Departmental news

WMG staff praised for international manufacturing project

Three members of staff from WMG, at the University of Warwick, have been praised for their ‘excellent’ work to support the Commonwealth Connectivity Agenda (CCA) in implementing Manufacturing 4.0 in Mauritius.

Three members of staff from WMG, at the University of Warwick, have been praised for their ‘excellent’ work to support the Commonwealth Connectivity Agenda (CCA) in implementing Manufacturing 4.0 in Mauritius.

The CCA is a major member-state led initiative to grow intra-commonwealth trade and investment and promote expanded investment to support global growth, create employment, and promote knowledge exchange among Commonwealth members.

The WMG team led by Dr Hamid Moradlou together with colleagues Tarek El-Said from the Supply Chain Group, and Onur Eren from the SME Group, responded to a funding call from the Commonwealth Secretariat to support Commonwealth countries with their connectivity agenda.

The trio were praised for delivering a well-received capacity building programme for local policymakers and manufacturing businesses including comprehensive understanding of Manufacturing 4.0; strategic vision and roadmap development; effective technology integration; change management and innovation; policy navigation; and performance measurement and sustainability.

Dr Hamid Moradlou explained: “This project was a great example of collaboration between industry, academia, and policymakers. The initiative was equally supported by both the Commonwealth Secretariat and the Ministry of Industrial Development, SMEs and Cooperatives in Mauritius, facilitating the work done by WMG in eight manufacturing companies from various sectors. The success of this project has led to further discussions around scaling this project in other Commonwealth countries.”

supported by both the Commonwealth Secretariat and the Ministry of Industrial Development, SMEs and Cooperatives in Mauritius, facilitating the work done by WMG in eight manufacturing companies from various sectors. The success of this project has led to further discussions around scaling this project in other Commonwealth countries.”

WMG supports SME manufacturers with digital technologies across the UK. Find out more here: https://warwick.ac.uk/wmg/for-industry/sme-support/

Collaborative project wins prestigious industry award

Researchers at WMG at the University of Warwick and the University of Victoria in Canada, have won the inaugural Synthos Rubber Circularity Award.

Researchers at WMG at the University of Warwick and the University of Victoria in Canada, have won the inaugural Synthos Rubber Circularity Award.

The international competition was launched to encourage cutting-edge ideas and solutions that will significantly improve the environmental performance of synthetic rubber-based tyre compounds, aligning with the sustainability objectives of the global automotive and tyre industries.

Synthos, a global leader in synthetic rubber, praised the two universities for their breakthrough technology research concept and global collaborative approach.

Professor of Nanocomposites at WMG, University of Warwick, Chaoying Wan explained: “Rubbers are ubiquitous materials in modern society and have played important roles across transportation; construction; oil and gas; biomedical devices; sports and electronics.

“As the key component to connect the vehicle to the road the performance of the tyre, including its rolling resistance, abrasion resistance and wet grip, directly determines the fuel efficiency, wear emission and safety.

“The emerging EVs and SUVs have raised increasing higher demands for performance that challenge the current technology. This new partnership, with Synthos Synthetic Rubber and the University of Victoria, will enable us to innovate rubber chemistry and develop functional rubber nanocomposites manufacturing technologies to address performance challenges. The new technology will also innovate traditional rubber systems to be actively recyclable.”

Matteo Marchisio, Vice President, Synthetic Rubber, stressed the importance of investing in research and development of sustainable rubber and tyre materials. “We are very proud of our diverse group of exceptional and talented scientists that make up the Synthos Rubber R&D team. Together with the University of Warwick and the University of Victoria, we see an exciting future in expanding our product development horizons. I firmly believe that by fostering innovation and collaborating with the brightest minds in scientific research, we move not only ourselves but also the entire value chain closer to our goal of carbon neutrality by 2050.”

Synthos Synthetic Rubber R&D Director Dr. Malte Wohlfahrt added, “We congratulate the University of Warwick and the University of Victoria for presenting an impressive research concept that we believe is the best fit for us. However, I also want to acknowledge the excellence of many other entries we received. The Synthos Rubber Circularity Award isn't just about crowning a winner; it's about advancing a culture of innovation. Therefore, we intend to collaborate with and invest in some of the other standout scientists and institutes we’ve had the honor to engage with. Overall, this award has sparked immense inspiration across our entire rubber business and given us much food for thought.”

The university collaborators will receive a three-year funding package to support a dedicated research team. They will also be provided with Synthos rubber materials and access to its state-of-the-art facilities. In addition, scientists from both institutions and Synthos will form a project team to work closely together and leverage the capabilities of all parties in a way that maximises the value of the collaboration to the tyre industry.

Find out more about Nanocomposites research at WMG here: Nanocomposites (warwick.ac.uk)

University programme credited for helping West Midlands cut energy consumption by 32%

A university programme which helped SMEs reduce energy consumption by 32% has been nominated for a national sustainability award.

A university programme which helped SMEs reduce energy consumption by 32% has been nominated for a national sustainability award.

WMG at The University of Warwick helped more than 50 SMEs in the West Midlands become more sustainable after the energy crisis left 60% of these critical UK manufacturers threatened with closure. The project has helped reduce the energy and fuel consumption of SMEs, which are responsible for 44% of non-household UK emissions.

WMG achieved this through its Net Zero Innovation Network which is now up for ‘Energy Efficiency Project of the Year Award’ – hosted by edie’s Net Zero Awards.

The Net Zero Innovation Network is helping to deconstruct the complexities of energy management, sustainability, and innovation for manufacturers across the UK. The network of engineers, innovation managers and industry experts offers practical tools and programmes to help SMEs overcome barriers such as lack of time, internal skills and cash-flow to invest. There is no cost for businesses involved, the only investment needed from SMEs is time.

Net Zero Innovation Network also provides access to state-of-the art equipment at the University, help companies reduce their energy consumption. The programme, built on the key themes of people, planet and profit, gets under the skin of the business to empower them to make real lasting change – upskilling staff and reducing scope 1 and 2 emissions.

The Net Zero Innovation Network designed a Manufacturing Energy Toolkit to provide provide solutions for SMEs impacted by the energy crisis. This toolkit measured and analysed energy consumption at a granular level, using WMG systems and research. The average energy saving of businesses using the toolkit was 32% and one SME reduced its energy consumption by 81%.

Other successful Net Zero Innovation Network projects included:

- Waste heat recovery simulation – assessing how to redirect heat in businesses to avoid additional energy (heating) being used.

- Process automation – using robots or software to help automate more mundane, repetitive and simple tasks, enabling other staff members to focus on more impactful projects.

- Granular material and energy monitoring – mapping out what materials and energy is currently being used, identifying ways to enhance efficiency or reduce waste

- Digitalisation – encouraging companies to utilise digital tech and systems e.g. upgrading their processes from paper to online/digital

Laura Downey, Innovation Manager at WMG, and technical lead of the programme, said: “The Net Zero Innovation Network has supported over 50 businesses and counting. As a result, the businesses we’ve partnered with have reduced their emissions whilst improving profitability, remained suppliers of choice and increased material and energy efficiency. We are honoured to have been shortlisted for the edie Net Zero Awards and look forward to supporting even more SMEs on their journey to net zero.”

Leslie Sharp, Director of Kingfisher Enamelling, who benefited from the WMG programme, said: “WMG staff provide a range of knowledge and expertise which we just did not have. Added to this, their drive and commitment to help SMEs is immeasurable.”

The winners of edie’s Net Zero awards will be announced on 15 November. Find out more about the awards here https://event.edie.net/netzeroawards/3554235

For SMEs wanting to get involved in the scheme, there was a webinar on 26 October with a guest talk from participant company Professional Polishing Services https://warwick.ac.uk/fac/sci/wmg/mediacentre/wmgevents/nzinwebinaroct23

WMG joins flagship electrification partnership

WMG at the University of Warwick, is part of a unique six-way partner collaborative research and development project led by Aston Martin.

Project ELEVATION has received £9m funding from the Advanced Propulsion Centre UK (APC) to supplement the research and development of Aston Martin’s in-house bespoke luxury battery electric vehicle platform.

Awarded following a competitive process, the government grant will support the development of Aston Martin’s luxury BEV platform and enable a route to net-zero, including investment in vehicle light weighting, a digital toolchain and electrification training.

Project ELEVATION is led by Aston Martin, and supported by the Manufacturing Technology Centre; Expert Tooling & Automation; Creative Composites; Fuzzy Logic Studio and WMG. The project will address the technical challenges of developing a lightweight, 800V traction battery pack and twin front electric drive unit (EDU) into a modular BEV platform with a bandwidth from supercar to SUV.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

Roberto Fedeli, Group Chief Technology Officer of Aston Martin, said: “The award of funding from the APC is another major boost to our electrification strategy and constant strive for innovation. Providing further resources to explore the possibilities of our bespoke BEV platform, it will help achieve our ambition to be an in-house BEV technology leader in the ultra-luxury, high-performance segment. We look forward to progressing this project with our collaborative partners and thank the APC for their incredible support.”

Ian Constance, APC Chief Executive, said: “The 23rd round of our collaborative R&D competition coincides with the APC’s 10th anniversary. We’ve seen over £1.4 billion of investment into automotive projects since the APC was set up, and I am proud of the impact that we have made here in the UK. This latest announcement includes a diverse set of OEMs and suppliers that demonstrate the strength of UK automotive. They will further add to our portfolio of innovative projects and continue to drive the UK to deliver on its net zero ambition.”

Find out more about WMG’s composite light-weighting research here https://warwick.ac.uk/fac/sci/wmg/research/materials/acrc

Mark Urbanowski, Principal Engineer, responds to the Government’s proposed cuts to active travel funding budgets

Expert comment from Mark Urbanowski.

Expert comment from Mark Urbanowski.

Mark Urbanowski, Principal Engineer at WMG at the University of Warwick, said: “Travelling around the UK’s towns and cities is getting increasingly congested, polluted and unsafe. A key part of the solution to this problem, along with helping reach the UK’s Net Zero goal, is getting people and goods moved in efficient and clean vehicles, correctly sized for the journey, passenger and job requirements.

“Active travel, walking and cycling, as well as emerging micromobility transport options like e-bikes, e-cargo vehicles and e-scooters, need the right infrastructure to make them convenient and safe to use. Without investment for infrastructure and integration into the broader public transport system, modal shift to these vehicle types; by commuters, families and businesses; will languish behind the rest of Europe. It’s an issue we will be addressing at our Micromobility event in May.”

Sustainable, low carbon circular plastic economy enabled by advanced plastic recycling process

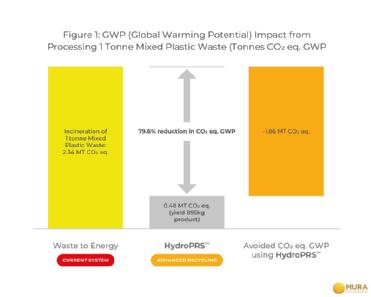

New research shows an 80% reduction in global warming potential (GWP), when compared to incineration, by processing waste plastic via a unique advanced recycling solution known as HydroPRS™, in a paper published by experts at WMG, University of Warwick.

solution known as HydroPRS™, in a paper published by experts at WMG, University of Warwick.

Researchers from WMG’s Sustainable Materials and Manufacturing team have been working with Mura Technology on a project focusing on the advanced recycling industry and the environmental impact of the associated processes.

Advanced recycling technologies (also known as chemical recycling) include a range of processes that break plastics down, converting them into hydrocarbon products that can replace the virgin fossil feedstocks used by the chemicals industry to create new plastics and other industrial products such as asphalt.

Dr Stuart Coles, Reader of Sustainable Materials and Manufacturing at WMG, University of Warwick, explained: “Advanced recycling will play an important role in realising the circular economy of plastics. The work conducted at WMG demonstrates a clear pathway towards Net Zero in recycled plastics and highlights improvements on the environmental footprint when compared with both existing production and disposal routes.

“We are delighted to see this work published as we explore the full potential of this technology moving forward.”

The peer-reviewed Life Cycle Assessment (LCA), reports that significantly reduced carbon emissions (measured as GWP in kilograms of CO2 equivalents) can be achieved if waste plastic is diverted towards HydroPRS™ and away from waste incineration – a comparable end of life treatment and currently, the fate of many ‘unrecyclable’ plastics.

Pioneered by Mura Technology, HydroPRS™, unlike pyrolysis, utilises supercritical water to convert post-consumer flexible, multi-layered and rigid plastics into high yields of stable, premium petrochemical feedstocks. Importantly, the products produced in the HydroPRS™ process were found in the LCA to have at least a comparable GWP when compared with naphtha, the fossil oil-based feedstock used in the production of plastics.

Dr Steve Mahon, Mura Technology’s CEO, said: “Resolving the global plastics crisis while reducing carbon emissions globally will inextricably require that the world is able to substitute fossil-based naphtha and other hydrocarbons for more sustainable feedstocks. This is Mura Technology’s ultimate goal and our innately scalable, innovative advanced recycling process using supercritical water is uniquely placed to pave the way to enable a low-carbon global circular plastics economy.”

Currently, the fate of unrecycled waste plastics is landfill, incineration or leakage into our waterways and oceans. All have negative impacts on the environment. Whilst incineration recovers some energy from plastic, none of these processes keep material within the circular economy, which in turn sustains the demand for virgin plastic from fossil-based sources.

Mura’s Chief Sustainability Officer, Dr Geoff Brighty, added: “As the global economy transitions away from fossil fuels, circular economies must operate at as low an environmental cost as possible. Alongside using the LCA to identify process improvements, the WMG team have demonstrated a clear, deliverable pathway to Net Zero for the HydroPRS™ process. This will help Mura decarbonise the petrochemical sector, whilst also reducing demand for fossil oil for plastic production by regenerating plastic waste into their feedstocks.”

The LCA is focussed on Mura’s first site in Teesside, UK and was funded through Innovate UK’s Smart Sustainable Plastic Packaging challenge (SSPP), as part of one of the demonstrator projects (grant number 49801).

Read the Hydrothermal Treatment of Waste Plastics: An Environmental Impact Study paper in full here s10924-023-02792-3.pdf (springer.com)

WMG in landmark battery development partnership

Researchers at WMG at the University of Warwick, are part of a unique four-way partnership, with Addionics, technology innovation catalyst CPI and James Durrans Group, which will position the UK as a technology hub for global battery development.

James Durrans Group, which will position the UK as a technology hub for global battery development.

Project Constellation is an extension of Project STELLAR which focused on improving battery power and cycle life. Project Constellation takes the research to the next level addressing improvements to battery performance, which will in turn lower development and production costs.

The team at WMG will use its expertise in pilot scale electrode production, cell manufacturing and electrochemical testing to support and de-risk rapid technology screening and accelerate the route to market.

Farid Tariq Ph.D, CTO and Co-founder of Addionics, explains:" Constellation builds on the success of Stellar taking it beyond basic tests and towards industrially relevant scales. We are excited because it provides a strong integration piece of our technology with world leaders in coating and fabrication, and active material fabrication (WMG, CPI, James Durrans) that can show how our very smartly designed and structured current collectors can fit into a viable battery ecosystem and provide benefits from our technology. This is readily transferable knowledge and will push the creation of new methods to overcome modern limitations of batteries and fabrication."

Mark Copley, Chief Engineer in WMG at the University of Warwick’s Electrochemical Materials and Manufacturing team said: “WMG is delighted to be a partner in the CONSTELLATION consortium. Utilising our experience in scaling up new technologies, from lab to pilot line, we feel that we will be able to further the development of Addionics’ current collector technology whilst coupling in Durrans’ graphite and formulation developments, as derived by CPI.

“The project goals fit very well with the ideals of WMG, which is to work collaboratively with industry to deliver high-quality, applied, research and development. We look forward to the results that will be generated through this funded collaborative effort.

Project Constellation is a two year project, funded by the UK Government’s Faraday Institution’s Faraday Battery Challenge Round 5 Innovation.

About the partners

Addionics

Addionics is a next-generation battery technology company revolutionizing battery performance through its chemistry-agnostic Smart 3D Electrode architecture. The company’s scalable, cost-effective manufacturing process combined with its AI-based optimization software significantly improves the performance of any kind of chemistry, achieving batteries with higher energy density, faster charging, and longer lifetime, at low cost. With the mission to accelerate an electrified economy and decarbonized future, Addionics is unlocking the full potential and accelerating the electrification revolution through its drop-in solutions.

CPI

We take great ideas and inventions, and we make them a reality. Born in the North East of England in 2004, CPI is an independent deep tech innovation organisation and a founding member of the High Value Manufacturing Catapult.

We're a team of intelligent people using advances in science and technology to solve the biggest global challenges in healthcare and sustainability. Through our incredible people and innovation infrastructure, we collaborate with our partners in industry, academia, government, and the investment community to accelerate the development and commercialisation of innovative products.

Our work ranges from health technologies, advanced drug delivery systems, and medicines manufacturing innovations for multiple modalities including small molecules, biologics, and nucleic acids; to developing sustainable materials for energy storage and packaging, as well as novel food, feed, and nutraceuticals, that are all underpinned by digital technology. We turn the entrepreneurial spirit and radical thinking of our people and partners into incredible impact that makes our world a better place.

Let’s innovate together: uk-cpi.comLink opens in a new window

Connect with us: LinkedIn TwitterLink opens in a new window InstagramLink opens in a new window FacebookLink opens in a new window

James Durrans Group

Long established family owned manufacturing company (1863) based in Penistone near Sheffield but with manufacturing sites across the globe. We provide pro-active solutions to our customer needs. Experts in carbon processing and technology and the manufacture of heat resistant coatings and graphitic dispersions.

Voi and Bumblebee Power partner on UK’s first wireless e-scooter charging trial launched at the University of Warwick

- Time-consuming and resource-intensive charging processes could be replaced by wireless charging for e-scooter rental fleets

- The ease of use for consumers and a reduction in operating costs through wider adoption of this technology would be a big advantage for the UK’s biggest rental scheme operator, Voi

- Trial in partnership with Bumblebee Power and WMG on the University of Warwick campus allows real-world testing in a ‘mini-city’ environment

- A successful trial will pave the way for seamless and convenient charging of e-scooters

Voi Technology, the UK’s largest e-scooter rental operator, has partnered with Bumblebee Power and WMG to trial the use of Bumblebee’s wireless e-scooter charging at the University of Warwick campus over a 6-month period potentially changing the future of the micromobility industry.

As with the charging of electric cars, the charging of e-scooters is a challenge for the operators of extensive rental schemes. The batteries powering their zero-emissions e-scooters are currently charged safely at their warehouse; however, they are replaced when vehicles are either receiving their regular in-house inspections or by the company’s in-field team who visit each e-scooter to perform fresh battery swaps.

These processes can lead to high operating costs for their business as the processes can be both time-consuming and often resource-intensive by requiring additional warehouse infrastructure for safe battery charging as well as transportation costs. Therefore, Voi began exploring new charging methodologies as a result that could provide the same excellent user experience whilst also delivering a similar vehicle efficient and effective battery performance. The potential solution: wireless charging.

additional warehouse infrastructure for safe battery charging as well as transportation costs. Therefore, Voi began exploring new charging methodologies as a result that could provide the same excellent user experience whilst also delivering a similar vehicle efficient and effective battery performance. The potential solution: wireless charging.

In partnership with Bumblebee Power, the wireless charging pads make it possible to charge e-scooters where they are parked, reducing not only operational costs but make their integration into the street and transport infrastructure more streamlined, making the modal shift to a convenient and flexible mode of transport easier for new and existing riders.

The University of Warwick campus ‘mini-city’ environment has been selected for this trial and provides an excellent, safe test bed for testing transport innovations. Available to estate staff only, a busy environment with a large population of students, staff, and industrial partners means the University of Warwick is an ideal ‘living lab’ environment to enable sustainable research and development of this technology.

The trial will provide data on the wireless system performance as well as user behaviour and interaction with the technology, which is crucial to any future large-scale deployment. If the trial proves successful it could be expanded to cover more of the Voi fleet across the UK.

David Yates, CTO of Bumblebee Power explains:

“The Bumblebee patented technology, which originated from Imperial College London, provides automatic connection via a very efficient wireless charging system, saving operational expenditure for the fleet operator by eliminating battery swaps. In addition, it makes possible the ability to extend the battery’s life, by controlling the charging regime whilst maximising vehicle availability.”

Sam Pooke, Senior Policy Manager at Voi UK and Ireland, said:

“We’re delighted to be partnering with Bumblebee Power to develop wireless charging for our e-scooters, an innovation that could change the whole micromobility industry.

“Applying this technology has the potential to not only reduce the operational impact of how we charge batteries for our vehicles but also in making an already convenient and flexible service even more accessible for new and existing riders. Over the coming months, we’ll look forward to working with our partners to maximise the innovative potential of this technology.”

David Evans, Lead Engineer at WMG, University of Warwick, said:

“Wireless charging technology for micromobility has the potential to reduce operational costs for fleet operators and provide a convenient charging solution for users. The University of Warwick campus is an ideal location to trial transport innovations such as these, providing a real world, mini city environment with world class teaching and research facilities.”

WMG PhD student heads to COP27

A PhD student, from WMG at the University of Warwick, is heading to Egypt this week for COP27.

Shravani Sharma, who is studying for a PhD in Travel Choices and Wellbeing, is heading to the climate summit as the Youth Transport Fellow for High Level Climate Champions UNFCCC, a role centred on building momentum towards an accelerated transition to zero emission vehicles.

Shravani’s work has always focused on the transport sector (which is responsible for a quarter of global greenhouse gas emissions), and on persuading policymakers, operators and the public of the benefits of cleaner and healthier modes of transport supported by evidence-based research and analysis.

She will be sharing her expertise at the “Youth on the move: Young people and transport in the 21st century” session on 10th November and at several other events.

Shravani, who is part of WMG’s Intelligent Vehicles Research Group, explained: "In a world where we are striving to adopt more sustainable forms of transport, it is paramount that our transportation systems and policies are designed to enable modal shift and promote positive travel behaviour.

“I was not even aware that transport planning was a career! I fell into it by accident after taking a module on planning infrastructure and found it not only fascinating, but so rewarding as it impacts the real world and real life. I I grew up watching TV shows about doctors in hospital environments and law firms where the protagonists save the world, which made me want to be a doctor or lawyer coming from an aspirational cultural background. I feel there should be more movies and TV shows made to inspire the upcoming generations to showcase the importance of city and transport planners, and use the power of media for positive drum rolling.

“If our towns and cities are the hearts of the nation, contributing to most of the economic activities, then transport infrastructure is our arteries. Therefore, to ensure good health of the nation we should ensure these arteries are clear of congestion, pollution, accidents etc. “

You can register for ‘Youth on the move: Young people and transport in the 21st century’ here: Youth on the move: Young people and transport in the 21st century (oecd-events.org)

Read more about WMG’s latest sustainability news here: WMG :: News (warwick.ac.uk)

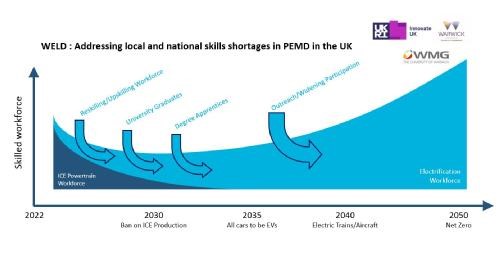

University of Warwick wins £1 million grant to help UK get ready for electric vehicles

- The funding will be used to launch a new programme called the Warwick Electrification Deployment (WELD)

- WELD will be contributed to by WMG's Power Electronics, Machines and Drives (PEMD) Group and the School of Engineering's Power Electronics group

- These two world class research groups will use Warwick’s unique facilities, as well as the university’s manufacturing and testing capability to help in the new education programme

- WELD is one of the winners of the ‘Driving the Electric Revolution: Building Talent for the Future 2’ competition, run by Innovate UK

- The new initiative will include industry workshops, outreach activity in school and increased teaching provision within PEMD

New content in power electronics, eMachines and drives will also be created at the University to use current expertise to both up-skill the existing workforce and support the pipeline of talent for future generations.

and support the pipeline of talent for future generations.

Finally, WELD will also focus on the design of IP-free eMachines, with parts manufacture, assembly and testing on campus to allow for hands-on learning.

As both transport and industrial equipment pivots from combustion technology to electrical power, skills for the design, manufacture and maintenance of electric drivetrains are increasingly in demand.

WELD will benefit from the two ‘Driving the Electric Revolution Industrialisation’ (DER-IC) facilities at the university: the Winding Centre of Excellence and the power electronics reliability and failure analysis space, both launching in Autumn 2022. The trained workforce will help UK businesses to develop and scale new PEMD technologies and manufacturing processes.

Dr Juliette Soulard, Associate Professor Electric Machines at WMG says: “Through our close collaboration with UK industry, we witness the huge difficulties faced when trying to recruit people with the right skills for PEMD research and development projects.

“The expertise exists in the UK, but the knowledge and skills transfer needs dedicated and urgent actions which normal higher education courses cannot deliver. WELD’s industry workshops with unique, hands-on learning about manufacturing and device testing aims to address this issue.”

Prof. Peter Gammon, Professor of Power Electronic Devices, Head of Research and Deputy Head of the School of Engineering says: “We are extremely proud to be leading the WELD project, which will help meet a national and international PEMD skills shortage.

“Our activities will also help increase the flow of engineering graduates into the industry via new PEMD and Automotive Electrification MScs, while an extensive outreach programme will help educate and inspire the next generation of engineers.”

ENDS

Note to Editors:

Useful Links:

Driving the Electric Revolution - Industrialisation Centres

WMG, University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes. As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG is one of the founding partners of the High Value Manufacturing (HVM) Catapult and leads HVM Catapult activities on Transport Electrification and Connected and Autonomous Mobility. The Catapult network’s mission is to leverage research and educational expertise to de-risk innovation for UK manufacturing, to improve business resilience, productivity, competitiveness and sustainability.

School of Engineering, University of Warwick

The School of Engineering benefits from its multidisciplinary approach, with research covering a broad range of topics. Key themes of Energy, Biomedical Engineering, and Future Cities, Materials and Manufacturing, and Technology and Society provide a framework to the research efforts, which are underpinned by four discipline streams and fourteen research groups. The School employs some of the leading engineers in their field, who regularly publish papers in top ranking journals. There are currently over 150 students undertaking postgraduate research degrees and 55 65 research post-doctorate staff.

DER-IC

DER-IC (Driving the Electric Revolution Industrial Centres) is building a globally recognised, sustainable UK-wide network with the relevant skills and capabilities to deliver the PEMD (power electronics, machines, and drives) necessary for a net zero future in all relevant applications. The network of DER-IC is instrumental in the UK’s progress towards its 2050 net zero target and a world leading response to the realisation of the industrial technology (IDT) revolution.

DER-IC is funded by UK Research and Innovation and was set up in 2020 as part of the Driving the Electric Revolution challenge.

DER-IC provides open access facilities to over £300 million worth of state-of-the-art equipment, bringing together the UK’s technology and manufacturing expertise in electrification research and development.

§ DER-IC is creating cost-effective, UK-based technologies and solutions, with export market opportunities, to help address and support climate change

§ DER-IC is educating about the art of what’s possible for governments, industry, academia, and schools

§ DER-IC is an industry led project which has so far engaged with 400 industrial organisations, as well as having 30+ academic institutions and RTO’s in its network