WMG News - Latest news from WMG

Warwick Agri-Tech ploughs the future of farming and forestry with robotics

The University of Warwick announces Warwick Agri-Tech to help the future of farming with automation – addressing issues such as labour shortages, food insecurity and loss of biodiversity.

The University of Warwick announces Warwick Agri-Tech to help the future of farming with automation – addressing issues such as labour shortages, food insecurity and loss of biodiversity.

Warwick Agri-Tech, will also support the UK to meet climate targets while enabling the production of enough nutritious food for the growing population. It will combine two world class faculties at WMG at The University of Warwick and the School of Life Sciences (SLS), working with the High Value Manufacturing Catapult to spearhead automation in areas such as horticulture, crops and forestry.

Robots will be a key tool for farmers as food production comes under increasing pressure. There is a constant demand to grow enough high quality, nutritious food to feed an expanding human population, and to do so in a way that won’t harm the planet.

According to scientists, the UK will need to produce 50% more food by 2050, while reducing land consumption by 50%. This is further challenged by labour shortages, a broken food system and the fact we are overusing the Earth’s biocapacity (the capability of ecosystems to produce useful biological materials and to absorb waste).

The University of Warwick is in a unique position to tackle these issues and develop farming technology, with expertise in both automation and life science.

Warwick Agri-Tech was born out of an initial project which developed a crop monitoring robot (Crombot) to move autonomously up and down glasshouses and check fruit for ripeness. Officially launching today, with a visit from the Department for Environment, Food & Rural Affairs (DEFRA), Warwick Agri-Tech will continue its research on several key projects:

· An Autonomous Logistics Project – developing an autonomous vehicle to help horticultural companies to optimise their product handling logistics.

· A Smart Tree Production System – Warwick Agri-Tech is working with J&A Growers, who are the leading UK growers of quality bareroot trees and hedging, to autonomously sort and grade sapling trees. This will ensure resilience against labour shortages and is scalable in the face of the UK’s ambitious tree planting targets.

· Autonomous Precision Application – creating an autonomous, AI-based weed control robot, to reduce utilisation of herbicides by over 90% - improving soil health and biodiversity.

The University’s leading crop research centre at based at the Innovation Campus, Stratford-upon-Avon is a leading, 200-hectare agricultural research site. Scientists at the University will collaborate directly with industry partners and the Government to drive implementation of new technology in the farming sector.

Professor Gideon Henderson, Chief Scientific Adviser, said: “Seeing the innovation going on here is really inspiring – I firmly believe that Agri-Tech in the UK has a huge future and I look forward to seeing new ways of working being trialled here at Warwick become mainstream agricultural practices in the future.”

Professor David Greenwood, Director for Industrial Engagement, and CEO of the High Value Manufacturing Catapult at WMG, said: “The emerging needs of the agriculture sector have provided a perfect opportunity for The University of Warwick to bring together our expertise in manufacturing automation with our expertise in life sciences, so we can simultaneously develop robots suitable for use in greenhouses and fields, and ways of growing crops which take advantage of the opportunities of automation. As the UK struggles with availability of agricultural labour, and high food prices, this promises to unlock nutritious and affordable food for all.”

Professor Miriam Gifford, School of Life Sciences, University of Warwick, said: “Warwick Agri-Tech will benefit from the entrepreneurship of WMG and the history of excellence in agricultural innovation from the School of Life Sciences’ Warwick Crop Centre, plus the combined stakeholder groups to inform and enable outputs. The fresh food industries need automation urgently. Warwick Agri-Tech will grow rapidly into research and innovation space screaming for workable solutions and expecting substantial funding initiatives.”

More information about Warwick Agri-Tech here: https://www.youtube.com/watch?v=vXC3jzqrga0

Revolutionising the manufacturing industry through digitalisation

Until now, smaller manufacturing companies have missed out on the productivity benefits of digital technologies and data-driven solutions. Too many manufacturers don’t know where to start, and lack the skills required to deploy and use digital solutions. The costs are perceived to be high and the return on investment is unclear.

A consortium, including WMG at the University of Warwick, has been awarded funding through the Government’s Manufacturing Made Smarter Challenge to tackle this problem by developing a Smart InforMation PLatform and Ecosystem for Manufacturing (SIMPLE).

Project SIMPLE will bring the benefits of digitalisation to manufacturers for whom the technology, skills, and business benefits are currently inaccessible. The project will deliver a platform that is fast to deploy, easy to use, cost-effective, and versatile. And it will be supported by an ecosystem that addresses skills and training requirements.

The consortium includes a wide range of end-user, academic, and technology partners to provide the necessary breadth of expertise:

● Innovare Systems (construction) is representative of SMEs seeking to improve their operations through the deployment of digital capabilities, but have a low skill level in the domain, bare bones IT capabilities and low levels of automation

● Lear Corporation (automotive) is representative of global organisations challenged by their operational complexity, the diversity of technologies deployed in production, fragmented software landscape and data repositories

● The UK Battery Industrialisation Centre is seeking a vendor independent solution that can support their short-term objectives and scale up rapidly to support multiple production campaigns in the future

● WMG, University of Warwick is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes

● The Science and Technology Facilities Council is a government agency that carries out research in science and engineering. The focus for project SIMPLE is on knowledge representations and knowledge models relevant to manufacturing

● Fully Distributed Systems (FDS), AI Idea Factory and 4thWall Virtual develop engineering tools, industrial software components and supply related services.

The benefits of SIMPLE will be validated via deployment of the platform at the end-user partners’ facilities - demonstrating the value in three different use cases. The deployment of a skills training system at WMG, University of Warwick, will validate the skills and training proposition.

Project SIMPLE is co-funded by the businesses in the consortium and the UK’s innovation agency, Innovate UK, through the Manufacturing Made Smarter Competition. The Industrial Strategy Challenge Fund (ISCF) Manufacturing Made Smarter Round 1 Competition offers grant funding investment in projects that focus on the use of industrial digital technologies (IDTs) to transform the productivity and agility of UK manufacturing. Of 34 applications submitted, project SIMPLE is one of 14 projects approved following independent assessment and expert review.

Dr Daniel Vera, from WMG at the University of Warwick comments:

Dr Daniel Vera, from WMG at the University of Warwick comments:

“At WMG, we will be focussing on making sure that manufacturers become fluent in deploying and using digital systems. Our training platform will mean that manufacturers can confidently use data-driven methods and digital solutions to optimise their processes, which in turn can speed up their project delivery and significantly improve their business operations.”

Jason Powell of Innovare Systems adds:

“The technology is important as it offers greater operational transparency, which allows greater scrutiny of performance whilst maintaining the production activities’ live information. Additionally, this system can also be used as a tool to drive production efficiency through optimising performance which will increase capacity. We are expecting this technology to boost productivity by 10% even from the early deployment.”

Matt Patching of the UK Battery Industrialisation Centre said:

“The SIMPLE toolset will help us deliver battery technologies and processes to industry at a rapid rate. The flexible design will be compatible with our range of manufacturing processes, ranging from electrode and cell assembly, to module and pack, and to consistently present the relevant information. The scalable nature means that new promising technologies in the battery field can be implemented into our digital systems as quickly as it can be installed at our site.”

The project will engage the wider manufacturing community to ensure the SIMPLE platform and methodology addresses the widest set of manufacturers’ needs. For further information, please contact peter.hopkinson@fullydistributedsystems.com.

ENDS

6 JANUARY 2021

NOTES TO EDITORS

About WMG, University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes.

As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG’s education programmes focus on lifelong learning of the brightest talent, from the WMG Academies for Young Engineers, degree apprenticeships, undergraduate and postgraduate, through to professional programmes.

An academic department of the University of Warwick, and a centre for the HVM Catapult, WMG was founded by the late Professor Lord Kumar Bhattacharyya in 1980 to help reinvigorate UK manufacturing and improve competitiveness through innovation and skills development.

About Innovare Systems

As the only provider to have complete design to delivery capability in-house, Innovare Systems is uniquely placed to simplify the offsite construction process to help clients manage time, cost and risk more effectively. Innovare Systems’ aim is to make it easy for clients to achieve the time and cost saving benefits of offsite construction and make full use of the greater flexibility offered through a joined-up design, manufacture and installation solution with its i-SIP panel system.

About Lear Corporation

Lear, a global automotive technology leader in Seating and E-Systems, enables superior in-vehicle experiences for consumers around the world. Lear’s diverse team of talented employees in 39 countries is driven by a commitment to innovation, operational excellence, and sustainability. Lear is Making every drive better™ by providing the technology for safer, smarter, and more comfortable journeys.

About UKBIC

The £130 million UK Battery Industrialisation Centre (UKBIC) is a pioneering concept in the race to develop battery technology for the transition to a greener future. The unique facility provides the missing link between battery technology, which has proved promising at laboratory or prototype scale, and successful mass production. Based in Coventry, the publicly-funded battery product development facility welcomes manufacturers, entrepreneurs, researchers and educators, and can be accessed by any organisation with existing or new battery technology – if that technology will bring green jobs and prosperity to the UK.

In addition to funding from the Faraday Battery Challenge through UK Research and Innovation and the Industrial Strategy Challenge Fund, UKBIC is also part-funded through the West Midlands Combined Authority. The project has been delivered through a consortium of Coventry City Council, Coventry and Warwickshire Local Enterprise Partnership and WMG, at the University of Warwick. UKBIC was created in 2018 following a competition led by the Advanced Propulsion Centre with support from Innovate UK

About Fully Distributed Systems

FDS specialises in the development and integration of control and software solutions for manufacturing industries. In the last 5 years, FDS has developed expertise in the development and deployment of Industrial IoT integration platforms and common manufacturing and production data models, in line with the requirements of Industry 4.0 and digital manufacturing solution development.

For further information please contact

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Transforming Foundation Industry (TFI) Large CR&D virtual workshop

WMG hosted a workshop to support launch of the Transforming Foundation Industries (TFI) Large CR&D call. The event was held to raise awareness of the funding call, which opens on 11th January 2021, to provide a space for discussion around two of the key themes and to showcase how WMG can play a role in projects for the foundation industries (manufacturers and suppliers of paper, cement, metals, glass, bulk chemicals and glass).

WMG hosted a workshop to support launch of the Transforming Foundation Industries (TFI) Large CR&D call. The event was held to raise awareness of the funding call, which opens on 11th January 2021, to provide a space for discussion around two of the key themes and to showcase how WMG can play a role in projects for the foundation industries (manufacturers and suppliers of paper, cement, metals, glass, bulk chemicals and glass).

Keynote talks were given by WMG’s Professor Robert Harrison and Dr Stuart Bradley. Their talks on 'Advanced automation for the foundation industries and Waste heat energy recovery' provided details on WMG’s expertise and capabilities, where there are commonalities across sectors and opportunities for these industries to work together.

There were four breakout rooms where attendees were able to network and discuss project ideas for the upcoming call. The breakout rooms, hosted by subject experts, were themed around waste heat and energy storage, recovery and conversion; how waste products could be communally used and shared by foundation industry firms; and how advanced automation, machine learning and Industry 4.0 could help to advance the industries. There was also a general discussion room, where subjects such as future business models and waste streaming were considered.

As a result of the workshop, there are likely to be several applications to the TFI Large CR&D call, which we hope will be successful. It is clear that these different industries can work together to solve common problems and that organisations, such as WMG, can provide the platform to bring them together successfully.

If you work in the foundation industries and would like to hear more on how you can access support for your project from WMG experts, please contact Dr Russ Hall at R.Hall.5@warwick.ac.uk.

Prof. Lord Bhattacharyya Building wins Sustainability category at the AIA Excellence in Design Awards 2020

The Prof. Lord Bhattacharyya Building, home to the National Automotive Innovation Centre (NAIC) has won yet another award, this time at the 2020 Excellence in Design Awards, hosted virtually by the AIA UK Chapter on the 28 October. The awards were chosen from three overarching categories: Professional, Emerging Practice and Sustainability, a new category addition. The building scooped the Sustainability-Large Project category.

The Prof. Lord Bhattacharyya Building, home to the National Automotive Innovation Centre (NAIC) has won yet another award, this time at the 2020 Excellence in Design Awards, hosted virtually by the AIA UK Chapter on the 28 October. The awards were chosen from three overarching categories: Professional, Emerging Practice and Sustainability, a new category addition. The building scooped the Sustainability-Large Project category.

This comes shortly after the building was recognised as one of the best workplaces in the Midlands and Central England at the annual British Council for Offices (BCO) regional awards, winning the British Council for Office Midlands and Central Innovation Award.

Based at the University of Warwick, NAIC was officially open on 18th February 2020 by HRH The Prince of Wales. The Centre is a partnership between WMG, University of Warwick, Jaguar Land Rover, and Tata Motors, and is the largest of its kind in Europe and is well timed, arriving when a global mobility revolution is underway, with a new age for transport mobility.

A beacon for automotive research it brings together the brightest minds from industry and academia, to develop future vehicles and mobility solutions. It is home to up to 1,000 staff working across design, engineering and research, as well as future engineers on degree programmes.

Designed by Cullinan Studios the brief for the Centre was for simplicity and strength of purpose, turning a complex assembly of spaces into an immediately legible building.

The potential of UK engineering companies to manufacture ventilators - expert comment from Professor Robert Harrison

Robert Harrison, Professor of Automation Systems, at WMG, University of Warwick, comments on the potential of UK engineering companies to manufacture ventilators.

Robert Harrison, Professor of Automation Systems, at WMG, University of Warwick, comments on the potential of UK engineering companies to manufacture ventilators.

He said: “JCB, Rolls Royce or others could potentially manufacture ventilators. They have relevant skills and capabilities, but given that all the design and manufacturing related information could be supplied to them, getting the parts and the tooling to manufacture such a thing will be a significant task, perhaps taking many months.

“They would have to tool up production lines and train workers to assemble and test the product. Sourcing the parts, e.g., electronics, valves and air-turbines, quickly could be difficult.

“These are sophisticated devices. It is crucial that they work correctly in order to keep the patient alive, as these are life-critical pieces of equipment.”

Autonomous guided vehicles to transform horticultural labour shortage

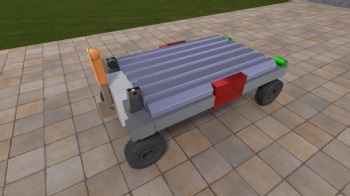

An Autonomous Guided Vehicle is being designed by researchers at WMG, University of Warwick in a bid to help the horticultural sector tackle a labour shortage.

The Agriculture and Horticulture Development Board (AHDB) launched the SmartHort project in 2018 in a bid to help the sector’s economy by reducing labour requirements in horticulture through new technology and automation.

Leading automation experts from the WMG, University of Warwick are creating the model alongside three horticultural businesses; Crystal Heart Salad (lettuce propagators, Yorkshire), Valefresco (salads, Worcestershire), and WD Smith & Son (bedding plants, Essex).

The model will have the potential to work in both glasshouse and outdoor environments to automate the movement of trays and boxes around the production area, speeding up production.

Agri2 from ASG_WMG2020 on Vimeo.

Professor Robert Harrison from WMG, University of Warwick comments:

“We’ve been able to apply the cutting-edge technology developed in the automotive industry to the challenging environment of horticultural production.

“We reviewed existing AGVs to ensure there wasn’t an available product that could meet the growers’ needs, and have run a full analysis on the potential prototype to ensure the investment could be repaid through offsetting future labour costs.”

Our research teams is working on a solution to specifically address needs within the horticulture sector. Having captured the requirements, we have produced a configurable solution, which we are now progressing via prototype designs. Key aspects of the solution include the ability to work both indoors and outdoors and for it to be usable in conjunction with application-specific attachments of different types.

Grace Emeny, Knowledge Exchange Manager at AHDB, said: “With the lack of available labour an increasing pressure for many businesses, there is a growing need to automate more routine tasks to enable staff to be reallocated to more skilled jobs.

“There are two main barriers that prevent the uptake of automation. Many off-the shelf solutions don’t work for diverse horticulture production systems and often the return on investment doesn’t stack up in the current trading climate. WMG were tasked with addressing both of these challenges, which we believe they are well on their way to achieving.”

The overall goal is for the prototype to be developed commercially and is likely to cost around £30,000 to £50,000 depending on its configuration. So it’s available to all kinds of businesses in the sector.

James Bean, Crystal Heart Salad Co. comments:

“WMG have made several visits to our nursery. They have carried out a study of our logistics and have identified a design of autonomous vehicle which can improve efficiency and remove low-skilled manual tasks.

“We are excited to see this move to the next stage, to conduct real-life tests of the technology. If it fulfils expectations, it will make a fundamental change to our business.”

Grace added: “We know horticulture is at the forefront of a digital revolution in farming and our SmartHort programme is designed to help connect growers with automation and robotics experts to help accelerate innovation. This project demonstrates the potential opportunities available from matching skills outside horticulture to meet the needs of the industry.”

The project is being funded by AHDB and match-funded by Innovate-UK-backed High Value Manufacturing Catapult.

To find out more about the SmartHort Automation Challenge, visit www.ahdb.org.uk/smarthort

ENDS

The digital journey – are you ready?

Are you a business who could benefit from automating your manufacturing processes?

Breakfast session with our experts: Wednesday 27th June, 8am to 10am

Our Business Team are holding a breakfast meeting, on Wednesday 27 June, to help businesses prepare and take advantage of the revolution in digital industry.

This session will show how collecting data can give you a greater insight into how to run your machines and operations more effectively, plan maintenance and introduce new processes without scarifying productivity. It will also show how new measurement techniques can give greater in-line data and how computer control has led to an entirely new way to make things.

WMG announce partnership with clean energy solution company Intelligent Energy

WMG at the University of Warwick are partnering with clean energy solution company Intelligent Energy to help develop manufacturing technologies via an advanced proof of process assembly line to significantly reduce the time to manufacture Intelligent Energy’s latest advanced air cooled fuel cell design, leading to a blueprint for a future fully integrated assembly and test line.

WMG at the University of Warwick are partnering with clean energy solution company Intelligent Energy to help develop manufacturing technologies via an advanced proof of process assembly line to significantly reduce the time to manufacture Intelligent Energy’s latest advanced air cooled fuel cell design, leading to a blueprint for a future fully integrated assembly and test line.

The 3 year, €3.5 million EU funded DIGIMAN programme brings together WMG at the University of Warwick, Intelligent Energy, Freudenberg, Pretexo, CEA Tech, and Toyota Motor Europe in a project pulling together the latest techniques in digital manufacture and automation in stack production processes to create a state of the art fuel cell manufacturing process for zero emission vehicles. The fuel cell’s use of air cooling gives the fuel cell significant efficiencies – particularly by reducing the weight of the device.

WMG to demo high-tech machining at DMG / MORI SEIKI event

WMG is to take part in a live demonstration of cutting edge machining technology as part of a technology seminar being run in Coventry by DMG / Mori Seiki next week.

WMG is to take part in a live demonstration of cutting edge machining technology as part of a technology seminar being run in Coventry by DMG / Mori Seiki next week.

The Ultrasonic Technology Seminar will focus on innovative machining strategies for challenging high-tech materials. As part of the seminar, attendees will visit WMG’s facilities to see the Ultrasonic 65 monoBLOCK in action.

WMG has a long-standing partnership with DMG / Mori Seiki and has recently taken delivery of the Ultrasonic 65 monoBLOCK at its International Manufacturing Centre workshop. The machine is capable of assisting conventional machining operations with the addition of ultrasonic vibrations which have been shown to significantly reduce the damage caused to materials which are difficult to machine, such as carbon fibre composites, while also improving the finished surface.

Robot welding gets 5 times faster as €4 Million project replaces guess work with maths

Remote Laser Welding (RLW) is rapidly emerging as a powerful replacement for spot welding technology in vehicle manufacturing. It promises 5 times the speed of spot welding and far more efficiency – however this can only be achieved through a frustrating process of guess work and trial and error today. Now WMG at the University of Warwick has been awarded 4 Million Euros by the European Commission Framework 7 Programme (FP7) to lead a project that will replace guess work and wasteful trial & error with precise mathematical modelling that will quickly deliver the efficiencies manufacturers want from this process.