WMG News

University of Warwick teams up with Ca’ Foscari University in Venice to create museum exhibitions of the future

The University of Warwick is collaborating with Ca' Foscari University of Venice to analyse Roman artefacts in a history project which could change the face of museums for the 21st century.

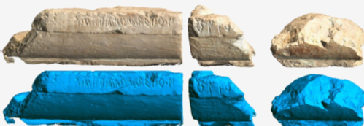

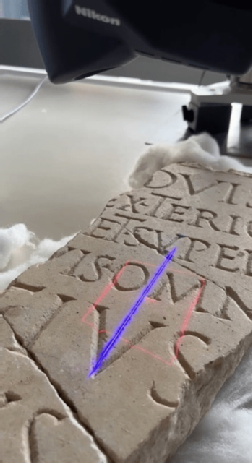

Warwick is working with historians at Ca’ Foscari to scan and analyse artefacts from ancient Roman and pre-Roman Venice, including in 3D and VR forms.

Researchers hope that these artefacts, scanned into 3D and virtual reality (VR), could revolutionise how people experience historical items, including in museums.

Rather than studying items in glass cases, artefacts could instead be scanned and produced using 3D printing or VR technology so visitors can hold and experience history in a whole new way.

This is especially vital when the items themselves are fragile or extremely old, meaning the originals can’t be held or examined by the public.

The collaboration between Warwick and Ca’ Foscari is focused on over 30 items related to religion from the Roman settlement of Altinum – the ancestor of the city of Venice.

Altinum is larger than Pompeii but remains mostly unexcavated, with researchers suggesting a trove of artefacts may be there waiting to be discovered.

The items themselves are from the Roman period and before, including from the Venetii natives who were assimilated into the Roman Empire over centuries.

The artefacts are being analysed by historians at Ca’ Foscari, with engineers at Warwick using cutting edge imaging technology to scan the items in incredibly high definition.

This helps historians read writing from the period and is especially vital when some artefacts have been damaged or are fragmented.

Academics at Warwick and Ca’ Foscari presented their findings at a conference in Venice on Friday (24th November), highlighting the potential of the combined arts knowledge of Ca ‘Foscari and the technology of WMG.

Professor Mark Williams, Head of the Centre for Imaging, Metrology and Additive Technology (CiMAT) at WMG commented: “This is an excellent example of universities working together, including across the arts and sciences. This scanning technology has truly exciting possibilities, including for the future of historical learning and we were delighted to be able to assist our Venetian colleagues in bringing a small section of their history to life”.

Professor Mark Williams, Head of the Centre for Imaging, Metrology and Additive Technology (CiMAT) at WMG commented: “This is an excellent example of universities working together, including across the arts and sciences. This scanning technology has truly exciting possibilities, including for the future of historical learning and we were delighted to be able to assist our Venetian colleagues in bringing a small section of their history to life”.

Associate Professor Lorenzo Calvelli, a historian at Ca’ Foscari University, said: “These artefacts represent the very beginnings of Venice from over two millennia ago, and we are very pleased to be able to bring this history to a wider audience, both here in Italy and in the UK.

“It has been excellent to meet and collaborate with colleagues from Warwick, and I am very excited about our future plans to dive deeper into the treasure trove of artefacts that is waiting for us in Altinum”.

Altinum developed over the course of the Roman Empire into a booming trading hub, particularly know for valuable amber and horses which were prized across Europe. Eventually, refugees from Altinum are believed to have contributed to the founding of Venice in the wake of the fall of the Roman Empire.

Professor Rachel Moseley, Chair of the Faculty of Arts at Warwick, commented: “This is an excellent example of science and the arts working together to create exciting new possibilities.

“Every day, we see scientific advances allowing us to delve deeper into history in a way which recently we would have thought was impossible. Equally, the arts give science that grounding and philosophy to make these advances tangible to the public.

“I’m delighted that our new base of Warwick Venice Centre has brought all these excellent researchers together and is already encouraging collaboration in a hugely positive way.”

Millions awarded to University of Warwick to turbocharge UK’s battery production

The University of Warwick has been awarded millions of pounds to boost British production of crucial materials for electric car batteries.

The University of Warwick has been awarded millions of pounds to boost British production of crucial materials for electric car batteries.

The £12 million in funding has been awarded by the Faraday Battery Challenge to the High Value Manufacturing Catapult at WMG at the University of Warwick, and CPI at NETPark (North East Technology Park), in County Durham.

It will be used to create the new Advanced Materials Battery Industrialisation Centre (AMBIC).

The Centre will bridge the gap between academic research and battery production and will focus on how batteries can be made to work more efficiently, as well as on equipment and skills development.

The Centre is needed to help the UK develop the electric vehicle batteries of the future, with reduced costs, more sustainable materials and improved performance.

Electric vehicle batteries make up around half the cost of a new electric vehicle, so reducing the cost of their production is crucial to lowering the cost of EVs to parity with combustion engine vehicles.

The funds are part of a wider investment strategy by the Faraday Battery Challenge and the High Value Manufacturing Catapult to ramp up Britain’s battery production and infrastructure to boost the UK’s domestic battery supply chain.

Professor David Greenwood, CEO of the WMG High Value Manufacturing Catapult Centre said: “Cathode and anode active materials make up more than 50% of the value of an automotive battery cell.

of an automotive battery cell.

“For the UK to take its great academic research into production, and to capture the billions of pounds of resulting economic value in the UK, we need facilities which allow Britain to scale up and fully evaluate new materials. This investment, alongside the combined skillsets of CPI and WMG will provide that capability for the UK.”

The funds are specifically to help turbocharge the scale up of battery materials manufacturing within the UK. Only by producing batteries on a wider scale domestically can the EV industry make sure there is no bottleneck in supply and demand. By strengthening UK supply chains of battery materials, WMG is working with UKBIC and others to create a more resilient supply chain.

Thomas Bartlett, Challenge Deputy Director for the Faraday Battery Challenge, said: “AMBIC will bring together two emerging regions of battery innovation and manufacturing; the North-East and Midlands, under one facility to de-risk and accelerate battery materials scale up in the UK.

“Through the Faraday Battery Challenge’s £12m investment in the High Value Manufacturing Catapult we will establish a truly world-class facility to support the growth of a battery materials supply chain. With AMBIC and previous investments in cell, module and pack scale-up at UKBIC and R&D in the wider ecosystem, the UK will now be in a position to support businesses from “powder to pack” and from lab to commercial scales.”

Katherine Bennett, CEO of the High Value Manufacturing Catapult, said: “The next generation of battery technologies are critical to the green energy transition and a major opportunity for UK manufacturing. Realising that potential will require combining our collective expertise and this investment from the Faraday Battery Challenge is a brilliant example of that in action.

“In CPI and WMG, the Advanced Materials Battery Industrialisation Centre has two centres that are at the very forefront of chemical processing and battery cell development; together they can turbo charge battery materials scale-up.”

Frank Millar, Chief Executive Officer at CPI, said: “The Advanced Materials Batteries Industrialisation Centre will enhance the UK’s existing competitive advantages in batteries technology, and it stands to become a catalyst for the UK to address some of the biggest challenges we face as a nation. By giving innovators the opportunity to harness our expertise we can tackle issues such as climate change, while growing a sector that will be vital to the future of the economy.”

WMG research helps develop new generation of graphene composites

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

The new PolygreneTM compounds are expected to have potential commercial applications in areas as diverse as sports equipment, construction products, aerospace and automotive components.

Since 2018, Versarien subsidiary 2-DTech Ltd (2DT), Composites UK member, has funded PhD and postdoctoral researchers to understand the use of its Nanene™ graphene powders and other nanomaterials in thermoplastic systems. Dr David Reinoso-Arenas, the first 2DT funded PhD student, with support from the EPSRC Doctoral Training Programme, worked with Versarien’s Nanene™ materials in thermoplastic elastomer (TPE) systems and joined Versarien full-time last year as part of the team at Versarien’s subsidiary Cambridge Graphene Ltd.

Dr David Reinoso-Arenas, explained: “The new PolygreneTM thermoplastics portfolio is a culmination of my PhD research, some of which is due to be published in peer-reviewed journals. Since then we’ve been able to further develop and test these materials using different nanomaterial fillers and process conditions to fully optimise the resulting product performance. My PhD experience at the IINM and WMG was really enjoyable and enabled me to work closely with industry to ensure that the outputs of my research could be validated and have commercial viability.”

David’s PhD was performed under the supervision of Professor Tony McNally, whose team has an established capability in incorporating a wide range of nanomaterials into bulk polymer systems.

Professor Tony McNally, who leads the Nanocomposites Research Group at WMG, University of Warwick, said: “Working with Versarien over the last few years has given the IINM and WMG access to alternative graphene materials that have shown interesting phenomena when blended in these TPE systems. By tuning the nanofiller loading and optimising process conditions, David’s research showed that exceptional gains can be achieved in mechanical properties across the board (tensile strength, modulus, elongation at break, toughness and abrasion resistance) without compromising any properties. The addition of graphene also highlights improvements in polymer processing which may offer lower energy usage and, therefore, improving sustainability.”

Professor McNally continues to work with Versarien by providing a funded PhD position in 2D material based rubber systems, making use of the IINM’s new state of the art rubber processing and testing capabilities With support from the High Value Manufacturing Catapult (HVMC), WMG has established a world class facility for the study of elastomers.

Dr Stephen Hodge, Versarien’s CEO, added: “We look forward to continuing our collaboration with the IINM and WMG in rubber processing and understanding the interactions of our graphene and other 2D materials in these more complex systems, and hope to be able to demonstrate significant benefits that can impact upon real-world applications.”

Find out more and download technical datasheets here: https://versarienproducts.co.uk/thermoplastics

Find out more about WMG’s Nanocomposites research here:https://warwick.ac.uk/fac/sci/wmg/research/materials/nanocomposites/

University programme credited for helping West Midlands cut energy consumption by 32%

A university programme which helped SMEs reduce energy consumption by 32% has been nominated for a national sustainability award.

A university programme which helped SMEs reduce energy consumption by 32% has been nominated for a national sustainability award.

WMG at The University of Warwick helped more than 50 SMEs in the West Midlands become more sustainable after the energy crisis left 60% of these critical UK manufacturers threatened with closure. The project has helped reduce the energy and fuel consumption of SMEs, which are responsible for 44% of non-household UK emissions.

WMG achieved this through its Net Zero Innovation Network which is now up for ‘Energy Efficiency Project of the Year Award’ – hosted by edie’s Net Zero Awards.

The Net Zero Innovation Network is helping to deconstruct the complexities of energy management, sustainability, and innovation for manufacturers across the UK. The network of engineers, innovation managers and industry experts offers practical tools and programmes to help SMEs overcome barriers such as lack of time, internal skills and cash-flow to invest. There is no cost for businesses involved, the only investment needed from SMEs is time.

Net Zero Innovation Network also provides access to state-of-the art equipment at the University, help companies reduce their energy consumption. The programme, built on the key themes of people, planet and profit, gets under the skin of the business to empower them to make real lasting change – upskilling staff and reducing scope 1 and 2 emissions.

The Net Zero Innovation Network designed a Manufacturing Energy Toolkit to provide provide solutions for SMEs impacted by the energy crisis. This toolkit measured and analysed energy consumption at a granular level, using WMG systems and research. The average energy saving of businesses using the toolkit was 32% and one SME reduced its energy consumption by 81%.

Other successful Net Zero Innovation Network projects included:

- Waste heat recovery simulation – assessing how to redirect heat in businesses to avoid additional energy (heating) being used.

- Process automation – using robots or software to help automate more mundane, repetitive and simple tasks, enabling other staff members to focus on more impactful projects.

- Granular material and energy monitoring – mapping out what materials and energy is currently being used, identifying ways to enhance efficiency or reduce waste

- Digitalisation – encouraging companies to utilise digital tech and systems e.g. upgrading their processes from paper to online/digital

Laura Downey, Innovation Manager at WMG, and technical lead of the programme, said: “The Net Zero Innovation Network has supported over 50 businesses and counting. As a result, the businesses we’ve partnered with have reduced their emissions whilst improving profitability, remained suppliers of choice and increased material and energy efficiency. We are honoured to have been shortlisted for the edie Net Zero Awards and look forward to supporting even more SMEs on their journey to net zero.”

Leslie Sharp, Director of Kingfisher Enamelling, who benefited from the WMG programme, said: “WMG staff provide a range of knowledge and expertise which we just did not have. Added to this, their drive and commitment to help SMEs is immeasurable.”

The winners of edie’s Net Zero awards will be announced on 15 November. Find out more about the awards here https://event.edie.net/netzeroawards/3554235

For SMEs wanting to get involved in the scheme, there was a webinar on 26 October with a guest talk from participant company Professional Polishing Services https://warwick.ac.uk/fac/sci/wmg/mediacentre/wmgevents/nzinwebinaroct23

The Manufacturing Commission calls for greater support for businesses to navigate further education reforms and upskill their workforce for a digital future

The Dean of WMG at the University of Warwick, Professor Robin Clark, spoke at the launch of Policy Connect’s new report on manufacturing skills this week (Wednesday 25th October). WMG supported the development of the report, including holding a roundtable with West Midlands employers; Higher Education (HE) and Further Education (FE) providers; and regional skills experts.

The Dean of WMG at the University of Warwick, Professor Robin Clark, spoke at the launch of Policy Connect’s new report on manufacturing skills this week (Wednesday 25th October). WMG supported the development of the report, including holding a roundtable with West Midlands employers; Higher Education (HE) and Further Education (FE) providers; and regional skills experts.

Lord Bilimoria of Chelsea CBE DL, launched Policy Connect’s latest report – Upskilling Industry: Manufacturing Productivity and Growth in England, alongside Minister for Enterprise and Markets, Keving Hollinrake MP; WMG Advisory Board member, Mark Pawsey MP and the Shadow Minister for Innovation, Chi Onwurah MP.

The Manufacturing Commission’s inquiry considers the implications of recent skills system reform in England on the manufacturing sector. It concludes that labour shortages are restricting productivity across the economy, with skills gaps in the manufacturing sector costing between £7.7 and £8.3 billion annually in lost economic output.

To address this the report recommends government make several reforms to the skills system:

· Support for SMEs in the manufacturing sector to help upskill their workforce, including incentives to deliver T-Levels and host skills boot camps.

· Greater flexibility in the use of the Apprenticeship Levy funds, including ring-fencing of unused Levy funding for investment in wider upskilling.

· A national campaign to increase the uptake of STEM subjects by women and people of minority ethnic backgrounds.

· Appointment of a government manufacturing ‘Champion’ to raise awareness of the manufacturing sector in schools and promote the role that the manufacturing sector is playing in combatting the climate crisis.

Inquiry Chair, Lord Bilimoria of Chelsea, CBE, DL said: “As Chair of the Manufacturing Commission and a proud supporter of British manufacturing, I am delighted to have been involved with this inquiry, which considers the impact of skills shortages across the sector.

“Throughout the evidence sessions that have informed this work, I have been inspired by accounts from manufacturing businesses that are using all levers available to them to upskill their workforces. The recommendations that we have made seek to help businesses, education providers, and individuals best navigate the current policy landscape and deliver the skills that the manufacturing sector so vitally needs.”

Inquiry Vice-Chair, and WMG advisory Board member, Mark Pawsey MP added: “As a member of the Business and Trade Committee and co-chair of the All-Party Parliamentary Manufacturing Group, I regularly hear of the skills shortages that limit productivity within the UK’s manufacturing sector. This inquiry explores how businesses can collaborate better with education providers to deliver the skills that local communities need. This is particularly important in the West Midlands, which is home to a significant part of the UK’s automotive and future battery technology capability.”

Professor Robin Clark, Dean of WMG, said: “The proposals in the report contain lots of good ideas on how to develop a system that really works for learners and employers, and suggests practical changes that can make a real difference to our skills system.

“The report is a call to action for all of us working in skills to encourage learners, course providers and employers to get engaged in manufacturing, give SMEs strong incentives to support skills and collaborate to improve course design, provision, and approval.

“We’ve got great examples of how skills can be transformative for businesses and students in manufacturing. Now we need to work together to make that the experience everyone has from our skills system.”

Read the full ‘Upskilling Industry’ report here: https://www.policyconnect.org.uk/research/upskilling-industry-manufacturing-productivity-and-growth-england

WMG research shapes the future of autonomous vehicles

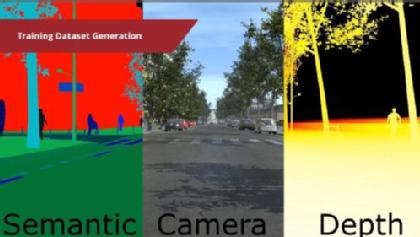

WMG, at the University of Warwick, is part a unique £2 million consortium, entitled Sim4CAMSens.

The Sim4CAMSens project, led by Claytex, is made up of a consortium of prominent industry partners, including AESIN, rFpro, Syselek, Oxford RF, National Physical Laboratory, Compound Semiconductor Applications Catapult and WMG.

The Sim4CAMSens project, led by Claytex, is made up of a consortium of prominent industry partners, including AESIN, rFpro, Syselek, Oxford RF, National Physical Laboratory, Compound Semiconductor Applications Catapult and WMG.

Together the consortium will create a framework for sensor evaluation that incorporates modelling, simulation, and actual testing. In order to enable Automated Driving Systems (ADS) and sensor developers to speed their development, this project will involve the development of new models for sensors, noise and materials, and new test methodologies.

The role of WMG will be to understand which noise factors have the higher impact on the different perception sensors (i.e., camera, LiDAR, RADAR,) and how to correlate virtual testing to real-life testing to support the entire supply chain.

Professor Valentina Donzella, who leads the Intelligent Vehicles Sensors research at WMG explains: “The Sim4CAMSens project is an extremely exciting opportunity for WMG, to work with UK based world leading industrial and research partners, to speed up the development of sensors models and testing methodologies. These are key considerations for the future safe deployment of robust and reliable ADS. The success of this project will ensure the UK leads the way globally in this field."

Find out more about WMG’s Intelligent Vehicles Sensors research here: https://warwick.ac.uk/fac/sci/wmg/research/cav/ivsensors

WMG with Solihull Council secure £300,000 for self-driving shuttle feasibility study

WMG at The University of Warwick, Solihull Council, National Highways, Transport for West Midlands, ZF, Aurrigo, Syselek and Liftango have successfully secured £300,000 to deliver a project looking into the feasibility of a self-driving shuttle service in the West Midlands.

The project will explore how a new automated transport link between Blythe Valley Business Park, near Shirley, and the new HS2 rail station in Solihull could operate in the future. The feasibility study will consider all aspects of the technology required in order to provide a safe and reliable automated public transport service between these important commercial centres. The proposed route would use the existing road network travelling along the M42 from Junction 4 and utilise the new Junction 5a currently under construction.

operate in the future. The feasibility study will consider all aspects of the technology required in order to provide a safe and reliable automated public transport service between these important commercial centres. The proposed route would use the existing road network travelling along the M42 from Junction 4 and utilise the new Junction 5a currently under construction.

As a world-class research institution with leading capabilities in the verification and validation of safety assurance of self-driving technologies, WMG will apply its Operational Design Domain (ODD) based Safety Assurance research methodologies to the specific project challenges.

This project is part of the wider Midlands Future Mobility (MFM) initiative, led by WMG. The MFM vision is to achieve zero road incidents, net-zero emissions and inclusive transport in the West Midlands. MFM enables stakeholders from across mobility to address the interlinked challenges of technology, policy, and behaviour to realise the vision.

Cllr Ken Hawkins, Solihull Council Cabinet Member for Environment & Infrastructure, said: “Connected Automated Vehicle (CAV) technology has the potential revolutionise the way we get around our towns, cities and rural areas. Working with our partners we are excited to be undertaking this latest project.

“We’ve already carried out a series of successful pathfinder trials here in Solihull, using our own automated shuttle, and have led the way in showing how it is possible to practically and safely incorporate automated vehicles into our existing transport infrastructure. We are now taking the next step and undertaking the vital feasibility work necessary in order to start thinking about more ambitious deployments and establishing new commercial public transport services.

“The outcomes from the study are likely to inform self-driving mobility challenges not just here in Solihull but nationwide.”

Jonathan Smith, Midlands Future Mobility Programme Manager said: "The business case for scaling new mobility solutions is complex. It involves a granular understanding of the use case, safety, users, operations, and infrastructure. This project brings together a group of diverse experts to apply state of the art research and knowledge to address this question. Of critical importance is that the outcomes of this feasibility will inform mobility business cases both in the Midlands and the UK as a whole."

More information about this project

Partners: Solihull Metropolitan Borough Council (Lead), Aurrigo, Syselek (Uk) Ltd, Liftango Ltd, ZF Services UK Limited, West Midlands Combined Authority, Highways England, University of Warwick

Grant awarded: £300,000 (£197,664 from Centre for Connected and Autonomous Vehicles’ Commercialising Connected and Automated Mobility programme and balance is made up by the commercial partners).

Find out more about WMG’s Validation and Verification research here: Verification and Validation (warwick.ac.uk)

Note to editors

Media contact:

Annie Slinn

Communications Officer (Sciences)

Gabbie Lau

WMG Marketing and Communications Executive

WMG joins flagship electrification partnership

WMG at the University of Warwick, is part of a unique six-way partner collaborative research and development project led by Aston Martin.

Project ELEVATION has received £9m funding from the Advanced Propulsion Centre UK (APC) to supplement the research and development of Aston Martin’s in-house bespoke luxury battery electric vehicle platform.

Awarded following a competitive process, the government grant will support the development of Aston Martin’s luxury BEV platform and enable a route to net-zero, including investment in vehicle light weighting, a digital toolchain and electrification training.

Project ELEVATION is led by Aston Martin, and supported by the Manufacturing Technology Centre; Expert Tooling & Automation; Creative Composites; Fuzzy Logic Studio and WMG. The project will address the technical challenges of developing a lightweight, 800V traction battery pack and twin front electric drive unit (EDU) into a modular BEV platform with a bandwidth from supercar to SUV.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

Roberto Fedeli, Group Chief Technology Officer of Aston Martin, said: “The award of funding from the APC is another major boost to our electrification strategy and constant strive for innovation. Providing further resources to explore the possibilities of our bespoke BEV platform, it will help achieve our ambition to be an in-house BEV technology leader in the ultra-luxury, high-performance segment. We look forward to progressing this project with our collaborative partners and thank the APC for their incredible support.”

Ian Constance, APC Chief Executive, said: “The 23rd round of our collaborative R&D competition coincides with the APC’s 10th anniversary. We’ve seen over £1.4 billion of investment into automotive projects since the APC was set up, and I am proud of the impact that we have made here in the UK. This latest announcement includes a diverse set of OEMs and suppliers that demonstrate the strength of UK automotive. They will further add to our portfolio of innovative projects and continue to drive the UK to deliver on its net zero ambition.”

Find out more about WMG’s composite light-weighting research here https://warwick.ac.uk/fac/sci/wmg/research/materials/acrc

WMG charges ahead with battery research

WMG, at the University of Warwick, has received a share of £19 million from the Faraday Institution - the UK’s flagship institute for electrochemical energy storage research.

storage research.

The funding has been allocated to four key battery research projects aimed at delivering an impact for the UK. These existing projects across three different research areas — next generation cathode materials, electrode manufacturing and sodium-ion batteries — have been reshaped to focus on the areas with the greatest potential for success.

WMG is taking a key role in two of the four, reshaped projects entitled FutureCAT and Nextrode.

WMG’s Professor of Battery Innovation, Louis Piper, will now co-lead FutureCAT, a battery cathode research project, focusing on understanding novel redox processes as a route to stabilise both high capacity, high performance, nickel rich and emerging cathodes and scalable designer morphologies. The project will build on its success in developing reliable, scalable routes to deliver a longer lifetime, high-energy/power cathodes, essential for electric vehicles.

Whereas in Nextrode, a battery electrode project, WMG is one of six university partners, led by the University of Oxford, alongside six industry partners. Researchers at WMG will investigate ways to make electrodes for Li-ion batteries unlocking the electrochemical potential.

Professor Pam Thomas, CEO, Faraday Institution, commented: “The Faraday Institution remains steadfast in its commitment to identify and invest in battery research initiatives that hold the greatest potential for making significant societal, environmental, and commercial contributions. This announcement signals the completion of our latest round of project refocusing, enabling us to allocate even more effort towards those areas of research that offer maximum potential in delivering transformative impact.”

James Gaade, Research Programme Director commented: “We are pleased that the reshaping process has bolstered the capabilities and expertise of researchers on the four projects. The realignment includes a focus around research into sustainable manufacturing methods and materials, and the need to further develop and scale up manufacture of promising materials discovered in the first three years of the projects.”

Project information

FutureCat – High nickel content, high performance cathode materialsLink opens in a new window

FutureCat, co-lead by WMG’s Professor Louis Piper, and the University of Sheffield’s Professor Serena Cussen is targeting step-changes in:

- Understanding novel redox processes as a route to stabilise both high capacity, high performance, nickel rich and emerging cathodes. The project continues its focus on doped and dual-doped lithium nickel oxides (LNO) (both polycrystalline and single crystals), including use of protective coatings. The team will also investigate the use of polyanionic cathodes, use modelling to inform the search for new candidate materials, and research designer electrolytes with the intention of stabilising the interphase layer.

- Scalable designer morphologies. The project will build on its success with doped-LNO in developing reliable, scalable routes to deliver a longer lifetime, high-energy/power cathodes through the use of gradient morphologies, co-doped cathodes (with the aim of delivering reversible discharge capacities exceeding 220 mAh/g), single crystal particles and thin coatings.

- Materials delivery: The scale up of the high nickel W-LNO material previously developed by FutureCat is being transferred to the Degradation project for testing in industry-relevant pouch cells. FutureCat will continue to investigate the manufacturing scale-up of other Ni-rich cathode materials, down-selecting promising active materials based on earth-abundant elements. Research includes the use of laser patterning to increase power densities, investigation of cracking as a failure mechanism to determine routes to resilient cathode manufacture, atomic layer deposition of coatings to improve electrode longevity, and optimisation of cycle life through the use of electrically conductive binders.

Nextrode – electrode manufacturingLink opens in a new window

Nextrode is focused on researching, understanding and quantifying the potential of smart electrode manufacturing to reduce manufacturing costs and improve the performance of batteries. Benefits could be realised in both mature material systems already used commercially and in new emerging high performance battery systems. The project is developing new practical manufacturing innovations – including traditional slurry cast electrodes and novel low or no solvent electrodes – that could deliver the benefits of smart electrodes to the industrial scale and improve sustainability of processes.

The project is researching the underpinning manufacturing science that could alleviate constraints in electrode manufacturing through engineering particle design and improved understanding of the relationship between powder properties and deposition/calendering techniques. Nextrode is designing manufacturing process steps and using advanced in-line measurements to enable slurry casting to be brought under closed-loop control. Researchers are manufacturing new arrangements of anode and cathode materials, identifying conditions where benefits are maximised and developing cells that expand the energy-power-lifetime design space.

The new phase of research projects described will progress over the two years from 1 October 2023 to 30 September 2025.

Find out more about WMG’s Electrochemical Engineering research here: Electrochemical Materials (warwick.ac.uk)

For more information on the Faraday Institution, visit www.faraday.ac.ukLink opens in a new window

Bhattacharyya Award finalists “inspiring and diverse examples” of innovative and impactful partnerships between industry and universities

· Improved footballs for use in the World Cup and new technologies for defence against biological and chemical attack are examples of outcomes from six industry–academia partnerships shortlisted for this year’s annual Bhattacharyya Award

· Winning partnership will be announced at awards ceremony in Birmingham on 24 October 2023

The Royal Academy of Engineering has shortlisted six exceptional industry–academia partnerships from across the UK for this year’s Bhattacharyya Award.

The Bhattacharyya Award 2023 and a cash prize of £25,000 will be presented on 24 October 2023 to the team who best demonstrate how industry and universities can work together.

The Bhattacharyya Award is a tribute to Professor Lord Kumar Bhattacharyya KT CBE FREng FRS, the Regius Professor of Manufacturing at the University of Warwick and founder of WMG who advocated for greater collaboration between industry and universities. Funded by the Department for Science, Innovation and Technology, the annual Bhattacharyya Award is open to UK universities and colleges that have demonstrated a sustained, strategic industrial partnership that has benefitted society and is deserving of national recognition. Industry–academia partnerships from any academic discipline are eligible for the Bhattacharyya Award.

of Warwick and founder of WMG who advocated for greater collaboration between industry and universities. Funded by the Department for Science, Innovation and Technology, the annual Bhattacharyya Award is open to UK universities and colleges that have demonstrated a sustained, strategic industrial partnership that has benefitted society and is deserving of national recognition. Industry–academia partnerships from any academic discipline are eligible for the Bhattacharyya Award.

This year’s shortlist illustrates the sheer diversity of challenges that can be successfully addressed through collaboration between universities and industry, including national defence against biological and chemical attack, the supply of drinking water, nuclear decommissioning, high-speed global communications, high-performance sportswear and equipment, as well as other challenges like decarbonisation that can be tackled through the power of process systems engineering.

The full shortlist of finalists is as follows:

University of Hertfordshire and the Defence Science and Technology Laboratory (Dstl)

New technologies for defence against biological and chemical threats

The collaboration between the University of Hertfordshire and the Defence Science and Technology Laboratory (Dstl) is focused on next generation devices and systems for monitoring and identifying biological and chemical threats. The collaboration aligns with the University of Hertfordshire’s objectives to stimulate enterprise and innovation, taking a pioneering approach to the transfer of knowledge from academic research to business and government. For Dstl, the collaboration has been central to its mission to explore, sustain, grow and evaluate state-of-the-art technological capabilities to develop protective measures against hazardous biological materials.

Imperial College London, UCL and the Sargent Centre Industrial Consortium

Unleashing the power of process systems engineering research

The Sargent Centre is the world’s largest multidisciplinary research centre in Process Systems Engineering, combining a deep understanding of chemical and biochemical processes with the ability to make fundamental advances across a wide range of systems and digital technologies for the benefit of society and industry. Bringing fundamental research advances to practice is deeply embedded in the Sargent Centre’s approach. For over 30 years, Sargent Centre researchers and process industry partners (e.g., ABB, BP, Eli Lilly and Company, Petronas, Pfizer, Procter and Gamble, Siemens, Shell, Syngenta) have collaborated to address challenges in manufacturing, decarbonisation, energy efficiency, optimisation, data science, multi-scale modelling, risk and uncertainty. This has resulted in successful spin-out creation and software licensing, with tools used across the pharmaceutical, agrochemical, consumer goods, food and energy sectors.

Loughborough University and adidas

Sports equipment and clothes for improved performance, safety and inclusivity

Since 2002, the Loughborough University and adidas cross-disciplinary teams have advanced engineering knowledge that has brought iconic products to market and been translated beyond the global sports sector for wider societal impact, making sport safer, more accessible and allowing people to perform at their best whilst developing the adidas talent pipeline.

The collaborative research has influenced all adidas major tournament footballs since 2004, and the analysis of short duration collisions in football has benefited other sports including new International Standards for cricket helmet performance that have eliminated facial injuries among professional helmeted batters. Another innovation is the first-ever sweat body maps of males, females and children to inform the company’s sector-leading clima® product range. This breakthrough underpins the first virtual Human Thermal Model which enables organisations worldwide to optimise product design for multiple populations across a range of industry sectors.

University of Sheffield and the UK water sector

Keeping drinking water crystal clear

Ageing infrastructure and the complexity of interacting physical, chemical and biological processes occurring within the vast hidden water distribution systems leads to discolouration, an indicator of water quality deterioration, and the number one service contact by consumers. Over the last two decades, by combining world-leading knowledge with a fundamental understanding of the processes and delivery of practical tools and techniques, the University of Sheffield has built the ‘Prediction and management Of Discolouration in Distribution Systems’ (PODDS) consortium across the UK water sector to address these challenges. This innovative partnership has helped the sector achieve improved levels of service without increasing costs, delivering more than 35% reduction in customer contacts regarding water discolouration and increased operational efficiency through better targeting of limited resources.

UCL Optical Networks Group and worldwide telecommunications industry

High-speed ultrawideband and low-delay optical communications networks for the cloud

Optical fibre communication networks underpin global communications, carrying over 95% of all digital data. The work of the Optical Networks Group has been key to the development of this critical high-capacity, low-delay, resilient and secure communications infrastructure. By deeply embedding their industrial collaborators within the group's research, the group has achieved society-wide impact, including a 100,000-fold increase in optical network data capacity, the doubling of transmission distances, and world record data rates, using its one-of-a-kind laboratories and expertise. Since the group was founded in 1994, it has become the centre of a web of over 60 leading international industrial laboratories and companies, across all telecommunications sectors: network operators and content providers (e.g., BT, Deutsche Telecom, Microsoft, KDDI), equipment and device manufacturers (Oclaro (now Lumentum), Nokia Bell Labs, Xtera, ADVA, Mitsubishi, Infinera) and optical fibre manufacturers (Corning, OFS).

University of Manchester and Nuclear Decommissioning sector

Providing expertise for quicker, safer nuclear decommissioning

The UK has been a nuclear nation for 75 years and has accumulated one of the largest. most complex nuclear legacies on Earth. Since 2002, Government has focused on cleaning up this legacy, a programme of work that will last over 100 years and cost over £140 billion. The Dalton Nuclear Institute coordinates the UK’s most comprehensive nuclear academic community, at The University of Manchester, to deliver skilled people, impactful research and support for Government policy development. The Institute’s research has, among other beneficial impacts, led to changes in effluent treatment at Sellafield and reduced discharges to the environment by 50-90%. The team have also developed robots for high hazard settings, including one of Time Magazine’s 200 best innovations for 2022; and improved the management of the UK’s separated plutonium stockpile. In a sector with a critical shortage of experts, the Institute also provides a vital pipeline of talent.

View the videos of the shortlisted partnerships.

Professor Dame Ann Dowling OM DBE FREng FRS, former President of the Royal Academy of Engineering and Chair of the judging panel for the Bhattacharyya Award, said: “The six finalists for this year’s Award are inspiring and diverse examples of successful collaboration between academia and industry—it’s terrific to be able to highlight and to celebrate their innovation and impact and I hope they will provide inspiration for others. We know that there are other great partnerships like these between universities and colleges and industries across the UK in all sectors but that we need many more if we are to fully reap the economic and societal benefit of our research investment and capability.”

The winner of the Bhattacharyya Award will be announced on the evening of 24 October 2023 at a ceremony at the Edgbaston Park Hotel in Birmingham that will showcase the shortlisted partnerships. Anyone wishing to attend should contact awards@raeng.org.uk for more details.

Notes for editors

- WMG, University of Warwick, is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes. As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

- The Royal Academy of Engineering is harnessing the power of engineering to build a sustainable society and an inclusive economy that works for everyone. In collaboration with our Fellows and partners, we’re growing talent and developing skills for the future, driving innovation and building global partnerships, and influencing policy and engaging the public. Together we’re working to tackle the greatest challenges of our age.

Media enquiries to: Pippa Cox at the Royal Academy of Engineering Tel. +44 207 766 0745; email: Pippa.Cox@raeng.org.uk