WMG News

Aerospace electrification: Accelerating the opportunity

The Aerospace Electrification event with WMG and ATI successfully brought together thought leaders and experts from across the aerospace supply chain and other sectors.

The Aerospace Electrification event with WMG and ATI successfully brought together thought leaders and experts from across the aerospace supply chain and other sectors.

Such events are vital to understand the opportunities and challenges faced by the sector, and a collaborative approach combining industry and academia will help the UK to continue its place at the forefront of transport electrification.

A series of presentations, workshops and Q&A led to a lively critical analysis of the topics at hand for aerospace electrification. These included safety, energy storage, electric drives, power electronics, thermal management, whole-vehicle optimisation and many more.

Alison Meir, Head of Business Development, WMG HVM Catapult, chaired the event, and introduced our first speaker, Mark Scully, Head of Advanced Systems and Propulsion at the ATI, who set the scene. Aerospace electrification has been a topic for some time now and technology is developing apace, with propulsion systems, subsystems and ancillaries all being electrified. Mark highlighted huge opportunities for the sector, with funding from UK Government supporting collaborative R&D in electrification. The ATI welcomes enquiries from industrial, academic and other stakeholders looking for R&D support.

Battery technologies and associated key metrics were presented by David Rawlins, Chief Technology Officer (CTO) at WMG. The safety-conscious nature of the aerospace industry has typically led to a modest pace of development in such technologies compared with, say, automotive. David identified that aerospace engineers are trained to design for perfection, but with future architectures and technologies still fledgling, no one knows what the perfect or ‘right’ solution yet is. So, there is opportunity for faster paced R&D. There is a growing evidence base on the limitations of battery technology and the trade-offs of power density against energy density, primarily driven by the automotive sector. As such, it is vital that the sector remains committed to influencing and leading battery technology for aerospace. An example is the ATI ACCEL programme, involving Electroflight and Rolls Royce, in partnership with Yasa, WMG and more. The continual need to engage with and influence the regulatory bodies for safety and certification was a poignant discussion point.

Future hybrid and all-electric aircraft will use radically different architectures to the aircraft of today, enhancing the need for a holistic systems engineering approach to design and integration. Sarabpal Bhatia, E-Fan X R&T Coordination Manager at Airbus, provided insight into the considerations currently underway at Airbus and the wider industry. Sarabpal reinforced that the aerospace and aviation industries have learnt many lessons since the dawn of flight and the jet age and that, as a collaborative sector, we must continue to learn lessons together. The integration challenges discussed included thermal management, high-voltage systems and arcing, human-machine interface, electromagnetic interference and protection. All of which are providing engineers with intricate problems to solve for future architectures.

On the topic of electric machines and more-electric aircraft (MEA), Marc Holme, Senior Director, at Collins Aerospace was able to share insight to delegates. The Boeing 787 currently has significant electrical energy generation capability (>1MVA) with electrification of pneumatic and environmental control systems. Marc identified that there are further electrification opportunities on the current fleet of conventional aircraft with technologies such as:

- Higher performance magnetics.

- Higher voltage systems.

- Improved semiconductor device efficiency.

The primary drivers for these are currently size, weight, power and cost. For future vehicles, electrical machines, power densities, power electronics and integrated drives, increased operating temperatures and systems safety were all topics of discussion. Composite enclosures for electrical machines were introduced, with the lower weight being traded for potentially lower EMI immunity.

These insightful presentations were followed by a series of hands-on workshops chaired by WMG and ATI to identify and address the key challenges and identify ways to overcome them. Following these sessions, delegates fed back and were able to ask questions of our expert panel.

During the Q&A, creation and availability of technology roadmaps was of interest. Roadmaps across electrification technologies have been produced by the ATI with industry and are available on the ATI's website.

Batteries and stored energy created much discussion. The thermal implications of energy storage failure cases were discussed and identified as a key challenge both at pack level and cell level. The design of experiments for a system with hundreds or thousands of battery cells is a complex topic ripe for innovation. Battery degradation over operational lifetime was discussed with the design considerations and in-service detection being key challenges. David Rawlins provided insight into how Lithium-ion cells are still leading for cost and volume primarily driven from the automotive sector.

The operational considerations of all-electric aircraft were also discussed. The flight-level optimisation of an aircraft that does not burn fuel (and lose mass) was challenged with the opportunities still all to play for.

Overall, the event was attended by a wide range of industry and academic contributors, all of whom believed that aerospace electrification holds huge opportunity for the UK. The Government’s net zero agenda, initiatives and R&D funding mean that aerospace electrification will require collaborative innovation for years to come.

The recording of the event and detailed challenge sessions overviews are available here.

Professor David Greenwood named as new CEO for WMG centre HVM Catapult

WMG is pleased to announce the appointment of Professor David Greenwood, as the new CEO of the WMG centre High Value Manufacturing (HVM) Catapult.

WMG is pleased to announce the appointment of Professor David Greenwood, as the new CEO of the WMG centre High Value Manufacturing (HVM) Catapult.

Professor Greenwood will replace Archie MacPherson, who has successfully led the WMG Catapult team since 2016.

WMG Executive Chair, Margot James, said: “We thank Archie for all that he has achieved in this period and wish him all the very best as he returns to a role in industry.”

The CEO role is part of Professor Greenwood’s remit as Director for Industrial Engagement at WMG.

He currently leads WMG’s Energy Research, and also holds advisory and board positions for the Advanced Propulsion Centre, Innovate UK (Faraday Challenge and IDP and the Faraday Institution, and is Head of the Advanced Propulsion Centre's Electrical Energy Storage Spoke. Professor Greenwood also provides academic leadership for the development of R&D activities within the National Automotive Innovation Centre at the University of Warwick.

Margot added: “Dave’s passion and unrivalled experience make him the ideal candidate to lead the HVM Catapult drive to de-risk innovation in UK manufacturing, enabling its productivity, growth and sustainability.”

Professor Greenwood added : “The focus of my career has been around bringing science and technology into industry, and I am delighted that these new roles will bring together the academic strengths of WMG with the transformative capability of the High Value Manufacturing Catapult to benefit Industry and the UK. I look forward to strengthening our existing partnerships and welcoming new ones.”

Professor Greenwood will officially start as CEO from 26th October 2020.

£6 million programme extension to help small manufacturers across the Midlands

· The SME Group at WMG, University of Warwick, has secured a £6m extension to their programme to help small manufacturing companies in the East and West Midlands

· Funded by the European Regional Development Fund (ERDF) and the High Value Manufacturing Catapult at WMG, to create a much-needed support for Midlands manufacturers

· The programme will work collaboratively with a further 250 manufacturing companies across the Midlands to solve manufacturing challenges, to improve productivity and boost competitiveness

· Support is provided from a dedicated and highly industry experienced team with expertise in materials and manufacturing, sustainability, digital manufacturing and business transformation

The programme delivered by the SME Group at WMG, University of Warwick has been a major success in the West Midlands over the last 2 years, helping over 100  companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

Companies, including Genius Facades, a construction company in Wolverhampton, who gained a 15% increase in productivity, thanks to the team helping them by digitising their factory floor.

Another example includes the team helping Power Panels Electrical, in Walsall, win £3m of contracts in the Niche Vehicles sector.

Given the success of the programme, the team have been awarded a further £6m from to take them through to March 2023, meaning the team has gone from a 2 year £5m programme, to an £11m 5 ½ year programme. This extension will enable the team to operate from Wolverhampton and Worcestershire in the West, to Loughborough and Luton in the East Midlands.

Over the next 2 ½ years they will help more than 350 SMEs benefit from the latest in digital manufacturing technologies and thinking, helping them become more productive, competitive and sustainable. Fully funded support from 2 to 15 days is available for eligible small manufacturers.

Dr Mark Swift, head small business programmes at WMG, University of Warwick comments:

“We are thrilled to have the manufacturing competitiveness programme extended, and look forward to being able to help hundreds of small businesses across the midlands to transform their business and become more sustainable.

“The support we offer will be especially helpful in light of Covid-19, as after months of lockdown businesses can be helped to get back on their feet and thrive.”

“We are here, ready to help our region’s manufacturing companies; to make manufacturing technology and thinking work for you, to help our businesses to grow become more productive and sustainable and ultimately make more in the UK.”

If you are a local manufacturing company please get in touch, the team would love to hear from you. E-mail them at: wmgsme@warwick.ac.uk

ENDS

9 SEPTEMBER 2020

NOTES TO EDITORS

High-res images available at:

Caption: The WMG SME team improve the shop floor productivity at Genius Facades

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

It’s electrifying!

WMG Centre High Value Manufacturing Catapult, with support from Advanced Propulsion Centre (APC) Electrical Energy Storage Spoke, has created a series of short educational videos to help explain the process of transport electrification.

WMG Centre High Value Manufacturing Catapult, with support from Advanced Propulsion Centre (APC) Electrical Energy Storage Spoke, has created a series of short educational videos to help explain the process of transport electrification.

There are a total of three episodes featuring WMG’s Electric Vehicle experts Professor David Greenwood, Research Fellow Faduma Maddar, and Dr Mel Loveridge.

In each episode, the experts explain more about the research carried out at WMG’s Energy Innovation Centre and address the key issues surrounding an electric future.

The videos will now be shared with policy makers, and schools across Coventry and Warwickshire to help support STEM learning.

The three episodes can be found in WMG’s Electric Vehicle playlist here.

The HVM Catapult Annual Review highlights how WMG is delivering real impact for the UK economy

HVM Catapult has, today, published it's 2019/2020 Annual Review.

Archie MacPherson, CEO, WMG Centre High Value Manufacturing Catapult commented: “The High Value Manufacturing Catapult Annual Review 2019/20 highlights how WMG and the other six centres are delivering real impact for the UK economy – contributing to £518m of industry R&D investment.

"This past year has seen many opportunities arise, for instance, the increasing emphasis on green manufacturing and journey to Net Zero transport. A leader in electrification for all sectors, WMG worked closely with industry innovators to accelerate this journey, including a collaboration with Nissan to develop a process for recycling and reusing EV batteries.

"As well as these exciting prospects, we have also seen many challenges this year, including the seismic effects of the COVID-19 pandemic. This Annual Review is a testament to our manufacturing sector, and highlights several outstanding examples that WMG are proud to have supported, from helping a firm develop life-saving ventilator products, to aiding the production and distribution of PPE to the frontline.

"As we look ahead, there are bound to be more difficulties to come as we begin on the road to recovery, but this Review demonstrates the invaluable role of the HVM Catapult, to help us emerge stronger. We remain committed to helping to restart our manufacturing economy, support the opportunity to enable business to reposition and transform with the opportunities for a more digital, decarbonised and sustainable future.”

Download a copy of the Annual Review here.

Warwick Moto superbike designs unveiled

As the government has announced proposals to ban the sale of petrol, diesel and hybrid cars by 2035 the race to electrify the motor industry is on, and motorbikes aren’t to be overlooked.

As the government has announced proposals to ban the sale of petrol, diesel and hybrid cars by 2035 the race to electrify the motor industry is on, and motorbikes aren’t to be overlooked.

This has inspired 25 students from a range of Departments including: WMG, School of Engineering, Computer Science, Physics, Law and Maths to work together to make Aurora, an electric superbike with thanks to support from WMG and the High Value Manufacturing (HVM) Catapult team at WMG.

The superbike, Aurora, will be raced when appropriate after the Coronavirus pandemic, however the students have been working hard at home, and have finalised their designs for the bike.

The WMG Battery School is back, and it’s virtual!

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

WMG battery experts will facilitate a mix of live lectures and pre-recorded practical hands-on-sessions, virtually, over the five days.

The lectures will cover manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical, pre-recorded in the Energy Innovation Centre, lab sessions, will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find the full lecture and demo programme and register your interest here or by email: WMGShortCourses@warwick.ac.uk

STEM support for home schooling

WMG’s Outreach Team, with support from the WMG centre HVM Catapult staff, have been helping children with fun and creative STEM activities to help with home schooling.

With schools currently closed, the Team have been working hard to create educational resources highlighting the value of engineering for children of all ages.

WMG Outreach Project Officer, Dr Phil Jemmett, has also taken part in the last two Global Science Shows, an initiative that brings together science activities and experiments from all over the world, live on Twitter.

In the first show, Phil demonstrated three separate science experiments, exploring density and floating, using 3D printed parts in just two minutes. In the second show Phil showcased the classic bottle rocket launch! However this time, instead of using a cork to hold back the pressure, the launcher used a rupture disk which acts as an important safety feature on some industrial equipment.

In the first show, Phil demonstrated three separate science experiments, exploring density and floating, using 3D printed parts in just two minutes. In the second show Phil showcased the classic bottle rocket launch! However this time, instead of using a cork to hold back the pressure, the launcher used a rupture disk which acts as an important safety feature on some industrial equipment.

Why Outreach?

“Coventry and the wider Midlands has a proud engineering history – take Sir Frank Whittle as an example. Hearsall Common features a plaque paying homage to a moment in history when Frank, as a child, saw a plane land on that field. He went on to pioneer the jet engine, receive a knighthood, give lectures at NASA and be voted amongst the top 100 Britons of all time. Quite the list of achievements! But each great journey starts with one small step, and the motivation to take that step,” explains Phil.

He adds: “At WMG, we take part in inspiring and amazing work that deserves to be shared and spread to young people in the area. The power of our research to inspire and motivate the next generation of children, by giving them an experience just like Sir Frank’s watching the plane land at Hearsall Common, is immense. While the demonstrations in the Global Science Show videos are only small we are not aiming to invent the next jet engine with each one – we are hoping to provide the spark that kindles a burning passion in a young person to succeed in engineering.”

Home schooling support

You can find all the WMG home schooling activities including video demonstrations at WMG Experiments and the Engineer Inside.

Inspiring the next generation of scientists, mathematicians and engineers

WMG’s Outreach team has completed another successful series of Royal Institution Masterclasses for school children across Coventry.

The classes aim to open the eyes of young people to the excitement of engineering, and in turn, inspire the next generation of scientists, mathematicians and engineers.

Local schools were invited to nominate two year nine students to take part, with a total of 24 students participating in the sessions overall.

The Masterclasses were held on Saturday mornings in the form of interactive workshop sessions focusing on a different aspect of engineering. The Series was delivered by staff and students from WMG, with several of this year’s classes led by researchers working on key WMG HVM Catapult projects.

Professor Margaret Low, Director of Outreach and Widening Participation at WMG explained: “Sadly, due to the Covid-19 pandemic, the final masterclass focusing on software and control could not be held as an interactive session on campus.

Professor Margaret Low, Director of Outreach and Widening Participation at WMG explained: “Sadly, due to the Covid-19 pandemic, the final masterclass focusing on software and control could not be held as an interactive session on campus.

“Instead myself and Helen Luckhurst, Project Officer at WMG HVM Catapult, held the final session virtually across two evenings.”

Professor Low added: “The virtual classes were a complete first for the Outreach team, a strange but still successful end to the Masterclasses. We presented a series of video tutorials and the students then used their programming and pattern skills to create an embroidered pattern design for a coaster. There were some really great designs.”

Masterclasses. We presented a series of video tutorials and the students then used their programming and pattern skills to create an embroidered pattern design for a coaster. There were some really great designs.”

Find out more about the 2020 RI Masterclasses here.

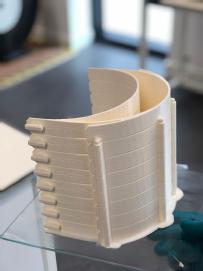

WMG staff use 3D printing in the fight against COVID-19

A team of WMG academics, technicians and engineers are using their 3D Printing skills, to help in the fight against COVID-19, by producing face shields for NHS front-line staff.

A team of WMG academics, technicians and engineers are using their 3D Printing skills, to help in the fight against COVID-19, by producing face shields for NHS front-line staff.

As the supply of PPE became a key issue in the pandemic, technicians Phil Gibbons, Joseph Benjamin and Martin Worrall, and PhD student Kevin Couling responded to 3D Crowd’s call asking volunteers to use their 3D Printing capabilities to produce face shields.

WMG’s nine 3D printers have now been programmed to run around the clock producing more than 400 shields each week.

The first batch of face shields have now been vigorously inspected, cleaned, packaged and distributed to 3D Crowd’s central assembly station in Warwickshire. They will now be sent to organisations running low on supplies.

The team have also managed to order extra materials and will keep the printers running until supplies literally run out.

Reader Greg Gibbons explains: “Demand for PPE is incredibly high, and we are in a unique position to be able to help.

“We have 3D Printers running in our Degree Apprenticeship Centre (DAC) and we are also planning to open up our Materials Engineering Centre (MEC) to enable mass production of the shields.”

In addition to the work with 3D Crowd, and with funding from WMG Centre High Value Manufacturing Catapult, the team are also working in collaboration with Queen Mary University of London on the development of an injection moulding process for face shield to enable mass production of the frame.

Associate Professor Jérôme Charmet, and Post-Doctoral Research Associate Rui Rodrigues explain: “It is fantastic that we are able to respond to this call and work towards providing the protection to the NHS that is so desperately needed.

“We are now finalising a tool design before we begin production. Once the process is up and running we then plan to transfer manufacture to Andel Plastics, an Injection Mould SME, who will continue with large scale production.”