WMG News

UK aims to be the first Country in the world to circulate steel and aluminium fully, supported by the CircularMetal programme

§ The UKRI National Interdisciplinary Circular Economy Research Programme aims to create a sustainable circular economy for lots of different industries, including metals

§ Metals and metal products create 10-20% of all the world’s harmful impacts, such as greenhouse gas emissions and pollution and energy consumption; we cannot do without goods made from metals; so we must learn how to make their use circular, i.e. extend their lifetimes and increase their repair, re-use and recycling

§ The Interdisciplinary Centre for Circular Metals aims to accelerate the transition from the current largely take-make-waste linear economy to full metal circulation by conducting high quality research and innovation through a systems approach. Its ambition is to make the UK the first country to realise full metal circulation (at least for the high-volume metals – steel and aluminium) by 2050. This will form an integral part of the government’s efforts to achieve Net Zero by 2050

§ To deliver the CircularMetal research programme, WMG at the University of Warwick will conduct inter-disciplinary research on steel production, recycling technologies, remanufacturing of steel components, and artificial intelligence in scrap separation

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The UKRI has established five Interdisciplinary Circular Economy Centres in the UK, coordinated by the Circular Economy Hub (CE-Hub), which together form the NICER Programme, a £30 million investment on research aimed at developing a circular economy in the UK, One of these CECs is CircularMetal, the Interdisciplinary Centre for Circular Metals, led by Brunel University London, with partners from WMG, University of Warwick, University College London and Loughborough University.

The ultimate aim of the group is to make the UK fully circulate all their steel and aluminium, thereby minimising or eliminating the extraction of raw materials and the production of waste.

WMG, at the University of Warwick, will specifically research steel, including opportunities for reuse and the technologies for scrap sorting to increase recyclability, working with partners in the project on business model supply chains and the economy and policy surrounding them.

The Interdisciplinary Centre for Circular Metals is a four-year project, which started in January 2021 thanks to £4.2m funding from UKRI. Discussions within the team on strategies to reuse / recycling / reduce / remanufacture / recovery and the technological barriers are on-going with input being provided to government groups.

Professor Claire Davis, from WMG, University of Warwick comments:

“To be part of the Interdisciplinary Centre for Circular Metals is incredibly exciting, especially in light of COP26, as the potential that a circular economy for metals could have towards meeting goals of sustainability and furthermore preventing climate change.

“At WMG, University of Warwick we hope to research how technology can help us to reuse and recycle steels, for example, understanding the end of life condition of steel components to determine whether and how they can be used, and using artificial intelligence to increase scrap recyclability.

“If metals can be fully recycled and reused the need to extract raw materials to make them in the first place could be eliminated, and the current workforce in the metals industry could be reskilled to work in recycling and repurposing metals.”

Professor Brian Cantor, Deputy Director, The UKRI Interdisciplinary Centre for Circular Metals BCAST, from Brunel University comments:

“Metallic materials are the backbone of manufacturing and the fuel for economic growth. They underpin the competitive position of almost every industrial sector and, including metal manufacture and downstream product processing, they collectively contribute 15-20% of all greenhouse gas emissions, pollution and energy consumption. Transformation of the metals industries from the current largely linear economy to a circular economy will, therefore, play a critical role in delivering the government’s industrial strategy for clean growth, doubling of resource productivity and reaching net zero carbon emissions in 2050.

“CircularMetal is focused on helping the UK become the first country to realise full metal circulation, concentrating on the two main bulk metals aluminium and steel, and the three main industrial sectors of transport, construction and packaging.”

ENDS

22 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture1.jpg

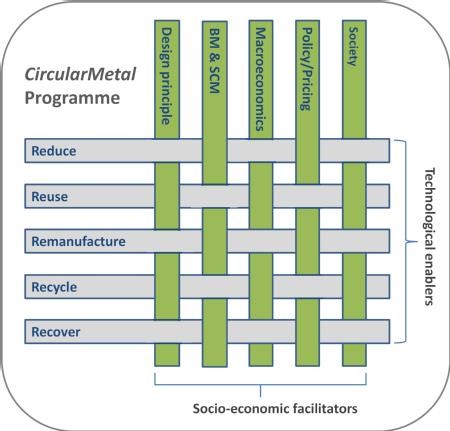

Caption: A graphic of the factors considered in the CircularMetal programme

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture2.jpg

Caption: The building the Warwick arm of the CircularMetal project are based in at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Wall climbing robot can reduce workplace accidents

- A wall climbing robot made by HausBots can reduce workplace accidents, as it can be used for inspection and maintenance tasks such as building and infrastructure inspection and surveying or even painting.

- However, to make sure the robot itself would work and is safe to use researchers from the WMG SME group helped the local business design and test the robot

- The robot is now on the market, after a four-year journey from a garage in Bournville to Singapore

A novel wall climbing robot, built designed and created by Birmingham based HausBots with the help of WMG at the University of Warwick is on the market, and could reduce the number of workplace accidents.

A novel wall climbing robot, built designed and created by Birmingham based HausBots with the help of WMG at the University of Warwick is on the market, and could reduce the number of workplace accidents.

HausBots is a Birmingham based company who are on mission to use technology to protect and maintain the built environment. They have designed, built and created an innovative wall-climbing robot, that can climb vertical surfaces and be used for inspection and maintenance tasks such as building and infrastructure inspection and surveying or even painting.

The idea of the HausBots started in the co-founder’s garage, and with the help of the WMG SME team the robot was bought to life, as the team were able to help with building the prototype and testing the technology.

Four years ago, when the first prototype was developed researchers at WMG, University of Warwick worked with HausBots on the circuit motor controls and designed the system to help them get production ready thanks to the Product Innovation Accelerator scheme with CWLEP.

One the key uses of the HausBots is to help reduce the number of workplace accidents, in the US 85,000 workers fall from height every year, of which 700 of them will be fatal. The accidents also cost insurance companies over $1bn in claims every year, therefore not only does reducing the amount of accidents mean less injuries and trauma, but also means there’s a huge economic saving.

However, to ensure the robot itself doesn’t fall it had to undergo extensive electro-magnetic compatibility (EMC) testing to make sure the fans, which essentially attach it to the surface are functioning correctly.

The WMG SME team tested the robot by placing it in the EMC chamber and assessing how it responds to noise and to make sure it didn’t emit any unwanted noise into the atmosphere itself. Using amplifiers to simulate noise and analysers, the researchers were able to detect any unwanted interference and emissions with the robot and record results.

Dr David Norman, from the WMG SME group at the University of Warwick comments: “It has been a pleasure to be with HausBots and help them develop their product, the concept of the robot is incredible, and could save lives and reduce the number of workplace accidents.

“Our facilities and expertise have helped HausBots develop a market-ready product, which is now on the market and has carried out many jobs from painting and cleaning the graffiti off the spaghetti junction in Birmingham. We hope to continue working with them in the future and can’t wait to see where they are this time next year.”

and cleaning the graffiti off the spaghetti junction in Birmingham. We hope to continue working with them in the future and can’t wait to see where they are this time next year.”

Jack Crone, CEO and Co-Founder of HausBots comments:

“The WMG SME group have helped us from day one, by helping us build the prototype all the way to making sure the robot safely sticks to the wall and carries out its job efficiently.

“We have worked tirelessly over the last 3 years to make HausBot, and we are incredibly excited to have sold our first one to a company in Singapore, we hope this is the first of many that will also help reduce numbers of workplace accidents.

“Going forward we hope to continue our work with WMG at the University of Warwick to make more robots for other uses that can reduce harm to humans.”

ENDS

14 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/graffiti_1.png

Caption: The HausBot robot in action covering up graffiti

Credit: HausBot

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/hausbot_house.png

Caption: The HausBot robot in action painting a house

Credit: HausBot

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/hausbot_in_action.jpg

Caption: The HausBot robot in action

Credit: HausBot

Video available to view at:

https://www.youtube.com/watch?v=b_hoPocYGAo

Caption: The robot covering up graffiti

Credit: HausBot

https://www.youtube.com/watch?v=VxDWJyLgBdM

Caption: The Robot in action in many ways

Credit: HausBot

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Challenges of transport electrification skills to be addressed by Universities of Warwick and Newcastle

Two leading universities in the field of electrification – WMG at the University of Warwick and Newcastle University – are coming together to ensure the UK workforce has the skills necessary to meet the challenges of the transition to fully electric production.

Two leading universities in the field of electrification – WMG at the University of Warwick and Newcastle University – are coming together to ensure the UK workforce has the skills necessary to meet the challenges of the transition to fully electric production.

As anchor higher education institutions with exceptional research and innovation programmes operating in regions at the forefront of the UK’s electric revolution, the universities intend the collaboration will enable the growth of a talent pipeline of graduates and postgraduates into UK business. Led by WMG at the University of Warwick and Zero Carbon Futures at Newcastle University part of the school of engineering, the effort will identify the people, skills and facilities needed across a range of academic disciplines and levels in order to deliver new curriculums to meet growing industry demand.

The UK’s move to fully electric vehicle production and domestic battery manufacturing represents the largest shift in industrial skills for the UK in a generation, leaving competency gaps at all job levels, particularly in engineering and manufacturing roles which will need to be filled with specific education and training. The Faraday Institution estimates that to meet automotive production demand by 2040, an additional 70,000 skilled employees will be needed for battery manufacture and in the associated material supply chain.

“In light of COP26, which stressed the need for electrification to help us combat climate change and reach Net Zero goals, it is imperative that researchers and industry work together to bridge the gaps and create a smooth transition to electrification,” commented Dr Benjamin Silverstone from WMG, University of Warwick. “We are delighted to be working with Newcastle University and believe that together we can define what and who needs upskilling, reskilling and new-skilling.”

and industry work together to bridge the gaps and create a smooth transition to electrification,” commented Dr Benjamin Silverstone from WMG, University of Warwick. “We are delighted to be working with Newcastle University and believe that together we can define what and who needs upskilling, reskilling and new-skilling.”

Professor Colin Herron CBE, Zero Carbon Futures at Newcastle University and Faraday Institution North East regional liaison said, “The bringing together of the two leading universities in electrification, located in the two regions leading on transport electrification is an exciting prospect, and one which should deliver the skills required for massive challenges ahead.”

“We fully support this collaboration between two powerhouse institutions working at the forefront of electrification,” said Professor Pam Thomas, CEO, The Faraday Institution. “Such innovative partnerships will enable the UK to anticipate and deliver the skills needed to fully electrify transport, grow new talent for battery production, and support green growth and economic development."

Another key objective of the collaboration is to help shape national and regional skills strategies and in so doing support national and regional economic development. The call for a collaborative approach to re-skilling, up-skilling and new-skilling the workforce for the electric revolution was published in a report by WMG, University of Warwick, the Faraday Institution and the High Value Manufacturing Catapult ‘The Opportunity for a National Electrification Skills Framework and Forum’ in September 2021.

ENDS

14 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wmg_ukbic-33.jpg

Caption: A battery pouch made at WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/d2807-27.jpg

Caption: A battery production line at WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wmg_ukbic-49.jpg

Caption: A battery production line at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Festive outreach gifts for young engineers

The WMG Outreach team has been making special Christmas deliveries to children across the West Midlands and Warwickshire.

A total of 45 festive STEM parcels have been delivered to young engineers at primary schools, community groups, Coventry’s Hospital Education Service, Coventry Transport Museum and IntoUniversity.

IntoUniversity.

Each parcel contained printed templates of Christmas-themed decorations on a flat sheet of card, along with instructions and a link to a video tutorial.

Phil Jemmett, WMG Outreach Project Officer, explained: “The activity teaches young people how 3D objects can be made from flat materials. This is often how real-world items are made and stocked in shops because it takes up so much less space. We’re all used to the idea of ‘flat-pack’ now – it's time to show young people why it’s so common.

“To cement the learning for our young audience, there is a final challenge! This is a creative activity where students design and make their own 3D item from paper or materials. The children then bring all their creations together around a central stand to make a festive display.”

Sophie Meeson, Brown Owl at Berkswell Brownies Brown Owl said: “Berkswell Brownies were thrilled to use the Christmas-in-a- box resource. The children enjoyed seeing their hard work become a 3D final product, and it was a great way of combining reading comprehension skills with fine motor skills and problem solving to ensure they had made the necessary cuts and folds for their final piece to fit together. Being able to tie it into our Christmas craft evening was a bonus for the leaders too, fitting the theme perfectly. Our thanks go to the outreach team at WMG.”

Professor Margaret Low, WMG’s Director of Outreach and Widening Participation added: “These boxes are only possible thanks to the support of our staff designing the items in the boxes, packing and delivering boxes to their local schools, as well as the support of WMG and the High Value Manufacturing Catapult. The contributions of our entire team, during a busy festive period, show our commitment as a department to inspiring the next generation of engineers.”

All of the resources are also available online for free here: www.warwick.ac.uk/wmgoutreach/resources/flatpack

Heritage locomotive project picks up steam thanks to WMG

WMG’s SME Team has been supporting 3D Heritage and The A1 Steam Locomotive Trust (A1SLT) in their quest to revive steam rail travel.

3D Heritage and The A1 Steam Locomotive Trust’s (A1SLT) plan was to build a brand new Gresley class P2 steam locomotive, No. 2007 Prince of Wales at its Darlington Locomotive Works (DLW). The original class P2s were designed by Sir Nigel Gresley to haul trains on the arduous Edinburgh to Aberdeen route, however sadly the design was never fully developed to its full potential.

its Darlington Locomotive Works (DLW). The original class P2s were designed by Sir Nigel Gresley to haul trains on the arduous Edinburgh to Aberdeen route, however sadly the design was never fully developed to its full potential.

With new technology and expertise, they decided to resurrect the class P2s and bring their dream to life. However, there were some design and materials challenges, specifically with the original Lentz valve gear and cambox, that needed to be resolved.

WMG’s Innovation Manager, Dr Paul Lansdell, worked with the 3D Heritage and the Trust to create a CAD model that could be tested and amended. He also recommended the use of 3D printing in ABS plastic to create a one-third scale model of the cambox for the team to see if any changes were required before committing to manufacture. The box also featured a series of windows that enabled the engineering team to see what was happening with the valve mechanism on the inside.

Following the creation of the model, Dr Lansdell went on to explore the material grades, surface coatings and heat treatment which previously caused issues. This work has been extremely transformative, giving the project huge advantage for making reliable and durable valve gear. He has gone on to explore the use of 3D printing to create sand moulds to manufacture various parts of the locomotive. Developing patterns for sand casted metal parts can be extremely expensive and if there is an issue with the casting of the part it can be costly to start the process again.

Martin Shepherd, Director of 3D Heritage said: “WMG’s support on this project has been invaluable. The advice we have received from Dr Lansdell has enabled us to look at options that we never would have considered before that have the potential to save the project tens of thousands of pounds.”

Martin Shepherd, Director of 3D Heritage said: “WMG’s support on this project has been invaluable. The advice we have received from Dr Lansdell has enabled us to look at options that we never would have considered before that have the potential to save the project tens of thousands of pounds.”

Dr Paul Lansdell, explained: “I have been honoured to work on this prestigious project which has allowed us to apply leading edge research and new techniques on a real-world business case.”

To find out more about the project contact Paul Lansdell: wmgsme@warwick.ac.uk

Virgin Media O2-led consortium wins DCMS “Diversifying the 5G Supply Chain” competition

· The “5G DRIVE” (Diversified RAN Integration & Vendor Evaluation) programme has been selected by the DCMS to support new 5G vendors to enter the market.

· The “5G DRIVE” (Diversified RAN Integration & Vendor Evaluation) programme has been selected by the DCMS to support new 5G vendors to enter the market.

· The consortium will develop a low cost and secure 5G Open & Diversified RAN Integration solution for private networks.

· It will also include a ‘Vendor Evaluation’ phase for RAN vendors to test their networks against the delivered solution.

· The consortium also consists of CISCO, Ori Industries, WMG at the University of Warwick, & wavemobile Ltd.

Wednesday 8th December: A consortium led by a team from Virgin Media O2 has won a DCMS grant to explore possible Open RAN solutions and encourage 5G vendor diversity. The winning project team also featured technology giant CISCO; global edge platform Ori Industries; the University of Warwick who will ensure the security of the platform; and rural network provider, operator and hardware vendor, wavemobile Ltd.

The “5G DRIVE” programme created by the consortium aims to enable a wider ecosystem of vendors to connect their 5G Private Networks to major networks securely. By providing a low cost, secure integration solution powered by a multi-access edge computing capability, which includes vendor evaluation services, the 5G DRIVE programme will pave the way for future deployment at scale.

The research will take place at the Harwell Science and Innovation Park, where Virgin Media O2 has a 5G Private Network and lab facilities. This will avoid compromising the main operational mobile network. The team will use the N32 Interface and an IPX to manage the security rule set before the traffic enters the Virgin Media O2 network.

Ultimately, the 5G DRIVE programme will support the development of an Open RAN ecosystem by encouraging more third party vendors to produce RAN solutions. This will also be done by enabling enterprises to leverage global cloud cores with a diverse set of O-RAN based radio vendors pre-integrated both at a 3GPP protocol level, and at a management level.

Jeanie York, Chief Technology Officer at Virgin Media O2 said: “The development of high performance 5G Open & Diversified RAN solutions is crucial to the continued rollout and densification of 5G networks across the UK. I’m very proud of the project team who worked tirelessly to deliver the winning submission, and we look forward to working with our partners to bring this to life alongside the DCMS.”

Shaun McCarthy, VP World Wide Sales, Mass-Scale Infrastructure Group at Cisco said: “There will be many cases where 5G should not be a stand-alone solution. Our partners in 5G DRIVE understand to ensure optimal performance, we need to be able to build 5G solutions to scale - securely and efficiently. Cisco is looking forward to working with our partners in 5G DRIVE to expand the potential and utility of private 5G networks.”

Mahdi Yahya, Chief Executive Officer at Ori Industries said: “The status quo in how we build and operate networks is rapidly changing. The continued deployment of 5G in the enterprise space at reduced costs and faster speeds enables modern organisations to become end-to-end service providers. We are pleased to be playing a part in this transformation alongside our partners in the 5G DRIVE programme empowering telecom operators and enterprises to roll out a set of a new generation of services for their users.”

Carsten Maple, Professor of Cyber Systems Engineering at WMG, University of Warwick said: “The Secure Cyber Systems Research Group at WMG are delighted to be part of a world-leading consortium that have been selected to deliver methods for diversity in the 5G supply chain. Developing vendor diversity will support innovation and enhance long-term resilience but requires methods to assess and ensure security. This programme of work builds upon our previous experience and is strongly aligned to the WMG mission of research excellence with industry relevance.”

Anthony Timson, Technical Director of wavemobile Ltd said: “The 5G ecosystem opens up many possibilities for private and pseudo-publicly connected networks. Until now, the biggest challenge has been a way to commercially connect incumbent and small operators in a secure, flexible manner. This project provides for a technically acceptable industry standard that will bring real value to businesses and rural communities alike.”

WMG Professor helps shape House of Lords Select Committee report

Professor Tim Watson, Director of WMG’s Cyber Security Centre, has shared his expertise in the House of Lords Select Committee on Risk Assessment and Risk Planning report entitled ‘Preparing for Extreme Risks: Building a Resilient Society.’

Professor Tim Watson, Director of WMG’s Cyber Security Centre, has shared his expertise in the House of Lords Select Committee on Risk Assessment and Risk Planning report entitled ‘Preparing for Extreme Risks: Building a Resilient Society.’

Professor Watson gave evidence to the panel which was used to shape the report published on Friday 3rd December.

The Committee was appointed in October 2020 to "consider risk assessment and risk planning in the context of disruptive national hazards". Following 29 oral evidence sessions with 85 witnesses and 90 written submissions, the Committee concluded that the UK must be better at anticipating, preparing for and responding to a range of challenging risk scenarios, including those which it has never experienced before.

The report emphasises that the Government's current strategy of centralised and opaque risk assessment and risk management, which fails to make adequate preparations, has left the UK vulnerable.

The Chair of the Committee, Lord Arbuthnot, said: "Our inquiry has concluded that the UK must adopt a whole of society approach to resilience, one which emphasises the important role played by all sections of society in preparing for, adapting to and recovering from the effects of risk. Risk and resilience are not solely the concern of central Government policymakers, and since they have the capacity to alter the lives of everyone in the country, everyone needs to be involved in shaping the response to the risks that we face."

Read the report in full here: https://publications.parliament.uk/pa/ld5802/ldselect/ldrisk/110/11002.htm

WMG unveils the world’s first EV Thermal Management Testbed

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

The Testbed, which is a world-first, was funded by the High Value Manufacturing Catapult, and is located at the University of Warwick’s Wellesbourne campus. It is designed specifically to develop and evaluate efficient thermal management systems for electric vehicles; including cabin climate control; thermal management of energy storage and electric machines; and the impact on the overall performance of the vehicle.

Truong Quang Dinh, Associate Professor of Energy System Management and Control at WMG, explains: “Effective heating and cooling of vehicle sub-systems is indispensable to ensure safety, reliability and comfort. Our unique thermal management testbed integrates a highly flexible HVAC rig and a hybrid physical-virtual powertrain for the holistic investigation of thermal management systems and other vehicle sub-systems under real-world conditions. This enables real-time tests from vehicle components, sub-systems, to entire systems at lowest time, cost and effort.”

One project that will be exploring the capabilities of the new Thermal Testbed is Cit-E-Van, - a collaboration between WMG, CoolVan and GAH, funded by Innovate UK. Cit-E-Van will look to develop an energy efficient electric refrigerated vehicle with an optimised electric transport refrigeration unit and retrofit the electric propulsion system with advanced thermal-energy management features.

In the coming months WMG experts will be working with more industry partners to develop HVAC solutions.

For further information about the testbed or HVAC solutions in general contact Truong Quang Dinh at: t.dinh@warwick.ac.uk

WMG research shortlisted for key industry tech award

WMG’s Secure Cyber Systems Research Group has been shortlisted for a TechWorks R&D Excellence Award.

WMG’s Secure Cyber Systems Research Group has been shortlisted for a TechWorks R&D Excellence Award.

The R&D Excellence Award celebrates innovative R&D activity involving strong Industry and Academic collaboration. This category showcases world-class technology development that has the very high potential of being adopted by industry.

Professor Carsten Maple explained: “I am extremely grateful to all of the team for their huge effort and fantastic outputs. I am so pleased that their efforts have been recognised by a national awards panel.

“The awards recognise outstanding collaboration, and we have certainly made our case based upon the many successful projects, including BeARCAT, IoT-Tram, Capri and S-CAV, that we have delivered with multinational partners and SMEs.

“Being recognised as a finalist is a fantastic achievement and testimony to the hard work of everyone here at WMG.”

Winners will be announced at the TechWorks Gala Dinner and Awards Ceremony on Thursday 9th December, at the Leonardo Royal Hotel London St Paul’s.

Read more about WMG’s cyber security research here: Cyber Security (warwick.ac.uk)

£1.5m gift creates new Lord Bhattacharyya Chair in Education role at WMG, continuing Lord Bhattacharyya’s legacy

§ University of Warwick receives £1.5 million philanthropic gift from an alumnus to WMG to create a new role, entitled the Lord Bhattacharyya Chair in Education

§ Gift recognises the opportunity to continue the late Professor Lord Bhattacharyya’s legacy to education

§ It will allow WMG to enhance their exceptional academic expertise in the understanding, development and teaching of engineering and manufacturing internationally

§ This is the most recent £1 million plus gift to Warwick’s portfolio, reflecting continuing enthusiasm for supporting exceptional research and education, despite the global financial impact of the pandemic

A private philanthropic gift of £1.5m from a Warwick alumnus has created a new role in WMG, entitled the Lord Bhattacharyya Chair in Education. The new role will continue the late Lord Bhattacharyya’s legacy enhancing WMG’s academic expertise in the understanding, development and teaching of engineering and manufacturing internationally.

The late Professor Lord Kumar Bhattacharyya passed away on the 1st March 2019, and in order to endure his legacy to global manufacturing and innovation, the new role of Lord Bhattacharyya Chair in Education will enhance WMG’s exceptional academic expertise in the understanding, development and teaching of engineering and manufacturing.

The late Professor Lord Kumar Bhattacharyya passed away on the 1st March 2019, and in order to endure his legacy to global manufacturing and innovation, the new role of Lord Bhattacharyya Chair in Education will enhance WMG’s exceptional academic expertise in the understanding, development and teaching of engineering and manufacturing.

The Lord Bhattacharyya Chair in Education will be a senior post and will be a member of the WMG Education Executive, that will drive forward innovations in research-led teaching and scholarship, using the evidence to bring about the changes the late Lord Bhattacharyya wanted to see in the world. This will include new ways to inspire young people from different backgrounds to pursue Engineering careers through the WMG Academies for Young Engineers, degree apprenticeships, and professional skills programmes, along with an opportunity to explore innovation in the higher education space more widely.

In 2016 WMG, at the University of Warwick, was awarded a Regius Professorship in Manufacturing, which was bestowed by Her Majesty the Queen in recognition of the transformational contributions that Professor Lord Kumar Bhattacharyya made to UK manufacturing. The new role of Lord Bhattacharyya Chair in Education will complement the Regius Professorship and celebrate Lord Bhattacharyya’s impact on engineering and manufacturing internationally.

The new post will provide academic leadership at the interface between research and teaching, helping to ensure that WMG’s fundamental and applied research outputs in engineering and manufacturing are placed at the heart of a teaching agenda that promotes and embeds innovation.

Margot James, Executive Chair of WMG, University of Warwick, comments:

“We are incredibly grateful for such a generous gift from a member of our alumni community, which will enable the new Lord Bhattacharyya Chair in Education role to ensure that Professor Lord Bhattacharyya’s emphasis on the pursuit of excellence in education is preserved.

“We anticipate that the successful appointee will extend further WMG’s teaching partnerships with industry and our international partners in Asia, enabling us to facilitate high quality and meaningful professional, international and intercultural learning opportunities, that broaden the global perspectives of our students.”

Professor Stuart Croft, Vice Chancellor of the University of Warwick, comments:

“We are extremely grateful to the alumnus who has gifted such a generous amount despite the financial impact of the pandemic. Donations like this help us stay committed to enhancing and exceeding education standards.

“The new role of Lord Bhattacharyya Chair in Education at WMG will continue Professor Lord Bhattacharyya’s legacy, and help us thrive in connecting education, research and industry, setting up our graduates for a successful future.”

Professor Robin Clark, Dean of WMG, University of Warwick adds:

“WMG is an internationally renowned academic department of the University, known for bridging the gap between industry and academia, working with companies and organisations on both fundamental and applied research and importantly the development of education programmes which will provide the skills needed for both the current and future needs of industry.

“The new Lord Bhattacharyya Chair in Education role will help us to further develop the relationship between our teaching and our research. In doing this it will enable us to develop an evidence base on which to create innovative, engaging and authentic learning opportunities for a diverse range of students. This, with strong industry links, is something that we feel Professor Lord Bhattacharyya would be excited about.”

While the generous gift of £1.5m from a Warwick alumnus will establish the post, the University is seeking further philanthropic support to achieve its goal for the Chair. It is hoped the new role will be recruited to in 2022.

ENDS

18 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/august2016/margot_james_mp_and_professor_lord_bhattacharyya_1st_september_2016.jpg

Caption: Margot James, Executive Chair of WMG, University of Warwick with the late Professor Lord Bhattacharyya in 2016

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk