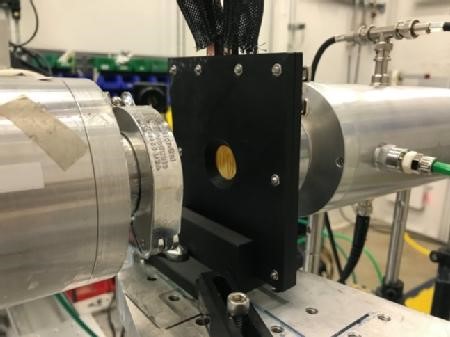

High energy storage batteries for EVs need high capacity battery cathodes. New lithium-excess magnesium-rich cathodes are expected to replace existing nickel-rich cathodes but understanding how the magnesium and oxygen accommodate charge storage at high voltages is critical for their successful adaption. Research led by WMG, University of Warwick in collaboration with U.S. researchers employed a range of X-ray studies to determine that the oxygen ions are facilitating the charge storage rather than the magnesium ions.

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Although progress has continued over the last 10 years to push the performance of state-of-the-art nickel-rich cathodes for EV, the material is unable to provide the energy density needed. To increase the capacity more lithium needs to be used, which means going beyond the ability of nickel to store electron charge.

Lithium-excess magnesium-rich cathodes offer sufficient energy density but to reach ultimately reach energy storage targets of 500Wh/Kg we need to understand how the electron charge is stored in the material. Simply put, is the electron charge stored on the magnesium or oxygen sites.

In the paper, ‘Whither Mn Oxidation in Mn-Rich Alkali-Excess Cathodes?’, published in the Journal ACS Energy Letters today the 17th of February, researchers from WMG, University of Warwick have overcome a significant milestone in understanding of charge storage in lithium-excess magnesium-rich cathodes.

Li-excess compounds that involve conventional and non-conventional redox, conventional refers to metal ions changing their electron density. Reversibly changing the electron density on the oxygen (or oxygen redox) without it forming O2 gas is unconventional redox. Various computational models exist in the literature describing different mechanisms involving both, but careful x-ray studies performed while the battery is cycling (operando) are ultimately required to validate these models.

Researchers between the UK and US, led by WMG at the University of Warwick, performed operando x-ray studies to precisely quantify magnesium and oxygen species at high voltages. They demonstrated how x-ray beams could irreversibly drive highly oxidized magnesium (Mn7+) to trapped O2 gas irreversibly in other materials.

However, by performing careful operando x-ray studies that circumvented beam damage and observe only trace amounts of Mn7+ forming upon charging in Li-excess cathodes during battery cycling.

Professor Louis Piper, from WMG, University of Warwick explains:

“We have ultimately resolved that oxygen rather than metal redox is driving the higher capacity, which means we can now design better strategies to improve cycling and performance for this class of materials.”

ENDS

17 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/operando_x-ray_louis_piper.jpg

Caption: Photo of the operando x-ray studies being performed at a Synchrotron facility.

Credit: WMG, University of Warwick

Paper available to view at: https://pubs.acs.org/doi/10.1021/acsenergylett.0c02418

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Child brain tumours can be classified by advanced imaging and AI

- Brain tumours are the most common solid tumours in childhood and the largest cause of death from cancer in this age group

- Being able to classify a brain tumour’s type, without the use of biopsy, is hard to do; however diffusion weighted imaging, an advanced imaging technique, when combined with machine learning, can help a UK-based multi-centre study, including WMG, University of Warwick has found.

- Being able to characterise the tumour(s) faster and more accurately means they can be treated more efficiently

Diffusion weighted imaging and machine learning can successfully classify the diagnosis and characteristics of common types of paediatric brain tumours a UK-based multi-centre study, including WMG at the University of Warwick has found. This means that the tumour can be characterised and treated more efficiently.

The largest cause of death from cancer in children are brain tumours in a particular part of the brain, called the posterior fossa. However, within this area, there are three main types of brain tumour, and being able to characterise them quickly and efficiently can be challenging.

Currently a qualitative assessment of MRI by radiologists is used, however overlapping radiological characteristics can make it difficult to distinguish which type of tumour it is, without the confirmation of biopsy. In the paper, ‘Classification of paediatric brain tumours by diffusion weighted imaging and machine learning’, published in the journal Scientific reports, led by the University of Birmingham including researchers from WMG, University of Warwick. The study found that tumour diagnostic classification can be improved by using non-invasive diffusion weighted imaging, when combined with machine learning (AI).

Diffusion weighted imaging involves the use of specific advanced MRI sequences, as well as software that generates images from the resulting data that uses the diffusion of water molecules to generate contrast in MR image. One can then extract an Apparent Diffusion Coefficient (ADC) map, analysed values of which can be used to tell you more about the tumour.

The study involved 117 patients from five primary treatment centres across the UK with scans from twelve different hospitals on a total of eighteen different scanners, the images from them were then analysed and region of interests were drawn by both an experienced radiologist and an expert scientist in paediatric neuroimaging. Values from the analysis of Apparent Diffusion Coeffcient maps from these images’ regions have been fed to AI algorithms to successfully discriminate the three most common types of paediatric posterior fossa brain tumours, non-invasively.

Professor Theo Arvanitis, Director of the Institute of Digital Health at WMG, University of Warwick and one of the authors of the study explains:

Professor Theo Arvanitis, Director of the Institute of Digital Health at WMG, University of Warwick and one of the authors of the study explains:

“Using AI and advance Magnetic Resonance imaging characteristics, such as Apparent Diffusion Coefficient (ADC) values from diffusion weighted images, can potentially help distinguish, in a non-invasive way, between the main three different types of paediatric tumours in the posterior fossa, the area of the brain where such tumours are most commonly found in children.

“If this advanced imaging technique, combined with AI technology, can be routinely enrolled into hospitals it means that childhood brain tumours can be characterised and classified more efficiently, and in turn means that treatments can be pursued in a quicker manner with favourable outcomes for children suffering from the disease.”

Professor Andrew Peet, NIHR Professor in Clinical Paediatric Oncology at the University of Birmingham and Birmingham Children’s Hospital adds:

“When a child comes to hospital with symptoms that could mean they have a brain tumour that initial scan is such a difficult time for the family and understandably they want answers as soon as possible. Here we have combined readily available scans with artificial intelligence to provide high levels of diagnostic accuracy that can start to give some answers. Previous studies using these techniques have largely been limited to single expert centres. Showing that they can work across such a large number of hospitals opens the door to many children benefitting from rapid non-invasive diagnosis of their brain tumour. These are very exciting times and we are working hard now to start making these artificial intelligence techniques widely available.”

ENDS

15 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/april2020/theoarvanitis.jpg

Caption: Professor Theo Arvanitis, from the Institute of Digital Healthcare at WMG, University of Warwick

Paper available to view at: https://www.nature.com/articles/s41598-021-82214-3

Paper DOI: 10.1038/s41598-021-82214-3

FOR FURTHER INFROMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk