WMG News

Report fears UK could lose out to the rest of Europe in crucial automotive battery recycling market

The UK is at significant risk of falling behind in the electric revolution and losing out to the rest of Europe on a crucial automotive lithium ion battery recycling market according to a new research report published this week by WMG at the University of Warwick and backed by the Advanced Propulsion Centre UK, the High Value Manufacturing Catapult and Faraday Battery Challenge at Innovate UK.

The new report entitled Automotive Lithium ion Battery Recycling in the UK by Anwar Sattar, David Greenwood, Martin Dowson and Puja Unadkat in WMG, at the University of Warwick calls for the UK to move quickly to establish commercial scale recycling for automotive lithium ion batteries

The WMG report notes that there are currently over a dozen such large scale lithium ion recycling facilities in the rest of Europe but none in the UK despite the fact that the UK is the second largest vehicle market in Europe with annual sales exceeding 2.3 million units in 2019, and is also amongst the top electric vehicle markets in Europe, with a 6% market penetration in the first quarter of 2020.

Jacqui Murray Deputy Challenge Director of the Faraday Battery Challenge at Innovate UK said:

“This new WMG report is a timely call for action. To achieve net zero carbon emissions, we need to be thinking about the whole system. Recycling of batteries is a challenge we see in the making, yet I am confident we can develop into a successful circular economy in the UK. Understanding, sharing and collaborating will accelerate the efforts needed to advance the right technologies and infrastructure to meet the future UK Automotive market.”

The report points out that the current costs of this recycling black hole are already enormous. As the UK lacks significant industrial capacity for lithium ion battery recycling, batteries are shipped to mainland Europe for material recovery. This can be a very expensive process, dependent on state of health of the pack, chemistry of the pack and size of the pack. This can mean that up to 75% of the total cost of recycling which can range from £3/kg to >£8/kg may be attributed to transportation costs and other factors such as the state of health and chemistry of the cells.

Even more concerning are the report’s comments that without its own significant recycling facilities, the UK could also be losing out on a major source of expensive and difficult to source materials to help manufacture new batteries.

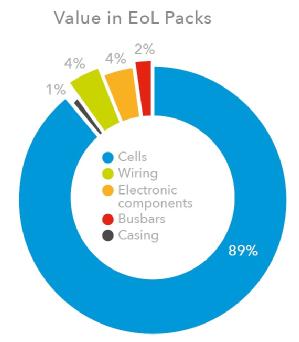

By 2040, 339,000 tonnes of EV batteries are expected to reach their end of their life annually. The average value in end of life automotive packs is £3.3/kg for Battery Electric Vehicles and £2.2/kg for Plug-in Hybrid Electric Vehicles.

By 2040, the UK will also require 140GWh worth of cell production capability, representing 567,000 tonnes of cell production per year. Recycling can supply 22% of this demand (assuming a 60% recycling rate and 40% reuse or remanufacture). The break-even point for an automotive lithium ion battery recycling plant is just 2,500 – 3,000 tonnes per year if the chemistry contains nickel and cobalt.

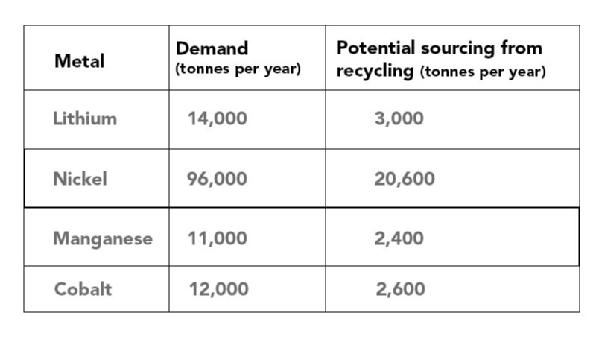

To satisfy 2040 demand, the UK will need 133,000 tonnes of cathode metals per year. Much of this material can be supplied by recycling end of life batteries as the report shows in the following table:

Based on 8:1:1 chemistry assuming 60% of end of life batteries are recycled in 2040.

Dick Elsy CEO of the High Value Manufacturing Catapult says in the report

“WMG has been at the forefront of the development of battery technology for the future of electric mobility in the UK. Internal combustion engines and systems will be replaced by electric motors, power electronics and battery packs. A key part of that future is how we responsibly recycle the materials contained in the batteries and thus create a commercially valuable circular economy. This report is one of the best that I’ve seen to present the challenges and the opportunities in such a clear way.”

One of the report's authors, Professor David Greenwood Professor of Advanced Propulsion Systems, in WMG at the University of Warwick, concludes:

“Electric vehicles offer huge potential for decarbonising transport and improving air quality, but as we accelerate their early market we must equally be thinking about what happens at the end of their useful life. Batteries in particular contain significant quantities of materials which are costly to extract and refine and which could be hazardous to the environment if improperly disposed of. Investment is needed to create suitable recycling facilities in the UK within the next few years, and beyond that, research is needed to allow economic recovery of much greater proportions of the battery material. In doing so we will protect the environment, secure valuable raw materials, and reduce the cost of transport.”

Engineering apprenticeship success for WMG duo

Congratulations to Joseph Benjamin and Tom Moore who have both completed a four year Engineering Technician Apprenticeship at WMG.

Congratulations to Joseph Benjamin and Tom Moore who have both completed a four year Engineering Technician Apprenticeship at WMG.

The pair started their apprenticeship journey after completing their studies at the WMG Academy for Young Engineers in Coventry.

They initially completed a Level 3 Engineering Technician Apprenticeship, before going on to a Level 4 Higher National Certificate (HNC) in Manufacturing Engineering, and have been dividing their time between working at WMG and studying at Warwickshire College.

Joseph explained: “What makes WMG a great place to work and learn is all the amazing staff, students and visitors I have had the pleasure of working with over the last four years. The support and detail of training I have received on equipment and systems is second to none. Therefore, I would like to say thank you and give a special shout out to anyone who has supported me along the way. You know who you are!

“The advice I would give to others considering an apprenticeship, is to look at what the programme can offer you. Especially in terms of development and opportunities such as qualifications and real-life experience in fields that interest you.”

Tom added: “My apprenticeship at WMG has been a fantastic opportunity, allowing me to explore a whole range of engineering disciplines, gain qualifications and ultimately find a keen interest in materials science, characterisation and microstructural analysis. Thank you to all the staff, students and external customers who have been a part of my journey. I look forward to continuing my career with you all.”

Next steps

Joseph and Tom have both now secured permanent positions as Mechanical Technicians within WMG’s Technical Services Team. Joseph is based within the Metrology research team whilst Tom is specialising in Electron Microscopy.

Zac Parkinson, WMG Workshop Manager who also line managed the apprentices, said: “ We are extremely pleased to announce that Thomas Moore and Joseph Benjamin will be joining our Technical Services team as Mechanical Technicians. Both of these young men have worked extremely hard during their apprenticeships, this is evident from their academic grades and ever-advancing skill set.

“We are grateful for their dedication to the group during their apprenticeships, achieving impressive grades and continuing to grow a network of stakeholders across WMG.

“We are also really appreciative of the role models that they have become to other younger members of our technical team.

“We are looking forward to working with them in their new roles, and watching them grow in the future.

“Well done chaps!”

Autistic children in Berkshire school to benefit from new Digital Healthcare Apprentice support

Prior's Court, a specialist residential school in Berkshire and training and development centre for young people aged between 5-25 who are severely affected by autism, is working with WMG at the University of Warwick to help recruit two specialist Digital Healthcare apprentice staff.

The new Digital Healthcare Apprentices will investigate and evaluate data collected on Prior’s Court pupils to support improvements in the wellbeing and experiences of young people with autism at Prior's Court –and will be part of the first wave of a new, innovative national digital healthcare science workforce, working in health and social care to improve people’s health and wellbeing.

Using ‘Big Data’ mining techniques the apprentices, working under joint supervision by academics and specialist autism practitioners, will be able to sift more than a million data points to identify circumstances which predict particular behaviour patterns. This will in turn enable earlier intervention steps to be taken.

This could make a major difference to their quality of life, minimising incidents and perhaps even enabling a young person at the school to later enter employment where this was may have not been previously possible.

The two new Digital Healthcare Apprentices will provide specialist support to the Foundation and its young people, while also studying towards a Bachelor of Science Undergraduate degree in Digital Healthcare Science with the University of Warwick drawing on the expertise of two departments – WMG and Warwick Medical School.

Prior’s Court Chief Executive Mike Robinson said: “Autism is a complex condition. The fundamental question ‘Why does someone with autism have a good day or a bad day?’ is a difficult one to answer. For the young people at Prior’s Court who are severely affected by autism, often with other complex coexisting conditions, it is almost impossible to answer. We believe that by applying the power of being able to collect and analyse large quantities of data to this problem, we will be able to start to answer the question.

“Our digital platform Prior Insight is capturing thousands of pieces of data on our young people every day but it is the practical application which is key. By working with the University of Warwick and recruiting Digital Healthcare Apprentices we can ensure that data is comprehensively analysed and applied to positively impact the lives of many more people with autism – both at Prior’s Court and in the wider world of autism.”

Professor Ed Peile, of Warwick Medical School, comments:

“On my first visit to Prior’s Court I was inspired by how the team there are constantly striving to help young people with severe autism lead happy and fulfilling lives. I was keen to see their cutting edge project using the digital platform ‘Prior Insight’ and to understand what role future members of the new specialism Digital Healthcare Science could play.

“It was immediately apparent to me that, both in their apprenticeship training and when they graduate, Digital Healthcare Scientists have so much to offer at Prior’s Court, and so much to gain there. Thanks to the investment in data collection at Prior’s Court, there is a huge amount of information about how each young person functions.

“Not only that, but working with other technologies including ‘wearable digital technology’ and using the skills of behavioural science and shared decision-making taught on our innovative ‘fusion science course’ will enable the apprentices to contribute as they learn in the workplace.”

How to apply

Applications for the two new roles close in just two weeks on 30th September 2020. Details on how to apply can be found here

You can train your brain to reduce motion sickness

- Everyone can suffer from motion sickness, and around one in three are known to be highly susceptible to motion sickness

- Motion sickness can occur during car travel, at sea, using virtual reality headsets and is expected to be a significant factor in self-driving car

- A cognitive training tool designed by researchers at WMG, University of Warwick has been proven to help ‘train the brain’ to reduce motion sickness by over 50%

Visuospatial training exercises can train the brain to reduce motion sickness, providing a potential remedy for future passengers riding in autonomous vehicles. Researchers at WMG, University of Warwick reduced motion sickness by over 50% using the training tool and it was found to be effective in both a driving simulator and on-road experimentation.

Everyone can experience motion sickness, with 1 in 3 of us being highly susceptible to motion sickness. Motion sickness, sometimes referred to as travel sickness usually can occur during travel in cars and boats, but also when using virtual reality headsets or in a simulator.

With the concept of autonomous vehicles coming closer to our roads, the need to reduce motion sickness is more apparent than ever. It is expected that due to potential vehicle designs and people’s desire to engage in non-driving related tasks such as reading or watching films, motion sickness will be a significant factor for vehicle occupants.

In fact, if we were able to reduce motion sickness so much that people could read and work in future cars, it’s predicted that this productivity boost could be worth as much as US$508billion per year according to Morgan Stanley.

Considering the number of people affected, relatively little research has been done into motion sickness, especially not into motion sickness and autonomous vehicles.

However, in the paper ‘A Novel Method for Reducing Motion Sickness Susceptibility through Training Visuospatial Ability – A Two-Part Study’, published in the journal Applied Ergonomics, researchers from WMG, University of Warwick have been successful in reducing motion sickness.

In the project, researchers have found by using visuospatial training you can essentially train the brain to reduce motion sickness by over 50%.

Participants in the study went in either the WMG 3xD simulator for a driving simulator trial, or on an on-road trial where they were driven around as passengers, imitating what it would be like to be in an autonomous vehicle.

Baseline motion sickness was first measured during their initial ride, using a verity of pre-validated questionnaires, to report severity of the symptoms. A ‘fast motion sickness scale’, was also used to capture ‘real-time’ symptoms as participants were asked to rate their sickness every minute on a scale of 0-20 considering nausea, discomfort, and stomach problems.

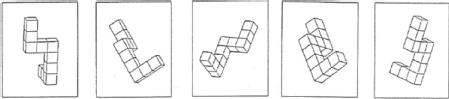

After their first run, participants completed various pen-and-paper visuospatial training tasks, once per day for 15 minutes per day, for 2 weeks. This included exercises such as a looking at a pattern of boxes that and having to identify which image out of three is the original just rotated, paper folding tasks and understand spatial patterns.

After their first run, participants completed various pen-and-paper visuospatial training tasks, once per day for 15 minutes per day, for 2 weeks. This included exercises such as a looking at a pattern of boxes that and having to identify which image out of three is the original just rotated, paper folding tasks and understand spatial patterns.

After the training period, participants took part in another motion sickness assessment and it was recorded that motion sickness reduced by 51% in the driving simulator, and 58% in the on-road trial.

Dr Joseph Smyth, from WMG, University of Warwick comments:

“Being able to reduce an individual’s personal susceptibility to motion-sickness using simple ‘brain training style’ tasks training is a massive step-forward in the development of future transport systems, including autonomous vehicles. Human factors research is all about how we can design products and services that are pleasurable. Motion sickness has, for a long time, been a significant limitation to many peoples transport options and this research has shown a new method for how we can address this.

“I hope that in the future we can optimise the training into a short, highly impactful method. Imagine if when someone is waiting for a test-drive in a new autonomous vehicle they could sit in the showroom and do some ‘brain training puzzles’ on a tablet before going out in the car, therefore reducing their risk of sickness. It’s also very likely this method can be used in other domains such as sea-sickness for navy staff or cruise passengers. We are particularly excited about applying this new finding to Virtual Reality headset use.”

Pete Bennett, from Jaguar Land Rover comments:

“Making our future autonomous vehicles as user friendly as possible is key, and motion sickness is something we knew we needed to research as so many people experience it even now as a passenger.

“The research done by WMG has shown that motion sickness can be reduced, and we can incorporate the research into our future vehicle design process.”

Warwick Racing team develop second electric race car during lockdown

Warwick Racing is a team of 30 dedicated members all working towards getting a single-seater electric race car designed, manufactured and tested in the space of a year. The team consists of students from multiple departments including the School of Engineering, Warwick Business School and the Department of Computer Science, with the help and facilities of WMG.

The team usually spend their summer in the workshop building a race car. The Covid-19 lockdown hasn’t stopped them from designing and virtually validating their second electric competition car, WRe2.

The design of WRe2 was started by the 4th year team in October last year who completed development of the powertrain, suspension and chassis. Over the last few months this work has ramped up, continually improving the designs.

The design of WRe2 was started by the 4th year team in October last year who completed development of the powertrain, suspension and chassis. Over the last few months this work has ramped up, continually improving the designs.

As a team first, the bespoke powertrain has not one, but two rear electric motors. The idea of two motors is to allow better control when deploying power in race conditions.

The Control Systems team have been working on developing a traction control system, employing the E400 Automotive Motor Controller under guidance kindly provided by Embed. The framework was developed in Simulink with future expansion kept in mind. Specifics of the vehicle powertrain, suspension configurations and tyre models were considered to achieve the fastest acceleration possible whilst effectively managing rear tyre slip.

Meanwhile, the workshop has very recently opened so students have started preparing the car that they’ll eventually see doing 0-60mph in 4.5 seconds. This has a power to weight ratio of around 300hp/tonne comes very close to the ratios seen in Formula E racing!

Rens Bossers, the chief powertrain engineer for the coming year says:

“WRe2 is a level up for Warwick Racing. By learning from issues found during the build of WRe1, our first electric car, the design is very resilient. As reliability is historically a very significant factor, WRe2 puts us in great stead for a very competitive finish at our annual competition, FSUK. The dual motor setup is also a massive step towards the 4-wheel drive powertrain that we aim to achieve in the near future.

“It is great that we have had the support of several major sponsors such as Catapult, Ford and RS Components – their support has got us to where we are and enables us to continually come up with new, innovative designs.”

However the design and validation of the new vehicle isn’t all the team have been up to, they’ve also been able to virtually race their current vehicle, WRe1, in the FSUK 2020 Virtual Challenge.

Sixty-six teams participated in the event, with the Warwick Racing team managing to get into the final for cost, finishing in 5th place. In their business presentation the team finished in 7th place.

As a first for this year, the dynamic events included wheel to wheel sim racing. Despite having little preparation time, the team finished in 10th place overall, with their best performance being 3rd place in an individual race out of 34 competing teams.

Iqra Hamid, Chief Powertrain Engineer for the 2019/20 season who oversaw the development of both vehicles, comments:

"I've always had a passion for engineering and all things motorsport so being involved with Warwick Racing over the past 4 years has been an amazing experience! The team have come a long way in such a short space of time with the development of WRe1 and now WRe2.

"I've always had a passion for engineering and all things motorsport so being involved with Warwick Racing over the past 4 years has been an amazing experience! The team have come a long way in such a short space of time with the development of WRe1 and now WRe2.

“Whilst we weren't able to showcase our performance live on the track this year, I'm proud of how well the team came together to make the most of the situation during lockdown, achieving some of our best results to date in the virtual Formula Student competition.

“As the team now enters the new season, I'm looking forward to watching the team continue to build upon this success and achieve even better results at FSUK 2021!"

The entire car is built using funds from sponsors – without their generous support the project would not be possible. With thanks to WMG, Catapult HVM, Ford, Embed, Zuken, Vector, Emrax, Demon Tweeks, Loctite, RS, Colt, Igus, Lohmann Technologies, Aquajet, IMI, GRM, ST Motorsport, B-G Racing, Race Parts, AIM, OBP, Powerflex and the many other supporters of the project.

ENDS

10 SEPTEMBER 2020

NOTES TO EDITORS

High-res images available to view at: https://warwick.ac.uk/services/communications/medialibrary/images/september_2020/warwick_racing_render.jpg

Caption: A render of WRe2 spaceframe.

Credit: Warwick Racing, University of Warwick

Caption: Wre1 on track

Credit: Warwick Racing, University of Warwick

£6 million programme extension to help small manufacturers across the Midlands

· The SME Group at WMG, University of Warwick, has secured a £6m extension to their programme to help small manufacturing companies in the East and West Midlands

· Funded by the European Regional Development Fund (ERDF) and the High Value Manufacturing Catapult at WMG, to create a much-needed support for Midlands manufacturers

· The programme will work collaboratively with a further 250 manufacturing companies across the Midlands to solve manufacturing challenges, to improve productivity and boost competitiveness

· Support is provided from a dedicated and highly industry experienced team with expertise in materials and manufacturing, sustainability, digital manufacturing and business transformation

The programme delivered by the SME Group at WMG, University of Warwick has been a major success in the West Midlands over the last 2 years, helping over 100  companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

Companies, including Genius Facades, a construction company in Wolverhampton, who gained a 15% increase in productivity, thanks to the team helping them by digitising their factory floor.

Another example includes the team helping Power Panels Electrical, in Walsall, win £3m of contracts in the Niche Vehicles sector.

Given the success of the programme, the team have been awarded a further £6m from to take them through to March 2023, meaning the team has gone from a 2 year £5m programme, to an £11m 5 ½ year programme. This extension will enable the team to operate from Wolverhampton and Worcestershire in the West, to Loughborough and Luton in the East Midlands.

Over the next 2 ½ years they will help more than 350 SMEs benefit from the latest in digital manufacturing technologies and thinking, helping them become more productive, competitive and sustainable. Fully funded support from 2 to 15 days is available for eligible small manufacturers.

Dr Mark Swift, head small business programmes at WMG, University of Warwick comments:

“We are thrilled to have the manufacturing competitiveness programme extended, and look forward to being able to help hundreds of small businesses across the midlands to transform their business and become more sustainable.

“The support we offer will be especially helpful in light of Covid-19, as after months of lockdown businesses can be helped to get back on their feet and thrive.”

“We are here, ready to help our region’s manufacturing companies; to make manufacturing technology and thinking work for you, to help our businesses to grow become more productive and sustainable and ultimately make more in the UK.”

If you are a local manufacturing company please get in touch, the team would love to hear from you. E-mail them at: wmgsme@warwick.ac.uk

ENDS

9 SEPTEMBER 2020

NOTES TO EDITORS

High-res images available at:

Caption: The WMG SME team improve the shop floor productivity at Genius Facades

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG Apprentice Technician graduates

Congratulations to WMG Apprentice Technician, Zach Clarke, who recently completed his engineering degree as part of his Degree Apprenticeship programme.

Congratulations to WMG Apprentice Technician, Zach Clarke, who recently completed his engineering degree as part of his Degree Apprenticeship programme.

After his GCSEs, Zach studied a Level 3 Extended Diploma in Engineering at Warwickshire College, before starting his degree apprenticeship journey in September 2017. For the first year Zach studied full-time at college, he then spent the following two years working as an Apprentice Technician, at WMG, whilst studying towards his engineering degree.

Zach explained: “I never thought it would be possible for me to get a degree within engineering, but with the help and support of colleagues at WMG and Warwickshire College I was able to achieve this.

“I’m now in the final year of my apprenticeship, and the next 12 months will enable me to really hone my engineering skills. During this final phase I will be completing a Level 4 NVQ to consolidate further learning within the apprenticeship course.

“I’d like to thank everyone at WMG who has helped me throughout the past three years, their help has been invaluable.”

In May 2017 the University of Warwick, along with over 30 other UK universities, backed a pledge to support technicians. The Technician Commitment is a sector-wide initiative led by the Science Council and the Gatsby Foundation, aimed at addressing key challenges facing technical staff.

The commitment identifies four target areas, which WMG has committed to in order to safeguard vital technical skills. The commitment will ensure greater visibility, recognition, career development and sustainability for technicians across all disciplines.

Risk factors for mortality in diabetic patients discharged from hospital identified

When patients are discharged from hospital those with diabetes are at an increased risk of readmission and mortality, there are guidelines for discharging patients with diabetes to reduce these risks, however researchers from the Institute of Digital Healthcare at WMG, University of Warwick and Warwick Medical School have identified known risk factors for mortality in adult patients discharged from hospital with diabetes.

When patients are discharged from hospital those with diabetes are at an increased risk of readmission and mortality, there are guidelines for discharging patients with diabetes to reduce these risks, however researchers from the Institute of Digital Healthcare at WMG, University of Warwick and Warwick Medical School have identified known risk factors for mortality in adult patients discharged from hospital with diabetes.

In the paper, ‘A Systematic Review Considering Risk factors for Mortality of Patients Discharged from Hospital with a Diagnosis of Diabetes’, published in the Journal of Diabetes and its Complications, researchers identified 35 studies that considered the risk factors relating to mortality for patients discharged from hospital with diabetes, they analysed these studies and identified 48 significant risk factors for mortality.

The 48 risk factors are grouped into the following nine categories:

· Demographic

· Socioeconomic

· Lifestyle

· Patient medical factors

· Inpatient stay factors

· Medication related

· Laboratory results

· Glycaemic status

Professor Theo Arvanitis, from the Institute of Digital Healthcare at WMG, University of Warwick comments:

“The most common risk factor is in the demographic category of age and the second most important factor is co-morbidity burden; this comes under the patient medical factors category, and means patients have more than one condition. We also identified BMI as a significant risk within the patient medical factors category, with those who were at the heavier end of the scales to be more at risk.

“Thirty-seven of the risk factors we identified from one research paper. This tell us that this research in general is still very early, and more studies are needed to identify the importance and possibly any other risk factors. This could decrease the mortality rate of diabetics discharged from hospitals in the future.”

ENDS

2 SEPTEMBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/april2020/theoarvanitis.jpg

Caption: Professor Theo Arvanitis, from the Institute of Digital Healthcare at WMG, University of Warwick

Paper available to view: https://doi.org/10.1016/j.jdiacomp.2020.107705

Battery life for wearable electronic devices could be improved with design considerations to stress asymmetry clues in cylindrical battery cell formats

Researchers in WMG and the Department of Physics at the University of Warwick have found that asymmetric stresses within electrodes used in certain wearable electronic devices provides an important clue as to how to improve the durability and lifespan of these batteries.

Batteries for medical applications and wearable devices continue to evolve in size and shape, with miniaturisation of Li-ion technologies becoming increasingly popular. However, as the size of the battery shrinks, the fabrication process for composite electrodes and the use of liquid electrolyte is becoming a processing challenge for microfabrication using conventional approaches.

Lithium cobalt oxide LiCoO2 (LCO) has remained a common choice of cathode for these small formats due to its high voltage platform and energy density. However, following the initial reported performance benefits of LCO, it is known that LCO cells have large impedance issues due to the growth of high surface layer resistance and charge transfer resistance. This can affect how efficiently the battery charges and discharges. There are also ethical and health considerations around the use of the element cobalt. The increasing impedance was thought to be attributable to the growth of a surface layer on both the anode (solid electrolyte interface, SEI) and cathode (cathode electrolyte interface, CEI) due to the reaction between the electrodes and the electrolyte.

Lithium cobalt oxide LiCoO2 (LCO) has remained a common choice of cathode for these small formats due to its high voltage platform and energy density. However, following the initial reported performance benefits of LCO, it is known that LCO cells have large impedance issues due to the growth of high surface layer resistance and charge transfer resistance. This can affect how efficiently the battery charges and discharges. There are also ethical and health considerations around the use of the element cobalt. The increasing impedance was thought to be attributable to the growth of a surface layer on both the anode (solid electrolyte interface, SEI) and cathode (cathode electrolyte interface, CEI) due to the reaction between the electrodes and the electrolyte.

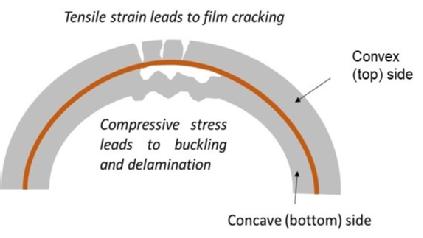

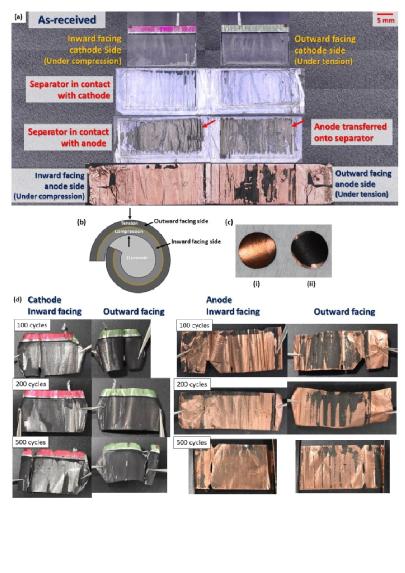

However, in the paper “Ageing analysis and asymmetric stress considerations for small format cylindrical cells for wearable electronic devices” published recently in the Journal of Power Sources, the University of Warwick’s WMG and Physics department researchers disassembled these cells. They have found that and the condition of the cathode and anode varied greatly after 500 cycles, as a function of which side of the current collector it was on.

The inward facing cathode (under compression) when rolled into a jelly-roll, develops significant signs of coating delamination from the aluminium foil. On the outward facing cathode side (under tension), however, only a partial delamination was evident and the coating was transferred unto the separator. By contrast, severe delamination was observed on both sides of the anode coating. The inward facing anode side (under compression) showed almost no coating still adherent to the copper foil, compared to the outward facing anode side (under tension). Likewise, the delaminated coating had become adhered to the separator during operation.

outward facing cathode side (under tension), however, only a partial delamination was evident and the coating was transferred unto the separator. By contrast, severe delamination was observed on both sides of the anode coating. The inward facing anode side (under compression) showed almost no coating still adherent to the copper foil, compared to the outward facing anode side (under tension). Likewise, the delaminated coating had become adhered to the separator during operation.

Dr Mel Loveridge from WMG, University of Warwick comments:

“It is interesting to note that, for both the cathode and the anode, the delamination is more severe on the electrode coating side that would have been subjected to compression stress, rather than tensile strain. This can be further explained by considering the asymmetric forces in place on either side of double side coated electrodes.”

The research team also carried out electrochemical testing, X-ray photoelectron spectroscopy (XPS), X-ray computed tomography (XCT) and scanning electron microscopy SEM), to reveal the battery’s structural features and changes. They found that it maintains 82% cell capacity after 500 continuous charging and discharging, after which it shows severe delamination due to high bending stress exerted on the cell components. However this seemingly has minimum impact on the electrochemical performance if the coating is sufficiently compressed in the jelly roll with a good electrical contact. After ageing, the surface layers continue to grow, with more LiF found on the cathode and anode.

Their research opens up exciting areas in battery manufacturing to address winding issues for cylindrical cells (especially miniaturised formats). For example, highlighting the need to understand whether there is merit in varying the coating properties on each side of double-sided coating for wound cylindrical cells, in order to improve the mechanical resilience of coatings that have asymmetric stresses exerted on them.

ENDS

25 AUGUST 2020

NOTES TO EDITORS:

Paper available to view: https://www.sciencedirect.com/science/article/abs/pii/S0378775320309307?via%3Dihub

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wearable_image.jpg

Caption: An image demonstrating the stresses to anodes and cathodes after cycles.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/mel_l.jpg

Caption: A diagram of how tensile strain leads to the film cracking

Credit: WMG, University of Warwick

The full research team on the paper were:

Ageing analysis and asymmetric stress considerations for small format cylindrical cells for wearable electronic devices C.C. Tan, Marc Walker, Guillaume Remy, Nadia Kourra, Faduma Maddar, Shaun Dixon, Mark Williams and Mel Loveridge.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

C3-Cloud: the digital coordinated care platform of the future

- The C3-Cloud could be the future for supporting coordinated care across GPs, hospitals and specialties

- The novel solution would benefit patients with multiple conditions who are most in need of a holistic care plan

- It has been recognised by the European Innovation Radar as ‘tech ready’ and could be used to support remote care, not only in everyday use but also in the current and future pandemics

Typically, when a patient is receiving care from GPs and Hospitals, these are normally uncoordinated and the patient is often presented with conflicting advice, or clinicians are required to assess patients without access to all of the patient’s relevant history, often making care fragmented and inefficient, particularly for an ageing population who may have multiple conditions and need care from multiple specialists and stakeholders.

Healthcare has seen an explosive growth in the amount of data produced, which has led to more data driven and evidence based protocols. However, this has also presented challenges as data can become locked in silos or to particular vendors, limiting their availability for reuse, dissemination and potential to improve patient outcomes.

However, C3-Cloud (collaborative cure and care system) is a digital infrastructure offering integrated care capability for multi-morbidity management. It enables collaboration across a number of healthcare systems and settings, allowing clinicians to semi-automatically generate a holistic personalised care plan, which offers an integrated view of the patient’s conditions, measurements, medication and goals.

Patients and their multi-disciplinary care team can collaboratively create, review and edit the plan, empowering the patient to make decisions about their care. The care plan personalisation process is supported by a Clinical Decision Support module, implementing over 500 rules, consolidating and reconciling multiple clinical practice guidelines of common comorbidities (for example, diabetes, heart failure, renal failure and depression). The system accommodates local organisational aspects such as roles, as well interoperability to existing systems, it is currently deployed in three pilot sites in the UK, Spain and Sweden, integrating with their health systems and supporting coordinated care.

The C3-Cloud technology is flexible enough to support other conditions, including supporting remote management generally, which can be applied to situations, such as in the current COVID-19 pandemic. The project has recently investigated plans for deployment in such pandemic scenarios.

Professor Theo Arvanitis, the C3-Cloud project co-ordinator from the Institute of Digital Healthcare at WMG, University of Warwick comments:

“As the world develops and becomes more digital it is essential our healthcare system does too. With an ever growing population and life expectancies increasing it’s important to make a digital healthcare system that works for everyone and that is what the C3-Cloud does.

“Not only does the C3-Cloud work across all systems, it can recommend treatments for patients with multiple health problems, which is helpful when someone is seeing multiple care outlets such as their GP and local hospital for different care needs.

“Our first pilot has taken place, and with the European Innovation Radar identifying C3-Cloud’s key components as tech ready, our next step is to expand this to large scale trials in multiple countries, this could lead to an enrolment in the system, and if there’s ever a pandemic like Covid-19 again different strategies for people with different health problems could be deployed rapidly.”

NOTES TO EDITORS

High-res images available to view at:

https://warwick.ac.uk/services/communications/medialibrary/images/april2020/theoarvanitis.jpg

Professor Theo Arvanitis, Institute of Digital Healthcare, WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/c3-cloud_logo.jpg

Caption: C3-Cloud Logo

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/c3-cloud-infographic.jpg

Caption: C3-Cloud Platform

Credit: WMG, University of Warwick

C3-Cloud introductory video to the public at youtube channel:https://www.youtube.com/watch?v=Y3K_lUQkupg

C3-Cloud Website

C3-Cloud website

C3-Cloud @European Innovation Radarhttps://www.innoradar.eu/resultbykeyword/c3-cloud