WMG News

Warwick International Higher Education Academy congratulates new fellows

Congratulations to Nancy Olson (pictured below left) and Celine Martin (below right) who have been announced as new fellows of the Warwick International Higher Education Academy (WIHEA).

The Academy is the UK’s first institutional academy of educators for staff and students engaged in the advancement of learning and teaching excellence. Becoming a Fellow provides the opportunity for Nancy and Celine to engage with colleagues across the University, to make a genuine difference to Warwick as well as to strengthen their career development.

It works to give a collective voice to learning and teaching at Warwick through projects, policy influence, governance and exchange of good practice.

By becoming a Fellow, staff and students can take part in exchanges, projects, learning circles, proposing teaching and learning policy or develop new academic practice that enhance the student experience and student outcomes.

There are currently 93 Fellows and the annual selection process recruits on average 25 Fellows each year.

WMG staff appointed as Fellows in the new Warwick Institute of Engagement

Congratulations to our staff members whose appointments as the new Foundation, Honorary and Associate Fellows have been announced by The Warwick Institute of Engagement (WIE).

The role of the Fellows will be to establish the Institute as an interdisciplinary hub for the whole university, and work together to create exciting new engagement opportunities for staff and students.

Over the next few months the Institute will be creating a series of Learning Circles with the new Engagement Fellows. These Circles will cover a range of topics such as the future of engagement in HE, collaborating with communities and student training in Public Engagement. Longer term they are committed to supporting staff and students in providing up to date training and development opportunities and supporting institutional level engagement events such as City of Culture.

Professor Michael Scott and Jane Furze, Directors of the Warwick Institute of Engagement, said:

“Congratulations to all our new Fellows! We’re delighted to have attracted such a diverse, multi-disciplinary range of colleagues and students to join the Institute. Engagement is all about universities working with people and listening to voices outside academia to create and share knowledge collaboratively. Collectively, we have a great foundation to build on the fantastic engagement work already happening at Warwick and drive forward our genuinely new and exciting approach to engagement.”

WMG staff WIE fellows:

Foundation Fellows:

Evé Wheeler-Jones

Ian Tuersley

Phil Jemmett

Honorary Fellows:

Caroline Meyer

Lisa Harding

Margaret Low

Associate Fellows:

Dave Harvey

Mark Williams

Celebrating International Day of Women and Girls in Science 2021

Today, 11th February, WMG is joining the world in celebrating International Women and Girls in Science Day 2021.

Science is everywhere in today’s world. Part of our daily lives and never far from news headlines.

The Day is a perfect opportunity to celebrate the inspiring female scientists at WMG, including PhD student Evé Wheeler-Jones, a Chemist, working in our  Battery Technology team.

Battery Technology team.

Evé explains: “Across my engagement work, I often meet girls and young women who do not think that science is an option to them, this saddens me and spurs me on. I work in an environment with some amazing female researchers, technicians, teachers and academics, and I wish I could share a glimpse of this to all the young people out there.

“Science is great place of learning and creativity, and also a place for all types of people. Diversity enhances science as it brings so many different ideas to the table, this is why it’s so important for young women to embrace science and, in turn, to be welcomed with open arms.”

The WMG Outreach Team has also created a virtual lesson for Year 9 pupils featuring female scientists and researchers including Evé. This was distributed to local schools via the University’s Central Outreach Widening Participation Team.

You can view the lesson here: https://warwick.ac.uk/fac/sci/wmg/about/outreach/resources/battery-lesson/

The University of Warwick will also be hosting a Women at Warwick Q&A Panel this evening. Find more details here.

WMG continues partnerships with employers to train Degree Apprentices

- Degree Apprenticeships (DA) at WMG include courses partnerships with employers and come with a competitive salary

- WMG's undergraduate DA courses include Digital and Technology Solutions, Applied Professional Engineering, and Digital Healthcare Science

- Postgraduate courses include Sustainable Automotive Electrification and Smart, Connected and Autonomous Vehicles

- National Apprenticeship Week 2021 runs until Sunday 14th February

- Applications for Jaguar Land Rover Degree Apprenticeships in Partnership with WMG close on Monday 15th February

WMG at the University of Warwick is set to continue its working partnership with employers to train the next wave of engineers and digital technologists - with new cohorts of degree apprentices set to start this September.

WMG at the University of Warwick is set to continue its working partnership with employers to train the next wave of engineers and digital technologists - with new cohorts of degree apprentices set to start this September.

WMG’s undergraduate degree apprenticeship courses, including Digital and Technology Solutions, Applied Professional Engineering Programme, and Digital Healthcare Science, and postgraduate Sustainable Automotive Electrification and Smart, Connected and Autonomous Vehicles courses, bring together the best of higher education and work-based learning and come with the additional benefits of earning a competitive salary while learning and no university tuition.

Over the duration of their courses the apprentices will be taught on the University of Warwick campus for a number of weeks each year to complement their practical work based experiences – including in WMG’s new Degree Apprenticeship Centre.

For those interested in developing a new career and starting as a degree apprentice this September, there is still time to apply for courses at WMG in partnership with Jaguar Land Rover.

WMG and Jaguar Land Rover’s partnership provides degree apprentices the opportunity to develop the technical skills and knowledge necessary to building Jaguar Land Rover’s engineering capability for an autonomous, connected and electric future, with applications for courses open until February 15th.

§ For details on the full range of available Jaguar Land Rover degree apprenticeships and how to apply please click here.

Further to degree apprentice opportunities in the automotive and engineering sectors, WMG now offers the opportunity to train in Digital Healthcare Science. The course provides a breadth of scientific training including high-level consultation skills, a holistic, evidence-based and values-based approach to shared decision making, psychology, behavioural science and clinical physiology.

Developed with extensive consultation with leading healthcare science academics, senior NHS staff and policy makers, the Digital Healthcare Science course also provides valuable study and professional skills including data handling, statistics, research ethics and methods, literature review skills and critical appraisal, standards of conduct performance and ethics.

§ For details on the Digital Healthcare Science degree apprenticeships please click here.

Sue Parr, Director of Apprenticeships at WMG, University of Warwick comments:

“National Apprenticeship Week is the ideal time to both reflect on the success of those who are currently gaining skills and experience, but also to encourage those looking to follow in their footsteps.

“At WMG we are delighted to host and teach so many aspiring degree apprentices in key sectors and support them in applying the knowledge they gain here with the experience and skills they are developing at work to have real and immediate impact for their organisations and their career.”

Beverley Ngo, a current Software with Data apprentice, said of her decision to apply for a degree apprenticeship with Jaguar Land Rover and WMG:

“I wanted to be able to apply what I was learning to the real world, so the apprenticeship was the perfect opportunity for that. The funded degree and salary was obviously a bonus too! The degree itself appealed to me as I have always enjoyed maths and problem solving, so DTS felt like the right fit for me.”

Jack Young, a current Software Engineer apprentice, said of his studies:

“I have really enjoyed being able to apply what I have learnt at WMG to my work and vice-versa. It has been beneficial to be able to implement knowledge from both sides of the course and get a deeper understanding of what we are learning and why we are learning it.”

WMG commends the advances to UK innovation, skills and industrial growth made by the Industrial Strategy Challenge Fund and supports NAO recommendations to further improve impact

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- Industrial Strategy Challenge Fund has brought government, business and researchers together at scale and at pace, supporting over 1,600 innovation projects, including Coventry’s UK Battery Industrialisation Centre

- NAO right to support streamlining start-up and approvals processes of up to 72 weeks, which can deter bids, especially among smaller businesses

- Longer term visibility of funding will be needed to give investment confidence to businesses and academia

- Mechanisms to engage private sector finance should be considered – especially as innovations become ready for market

- As industry faces challenges of the pandemic, flexibility in financing bids, especially to support smaller businesses, should be considered

- Regional and Skills strategies should be a key part of innovation funding approach

- The Catapult network provides an established and successful platform for innovation, and its geographic locations also suggest it could play a big role in regional levelling-up

- Skills must be developed alongside innovation to give the UK the ability to exploit our ISFC investments. WMG, at the University of Warwick, have been pioneers in developing skills programmes alongside innovation and industrialisation

WMG at the University of Warwick has welcomed today’s National Audit Office report on the Industrial Strategy Challenge Fund, supporting their positive assessment of the fund, and backed their calls for a more streamlined approach to innovation funding, alongside a greater emphasis on the importance of innovation for regional development and skills growth.

Professor Dave Greenwood, Director of Industrial Engagement at WMG, University of Warwick and Chief Executive of the WMG High Value Manufacturing Catapult said:

“The Industrial Strategy Challenge Fund (ISCF) has been a powerful tool to support innovation that meets the most pressing national challenges.

“The ISCF has bought government, business and researchers together at scale, and at pace, to help our transport industry decarbonise through the Faraday Battery Challenge, and is delivering vital vaccine capacity through the Vaccine Manufacturing and Innovation Centre. It has supported over 1,600 projects, including the new UK Battery Industrialisation Centre in Coventry, with over forty per cent of support in the first two waves going to small and Micro companies.

“These projects are making a difference to UK innovation, skills and industrial growth, and these successes should be celebrated.

“As the report says, however, there are always opportunities to improve how the Fund operates.

“First, we need to make the funding process faster and more agile – especially given rapid changes in the external Business and social environment, from Brexit to the Pandemic. Lengthy Approvals processes of up to 72 weeks for selecting challenges and awarding projects can deter bids, especially among smaller businesses.

“Alongside this, with much of industry dealing with financial pressures from the pandemic, government should consider relaxing some of the funding constraints on the programmes – especially where they fall significantly short of what state aid would allow, such as in the co-investment requirement from Industry, which was increased in Wave 3 of the Fund.

“Together, these steps would help position the UK for clean growth post-COVID and deliver on opportunities created for the UK supply chain by the UK/EU trade agreement.

“Looking forward, it’s essential that there is a long-term funding package in place to support the Industrial Strategy Challenges. As the report notes “The Fund was part of a one-year settlement in the spending review in November 2020.” Short term spending decisions will ultimately be detrimental to large scale industrial and academic investments – a 5 year rolling funding horizon is needed for full confidence from Industry partners. To help deliver this, we should consider the role of private finance in these programmes, and what mechanisms might de-risk industry investments to support clean growth.

“It’s also crucial that the ISCF supports regional development as part of the Government’s ‘levelling up’ agenda. Currently, almost half of funding has gone to projects in London and the South East, and while we in the West Midlands have secured significant investment, the ISCF should reflect the regional profile of Industrial R&D more closely. It is notable that government funding relative to private sector investment is much lower in the Midlands than in the South East for instance.

The Catapult network, with centres of excellence across the country, strong links to regional industries, and good networking between them, is an exemplar of how levelling up should be delivered. This established and successful platform could provide an efficient and effective means to boost R&D in under-represented regions in accordance with the recommendations of this report.

“We also need to link innovation spending to the education and skills agenda. The UK needs not just the best technologies but also the people to develop, manufacture and support them. These cannot be developed in isolation. Here, WMGs approach of delivering innovation and skills programmes together and in partnership with industry is an established model, allowing degree apprenticeships, re-training, lifelong learning to support industry innovation programmes. As the Government considers responses to the skills white paper, it should consider how future industry skills needs will be shaped by the innovations being delivered by the challenge fund, from transport electrification to digital skills.

Student recruited by West Midlands SME following success of WMG Internship Programme

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

The Programme is designed to allow companies and students to work together to overcome a business challenge or investigate ways of improving business performance. Interns, placed at companies, are supervised by an expert member of the WMG team to ensure objectives are met and to provide access to world-renown facilities. This means participating companies get the benefit of both the resources and industry-leading knowledge.

Tom Lockhart, WMG SME Project Officer, explains: “Over the past 10 years, we have supported more than 300 internship projects. We work with businesses to identify their challenges, scope out a project and set clear objectives for a short, but focused piece of work.”

One particular highlight of this year’s programme was an internship placement at Alucast, an aluminium casting foundry that supply the automotive industry.

Through a collaborative approach, the student intern, Farhan, was, within just 12 weeks, able to help boost productivity by an impressive 30% and has now been offered a full time position. This is a particularly positive outcome in such challenging times and a real testament to Farhan’s hard work.

John Swift, Managing Director at Alucast, commented: “We have long been an advocate of promoting engineering as a career choice and, with this in mind, it was great to work with Farhan. It reinforced our belief that young students and graduates make excellent employees, combining a great work ethic with technical knowledge and insight. The project really exceeded expectations and we’re pleased to be able to offer Farhan a full-time role with us.”

Read more about the SME Team’s project with Alucast, an aluminium casting company based in the Black Country and more success stories here: warwick.ac.uk/smesuccessstories

To find out more about working with the WMG SME Internship Team email wmgsme@warwick.ac.uk

Immersion Cooled EV battery initiative, project i-CoBat, wins The Engineer’s Collaborate to Innovate Automotive Award

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

Project i-CoBat has been recognised by The Engineer in winning its ‘Collaborate to Innovate’ Award in the automotive category. The Innovate UK research initiative is designed to explore and validate direct immersion cooling of electric vehicle batteries.

The project, led by M&I Materials, is a consortium involving battery systems developer Ricardo and WMG, at the University of Warwick which works to commercially and technically validate new technologies for industry.

Funded by Innovate UK, project i-CoBat uses a novel thermal management system for EV batteries using a novel, biodegradable dielectric fluid called MIVOLT, which allows for faster charging than conventional systems and a higher performance battery.

On receiving the news of the award for i-CoBat, Project Lead, M&I Materials Technical Director, Mark Lashbrook commented:

“We’re thrilled for project i-CoBat to have been recognised with this award, particularly since we were up against some incredibly exciting and forward thinking companies. This award is a testament not only to this type of initiative and what its implications are for the wider EV market, but to both Ricardo and Warwick Manufacturing Group for their extensive knowledge, expertise and leadership. Innovate UK have also been incredibly supportive throughout, so this award is also in recognition of the pioneering research projects, like i-CoBat, which they initiate.”

WMG's Principal Engineer, Stene Charmer, added: “I am thrilled and delighted that the ICO-BAT team have won this award. It has been wonderful to work with M&I materials and Ricardo, supporting the research of our advanced battery cell, module testing and advanced simulation techniques. At WMG we are leading innovative battery research and development, and innovative battery thermal management systems, the technology researched within ICO-BAT, are key to realising cost effective electrical energy storage systems for passenger vehicles.”

ENDS

Highly efficient grid-scale electricity storage at fifth of cost – researchers modify hybrid flow battery electrodes with nanomaterials

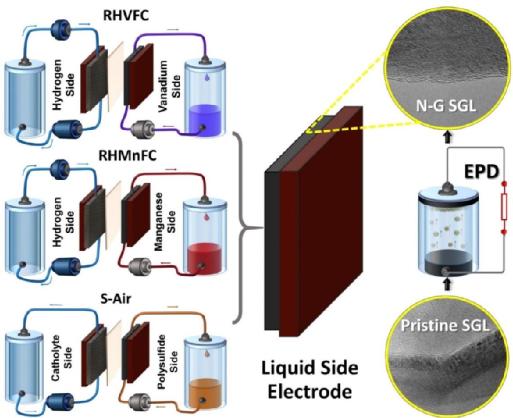

Researchers in WMG at the University of Warwick, in collaboration with Imperial College London, have found a way to enhance hybrid flow batteries and their commercial use. The new approach can store electricity in these batteries for very long durations for about a fifth the price of current technologies, with minimal location restraints and zero emissions.

The researchers enhanced three hybrid flow cells using nitrogen doped graphene (exposed to nitrogen plasma) in a binder-free electrophoresis technique  (EPD)

(EPD)

Wind and solar power are increasingly popular sources for renewable energy. Unfortunately, intermittency issues keep them from connecting widely to the National grid. One potential solution to this problem involves in the deployment of long-duration battery technology, such as the redox flow battery. Despite its great promise the current costs of this system are a key determining factor to real-world adoption. An affordable grid battery should cost £75/kWh, according to the US Department of Energy. Lithium-ion batteries, which lead the charge for grid storage, cost about £130/kWh.

Now WMG researchers have found a way of enhancing hybrid flow batteries or regenerative fuel cell (RFC) technology that could store electricity for very long durations for about one-fifth the cost of current storage technologies, with flexibility in siting and with minimal environmental impact. The technology combines carbon-based electrodes with economically sourced electrolytes, (manganese or sulphur, which are abundant chemicals in the planet) by means of a simple and yet highly effective electrophoretic deposition of nano-carbon additives (nitrogen-doped graphene) that enhance the electrode durability and performance significantly in highly acidic or alkaline environments.

The researchers have published their findings in a paper entitled, ‘Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes’ in the December 2020 edition of the journal ACS Applied Materials & Interfaces.

Dr Barun Chakrabarti, a Research Fellow in WMG at the University of Warwick and one of the lead authors on the paper said:

“This EPD technique is not only simple but also improves the efficiencies of three different economical hybrid flow batteries thereby increasing their potential for widespread commercial adoption for grid-scale energy storage.”

The hybrid flow battery’s total chemical cost is about 1/30th the cost of competing batteries, such as lithium-ion systems. Scaled-up technologies may be used to store electricity from wind or solar power, for multiple days to entire seasons, for about £15 to £20 per kilowatt hour. These batteries are also extremely useful for grid-scale load levelling applications as their design is very flexible due to their unique feature of sizing their power independently of their energy.

The energy density of a hybrid flow battery, especially the polysulphide/air system (S-Air), is 500 times higher than pumped hydroelectric storage. It is also so much more compact and can be placed near any renewable generation.

ENDS

22 JANUARY 2021

Notes for Editors

High-res image available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january_2021/barun_release_image.jpg

Caption: A Binder-Free Horizontal Electrophoretic Deposition (EPD) Process Is Used to Activate Commercial Carbon Paper Electrodes Using Nitrogen-Doped Graphene

Credit: WMG, University of Warwick

Full list of researchers: Co-investigators with Dr Chakrabarti at the WMG Energy Innovation Centre at the University of Warwick are: Evangelos Kalamaras (Project Engineer, Battery Testing) and Professor Jon Low (Associate Professor, Electrochemical Engineering). Co-investigators from Imperial include Anthony Kucernak and Nigel Brandon.

The full paper with all author details can be found here: Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes

Background history to this area of research

Development of the EPD technology began in 2013, when Professor Low joined WMG as an Assistant Professor and researched industrial Lithium-ion battery manufacturing processes. EPD involves the migration of electrically charged particles through a fluid that is under the influence of an electric field generated by applying the right potential.

Although EPD is an industrially adopted process such as for depositing industrial coatings onto conductive substrates, its mass-scale adoption for energy storage applications has only recently seen some success. Supported by EPSRC’s First Grant (EP/P026818/1, https://gtr.ukri.org/projects?ref=EP%2FP026818%2F1) and Industrial Strategy Challenge Fund on battery and supercapacitor manufacturing (EP/R023034/1, https://gtr.ukri.org/projects?ref=EP%2FR023034%2F1), Low’s research team have developed EPD for preparing lithium-ion battery electrodes that meet industrial standards for thickness and mass loadings and published their finding in ‘Batteries and Supercaps’ (https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/batt.201900017). They have also produced carbon electrodes with nanomaterials for improving the practical performance of vanadium-based flow batteries using deep eutectic solvent electrolytes, and published their finding in ‘Batteries’ (https://www.mdpi.com/2313-0105/6/3/38).

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG one of three major Midlands industry partners in new alliance

Three of the major industry partners in the region are to work closer together for the good of the local economy as part of a new 12-month pilot.

WMG, at the University of Warwick, The Coventry and Warwickshire Local Enterprise Partnership (CWLEP) Growth Hub, and The Manufacturing Technology Centre have signed a new agreement which will make it easier for manufacturers to access equipment and expertise they need to develop new and existing products and processes.

The three organisations will form a working party meeting weekly to co-ordinate areas of common working, ensure that initiatives are shared across the three organisations, and look at joint campaigns.

The partners will focus on manufacturing and engineering companies across the CWLEP area, and the new alliance will work closely with other partners such as the West Midlands Combined Authority, the Coventry and Warwickshire Chamber of Commerce and the Federation of Small Businesses.

Mark Swift, Head of SME Programmes at WMG, University of Warwick said: “The agreement will help manufacturing unlock the opportunities presented by green manufacturing, digitalisation and the journey to Net Zero transport. Coventry and Warwickshire already has very strong partnerships and we believe the work of WMG and the MTC combined with the extensive network and market intelligent of the Coventry and Warwickshire LEP will form a powerful offer to local companies.”

by green manufacturing, digitalisation and the journey to Net Zero transport. Coventry and Warwickshire already has very strong partnerships and we believe the work of WMG and the MTC combined with the extensive network and market intelligent of the Coventry and Warwickshire LEP will form a powerful offer to local companies.”

Craig Humphrey, Managing Director of the CWLEP Growth Hub, said: “The three organisations had worked with each other in the past but the pilot would make the collaboration far more effective.

“The three organisations know each other well and collaborate when the need arises, but we have a tremendous amount of common ground and market intelligence which we all felt would be more powerful and useful to local companies if it was harnessed effectively and the formation of the working party is the first stage in that.”

The working party will be overseen by a senior management team which will review its effectiveness on a monthly basis.

Clive Hickman, the founder and Chief Executive of the MTC, said: “We work right across the UK, but are based in Coventry and Warwickshire which is internationally recognised as a centre of excellence for manufacturing and engineering, and believe that we always have more to offer in terms of support to local companies.

“The three organisations are ideally placed in slightly different areas of the market to bring unique advantages to what could be a very powerful alliance.”

ENDS

21 JANUARY 2021

NOTES TO EDITORS

About WMG, University of Warwick

WMG is an academic department at the University of Warwick and is the leading international role model for successful collaboration between academia and the public and private sectors, driving innovation in science, technology and engineering. They are a founding partner of the HVM Catapult, and are one of seven centres within this government initiative.

About the CWLEP Growth Hub

The CWLEP Growth Hub was founded to help companies across the region access support and help in a range of areas and has now helped create more than 5,000 jobs across Coventry and Warwickshire.

About the MTC

The MTC was established in 2010 with the objective of bridging the gap between academia and industry and employs more than 700 staff across three centres – two of which are at Ansty Park, near Coventry.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Warwick Racing Engineering Team unveils its production during COVID

While the Summer months are used for relaxing and revision for most students, a group of students who form Warwick Racing stayed behind to continue their work on the single-seater electric race car, ready for the Formula Student events later in the academic year.

The Warwick Racing team consists of students from the School of Engineering, Warwick Business School and the Department of Computer Science, with support and facilities courtesy of WMG. The team comprises members of different gender, race, nationality and degree, with an expansion to the business team in term one adding 12 additional new members to the fold, overseeing the website, marketing and social media.

Due to the pandemic the students worked remotely to design the second race car, WRe2. But as labs reopened over the summer it was time to start putting  the real-world production of components into action.

the real-world production of components into action.

Following social distancing guidelines, wearing protective equipment and ensuring that workstations are properly sanitized, Warwick Racing has been able to successfully ensure that component production was able to continue safely.

They were able to focus on two critical components of the car, the front upright and the wiring harness.

Watch videos documenting the creation of these two components at https://youtu.be/IF2RFvn5pYE and at https://www.youtube.com/watch?v=mSQqVBKCD5Y

Angel Marco Ansenjo, Chief Chassis Engineer at Warwick Racing comments:

“The front uprights are the real workhorses of the vehicle: holding the front wheels in place and resisting the various dynamic loads that affect the car whilst cornering, braking and moving over bumps. As such the uprights must be one of the sturdiest and most resilient parts of the whole car.

“The process of creating an upright begins in the telemetry of last year’s car. By understanding what loads are going through the car at various points in the drive, we can better design the updated component in line with the needs of the new car. From there, the entire suspension system is digitally recreated on Autodesk Fusion 360 and simulated against a variety of stresses and load combinations to test how the suspension holds up against them. These include a hard braking scenario where the steering is put on full lock and the car hits a bump at the most loaded corner of the vehicle. This is to ensure that even in the most extreme of circumstances the part remains intact and the driver is safe.”

From here, the engineers decide on many of the intricate specifics of the upright, such as deciding on the component volume, the wheel bearings and the seals. Then, the exact material for the upright is chosen in order to allow the component to perform its job in the optimal manner. In this case, the team chose to use an aluminium-silicon alloy.

Once the volume and material are chosen, the design is run through a second phase of CAD tests to optimize the efficiency of the component and to ensure that any additional weight is shed. The engineers will then re-subject the part to digital testing and produce the toolpath which is sent to the computer-controlled manufacturing machines (CNC).

Once the part has been machined, it will be cut and measured to exact specifications and the additional bracketry will be manufactured. The wheel bearings are pressed in, followed by all the mounting hardware and the wheel hub, before the component is eventually mounted onto the chassis.

The wiring harness of a race car connects and controls various electronic components of the vehicle and ensures that wires are connected in the shortest, safest and most efficient ways possible.

Rens Bossers, Chief Powertrain Engineer at Warwick Racing comments:

“The first stage of designing a wiring harness is identifying what sensors, control units and actuators need to be connected to the circuit. On the WRe2 this contains over 50 components including, but not limited to: Battery Monitoring Systems (BMS), Inverter Data, Coolant monitors, speed sensors, steering wheel position sensors, brake pressure sensors and GPS.

“Once the components are decided on, we used smart wiring software to add all the connectors in and all the shielding and seals to protect the wiring from water and dust. The system must also be designed to ensure that it can survive the vibrations and stresses of racing without braking or compromising the safety of the car. Once the design is decided upon it is refined to ensure maximum efficiency (both in terms of cost and performance) by reducing the length of wires where possible and saving weight. “

Once the digital section of the design stage is complete, the team map out the building process using a Nailboard Wiring Diagram and begin cutting and crimping the wires to motorsport grade standards. In total there are over 5 meters of wires cut for the harness and over 200 separate connections which must be individually tested and validated. Once the tests are certified, the loom is sealed to make it both waterproof and fireproof, ensuring the elements can’t get into the circuit even in the event of a crash. Once the loom is completed, it is carefully installed and secured within the chassis.

ENDS

20 JANUARY 2021

NOTES TO EDITORS

High-res images available at:

Caption: A render of WRe2 spaceframe.

Credit: Warwick Racing, University of Warwick

Video available to view at:

https://youtu.be/IF2RFvn5pYE and at https://www.youtube.com/watch?v=mSQqVBKCD5Y

Credit: Warwick Racing

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk