WMG News

WMG joins the Electric Revolution challenge

WMG is proud to be playing its part in the government’s Driving the Electric Revolution challenge.

WMG is proud to be playing its part in the government’s Driving the Electric Revolution challenge.

Fourteen winning projects, announced by the Business Secretary in March, will share a total of £6.7 million. These projects will help boost supply chain efficiencies in industries affected by electrification, from aerospace to automotive, to energy and rail.

Transport Minister Rachel Maclean said:

“Funding and increased support for state-of-the-art electric manufacturing centres will help people, goods and services move across the nation, in a greener, safer and more reliable way than ever before.

By investing in world-leading science and engineering institutions, we are creating a modern transport system, bringing communities closer together while reducing the UK’s contribution to climate change.”

Co-ordinated by WMG Centre High Value Manufacturing Catapult, WMG at the University of Warwick, will be part of the project consortiums for High Volume E-Machine Stack Manufacture and Lightweight Aluminium Winding (LAW).

High Volume E-Machine Stack Manufacture

This project brings WMG together with Brandauer, and Jaguar Land Rover to improve the production methods, tooling design, processes and material selection used in the creation of rotor and stator components to pave the way to a high volume production of thinner laminations in the UK.

Given the rise of electric vehicles and more electrified systems it is strategically desirable for the UK to develop its own supply chain for the production and distribution of high-performance electric machines at volume. This project seeks to close the gap in UK-based supply of rotor and stator lamination stacks.

Brandauer is already established as a market leader in high precision stampings and pressings in multiple sectors but does not currently have the capability to meet the demand of the automotive sector. This will create the opportunity for Brandauer to not just enter the automotive supply chain, but to do so as best-in-class.

Lightweight Aluminium Winding (LAW)

A consortium, led by Aspire Engineering, with WMG, Voltalogic, Ashwoods Automotive, Hydro Aluminium Rolled Products will develop a winding machine for aluminium wires. The winding machine will provide the first UK supply chain solution for manufacturing aluminium coils. Coil winding is a critical component of eMachine manufacture and is not provided by any UK manufacturer. UK based companies of eMachines have to purchase winding machines from overseas suppliers or have wound coils shipped to them.

Ashwoods and Voltalogic will provide copper coil designs that will be redesigned to use aluminium wire. Hydro Aluminium Rolled Products will provide coated aluminium wire with the preferred electrical conductivity and mechanical properties. Aspire will build their work on winding machines to provide a volume manufacturing solution, and WMG will leverage their development work on volume e-Machine manufacture to guide the partners to the provision of a volume manufacturing solution.

The successful completion of the project will provide a UK supply chain for the manufacture of e-Machine coil winding. Through this, it will enhance the UK's competitiveness to deliver e-Machine manufacturing technology. It will embed the design and manufacturing expertise for coil winding into the UK supply chain.

The project will develop the reduction in weight of e-Machines by 15% without compromising performance by developing manufacturing processes for winding coils from alternative material.

It will also deliver, for the first time, to the off-highway market a single source drive system incorporating advanced IPM motor technology, radically lighter BUT equally as efficient as current IPM technology.

Find out more about WMG’s Transport Electrification and Energy research here.

Teach your kids STEM at home – tips from real engineers

Now that schools across the UK are closed due to Covid-19, the challenge is on for parents to keep their children educated. Or failing that – just keep them occupied.

Now that schools across the UK are closed due to Covid-19, the challenge is on for parents to keep their children educated. Or failing that – just keep them occupied.

The outreach team from WMG, University of Warwick, want to encourage children and their parents and carers to use this time to explore some of the fun, creative STEM learning opportunities which are available online. With support from WMG centre HVM Catapult, the outreach team at WMG has produced a number of online activities for children of all ages to get involved and learn something new.

Professor Margaret Low, Director of Outreach and Widening Participation for WMG, explains:

"With schools closing it’s a real opportunity to engage parents and carers with online teaching resources, to ensure children are getting an education at home during these uncertain times.”

“We hope these resources, which are suitable for young people of all ages, will inspire children to take up careers in STEM. Many children may think of engineering as physically making things, but don't realise the maths or computer design skills required, which could open up a great career for them in the future.”

The first resource suggested by WMG outreach team is Turtlestitch, which is great for children in school years 5 to 9. Turtlestitch is a free website on which users can write a program to control a digital embroidery machine. It is used by WMG for outreach activities, as a means of raising awareness of the breadth of engineering. Young people really enjoy using Turtlestitch for pattern design, with or without access to a digital embroidery machine, which makes it ideal for learning at home while schools are closed.

The first resource suggested by WMG outreach team is Turtlestitch, which is great for children in school years 5 to 9. Turtlestitch is a free website on which users can write a program to control a digital embroidery machine. It is used by WMG for outreach activities, as a means of raising awareness of the breadth of engineering. Young people really enjoy using Turtlestitch for pattern design, with or without access to a digital embroidery machine, which makes it ideal for learning at home while schools are closed.

Helen Luckhurst, a Project Officer at WMG, University of Warwick comments: “Turtlestitch is great for children learning at home because it gives them a fun context for applying maths skills. It is interactive and engaging as children discover the patterns they can make using maths.”

“We have created a number of resource cards and video tutorials to support its use, so I hope that parents and carers will encourage their children to use this as a different way of learning.”

Find WMG video tutorials, how-to cards and maths tasks to guide users through Turtlestitch here. Explore the learning materials on basic programming skills, year 5 and 6 maths, craft projects and further mathematical investigations.

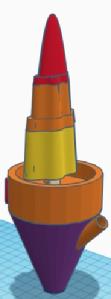

Another fun activity for both primary and secondary school children is Tinkercad, a colourful, easy to use computer-aided design software, which is free to use in the web browser and suitable for children from around 8 years of age. Teachers, kids, hobbyists, and designers use it to imagine, design, and make anything. It is used by WMG outreach as part of the Warwick Bright Stars programme in primary schools. Parents can find video tutorials and ideas for several projects here, including keyrings, money pots and lolly drip trays.

Diane Burton, a Project Officer at WMG, University of Warwick explains: "These Tinkercad projects engage children in the design process, and get them using measurements and maths as an essential part of their design work.”

Autodesk Fusion 360 is a powerful, professional CAD package. It is used in secondary schools and is suitable for ages 14+, and a free download is available to students, educators and enthusiasts. WMG video and written tutorials are available here, where you will find projects including design of assistive technology.

Autodesk Fusion 360 is a powerful, professional CAD package. It is used in secondary schools and is suitable for ages 14+, and a free download is available to students, educators and enthusiasts. WMG video and written tutorials are available here, where you will find projects including design of assistive technology.

Parents may also want to do some experiments at home with their children, which are fun and educational for any age.

WMG staff have made videos available of demonstrating experiments to do at home, using household items and toys you might already have. It is advisable that children are supervised during these experiments.

Watch Graduate Trainee Engineers Lauren, Jacob, Josh and Lucas demonstrating STEM experiments, and follow a guide to building a pulley from a toy construction set. There are many more experiments to come, telling the engineering story behind household objects.

Dr Phil Jemmett, a Project Officer at WMG, University of Warwick comments: “Every product in your house has been made by engineers and shaped by scientists. We want to tell the story behind those items and show you experiments that you can do with everyday stuff. Now that we are all staying in our homes, we just have to find a way to do STEM with what we’ve got!”

Parental supervision is advised when accessing external websites.

Introducing CAD to Coventry children

The WMG Outreach team, funded by the lmagineering Foundation, has delivered a special CAD and 3D printing programme to more than 200, ten and 11 year olds across Coventry and Warwickshire.

Four University of Warwick undergraduate engineering students delivered the programme, throughout 2019, in a series of workshops designed to raise awareness and knowledge of CAD and 3D printing.

Workshop 1: Introduction to the programme and learning about 3D printing

Workshop 1: Introduction to the programme and learning about 3D printing

In the first session the team explained the role of engineers in the design process. The children were also shown how 3D printers are used to create prototypes.

Ice lollies!

In small groups the children were tasked with designing, (using CAD), and creating, (using 3D printing), an ice-lolly drip tray. During the design process the Outreach Team explained the importance of taking accurate measurements to ensure that the designs would actually work.

The challenge

Using a hairdryer (to create the feel of a warm summer’s day!) the children were presented with the problem of dripping lollies! The challenge to design a suitable drip tray was then set.

The children used life-sized 3D printed ice lollies on sticks to take key measurements needed for their drip tray designs. The pupils discussed and sketched design ideas including adding key measurements. These measurement and design sheets were then used in the next two workshops to help develop their CAD designs.

Workshop 2: Using Tinkercad to draw lolly drip tray designs in CAD

A video tutorial was used to show the children how to use Tinkercad. Building on their design work from Workshop One, the children began producing CAD drawings for the drip trays.

Workshop 3: Using scaled digital lolly model to assess and improve designs

Pupils put the finishing touches to their designs and used the scaled digital lolly models to visualise and assess their designs, considering any design modifications that were needed to ensure the drip tray was effective. The children were encouraged to continue this process until they were confident the design would work.

Towards the end of the workshop, the class shared their finished designs. The class then voted for their favourite two, these were then 3D printed and returned to the school as a momentum.

Diane Burton, Project Officer STEM Outreach explained: “The school pupils had fun learning key design principles, and they have successfully produced products that are both functional and creative.”

You can find out more about all of WMG’s Outreach activities here.

Charging ahead at Battery School

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG battery experts will facilitate a mix of lectures and practical hands-on-sessions, with the intention of inspiring the next generation of engineers into battery related careers, crucial for the UK’s electrification sector.

The lectures will cover areas including manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical lab sessions will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find out more and book your place here.

Car batteries can be frozen for safer transportation

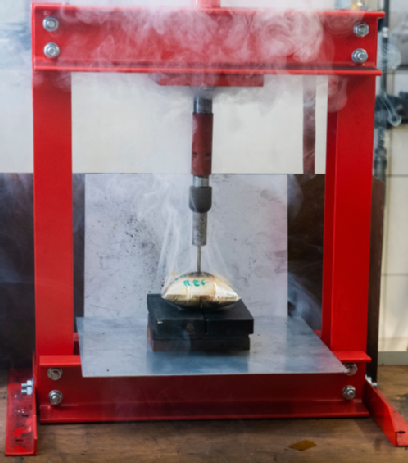

Currently transporting damaged and defective car batteries is an expensive process as they need to be placed in an explosion proof box which costs thousands of pounds, however researchers from WMG at the University of Warwick in collaboration with Jaguar Land Rover engineers have been able to freeze batteries with Liquid Nitrogen.

An explosion proof box to transport a typical Tesla sized battery costs €10,000 and a further €10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

€10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

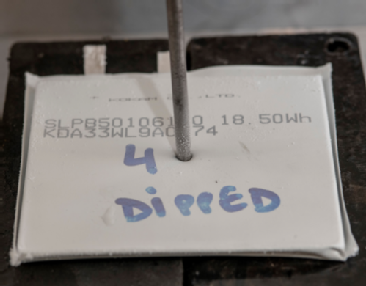

In the paper, ‘Cycle life of lithium ion batteries after flash cryogenic freezing’ published in the Journal of Energy Storage, researchers highlight that cryogenic freezing does not reduce lithium ion battery’s energy capacity or affect cycle or service life, and could be transported in a safer way.

As the sales of electric vehicles increases, there is more concern for the transportation of damaged and defective lithium ion battery packs. Currently, it is an expensive process, as they are put in an explosion proof box that costs €10,000 and a further €10,000 for the UN accreditation, which EV manufacturers are picking up the bill for.

Explosion boxes are used to contain the battery in case it goes into thermal runway, an overheating condition which can lead to violent explosions and toxic gases being released. However being able to cryogenically flash freeze the batteries completely removes the risk of an explosion, and could therefore mean they can be transported safely in a plastic box.

Researchers who were part of the ELEVATE project funded by EPSRC, WMG Centre High Value Manufacturing Catapult, and  supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

When being transported batteries will have to be kept in a lorry at -35 degrees, however the amount of packaging is significantly less than explosion proof boxes, making the process more sustainable.

Dr Thomas Grandjean from WMG, at the University of Warwick comments:

“Transporting damaged and defective batteries is an expensive and unsustainable process, however being able to freeze them with liquid nitrogen could save thousands of pounds and help electric vehicle manufacturers be more sustainable.

“We tested the batteries in the most extreme abuse conditions, such as driving nails through the cells and inducing external short circuits, proving that the freezing process is effective and safe.”

ENDS

2 DECEMBER 2019

NOTES TO EDITORS

High-res images available credit to WMG University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_3_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_5_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_7_.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_6.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_2_.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/untitled.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or + 44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Experience Warwick Summer School: Raising awareness of engineering in society

The WMG Outreach Team had a busy summer term concluding with the Experience Warwick Year 10 Summer School, which ran from 3-6 July and was supported by the High Value Manufacturing Catapult.

The WMG Outreach Team had a busy summer term concluding with the Experience Warwick Year 10 Summer School, which ran from 3-6 July and was supported by the High Value Manufacturing Catapult.

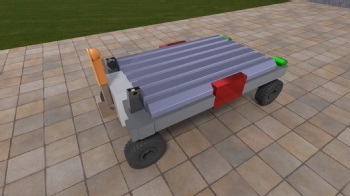

The programme was created and led by Phil Jemmett and saw a total of 42 students, aged 14 and 15 years, work on mini-engineering projects in small teams. They were supported by University of Warwick student ambassadors, research staff and Graduate Trainee Engineers from WMG.

Professor Margaret Low, Widening Participation Officer for WMG explained: “The projects were designed to introduce the youngsters to key engineering skills and to help them to recognise the importance of resilience and team work.

“The students had some fantastic ideas, including a smart city model, radio based game and remote controlled cars, which were presented to their families and teachers at a special showcase event.”

“The students had some fantastic ideas, including a smart city model, radio based game and remote controlled cars, which were presented to their families and teachers at a special showcase event.”

The Summer School, organised by Warwick Outreach and Widening Participation Team, gave the students a true insight into life at university: they got to stay in University of Warwick halls of residence, attend academic sessions and experience the social and sport facilities on campus.

Based on the success of the project, next summer it will be expanded into a full work experience programme in July 2020. To find out more contact wmgoutreach@warwick.ac.uk

Researchers convert car batteries into units that could power farms in the developing world

As part of a Circular Economy for electric vehicle battery systems, as the number of such vehicles increases rapidly, the need to find the best way to reuse and recycle vehicle batteries becomes just as intense.

In partnership with Jaguar Land Rover, Connected Energy and Videre Global, researchers at WMG, University of Warwick, have found a way not just to recycle those used batteries, but repurpose them as small energy storage systems (ESS) for off grid locations in developing countries or isolated communities.

The repurposed units, each containing approximately 2kWh of energy capacity, will be able to power a small shop, a farm holding, or multiple residential homes.

WMG’s Professor James Marco who was lead researcher on the project said:

“When an electric vehicle’s battery reaches the end of its useful life it is by no means massively depleted. It has simply reached the end of its useful life in a vehicle.

"It is generally accepted that an EV battery has reached end of life when its capacity drops to 80% of a fresh battery. While this is no longer enough to satisfy drivers, it remains immensely useful for anyone who seeks to use the battery in a static situation.”

While such partially depleted batteries remain potentially very useful to other users there are still challenges to overcome, particularly to ensure that they can be used reliably, sustainably, and cheaply in remote locations. These challenges include:

· How to protect the lithium-ion cells from over-charge and discharge

· Can the ESS be made compatible with a variety of other used battery cells and modules from other manufacturers

· How to keep it low cost and easy maintenance, while providing an interface that is easy to use and understand

The WMG team, at the University of Warwick, set about overcoming these challenges with the help of the WMG HVM Catapult and Jaguar Land Rover who supplied batteries and components from the Jaguar I-PACE, their first all-electric performance SUV. The team designed a new Battery Management System (BMS) and packaging that allowed them to create a working and easily portable prototype ESS which included:

• The use of standard low cost components for control, communication and safety functions. All parts were either sourced from the JLR service department or were low cost components purchased from any electrical retailer.

• The ability to use different modules that could be interchanged within the 2nd-life system without having to recalibrate the whole BMS

• Enough energy for a small shop, farm holding or multiple residential homes

• Multiple 12V DC sockets and 5V USB charge ports

• The ability to have the 2nd –life module charged via reclaimed laptop chargers

• Simplified control system for easy integration and deployment

Professor James Marco continues:

“This is a great result that not only provides a highly efficient repurposing solution for automotive batteries but which could also change lives in remote communities. We are now looking for support to allow these new units to be further developed and tested in remote or off grid locations.”

The research project was part of the Innovate UK funded Project: 2nd hEVen (2nd-Life Energy Storage Systems) and is supported by the WMG High Value Manufacturing (HVM) Catapult.

Charging ahead!

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

In its role as the Electrical Energy Storage APC Spoke, WMG’s battery experts together with guest lecturers facilitate a mix of presentations and practical hands-on lab sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

The new collaborative Battery School was officially opened by Neil Morris, CEO of the Faraday Institution, with the first session held for 25 PhD students and future battery engineers, in June.

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is situated at WMG’s Energy Innovation Centre – the largest facility of its kind in the UK. Find out more about the Energy Innovation Centre here.

WMG brings together key experts to discuss the future of transport

Last week, WMG High Value Manufacturing Catapult hosted an Autonomous, Connected, Electric and Shared (ACES) networking dinner in partnership with NatWest and Lombard.

Last week, WMG High Value Manufacturing Catapult hosted an Autonomous, Connected, Electric and Shared (ACES) networking dinner in partnership with NatWest and Lombard.

The event brought together CEOs, CTOs and senior executives from UK leaders in the sector, speakers included Jaguar Land Rover, Aston Martin, Rolls Royce, GiffGaff, WMG, You.Smart.Thing and FiveAI, to discuss how ACES technologies will radically change the way we travel.

There is a global call to both reduce emissions and also to ease congestion and increase the simplicity, safety and speed at which passengers are able to get from point A to B. There is no doubt that the future of transport will be ACES.

The UK has always been at the forefront of transport innovation and manufacturing, and needs to continue to bring manufacturers and governing bodies together to push forward the ACES transport agenda and ensure the UK remains competitive in a global market.

WMG, NatWest and Lombard will be releasing thought leadership pieces from expert industry leaders, sharing the challenges and opportunities for the UK transport sector.

Click here to read the Natwest article

For more information or to get involved please contact: wmgbusiness@warwick.ac.uk

Archie MacPherson presents at key ERC conference

Archie MacPherson, CEO of the High Value Manufacturing (HVM) Catapult at WMG is part of the expert panel at the Enterprise Research Centre (ERC)’s State of Small Business Britain Conference 2019, taking place at The Shard in London today.

Archie joins automotive experts as well as representatives of the FSB and officials from the Department of Business, Innovation and Industrial Strategy, to discuss how to strengthen key sectors of the economy.

Archie joins automotive experts as well as representatives of the FSB and officials from the Department of Business, Innovation and Industrial Strategy, to discuss how to strengthen key sectors of the economy.

He explains: “Support is needed now, more than ever, from the High Value Manufacturing Catapult to ensure that UK businesses maintain competitiveness during this period of uncertainty in UK Manufacturing.”

The ERC’s State of Small Business Britain report, which was launched at the Conference, presents a new analysis of the fortunes of the manufacturing and services sectors since the Great Recession of a decade ago.

The report provides a broader snapshot of the health of UK manufacturers in light of recent announcements about factory closures and job losses by the carmakers Ford at Bridgend and Honda at Swindon which the Society of Motor Manufacturers and Traders (SMMT) has estimated could lead to the loss of 60,000 jobs directly and in supply chains. In May, British Steel collapsed into administration after a last-ditch appeal to the Government, putting a further 25,000 jobs at risk.

Following the Conference, Archie will be making his way back to WMG for “The Future will be Autonomous, Connected, Electric and Shared (ACES)” networking dinner bringing together global leaders in the transport and communications sector. Guests will discuss the opportunities and challenges that ACES technology can bring.

ENDS

About High Value Manufacturing (HVM) Catapult at WMG

WMG is one of the founding members of the High Value Manufacturing Catapult (HVMC), and the lead centre for Vehicle Electrification and Connected and Autonomous Vehicles (CAV) within the HVMC network. The centre is also active in showing how Digital Manufacturing technologies can help improve company and supply chain competitiveness.

As part of the £640m Government funding package for HVM Catapult, WMG was allocated £100m in 2018 to continue strengthening UK industry through collaborative R&D, innovation and technology transfer from automotive into other transport sectors over the next five years.

About the Enterprise Research Centre

ERC is the UK’s leading independent research institute on the drivers behind the growth and productivity of small and medium-sized enterprises (SMEs). It is funded by the Department for Business, Energy and Industrial Strategy (BEIS), the Economic and Social Research Council (ESRC), Innovate UK, The Intellectual Property Office (IPO) and the British Business Bank (BBB).

ERC is producing the new knowledge around SMEs that will allow us to create a business-friendly environment nationwide, grounded in hard evidence. We want to understand what makes entrepreneurs and firms thrive so we can spread the lessons from best practice and make the UK a more successful economy.

The Centre is led by Professors Stephen Roper of Warwick Business School and Mark Hart of Aston University, Birmingham. Our senior researchers are world-class academics from both Aston and Warwick Universities as well as from our partner institutions which include Imperial College, Queens University Belfast and the University of Strathclyde.