Steels - Innovation in steel research

Advanced Steel Research Centre

Advanced Steel Research Centre (ASRC)

Steel is used in every aspect of our modern lives and is the backbone of national economy. The demand of new alloys has been ever increasing while the industries face global mega trends of net zero emissions, alternative energy and materials, abundant information and cost efficiency. This requires a new way of conducting research and a new set of competence.

About our research

Our research is focused on developing low carbon low energy steel manufacturing technologies and new and improved steels. We address key issues relating to iron and steel manufacturing and applications of steel products, and conduct fundamental and applied research, from iron- & steelmaking, through to production e.g. casting, forming, coating and joining, product performance, inspection, measurement, and steel circularity.

Our expertise spreads from steel processing through steel prototyping to non-destructive testing, supported by advanced microstructural characterisation and multiscale modelling.

Our strength in steel processing lies in in-situ, inline study of high-temperature multiphase reactions under controlled atmospheres, low carbon low energy steel manufacturing technologies, scrap metal recycling, energy and materials recovery, and thermo-mechanical processing.

Our rapid alloy prototyping (RAP) allows for fast investigation of systematic variations to, or completely new, alloy systems through the combination of small-scale processing, mechanical testing and modelling. Our RAP facilities replicate all stages of processing within the steel plant, from the production of material, thermo-mechanical processing to a final product, application of coatings, mechanical testing and microstructural characterisation.

We use electromagnetic (EM) sensors to characterise steel microstructures in a non-destructive manner, including in-situ during steel processing, and provide insights into the fundamental relationship between EM signals and steel microstructure.

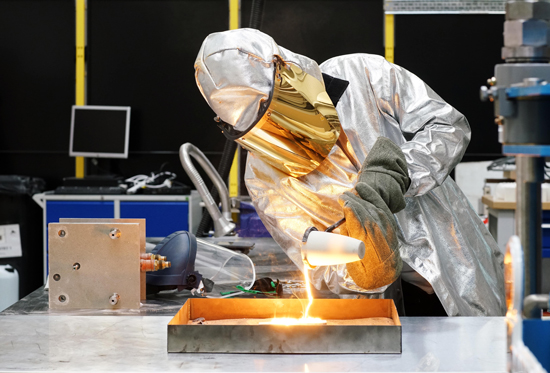

High temperature reactions

In-situ observation, detailed characterisation and advanced modelling to understand the underlying mechanisms of high temperature multiphase reactions during steel processing, by using a range of modern techniques including high temperature confocal laser scanning microscopy, controlled atmosphere furnaces (including flammable gases), droplet levitation furnace, high temperature viscometer, mass spectrometer and micro XCT.

Alternative ironmaking

Through experiment, thermodynamic/kinetic analysis and process modelling, we reveal the underlying mechanisms of high temperature slag-metal-gas multiphase reactions and investigate the use of alternative fuels such as biomass and various gas fuels in alternative ironmaking technologies (e.g. HIsarna technology).

Green hydrogen steel manufacturing

Green hydrogen may play a key role in decarbonising the steel industry. Our research focuses on revealing the mechanisms of the reactions between hydrogen and iron oxides in molten slags, effect of green hydrogen-based direct reduced iron (H-DRI) on steel manufacturing process, and mechanisms and influencing factors during H-DRI production.

Scrap recycling

Our research effectively supports the increased scrap usage in steel manufacturing. This includes artificial intelligence-based tools for improved scrap sorting and quality control, scrap melting and scrap-based EAF process for production of high-quality steel products at competitive costs, effect of residual elements on downstream processability and product quality, more circular scrap supply chain, and steel circularity. Our research extends to critical materials recovery in end-of-life EV batteries and electric machines.

Reuse and remanufacturing

Our research explores how decisions can be made on the end-of-life processing of steel components. In particular, the work is using the concept of the digital twin that will monitor data from sensors that will feed into a machine learning model to identify the way and the length of time the product was used. At the end-of-life, the usage pattern will be used to calculate remaining fatigue life of the product, which will allow decisions to be made about whether to reuse (if it was lightly used), remanufacture (if it was moderately used) or recycle (if it was heavily used) the product.

Forming and joining

Warm or cold forming as well as joining are essential processes in the production of final component parts. We focus on examination of the role of the materials on processeability; for example, formability and local strain partitioning in dual phase steels using in-situ deformation in a SEM or formation of defects and intermetallics in dissimilar (steel to aluminium, Al to Cu etc) weld joints using microscopy and X-ray tomography for 3D characterisation

Product and process characterisation

Characterisation is essential to develop understanding of behaviour and provide valuable data for modelling approaches. Our extensive characterisation facilities allow measurement of process parameters such as viscosity and phase stability, whilst microscopy can provide quantitative microstructural data over a wide range of scales and areas, texture information at high temperature, compositional mapping, high resolution imaging and localised hardness tests. Modelling is carried out using in-house developed code or commercial software packages

Coating and surface engineering

To ensure durability of engineered components coatings and surface modification are routinely applied. We work on development of new coatings and their inherent properties as well as understanding how both uncoated and coated materials perform in service, for example predicting local corrosion behaviour by advanced modelling and examining tribological behaviour.

EM Sensors

It is desirable to be able to characterise steel microstructures in a non-destructive manner, particularly in-situ during steel processing. Our research provides an insight into the fundamental relationship between electromagnetic (EM) signals and microstructure using laboratory sensor systems, commercial sensor systems and advanced magnetic domain imaging techniques as well as modelling the behaviour at different scales.

Ready to work with WMG?

Register your interest in our steel research to start the conversation with us.