WMG News

Revolutionising the manufacturing industry through digitalisation

Until now, smaller manufacturing companies have missed out on the productivity benefits of digital technologies and data-driven solutions. Too many manufacturers don’t know where to start, and lack the skills required to deploy and use digital solutions. The costs are perceived to be high and the return on investment is unclear.

A consortium, including WMG at the University of Warwick, has been awarded funding through the Government’s Manufacturing Made Smarter Challenge to tackle this problem by developing a Smart InforMation PLatform and Ecosystem for Manufacturing (SIMPLE).

Project SIMPLE will bring the benefits of digitalisation to manufacturers for whom the technology, skills, and business benefits are currently inaccessible. The project will deliver a platform that is fast to deploy, easy to use, cost-effective, and versatile. And it will be supported by an ecosystem that addresses skills and training requirements.

The consortium includes a wide range of end-user, academic, and technology partners to provide the necessary breadth of expertise:

● Innovare Systems (construction) is representative of SMEs seeking to improve their operations through the deployment of digital capabilities, but have a low skill level in the domain, bare bones IT capabilities and low levels of automation

● Lear Corporation (automotive) is representative of global organisations challenged by their operational complexity, the diversity of technologies deployed in production, fragmented software landscape and data repositories

● The UK Battery Industrialisation Centre is seeking a vendor independent solution that can support their short-term objectives and scale up rapidly to support multiple production campaigns in the future

● WMG, University of Warwick is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes

● The Science and Technology Facilities Council is a government agency that carries out research in science and engineering. The focus for project SIMPLE is on knowledge representations and knowledge models relevant to manufacturing

● Fully Distributed Systems (FDS), AI Idea Factory and 4thWall Virtual develop engineering tools, industrial software components and supply related services.

The benefits of SIMPLE will be validated via deployment of the platform at the end-user partners’ facilities - demonstrating the value in three different use cases. The deployment of a skills training system at WMG, University of Warwick, will validate the skills and training proposition.

Project SIMPLE is co-funded by the businesses in the consortium and the UK’s innovation agency, Innovate UK, through the Manufacturing Made Smarter Competition. The Industrial Strategy Challenge Fund (ISCF) Manufacturing Made Smarter Round 1 Competition offers grant funding investment in projects that focus on the use of industrial digital technologies (IDTs) to transform the productivity and agility of UK manufacturing. Of 34 applications submitted, project SIMPLE is one of 14 projects approved following independent assessment and expert review.

Dr Daniel Vera, from WMG at the University of Warwick comments:

Dr Daniel Vera, from WMG at the University of Warwick comments:

“At WMG, we will be focussing on making sure that manufacturers become fluent in deploying and using digital systems. Our training platform will mean that manufacturers can confidently use data-driven methods and digital solutions to optimise their processes, which in turn can speed up their project delivery and significantly improve their business operations.”

Jason Powell of Innovare Systems adds:

“The technology is important as it offers greater operational transparency, which allows greater scrutiny of performance whilst maintaining the production activities’ live information. Additionally, this system can also be used as a tool to drive production efficiency through optimising performance which will increase capacity. We are expecting this technology to boost productivity by 10% even from the early deployment.”

Matt Patching of the UK Battery Industrialisation Centre said:

“The SIMPLE toolset will help us deliver battery technologies and processes to industry at a rapid rate. The flexible design will be compatible with our range of manufacturing processes, ranging from electrode and cell assembly, to module and pack, and to consistently present the relevant information. The scalable nature means that new promising technologies in the battery field can be implemented into our digital systems as quickly as it can be installed at our site.”

The project will engage the wider manufacturing community to ensure the SIMPLE platform and methodology addresses the widest set of manufacturers’ needs. For further information, please contact peter.hopkinson@fullydistributedsystems.com.

ENDS

6 JANUARY 2021

NOTES TO EDITORS

About WMG, University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes.

As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG’s education programmes focus on lifelong learning of the brightest talent, from the WMG Academies for Young Engineers, degree apprenticeships, undergraduate and postgraduate, through to professional programmes.

An academic department of the University of Warwick, and a centre for the HVM Catapult, WMG was founded by the late Professor Lord Kumar Bhattacharyya in 1980 to help reinvigorate UK manufacturing and improve competitiveness through innovation and skills development.

About Innovare Systems

As the only provider to have complete design to delivery capability in-house, Innovare Systems is uniquely placed to simplify the offsite construction process to help clients manage time, cost and risk more effectively. Innovare Systems’ aim is to make it easy for clients to achieve the time and cost saving benefits of offsite construction and make full use of the greater flexibility offered through a joined-up design, manufacture and installation solution with its i-SIP panel system.

About Lear Corporation

Lear, a global automotive technology leader in Seating and E-Systems, enables superior in-vehicle experiences for consumers around the world. Lear’s diverse team of talented employees in 39 countries is driven by a commitment to innovation, operational excellence, and sustainability. Lear is Making every drive better™ by providing the technology for safer, smarter, and more comfortable journeys.

About UKBIC

The £130 million UK Battery Industrialisation Centre (UKBIC) is a pioneering concept in the race to develop battery technology for the transition to a greener future. The unique facility provides the missing link between battery technology, which has proved promising at laboratory or prototype scale, and successful mass production. Based in Coventry, the publicly-funded battery product development facility welcomes manufacturers, entrepreneurs, researchers and educators, and can be accessed by any organisation with existing or new battery technology – if that technology will bring green jobs and prosperity to the UK.

In addition to funding from the Faraday Battery Challenge through UK Research and Innovation and the Industrial Strategy Challenge Fund, UKBIC is also part-funded through the West Midlands Combined Authority. The project has been delivered through a consortium of Coventry City Council, Coventry and Warwickshire Local Enterprise Partnership and WMG, at the University of Warwick. UKBIC was created in 2018 following a competition led by the Advanced Propulsion Centre with support from Innovate UK

About Fully Distributed Systems

FDS specialises in the development and integration of control and software solutions for manufacturing industries. In the last 5 years, FDS has developed expertise in the development and deployment of Industrial IoT integration platforms and common manufacturing and production data models, in line with the requirements of Industry 4.0 and digital manufacturing solution development.

For further information please contact

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG delivers special STEM parcels to local schools

The WMG Outreach team has been making special Christmas deliveries to children across the West Midlands and Warwickshire.

The WMG Outreach team has been making special Christmas deliveries to children across the West Midlands and Warwickshire.

Young engineers from a total of 15 local schools have been sent parcels with card templates of stars, stags, sleighs and baubles; a mini laser-cut Christmas tree and 3D printed cubes, octopuses and dinosaurs.

The year five and six children were also set some special STEM challenges including creating their own 3D Christmas decorations but without the use of glue.

WMG Outreach Project Officer, Phil Jemmett explained: “These boxes use the expertise of engineers at WMG to create exciting activities to engage children with ‘engineering’ - without a car in sight. We want to provide children with a chance to see creativity and engineering as two parts of the same approach to solving a problem.

“Inside the boxes are templates to build Christmas decorations out of paper – and once they have made a few they will notice the advantages of flat-packing the items we see in shops because they won’t all fit back in the box they came from!

“Last year, this resource box was the most fun activity we worked on. It has been a bit different this year and without the help of our fantastic technicians Beth Haynes; Joe Benjamin and Ehman Altaf, it would not have been possible to laser cut or 3D print any items to go in these boxes.”

WMG Director of Outreach and Widening Participation , Professor Margaret Low added: “I’m delighted that WMG is again able to share the engineering activity boxes with local primary schools. It’s important that we work in partnership with teaching colleagues at all stages of education, to raise awareness of engineering and how it contributes to our society.”

Find out more about WMG’s Outreach programme here.

*In total 25 boxes were sent out. Local schools involved were:

· St Giles Junior School, Bedworth

· Charter Primary School, Coventry

· St Joseph, Kings Norton, Birmingham

· St Columba, Rednal, Birmingham

· St James, Rednal, Birmingham

· St Thomas More, Sheldon, Birmingham

· St Brigid, Northfield, Birmingham

· St Paul, Birmingham

· Arley Primary School, Nuneaton

· Burton Green Primary School, Coventry

· Balsall Common Primary School, Balsall Common

· Burbage Junior School

· Dorridge Primary School, Solihull

· Shottery St Andrews Primary School

· Clifford Bridge Academy, Coventry

High-rate Li-ion batteries demonstrate superior safety

As the inevitable growth of transport electrification continues, the types of batteries that will be used in such vehicles, their charging parameters, infrastructure and timeframes are key considerations that will speed up the transition to electrification.

In the paper, ‘Determining the Limits and Effects of High-Rate Cycling on Lithium Iron Phosphate Cylindrical Cells’ published in and on the cover of the Journal Batteries, researchers from WMG, University of Warwick investigated the impacts on battery cell ageing from high current operation using commercial cells.

They used two tests to establish the maximum current limits before cell failure and applied this maximum current until cell failure. Testing was performed to determine how far cycling parameters could progress beyond the manufacturer’s recommendations.

During testing, current fluxes were increased up to 100 C cycling conditions. Charge and discharge current capabilities were possible at magnitudes of 1.38 and 4.4 times, respectively, more than that specified by the manufacturers’ claims. This increased current was applied for 500 charge-discharge.

However, the application of these currents resulted in a rapid decrease in capacity in the first 60 cycles as well as an increase in resistance. Furthermore, the application of such currents resulted in the increase of cell temperature, during both charge and discharge with natural convection during the rest step cooling the cell. Batteries operate in an optimum temperature range, and any deviations outside this can cause components and chemicals to start decomposing inside them.

They also identified deformation of the “jelly roll” (coiled electrodes and separator) with formation of lithium plating from testing and ageing. These deformations emanate from the centre of the cell in an axial direction towards the outside of the cell, suggesting the core of the cell was the hottest.

Lead Engineer, Justin Holloway, from WMG, University of Warwick comments:

Lead Engineer, Justin Holloway, from WMG, University of Warwick comments:

“The testing showed there is a window for operating batteries above manufacturer stated current limits, however, whilst maintaining manufacturer stated voltage limits. We need to ensure that batteries operate in as the safest manner possible, and for an appropriate practical lifetime, which is why the manufacturers have these limits.

“We also identified thermal fatigue as the driving mechanism for jelly roll deformation. With each cycle of charge and discharge, the cell experienced thermal stresses causing deformation of its components. These deformations grew progressively with cycle number, while the jelly roll was constrained mechanically by the rigid outer can and centre pin.

“If convection cooling could be applied to the centre of the cell where the cell was the hottest, these deformations could be mitigated and controlled, allowing the cell to maintain capacity and resistance criteria for longer.”

The researchers would like to thank all involved in this work, including WMG’s High Value Manufacturing Catapult and The Faraday Institution. WMG’s Battery Forensic Group, led by Dr Mel Loveridge is keen to engage with industry and academia alike to grow advances in understanding new materials, battery performance and degradation modes.

ENDS

14 DECEMBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/december_2020/justin_holloway.jpg

Caption: Justin Holloway, from WMG, University of Warwick

Credit: WMG, University of Warwick

Paper available to view at: https://www.mdpi.com/2313-0105/6/4/57/pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG supports key Midlands Manufacturing report

WMG Centre HVM Catapult was pleased to contribute a chapter to the recent Midlands Manufacturing Resilience Commission (M2R) report: Manufacturing Confidence.

WMG Centre HVM Catapult was pleased to contribute a chapter to the recent Midlands Manufacturing Resilience Commission (M2R) report: Manufacturing Confidence.

Led by M2R Chairman, Dr Clive Hickman, the Commission gathered evidence from a series of roundtables, surveys and contributions from some 200 participants from industry, academia and Government, including WMG’s Professor of Operations and Supply Chain Strategy, Jan Godsell.

The various discussions centred around key issues impacting Midlands’ manufacturing including skills, productivity, supply chains, leadership, innovation and finance, plus the region’s identity and reputation now and in the future.

This work culminated in “Manufacturing Confidence,” which shares the findings of those discussions, supported by a series of independently authored chapters focusing on key themes.

CEO WMG centre HVM Catapult and Director of Industrial Engagement, Professor David Greenwood authored the Manufacturing Business Support section of the report. This chapter considered the specific needs of Midlands Manufacturers, with one of the recommendations being the provision of a ‘one-stop-shop’ for business support focusing on sustainability, innovation and skills development.

An official launch event took place, virtually, on 2nd December, with presentations from Andy Street, Mayor of the West Midlands; Nadhim Zahawi MP and Hannah Boardman, Director, Advanced Manufacturing, BEIS.

Download the report here.

WMG's Professor David Greenwood responds to the Government’s new climate target plan that was announced today

Professor Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement, comments:

Professor Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement, comments:

"Today’s announcement, alongside the previously announced Ten Point Plan for a green industrial revolution, shows that the UK intends to take a leading role in decarbonisation, and to reinvigorate our economy in doing so. Delivering this will not be easy, but this clear and consistent policy is an essential first step.

“The decarbonisation of the transport sector will be a major contributor to delivering on this challenge. The current generation of EV technology performs well in passenger cars but remains too expensive for many people, and the cost of the battery is the biggest factor in this. To reduce costs, two things must happen – significant investment in fast charging infrastructure, meaning that battery sizes can be reduced, and sustained investment in R&D into the technology of batteries and their manufacturing processes.

“Beyond passenger cars there are great opportunities for the UK in micro-mobility (e-bikes, scooters, motorcycles and small vehicles), low carbon freight, rail, maritime and aviation. To ensure sustainability of the products we roll out today, we must also be investing in the technologies of recycling and re-use of their component parts – and these too will present industrial opportunities for the UK to secure material supply chains and minimise environmental impact.

“To ensure our innovation investment benefits Britain’s economy, we need a clear action plan to expand and strengthen our transport supply chain. This includes supporting skills and retraining, widening access to finance, improving the industrialisation of innovation and attracting manufacturing investment to the UK.

"Investment in the industries and people striving to make transport zero carbon is the only way that we will achieve a green transport future that is convenient for its users and achieves long term sustainability."

WMG partners with Pashley Cycles and a team of UK SMEs to bring a novel e-assisted cargo trike to market

WMG is collaborating with Pashley Cycles and three other SMEs across the Midlands to develop an electrically assisted, last mile delivery trike. The trike features an innovative tilting suspension system which will provide greater stability on corners (and therefore speed and manoeuvrability) than a conventional tricycle configuration of the same size.

Supported and part-funded by the Niche Vehicle Network, through a “Production Readiness” funding call, the Articulating Lightweight Electrically-assisted Cargo Solution (ALECS) project, will form the platform for a new generation of configurable products to meet the rapidly growing market for zero-emission last mile cargo vehicles.

Project Manager, Dr Alex Attridge, explained: “This project provides a fantastic opportunity for WMG to apply its knowledge and expertise in vehicle electrification, and in product testing and evaluation, to a real-world product development process, helping a consortium of UK SMEs bring a new, zero-emission delivery vehicle to a rapidly growing market.”

ALECS is designed to carry cargo on a versatile and customer configurable, multi-functional rear platform. It is particularly suited to parcel and package deliveries in an urban environment where fast and efficient multiple deliveries are the key to success.

The consortium brings together the engineering and simulation capabilities of Simpact Engineering, with the high strength, lightweight tubing expertise of Reynolds Technologies, and the composite panelling and cargo structures expertise of Foresight Innovations. Coupled with Pashley’s heritage and capability in the personal mobility, mobility as a service, and cargo cycles markets, and WMG’s knowledge and experience in progressing innovation through the TRL levels into finish products, the project is set to be completed in April 2021.

One of the seven High Value Manufacturing Catapult centres, WMG brings a number of key technical capabilities to the project. These specifically include the development of photorealistic visualisations (in the form of still renders and interactive digital models) of the concept, and the delivery of digital design review content for both desktop and virtual reality environments. WMG is also responsible for the modelling and optimisation of the production facilities in an immersive, digital environment, utilising large scale laser scanning technology and the latest game engine software. Finally, as the consortium begins the physical testing stage, we will be responsible for the instrumentation of prototype and pre-production vehicles, and the subsequent data acquisition and analysis.

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

WMG's Margot James and Professor David Greenwood respond to the news that Britishvolt will be establishing their UK headquarters and R&D centre in Warwickshire

WMG, at the University of Warwick, welcomes the news that Britishvolt will be establishing their UK headquarters and R&D centre on the MIRA technology park in Warwickshire.

This move underlines the Midlands region's role as the UK's leading innovator in battery technology, building on investments and expertise at WMG and the UKBIC.

WMG’s Executive Chair, Margot James, said: “The West Midlands has a strong position in battery research and innovation, and in the future we aim to take a key role in battery manufacturing. Britishvolt's recent announcement is further affirmation of the region's capability.”

Professor David Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement adds: “The establishment of large scale battery manufacturing in the UK is critical to retaining and growing the UK car industry. With such a facility in place, this opens up opportunities for both upstream and downstream supply chain companies.”

WMG Assistant Professor joins Micromobility Research Fund

WMG Assistant Professor of Human Factors, Roger Woodman, has been selected to join the Micromobility Research Fund set up by the Ford-owned e-scooter firm Spin.

WMG Assistant Professor of Human Factors, Roger Woodman, has been selected to join the Micromobility Research Fund set up by the Ford-owned e-scooter firm Spin.

Roger is one of only 12 academics selected to join the panel made up of experts from ten leading UK and US universities and industry. Together they will study various safety aspects of e-scooter use as well as rider behaviour, and the challenges and opportunities of the integration within a city’s road systems and existing public transport networks.

Roger Woodman explains: "Ultimately, the point of introducing e-scooter schemes is to advance our society and to bring a greater benefit to all, not just to the e-scooter riders and the service providers but to all who live in our towns and cities. Just as with many new services, this will require ongoing reflection and review from everyone, including the general public and stakeholders and the path may not always be straightforward. I’m confident that building a strong body of independent research will allow policy makers, e-scooter advocates, as well as sceptics, to advance the dialogue and put forward legislation that best supports everyone.”

Josh Johnson, Public Policy Manager at Spin, adds: “The willingness to share independent research and learnings about the adoption of e-scooters with key stakeholders has become less of a priority for operators and this needs to change. Spin is committed to improving and advancing micromobility policy frameworks globally in the markets we operate in. These studies will give everyone fresh and actionable insights. We look forward to sharing best practices with stakeholders in the UK and beyond around how to best integrate e-scooters into local transport networks while maximising safety of all road users and provide communities with a green, fun and socially-distanced way to travel.”

Safe travel behaviour will be at the centre of research topics and will build on Spin's solid research-based policy work developed in the US over the past two years.

Josh adds: “Our top priority has always been rider safety. All operators have a responsibility to their riders to not only exceed vehicle safety standards but provide a platform to educate riders on safety best practices and how to be mindful of pedestrians and other road users.”

Preparation for the first piece of research is under way in Milton Keynes. This study will explore factors that influence road-user safety including:

● Where do e-scooter users ride most often (cycle lane, roadway, pavement) and why?

● How often do safety incidents occur, and what are common factors?

● What factors or conditions (i.e. cycling infrastructure, weather, traffic volume, etc…) impact real or perceived safety of e-scooters for users and for non-users?

The study will be informed by a diverse set of data sources including qualitative and quantitative consumer survey data and on-street AI and IoT sensor data of e-scooter interactions with pedestrians, cyclists and cars captured by Vivacity Lab’s sensors that are installed in the city. The researchers will also have access to anonymised e-scooter movement data (GPS).

Vivacity’s roadside sensors employ machine learning algorithms to detect near-miss incidents and are able to analyse movement patterns of vulnerable road-users such as cyclists and pedestrians, as well as non-connected vehicles. Such data will be invaluable to assess why near-misses may happen and what could be possibly done to minimise them. All data shared by the sensors is anonymised with video feeds discarded at source, enabling safer roads without intruding on privacy.

The research may include outputs such as a mapping of “safe routes” based on riding patterns and user feedback, and recommendations on how local authorities and operators could encourage riders towards a safer use of e-scooters. Recommendations may also include infrastructure improvements or other policy changes to enhance roadway safety for all users.

Find out more about WMG’s Human Factors research here.

The ultimate conditions to get the most out of high-nickel batteries

It is common knowledge in battery manufacturing that many cathode materials are moisture sensitive. However, as the popularity of high nickel-based battery components increases, researchers from WMG, University of Warwick have found that the drier the conditions that these cathodes are stored and processed in, then significant improvement in performance of the battery is gained.

High-Ni (Nickel) batteries are becoming increasingly popular worldwide, with more automotive companies investigating the use of high-Ni batteries for electric vehicles.  However, high-Ni cathode materials are prone to reactivity and instability is exposed to humidity, therefore how they are stored in order to offer the best performance is crucial.

However, high-Ni cathode materials are prone to reactivity and instability is exposed to humidity, therefore how they are stored in order to offer the best performance is crucial.

In the paper, ‘The effects of Ambient Storage Conditions on the Structural and Electrochemical Properties of NMC-811 Cathodes for Li-ion batteries,’ published in the journal Electrochimica Acta, researchers from WMG, University of Warwick propose the best way to store high-nickel cathodes in order to mitigate premature degradation.

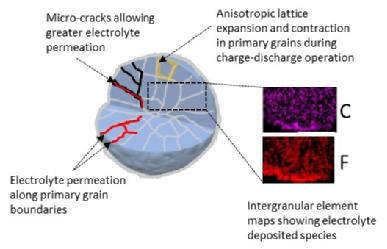

Researchers exposed NMC-811 (high-Ni cathode material) to different temperatures and humidities, then measured the material’s performance and degradation in a battery over a 28 day period, analysing them using a combination of physical, chemical and electrochemical testing. This included high-resolution microscopy to identify the morphological and chemical changes that occurred at the micron and sub-micron scale during the batteries charging and discharging.

The storage conditions included vacuum oven-dried, as exposed (to humidity) and a control measure. Researchers looked for surface impurities, which include carbonates and H2O, and found there were three processes that can be responsible for impurities, including:

1. Residual impurities emanating from unreacted precursors during synthesis

2. Higher equilibrium coverage of surface carbonates/hydroxides (present to stabilise the surface of Ni-rich materials after the synthesis process)

3. Impurities formed during ambient storage time

They found that in all conditions, (oven dried and as-exposed) showed inferior first discharged specific capacity and cycling performance, compared to the control. However the as-exposed measure showed that after 28 days of ambient moisture exposure the H2O and CO2 react with the Li+ ions in the battery cell, resulting in the formation of lithium carbonate and hydroxide species.

The formation of carbonates and oxides on the surface of NMC-811 contribute to the loss of the electrochemical performance during ageing of the materials, due to the inferior ionic and electronic conductivity, as well as the electrical isolation of the active particles. This means that they can no longer reversibly store lithium ions to convey “charge”. SEM analysis confirmed the inter-granular porosity and micro-cracks on these aggregate particles, following the 28 days of ambient exposure.

The formation of carbonates and oxides on the surface of NMC-811 contribute to the loss of the electrochemical performance during ageing of the materials, due to the inferior ionic and electronic conductivity, as well as the electrical isolation of the active particles. This means that they can no longer reversibly store lithium ions to convey “charge”. SEM analysis confirmed the inter-granular porosity and micro-cracks on these aggregate particles, following the 28 days of ambient exposure.

They can therefore conclude that the driest conditions, at dew points of around -45 oC, are the best for storing AND processing the materials, in order to then produce the best battery performance. Humidity conditions and exposure at junctions along the manufacturing process will cause the materials and components to experience; this results in shorter battery lifespan.

Dr Mel Loveridge from WMG at the University of Warwick comments:

“Whilst moisture is well known to be problematic here, we set about to determine the optimal storage conditions that are required to mitigate unwanted, premature degradation in battery performance. Such measures are critical to improve processing capability, and ultimately maintain performance levels. This is also of relevance to other Ni-rich systems e.g. NCA materials.”

Professor Louis Piper from WMG at the University of Warwick adds:

“Considerable global research effort will continue to focus on these materials, including how to protect their surfaces to eliminate risks of parasitic reactions prior to incorporation into electrodes. In the UK, leading research by the Faraday Institution has a project consortium entirely devoted to unravelling the degradation mechanisms of such industry-relevant materials.”

ENDS

18 NOVEMBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/the_effects_of_ambient_air_storage_on_the_surface_stability_of_nmc-811.jpg

(1) Caption: The effects of ambient air storage on the surface of NMC-811

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/post-mortem_nmc811_particle.jpg

(2) Caption: a-b) Post-mortem NMC811 particle, with no prior exposure to moist air, analysed by FIB-SIMS, targeting Lithium detection. c-d) Post-mortem NMC811 particle, after 28 days exposure to moist air, analysed by FIB-SIMS, targeting Lithium detection.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/schematic.jpg

(3) Caption: Schematic illustration of particle breakdown during charge-discharge of a battery

Credit: WMG, University of Warwick

Paper available to view at: https://www.sciencedirect.com/science/article/pii/S0013468620317515?via%3Dihub

WMG Centre HVM Catapult hosts ’System Safety and Accident Analysis conference

WMG Centre HVM Catapult was proud to host the first virtual European STAMP Workshop and Conference (ESWC) from 21st-22nd October.

The conference focussed on safety analysis of complex systems in diverse domains including self-driving cars, marine, aviation and healthcare. The conference brought together researchers and practitioners to hear more about Systems-Theoretic Accident Model and Processes (STAMP).

The conference focussed on safety analysis of complex systems in diverse domains including self-driving cars, marine, aviation and healthcare. The conference brought together researchers and practitioners to hear more about Systems-Theoretic Accident Model and Processes (STAMP).

STAMP is a new accident causality model based on systems theory, increasing our understanding of why complex systems fail, and helping to make them safer by predicting accidents and analysing hazards.

The varied agenda featured world-leading speakers from General Motors, Thales, Ansys, Codethink, as well as experts from the Intelligent Vehicles research group at WMG.

Presenters included Dr John Thomas from Massachusetts Institute of Technology and Professor Nancy Leveson (at MIT) who have introduced STAMP methods (STPA and CAST) to the world.

Over 300 people attended over the two days from more than 30 countries, including Japan, South Korea, Israel, Turkey, UAE, USA, Sweden, Finland, France, Russia and the UK, with diverse representation from both academia and business.

WMG has also been selected by the European conference steering committee to host the 9th European STAMP Workshop and Conference (ESWC) in October 2021. This is the first time the conference will be physically hosted in the UK, providing a valuable opportunity to showcase the UK’s world-leading capabilities in complex systems like Connected and Automated mobility (CAM) technology and systems, Electric Vehicles, Aviation and Marine.

Find out more about STAMP and WMG System Safety research here or contact Dr Siddartha Khastgir.

To register your interest in the 9th European STAMP Workshop and Conference (ESWC) in October 2021 click here.