WMG News - Latest news from WMG

UK-based consortium established to develop prototype solid-state batteries

MOU signed between Johnson Matthey, Faraday Institution, Britishvolt, Oxford University, UK Battery Industrialisation Centre, Emerson & Renwick and University of Warwick

HARWELL, UK (19 August 2021) A consortium of seven UK-based organisations has signed a memorandum of understanding to combine ambitions to develop world-leading prototype solid-state battery technology, targeting automotive applications.

develop world-leading prototype solid-state battery technology, targeting automotive applications.

Solid-state batteries offer significant potential advantages over conventional lithium-ion batteries and could be transformational in meeting the UK’s net zero commitments through the electrification of transport. The successful outcome of the collaboration would be to harness and industrialise UK academic capability to produce cells using highly scalable manufacturing techniques that leapfrog the cost-effectiveness and performance achieved elsewhere.

The consortium comprises the following world-leading organisations in battery research, development and manufacturing:

· Faraday Institution – the UK’s independent institute for electrochemical energy storage research, which has led the consortium’s formation and will lead its development.

· Britishvolt – the UK-based Gigaplant developer, with a site in NE England.

· E+R (Emerson & Renwick) – a world leading designer of manufacturing equipment.

· Johnson Matthey – a global leader in sustainable technologies and the UK’s leading battery materials business.

· Oxford University – that leads the Faraday Institution’s solid-state battery project (SOLBAT) and provides the necessary scientific understanding to the consortium.

· UK Battery Industrialisation Centre – the pioneering battery manufacturing development facility to enable UK battery manufacturing scale-up and facilitate upskilling in the battery sector.

· WMG, University of Warwick – leaders in battery R&D and initial scale-up capability, as well as academic and apprenticeship skills development.

The preliminary design for a prototyping facility has been developed. Sources of funding are currently being sought.

Minister for Investment Lord Grimstone said: “Collaboration between industry, government and our world-leading academic institutions is putting the UK at the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

“It is the work of our internationally-renowned research and development base, like those brought together by this consortium, that will give us the tools needed to forge a strong and sustainable future for the automotive sector and increase our contribution to combatting climate change.”

“I am delighted to be able to announce the formation of this unique consortium for the advancement of solid-state battery prototyping that includes leading UK-based organisations at many stages in the value chain,” said Professor Pam Thomas, CEO of Faraday Institution. “Our leadership in this venture signals a move towards a role that the Faraday Institution will increasingly play as a trusted convener of significant partnerships between UK industry and academia as a route to commercialise breakthrough science emerging from our research programmes to maximise UK economic value.”

Solid-state batteries (SSBs) offer significant potential advantages over existing lithium-ion battery technologies, including the ability to hold more charge for a given volume (leading to increased electric vehicle (EV) range) and reduced costs of safety-management. Early deployment of SSBs is likely to be in consumer electronics, niche automotive applications and unmanned aerospace, before being used in broader EV markets. The Faraday Institution forecasts that, in 2030, SSBs are likely to take a 7% share of the global consumer electronics battery market and a 4% share of the EV battery market[1]. Global SSB revenues from sales to EV manufacturers are expected to reach $8 billion by 2030[2] and then grow rapidly to 2040 and 2050 when the market is expected to become extensive.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

The construction of the one-of-a-kind facility being developed by the collaboration will enable SSB technology to emerge from UK university laboratories. It will allow larger cells to be produced using scalable manufacturing techniques that will be improved iteratively through deep investigation of the causes of problems that emerge during manufacture and testing of prototype batteries. This will leverage the collective knowledge of Faraday Institution SSB researchers and the industrial partners.

Christian Gunther, CEO, Battery Materials at Johnson Matthey comments, “The realisation of a prototype solid-state battery cell will be a great achievement for the UK battery industry, and this consortium will be a critical enabler for delivering this milestone. Delivering enhanced range and safety over traditional lithium-ion battery technologies will be a key driver for battery electric vehicle adoption, supporting the transition to a net zero future.”

Dr Allan Paterson, Chief Technology Officer, Britishvolt comments, “Solid-state is the holy grail of battery solutions. Solid-state batteries have the potential to increase energy density significantly over battery technology available today and could dramatically, and positively, change the world of electric vehicles. Britishvolt will be at the forefront of commercialising this step change over the coming years. This collaboration, which includes major global industrial leaders such as Johnson Matthey and academic leadership from University of Oxford, underscores another key objective in our technology roadmap – home grown intellectual property.”

Professor Peter Bruce, Principal Investigator of SOLBAT, comments: “It’s fantastic to see the culmination of combined UK academic strength in solid-state battery research come to fruition. I’m proud that the work of the Faraday Institution SOLBAT project, led by Oxford University, will make a significant contribution to the UK’s green energy revolution.”

Ian Whiting, Commercial Director at UKBIC added: “Our newly opened national battery manufacturing scale up facility is already contracted to scale new cells and battery packs by companies basing their manufacturing centres in the UK. It’s a really exciting time for this fast-growing industry. We’re scaling technologies that will be the core products of the UK’s emergent Gigafactories. But we need to think even further ahead and solid-state battery technology is going to be a big part of that. This collaboration is what is needed to give the UK the edge it needs in creating a centre of excellence for solid-state batteries and we’re excited to be part of it. The bringing together of academic and industrial know how in this space is key to unlocking Britain’s electrified potential.”

David Greenwood, Professor of Advanced Propulsion Systems, and CEO of WMG High Value Manufacturing Catapult comments: “Early forms of solid-state battery are already around us, but we have yet to see solutions which are both mass-manufacturable and meet the performance and cost targets for future transport applications. There remains huge opportunity for innovation in this space, and this initiative will provide the route for the UK to fast-track candidate technologies to industrialisation.”

Andrew C Jack, Sales Director, E&R Group comments, “E&R Group are delighted to be contributing our world renowned engineering expertise working in partnership Faraday and the wider consortium on this exciting development for next generation battery production for the UK.

For more information on the Faraday Institution, visit www.faraday.ac.uk and follow @FaradayInst on twitter.

Battery ageing model developed by WMG to support all-electric vehicles

- The issue of how long a battery pack will remain in useful operation, to guarantee a warranty for an electric vehicle battery, is a challenge faced by most car manufacturers, as they haven’t been around long enough for them to know their full lifetime

- Working as part of an APC6 funded project, WMG at the University of Warwick developed a battery model capable of forecasting the battery health for realistic usage cases

- Researchers at WMG experimentally tested the batteries for several usage cases and the model predicted the evolution of battery health with 98% accuracy

Extensive research, carried out by researchers from WMG, University of Warwick included characterisation, performance, safety and degradation testing of an EV battery, with degradation being the key focus to understand the impact on battery pack warranty.

To predict the degradation of the battery capacity researchers had to build a complex battery model, incorporating the key physics that causes batteries to age. The model was capable to predict scenarios under which a battery health will gradually fade and fulfil the warranty requirements and scenarios where the battery health will suddenly decrease after a certain usage duration.

Knowing when a battery’s health, can suddenly decrease, known as the ‘knee-point’ effect is a hotly studied problem among lithium-ion battery researchers. Researchers found that, for the particular battery investigated, by avoiding deep discharges and reducing the number of fast-charging a week, enabled the battery to perform and last the expected lifetime of the battery pack.

The aged cells were subsequently disassembled and examined for failure evidences. Fully discharging the battery at different rates demonstrated a thin film to deposit on the electrode and deform the electrode causing the active material in the batteries to delaminate. These effects can bring about a sudden reduction in the battery health.

Dr Dhammika Widanalage, from WMG, University of Warwick comments:

“We worked with the project partners to understand the needs of the battery ageing model and the usage scenarios. Using the data from our laboratories, we were then able to calibrate our model and also predict the voltage response and capacity fade of the battery under new usage cases with a very high accuracy of around 98%.”

The WMG Battery School is back, and it’s virtual!

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

WMG battery experts will facilitate a mix of live lectures and pre-recorded practical hands-on-sessions, virtually, over the five days.

The lectures will cover manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical, pre-recorded in the Energy Innovation Centre, lab sessions, will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find the full lecture and demo programme and register your interest here or by email: WMGShortCourses@warwick.ac.uk

Charging ahead at Battery School

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG battery experts will facilitate a mix of lectures and practical hands-on-sessions, with the intention of inspiring the next generation of engineers into battery related careers, crucial for the UK’s electrification sector.

The lectures will cover areas including manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical lab sessions will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find out more and book your place here.

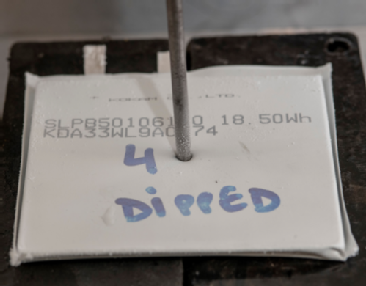

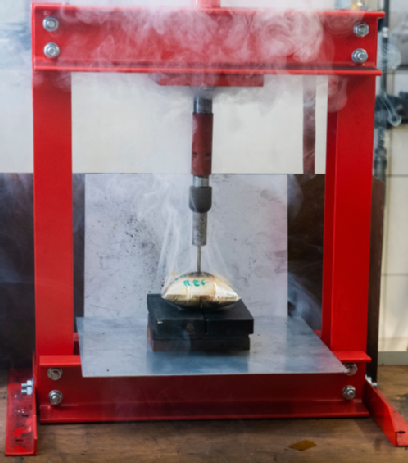

Car batteries can be frozen for safer transportation

Currently transporting damaged and defective car batteries is an expensive process as they need to be placed in an explosion proof box which costs thousands of pounds, however researchers from WMG at the University of Warwick in collaboration with Jaguar Land Rover engineers have been able to freeze batteries with Liquid Nitrogen.

An explosion proof box to transport a typical Tesla sized battery costs €10,000 and a further €10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

€10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

In the paper, ‘Cycle life of lithium ion batteries after flash cryogenic freezing’ published in the Journal of Energy Storage, researchers highlight that cryogenic freezing does not reduce lithium ion battery’s energy capacity or affect cycle or service life, and could be transported in a safer way.

As the sales of electric vehicles increases, there is more concern for the transportation of damaged and defective lithium ion battery packs. Currently, it is an expensive process, as they are put in an explosion proof box that costs €10,000 and a further €10,000 for the UN accreditation, which EV manufacturers are picking up the bill for.

Explosion boxes are used to contain the battery in case it goes into thermal runway, an overheating condition which can lead to violent explosions and toxic gases being released. However being able to cryogenically flash freeze the batteries completely removes the risk of an explosion, and could therefore mean they can be transported safely in a plastic box.

Researchers who were part of the ELEVATE project funded by EPSRC, WMG Centre High Value Manufacturing Catapult, and  supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

When being transported batteries will have to be kept in a lorry at -35 degrees, however the amount of packaging is significantly less than explosion proof boxes, making the process more sustainable.

Dr Thomas Grandjean from WMG, at the University of Warwick comments:

“Transporting damaged and defective batteries is an expensive and unsustainable process, however being able to freeze them with liquid nitrogen could save thousands of pounds and help electric vehicle manufacturers be more sustainable.

“We tested the batteries in the most extreme abuse conditions, such as driving nails through the cells and inducing external short circuits, proving that the freezing process is effective and safe.”

ENDS

2 DECEMBER 2019

NOTES TO EDITORS

High-res images available credit to WMG University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_3_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_5_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_7_.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_6.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_2_.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/untitled.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or + 44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The future of mobility: Times are changing

Times are changing

If we are to seize electrification and autonomy opportunities, it’s essential that the UK develops an environment suitable for breakthrough technologies. From domestic charging solutions to developing repeatable testing environments, the UK faces big challenges and we are addressing these through our lead centre for Vehicle Electrification and Connected and Autonomous Vehicles at WMG, University of Warwick.

Electrification shaping a low carbon future

David Greenwood – Professor, Advanced Propulsion Systems at WMG, University of Warwick

Demand for electric vehicles (EVs) is surging in the UK and registrations of plug-in cars increased by more than 160,000 between 2013 and 2018. With the electrification industry estimated to be worth over £6billion by 2025, the next decade presents a massive opportunity.

As our society continues to grow, transformation in energy and mobility is required to create sustainable environments. The electrification of transport is shaping that low carbon future. Our vision at WMG is to enable the development of cleaner, safer and smarter vehicles and help drive sustainable mobility across the UK, which aligns with the Government’s ‘Road to Zero’ strategy, aiming to make road transport emission-free by 2050. Our research focuses on establishing advanced hybrid and electrical vehicles, including commercial, rail and marine, battery technology, supply chain, manufacturing and automation.

At WMG, we’re working with the UK Battery Industrialisation Centre to deliver on the UK’s Industrial Strategy ‘Future of Mobility’ Grand Challenge to transform the UK into a world leading battery manufacturer for vehicle electrification.

Connected and Autonomous Vehicles

Siddartha Khastgir – Head of Verification and Validation, Intelligent Vehicles at WMG, University of Warwick

The global Connected and Autonomous Vehicles (CAV) industry is estimated to be worth over £50billion by 2035, with the UK CAV industry comprising over £3billion of this. The UK Government's Industrial Strategy aims to bring fully autonomous cars without a human operator on UK roads by 2021, which will make us one of the first countries to achieve this.

The CAV vision is motivated by the potential societal benefits the technology offers – increasing safety, decreasing traffic congestion and driving lower emissions. At WMG, we’re striving to deliver these through Intelligent Vehicles research exploring Verification and Validation, Communications (i.e. 5G), Experiential Engineering, Supply Chains, Cyber Security and Cooperative Autonomy.

Our involvement in research programmes like the £35m Midlands Future Mobility focuses on “smart miles”, proving concepts and getting products to market. Led by WMG, Midlands Future Mobility is an “on-road ecosystem” comprising nine partners with a shared objective – To launch the first service offering of public road testing by mid-2020.

Times are changing.

WMG partners with Triumph Motorcycles in electric motorcycle project

Triumph Motorcycles has announced a new collaboration with UK industry experts, academic leaders including WMG at the University of Warwick, and Innovate UK, to develop specialist electric motorcycle technology which will provide significant input into potential future electric motorcycle offers from Triumph. This two-year project (TRIUMPH TE-1) also includes partnership work with Williams Advanced Engineering, and Integral Powertrain Ltd.

Triumph Motorcycles has announced a new collaboration with UK industry experts, academic leaders including WMG at the University of Warwick, and Innovate UK, to develop specialist electric motorcycle technology which will provide significant input into potential future electric motorcycle offers from Triumph. This two-year project (TRIUMPH TE-1) also includes partnership work with Williams Advanced Engineering, and Integral Powertrain Ltd.

This new collaboration will combine Triumph’s globally-renowned motorcycle expertise with advanced automotive-based capabilities to generate technological innovation for future electric motorcycles.

“This new collaboration represents an exciting opportunity for Triumph and its partners to be leaders in the technology that will enable the electrification of motorcycles, which is driven by customers striving to reduce their environmental impact, combined with the desire for more economical transportation, and changing legislation,” said Nick Bloor, Triumph CEO. “Project Triumph TE-1 is one part of our electric motorcycle strategy, focused on delivering what riders want and expect from their Triumph, which is the perfect balance of handling, performance and usability.”

A unique collaboration between industry experts, academic leaders and Innovate UK

Project Triumph TE-1 now represents a ground-breaking collaboration between Triumph Motorcycles and the UK’s electrification experts, each of whom will create innovations in their own areas:

- Triumph Motorcycles will lead the project, providing advanced motorcycle chassis design and engineering expertise, manufacturing excellence and pioneering functional safety systems, as well as defining electric drivetrain power delivery characteristics.

- WMG, at the University of Warwick will provide electrification expertise, and the critical vision to drive innovation from R&D to commercial impact, through modelling and simulation based on future market needs.

- Williams Advanced Engineering will provide industry-leading lightweight battery design and integration capability, using its test and development facilities to deliver an innovative battery management system combined with vehicle control unit.

- Integral Powertrain Ltd’s e-Drive Division will lead the development of bespoke power-dense electric motors and a silicon carbide inverter, integrating both into a singular motor housing.

- Innovate UK, the government agency that promotes science and technology programmes expected to grow the UK economy, will support the partners and administer funds. This forms part of the BEIS modern funding strategy with the aim of creating a market-leading UK electric vehicle capability.

A two-year project focused on developing technical innovation and advanced electric motorcycle capabilities

The project will be organised into four main phases, with one of its key aims being increased systems integration. By developing individual components of automotive-based electric drivetrains and optimising them into innovative combined units, the project aims to deliver sophisticated electric motorcycle systems which reduce mass, complexity and package requirements.

Triumph Motorcycles will work alongside the partner organisations to accelerate joint expertise in the packaging and safety of batteries, optimum electric motor sizing and packaging, the integration of braking systems including regenerative braking, and advanced safety systems. The innovation and capabilities developed in these areas will input into Triumph’s future electric motorcycle strategy.

The Project Triumph TE-1 partnership, with the support of Innovate UK, is focused on facilitating the creation of:

- Electric motorcycle capability that meets the needs of customers seeking lower environmental impact transportation, delivering against the UK’s focus on reducing emissions

- Strong, commercially viable and sustainable partnerships with UK industry manufacturers and supply chains

- Expertise and capability within the UK workforce, creating jobs and a talent base that both ensures sustainable employment and drives the UK’s reputation and influence on the world stage.

Professor David Greenwood, Professor of Advanced Propulsion Systems at WMG, University of Warwick said: “Electric motorcycles will have a vital role to play in future transport across the globe - delivering reduced congestion and improved urban air quality as well as easing parking. They will also be great to ride, with copious, easily controlled torque delivered smoothly at all road speeds. WMG has experience of battery technology and vehicle electrification for road, rail, sea and air which it will bring to this exciting sector. Our expert team will lead the modelling and simulation work within the project, to ensure the vehicles are safe and efficient without compromise to dynamic performance.”

“The team at Williams Advanced Engineering is looking forward to applying our expertise in the electrification of transport with our partners,” said Craig Wilson, Managing Director of Williams Advanced Engineering. “Williams has powered a number of world-renowned electric vehicles already and this will be a significant further step in our work by taking that knowledge onto two wheels.”

“Integral Powertrain has always pushed the boundaries of e-drive technology working with clients to find the best solution to meet their exact requirements”, said Andrew Cross, Chief Technical Officer at Integral Powertrain Ltd. “This project will draw upon the extensive motor and EV experience gained over the past 20 years working with major OEMs and Tier 1 suppliers in the automotive and motorsport sectors. We are extremely pleased to be supporting Triumph Motorcycles with their future electrification strategy and in a project where we can apply our experience to engineer an extremely power dense, efficient and highly integrated motorcycle electric drive.”

Steve Sargent, Triumph’s Chief Product Officer said “Our future product strategy is focused on delivering the most suitable engine platforms for the changing landscape of customer needs, and we see a Triumph electric powertrain as a significant requirement alongside our signature twin and triple cylinder engines. As part of our electric motorcycle initiative, Project Triumph TE-1 represents an exciting collaboration that will provide valuable input into our future line-up. We are incredibly pleased to have the support of OLEV and Innovate UK, and to be working together with the UK’s electrification experts and academic leaders, in an endeavour that ultimately is focused on the future prosperity of British industry, and the future of motorcycling.”

PhD Students Gain Hands-On Battery Engineering Experience at WMG's Battery School

PhD students, and future battery engineers, from leading universities across the UK joined us for a special week-long Battery School at our Energy Innovation Centre, for the Faraday Institution, recently.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

Fran Long, Education and Training Co-ordinator, at The Faraday Institution, said: “The WMG Battery School, at the University of Warwick, gave our PhD students a wonderful week of detailed theory and practice with an abundance of high quality lectures and ‘hands-on’ lab sessions.

“We would like to thank all of the WMG staff involved in making this such a valuable experience for the students. Encouraging the next generation of engineers into battery related careers, is extremely important for the UK’s electrification sector.”

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is part of the Faraday Battery Challenge, along with the UK Battery Industrialisation Centre (of which WMG was part of the winning consortium).

Find out more about our Energy Innovation Centre here.

RESOLVE prototypes shape future of electric urban commuting

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The European project – named ‘Range of Electric Solutions for L-category Vehicles’ – designed and developed two stylish tilting four-wheeler prototype ELVs with leading European manufacturers Piaggio and KTM. These demonstrators were unveiled, and presented to representatives from the European Commission, at an event in Brussels in April 2018.

WMG was one of fourteen partners in the project, which included leading names from industry and research such as Piaggio, KTM, Bosch, Ricardo, the Austrian Institute of Technology, and the University of Florence.

£5.6m Vehicle-2-Grid project develops charging technology in real world

Electric vehicle charging infrastructure on UK roads is to be advanced, thanks to a new £5.6 million project – funded by Innovate UK – to develop Vehicle-2-Grid (V2G) technologies, involving WMG at the University of Warwick.

For three years from April 2018, the EV-elocity consortium will conduct a project to demonstrate and develop V2G technology across a variety of UK locations, including airports and business parks – with the aim of proving its viability and worth to business and the wider public.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Dr Marco’s team will also analyse real-world usage data from a range of different electric fleet vehicles as they are used within a V2G context.

The project will break new ground in helping consumers, businesses and infrastructure providers to financially benefit from adapting their charging behaviour and vehicle use.

In doing so, the project will help to further accelerate and incentivise the transition from traditional fuel sources to electric vehicles.