WMG News

WMG research helps develop new generation of graphene composites

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

The new PolygreneTM compounds are expected to have potential commercial applications in areas as diverse as sports equipment, construction products, aerospace and automotive components.

Since 2018, Versarien subsidiary 2-DTech Ltd (2DT), Composites UK member, has funded PhD and postdoctoral researchers to understand the use of its Nanene™ graphene powders and other nanomaterials in thermoplastic systems. Dr David Reinoso-Arenas, the first 2DT funded PhD student, with support from the EPSRC Doctoral Training Programme, worked with Versarien’s Nanene™ materials in thermoplastic elastomer (TPE) systems and joined Versarien full-time last year as part of the team at Versarien’s subsidiary Cambridge Graphene Ltd.

Dr David Reinoso-Arenas, explained: “The new PolygreneTM thermoplastics portfolio is a culmination of my PhD research, some of which is due to be published in peer-reviewed journals. Since then we’ve been able to further develop and test these materials using different nanomaterial fillers and process conditions to fully optimise the resulting product performance. My PhD experience at the IINM and WMG was really enjoyable and enabled me to work closely with industry to ensure that the outputs of my research could be validated and have commercial viability.”

David’s PhD was performed under the supervision of Professor Tony McNally, whose team has an established capability in incorporating a wide range of nanomaterials into bulk polymer systems.

Professor Tony McNally, who leads the Nanocomposites Research Group at WMG, University of Warwick, said: “Working with Versarien over the last few years has given the IINM and WMG access to alternative graphene materials that have shown interesting phenomena when blended in these TPE systems. By tuning the nanofiller loading and optimising process conditions, David’s research showed that exceptional gains can be achieved in mechanical properties across the board (tensile strength, modulus, elongation at break, toughness and abrasion resistance) without compromising any properties. The addition of graphene also highlights improvements in polymer processing which may offer lower energy usage and, therefore, improving sustainability.”

Professor McNally continues to work with Versarien by providing a funded PhD position in 2D material based rubber systems, making use of the IINM’s new state of the art rubber processing and testing capabilities With support from the High Value Manufacturing Catapult (HVMC), WMG has established a world class facility for the study of elastomers.

Dr Stephen Hodge, Versarien’s CEO, added: “We look forward to continuing our collaboration with the IINM and WMG in rubber processing and understanding the interactions of our graphene and other 2D materials in these more complex systems, and hope to be able to demonstrate significant benefits that can impact upon real-world applications.”

Find out more and download technical datasheets here: https://versarienproducts.co.uk/thermoplastics

Find out more about WMG’s Nanocomposites research here:https://warwick.ac.uk/fac/sci/wmg/research/materials/nanocomposites/

Expert comment from Professor Siddartha Khastgir

Professor Siddartha Khastgir, Head of Verification and Validation at WMG, University of Warwick, comments on the Government’s plans to introduce the primary legislation for automated vehicles in the upcoming parliamentary session, as announced in the King’s Speech today (Tuesday 7th November).

Professor Siddartha Khastgir, Head of Verification and Validation at WMG, University of Warwick, comments on the Government’s plans to introduce the primary legislation for automated vehicles in the upcoming parliamentary session, as announced in the King’s Speech today (Tuesday 7th November).

Professor Khastgir said: ‘‘We welcome the Government’s decision to introduce the primary legislation on automated vehicles in the King’s Speech today. Following on from the discussions at the AI Safety Summit last week, this very first legislation on AI-powered technology is an important step for the UK to reach its target of rolling out automated cars in 2025.

“Regulation is the key enabler for the safe introduction of automated vehicles on UK roads. Not only does it provide regulatory certainty for the industry, but it is also key to setting high safety thresholds and gaining the public’s trust. We urge the Government to ensure that the regulatory framework is robust and underpinned by strong research outcomes. International and national self-driving standards should be built upon when creating this legislation.

“We also urge the Government to speed up the secondary legislation on automated vehicles to provide more information on the engineering requirements. The Government needs to ensure public views are incorporated into this legislative journey and take future users’ viewpoints into account. As a result, along with the legislation, a public awareness programme should be introduced to ensure an accurate understanding of the capabilities and limitations of this emerging technology. The Government needs to act quickly to be at the forefront of this technology.

“WMG will continue to fully support the Government and the eco-system to develop research and evidence-based self-driving regulation in the UK.’’

Find out more about WMG’s Verification and Validation research here: https://warwick.ac.uk/fac/sci/wmg/research/cav/vandv/

Expert comment from Shravani Sharma

Shravani Sharma, Researcher at WMG at the University of Warwick, comments on the news that the Government is to cancel rail industry plans to close the vast majority of railway station ticket offices in England.

vast majority of railway station ticket offices in England.

Shravani Sharma, whose recent work focused on the impact of travel on those with disabilities, said: “It’s a relief to hear of the U-turn of the ticket office closures. Through working with a range of disability charities, it’s clear that the removal of ticket offices would have a profound impact on the disabled. Working with CASBA (Citizen Advocacy South Birmingham Area), which supports people with learning difficulties, Royal National Institute of Blind People (RNIB) and Cerebral Palsy Midlands has shed light on the problems removing the ticket offices would have on the disabled.

“People with different visible and non-visible disabilities – including blindness, mobility problems, hearing loss, cerebral palsy and ADHD amongst others – would be severely impacted by the loss of ticket offices. People could be challenged by the technology, unable to distinguish train tickets from receipts, or simply need the guidance or assistance of a ticket officer.

“The U-turn will be a relief for so many people across the UK. When planning policies for the transport industry, people from a wide range of backgrounds, with different needs, must be properly listened to before making any big decisions. I would urge the government to consult both disability charities and the disabled in future policymaking.”

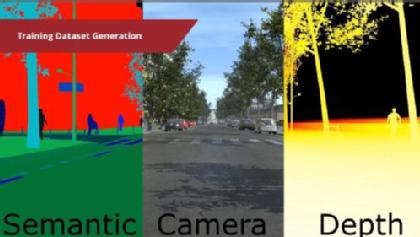

WMG research shapes the future of autonomous vehicles

WMG, at the University of Warwick, is part a unique £2 million consortium, entitled Sim4CAMSens.

The Sim4CAMSens project, led by Claytex, is made up of a consortium of prominent industry partners, including AESIN, rFpro, Syselek, Oxford RF, National Physical Laboratory, Compound Semiconductor Applications Catapult and WMG.

The Sim4CAMSens project, led by Claytex, is made up of a consortium of prominent industry partners, including AESIN, rFpro, Syselek, Oxford RF, National Physical Laboratory, Compound Semiconductor Applications Catapult and WMG.

Together the consortium will create a framework for sensor evaluation that incorporates modelling, simulation, and actual testing. In order to enable Automated Driving Systems (ADS) and sensor developers to speed their development, this project will involve the development of new models for sensors, noise and materials, and new test methodologies.

The role of WMG will be to understand which noise factors have the higher impact on the different perception sensors (i.e., camera, LiDAR, RADAR,) and how to correlate virtual testing to real-life testing to support the entire supply chain.

Professor Valentina Donzella, who leads the Intelligent Vehicles Sensors research at WMG explains: “The Sim4CAMSens project is an extremely exciting opportunity for WMG, to work with UK based world leading industrial and research partners, to speed up the development of sensors models and testing methodologies. These are key considerations for the future safe deployment of robust and reliable ADS. The success of this project will ensure the UK leads the way globally in this field."

Find out more about WMG’s Intelligent Vehicles Sensors research here: https://warwick.ac.uk/fac/sci/wmg/research/cav/ivsensors

WMG with Solihull Council secure £300,000 for self-driving shuttle feasibility study

WMG at The University of Warwick, Solihull Council, National Highways, Transport for West Midlands, ZF, Aurrigo, Syselek and Liftango have successfully secured £300,000 to deliver a project looking into the feasibility of a self-driving shuttle service in the West Midlands.

The project will explore how a new automated transport link between Blythe Valley Business Park, near Shirley, and the new HS2 rail station in Solihull could operate in the future. The feasibility study will consider all aspects of the technology required in order to provide a safe and reliable automated public transport service between these important commercial centres. The proposed route would use the existing road network travelling along the M42 from Junction 4 and utilise the new Junction 5a currently under construction.

operate in the future. The feasibility study will consider all aspects of the technology required in order to provide a safe and reliable automated public transport service between these important commercial centres. The proposed route would use the existing road network travelling along the M42 from Junction 4 and utilise the new Junction 5a currently under construction.

As a world-class research institution with leading capabilities in the verification and validation of safety assurance of self-driving technologies, WMG will apply its Operational Design Domain (ODD) based Safety Assurance research methodologies to the specific project challenges.

This project is part of the wider Midlands Future Mobility (MFM) initiative, led by WMG. The MFM vision is to achieve zero road incidents, net-zero emissions and inclusive transport in the West Midlands. MFM enables stakeholders from across mobility to address the interlinked challenges of technology, policy, and behaviour to realise the vision.

Cllr Ken Hawkins, Solihull Council Cabinet Member for Environment & Infrastructure, said: “Connected Automated Vehicle (CAV) technology has the potential revolutionise the way we get around our towns, cities and rural areas. Working with our partners we are excited to be undertaking this latest project.

“We’ve already carried out a series of successful pathfinder trials here in Solihull, using our own automated shuttle, and have led the way in showing how it is possible to practically and safely incorporate automated vehicles into our existing transport infrastructure. We are now taking the next step and undertaking the vital feasibility work necessary in order to start thinking about more ambitious deployments and establishing new commercial public transport services.

“The outcomes from the study are likely to inform self-driving mobility challenges not just here in Solihull but nationwide.”

Jonathan Smith, Midlands Future Mobility Programme Manager said: "The business case for scaling new mobility solutions is complex. It involves a granular understanding of the use case, safety, users, operations, and infrastructure. This project brings together a group of diverse experts to apply state of the art research and knowledge to address this question. Of critical importance is that the outcomes of this feasibility will inform mobility business cases both in the Midlands and the UK as a whole."

More information about this project

Partners: Solihull Metropolitan Borough Council (Lead), Aurrigo, Syselek (Uk) Ltd, Liftango Ltd, ZF Services UK Limited, West Midlands Combined Authority, Highways England, University of Warwick

Grant awarded: £300,000 (£197,664 from Centre for Connected and Autonomous Vehicles’ Commercialising Connected and Automated Mobility programme and balance is made up by the commercial partners).

Find out more about WMG’s Validation and Verification research here: Verification and Validation (warwick.ac.uk)

Note to editors

Media contact:

Annie Slinn

Communications Officer (Sciences)

Gabbie Lau

WMG Marketing and Communications Executive

WMG joins flagship electrification partnership

WMG at the University of Warwick, is part of a unique six-way partner collaborative research and development project led by Aston Martin.

Project ELEVATION has received £9m funding from the Advanced Propulsion Centre UK (APC) to supplement the research and development of Aston Martin’s in-house bespoke luxury battery electric vehicle platform.

Awarded following a competitive process, the government grant will support the development of Aston Martin’s luxury BEV platform and enable a route to net-zero, including investment in vehicle light weighting, a digital toolchain and electrification training.

Project ELEVATION is led by Aston Martin, and supported by the Manufacturing Technology Centre; Expert Tooling & Automation; Creative Composites; Fuzzy Logic Studio and WMG. The project will address the technical challenges of developing a lightweight, 800V traction battery pack and twin front electric drive unit (EDU) into a modular BEV platform with a bandwidth from supercar to SUV.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

Roberto Fedeli, Group Chief Technology Officer of Aston Martin, said: “The award of funding from the APC is another major boost to our electrification strategy and constant strive for innovation. Providing further resources to explore the possibilities of our bespoke BEV platform, it will help achieve our ambition to be an in-house BEV technology leader in the ultra-luxury, high-performance segment. We look forward to progressing this project with our collaborative partners and thank the APC for their incredible support.”

Ian Constance, APC Chief Executive, said: “The 23rd round of our collaborative R&D competition coincides with the APC’s 10th anniversary. We’ve seen over £1.4 billion of investment into automotive projects since the APC was set up, and I am proud of the impact that we have made here in the UK. This latest announcement includes a diverse set of OEMs and suppliers that demonstrate the strength of UK automotive. They will further add to our portfolio of innovative projects and continue to drive the UK to deliver on its net zero ambition.”

Find out more about WMG’s composite light-weighting research here https://warwick.ac.uk/fac/sci/wmg/research/materials/acrc

The University of Warwick celebrates 200 engineering internships in manufacturing to mark National Manufacturing Day

The University of Warwick is celebrating a new milestone for its engineering internship scheme, with over 200 internships now completed.

The milestone will be celebrated at a special event tomorrow on campus to mark the UK’s National Manufacturing Day – Thursday 28th September.

The internship scheme, which was established by the University’s WMG in 2013, places students in engineering internships at manufacturing businesses across the Midlands.

The scheme has been a hit with both students and businesses, with 75% of businesses experiencing increases in productivity and 95% saying they had noticed a positive cultural change thanks to the interns.

Most businesses who hired one intern through the scheme returned in the future, with around 70 interns now having been offered full time positions as a result of their internships.

The scheme was established to address the skills gap, with businesses needing more engineers than are available. Research suggests this gap is likely to get worse as demand increases, particularly for ‘green’ engineering roles.

Febry Wardhana, an Engineering Project Management postgraduate, recently completed his internship at Midtherm Flue Systems. They were so pleased with his work Febry now works for the company permanently.

with his work Febry now works for the company permanently.

Michael Whale, Midtherm’s Training and Development Manager said: “Febry’s work has opened up a lot of new doors for us and he has done a great job, so much so that we offered him a full-time position as a process engineer.”

Other interns have gone into a range of high-profile roles in both small and large organisations. Warwick graduate Sam Woodcock who undertook an internship at Pashley Cycles is now working at Arup as a mechanical engineer. He said:

“My internship with WMG and Pashley helped me to become comfortable in not knowing the answer to every problem I faced, and therefore taught me how to persevere and overcome engineering challenges.”

Dr Mark Swift, Director of SME Engagement at WMG commented:

“Our internship programme is hugely important for us. It has supported over 200 manufacturers while tackling a range of important projects in their businesses and proves that young engineers can add real value. It is critical that we kick start the careers of our future engineers so that they can get onboard to deal with the manufacturing challenges of both today and tomorrow.”

WMG Professor made Fellow of the Royal Academy of Engineering

WMG at the University of Warwick’s Professor David Greenwood has been elected a Fellow of the prestigious Royal Academy of Engineering.

WMG at the University of Warwick’s Professor David Greenwood has been elected a Fellow of the prestigious Royal Academy of Engineering.

Professor Greenwood is CEO of the High Value Manufacturing Catapult and Director for Industrial Engagement at WMG.

Professor Greenwood has been elected as part of a group of 73 leading figures in the field of engineering and technology to the fellowship.

The group consists of 60 Fellows, eight International Fellows and five Honorary Fellows, each of whom has made exceptional contributions to their own sector, pioneering new innovations, leading progress in business or academia, providing high level advice to government, or promoting wider understanding of engineering and technology.

The new Fellows will be formally admitted to the Academy at a special ceremony in London on 28 November, when each Fellow will sign the roll book. In joining the Fellowship, they will lend their unique capabilities to achieving the Academy’s overarching strategic goal to harness the power of engineering to create a sustainable society and an inclusive economy for all.

Professor Greenwood commented: "I am truly honoured to be elected as a Fellow of the Royal Academy of Engineering. The UK has tremendous capability in engineering and manufacturing and the work of the Royal Academy is pivotal in helping to achieve its full potential. I look forward to playing my part in that."

Professor Sir Jim McDonald FREng FRSE, President of the Royal Academy of Engineering, said:

“Engineering is everywhere, but nowhere the same, and our new Fellows represent the great breadth and diversity of engineers who are striving to address some of the world’s most complex challenges – benefiting society and the economy in the process. From next generation power networks and water systems to quantum computing and artificial intelligence, our new Fellows are shaping the future.

“We live in an era of rapid change across our communities, our country, and of course our planet. Today we welcome to our Fellowship an inspiring group of people who are harnessing their creativity, courage and commitment to drive positive change in the world around us and we look forward to their contribution to our work.”

View the full list of 2023 fellows here.

WMG secures funding for two new knowledge transfer partnerships with SME manufacturers pushing the boundaries on process and management innovation

The SME Group at WMG, University of Warwick, has embarked on two major projects with Bellagio Stone and Radius Systems thanks to over £200k in funding from Innovate UK’s Knowledge Transfer Partnership (KTP) scheme.

funding from Innovate UK’s Knowledge Transfer Partnership (KTP) scheme.

A KTP is a three-way collaboration between a company, an academic institution (in this case WMG at the University of Warwick) and a graduate or postgraduate. KTPs are designed to help businesses improve their competitiveness and productivity through shared knowledge, technology, and skills.

Bellagio Stone’s two-year project will create a new cultural management and leadership framework within the business following a recent merger, enabling it to push productivity and prepare for future expansion. Bellagio will transform its operations in the stonemasonry industry, capitalising on a range of long-term growth ambitions.

Radius Systems manufacturers of innovative plastic pipeline solutions will work on a two-year project with WMG to analyse, design and implement a process control system to reduce process variation in the continuous manufacture of water, gas and hydrogen infrastructure pipes.

Simon Broome, Innovation Manager at WMG who works with SMEs to secure KTP funding said: “We are delighted to announce these major new KTP projects. Both Bellagio Stone and Radius Systems have showed a fantastic appetite to grow their businesses and engage with the University to achieve their goals. We are excited about the potential ahead and are now in the process of recruiting the KTP Associates who will deliver the projects in the businesses.”

Mike Boyden, Operations Director at Bellagio Stone Ltd said: “We are really excited to have been awarded the funding to begin the KTP project in conjunction with WMG. We have worked on a number of really successful projects with WMG in the past and feel the KTP has great potential to help develop our business further. Having recently completed a business merger, this targeted approach of supporting specific hurdles we are facing, will help unite both businesses and really drive improvements in productivity, purchasing power and overall efficiencies. We are really grateful to all the team involved with supporting the application and look forward to getting started.”

Allen Clarke Technical Director at Radius Systems Ltd said: “We are delighted to be awarded the funding through Innovate UK and the opportunity to further work with WMG. We have many ideas and initiative to further enhance our manufacturing processes and drive or business to the next level. The scheme will give us great insight into our chosen technical subjects whilst enhancing our World class manufacturing and Industry 4.0 philosophy. Thank you to all involved with this venture and looking forward to getting started in Autumn 2023.”

Find out more about WMG’s SME programmes here: WMG SME Group | How can we help you? (warwick.ac.uk)

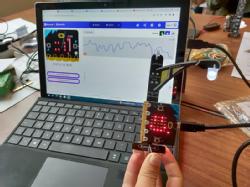

WMG supports holiday workshops

WMG at the University of Warwick’s Outreach Team was pleased to take part in the Royal Institution’s (Ri) holiday workshops.

Professor Margaret Low and Dr Phil Jemmett both led sessions at the holiday workshops designed to bring all areas of science - including mathematics, computing and engineering - to life for 9 to 14 year olds.

Professor Margaret Low and Dr Phil Jemmett both led sessions at the holiday workshops designed to bring all areas of science - including mathematics, computing and engineering - to life for 9 to 14 year olds.

Professor Margaret Low’s session was a fun and creative introduction to programming using TurtleStitch. TurtleStitch is free, easy to use, and generates patterns that can be stitched by embroidery machines, enabling the creation of physical things from code.

At Dr Phil Jemmett’s session he asked, ‘Where is engineering?’ Dr Jemmett explained how every product, tool, device and service relies on engineers designing, refining and creating solutions to problems. Students used programmable electronics and sensors, and had the opportunity to make a product for the future.

Dr Phil Jemmett, Widening Participation Co-ordinator at WMG, University of Warwick, said: “The Royal Institution has centuries of tradition in educating people about science in a fun and engaging way. We are so proud to have supported the holiday workshop programme for another year, and continue to work with one of the most famous scientific bodies in the world. What better place to showcase the engineering and innovation that WMG is part of in building the future? We aimed to show people how simple it can be to start to create their own projects, whether making a smart city for the future, or controlling an embroidery machine in Margaret’s workshop. And it really showed in the engagement of the students in the activities – the things they were able to build in one day were mind-blowing.”

people about science in a fun and engaging way. We are so proud to have supported the holiday workshop programme for another year, and continue to work with one of the most famous scientific bodies in the world. What better place to showcase the engineering and innovation that WMG is part of in building the future? We aimed to show people how simple it can be to start to create their own projects, whether making a smart city for the future, or controlling an embroidery machine in Margaret’s workshop. And it really showed in the engagement of the students in the activities – the things they were able to build in one day were mind-blowing.”

Professor Margaret Low, Director of Outreach and Widening Participation at WMG, University of Warwick, showed her commitment to making science accessible: “Science, engineering, mathematics, and computer science are not traditionally seen as being fun subjects to dip into. With these workshops we were able to provide an inspiring introduction for young people, and perhaps set them on a path to becoming scientists or engineers in the future. Working in partnership between a university and a public body like the Ri is a good example of how we can create opportunities for young people to discover what they want to do, and be empowered to achieve it.”

Peter Gallivan, Family Programme Manager, at the Royal Institution, explains: “Holiday Workshops at the Royal Institution are one of the main ways we work with young people, welcoming around 2,000 young people across the summer to get hands-on exploring STEM subjects. The sessions run by Margaret and Phil are some of my favourites, as they showcase how creativity and imagination are important skills used by scientists and engineers. It was a delight to see their sessions packed full of excited young scientists happily working together to solve a variety of engineering challenges. How else would you want to spend your summer holidays?!”

Find out more about WMG’s Outreach programmes here: https://warwick.ac.uk/fac/sci/wmg/about/outreach/