WMG News

Project workshop addresses cyber-security in connected and autonomous mobility

Researchers from WMG, at the University of Warwick, were pleased to welcome partners and guests to a live trial and project workshop on the AirQKD project.

Researchers from WMG, at the University of Warwick, were pleased to welcome partners and guests to a live trial and project workshop on the AirQKD project.

AirQKD addresses the cyber security of Connected and Autonomous Vehicles (CAV) and specifically addresses components, manufacturing, software, and testing for last-mile Quantum Key Distribution (QKD) systems between shared parties for 5G and connected cars.

It is an Innovate UK funded collaboration between BT; Lexden Technologies; OLC; Duality, Bristol University; Fraunhofer Centre for Applied Photonics; Strathclyde University; WMG; Bay Photonics; Heriot Watt University; Angoka; ArQit; Nu Quantum; National Physical Laboratory; CSA Catapult and Edinburgh University.

The trial combines BT’s expertise in building quantum-secure networks using QKD – an essentially un-hackable, cutting-edge technique for sharing encryption ‘keys’ between locations using a stream of single photons) with other new techniques for applying quantum security to mobile devices, developed by UK start-ups Nu Quantum, Angoka and Duality.

On the University of Warwick campus, as part of the Midlands Future Mobility testbed, WMG has created a Vehicle to Infrastructure (V2I) testing facility enabling AirQKD partners’ technology in key management, key consumption, and security protocols to be used for secure communications.

The AirQKD system implements Free Space Optics (FSO) cryptographic key generation and standards-compliant key management. WMG is now managing the workstream between telecommunications (4G/5G cellular at BT’s Adastral Park site) and V2I communications on the University of Warwick campus. In combination, these technologies will be used to deliver an ultra-secure link between connected 5G towers and mobile devices, as well as to connected cars.

the workstream between telecommunications (4G/5G cellular at BT’s Adastral Park site) and V2I communications on the University of Warwick campus. In combination, these technologies will be used to deliver an ultra-secure link between connected 5G towers and mobile devices, as well as to connected cars.

Find out more about CAV research at WMG here: https://warwick.ac.uk/fac/sci/wmg/research/cav/connectivity/

Read more about AirQKD here: https://warwick.ac.uk/fac/sci/wmg/research/transformation/securecybersystems/projects

Professor David Greenwood on UK Gigafactory announcement from TATA Sons/JLR

Reactive statement from Professor David Greenwood, CEO of the High Value Manufacturing Catapult and Director of Industrial Engagement at WMG at the University of Warwick

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This announcement means that the UK is now above “critical mass” for supply chain companies and therefore sets the UK up to be an attractive place for businesses in the supply chain to invest to supply upstream and downstream materials needed for electric vehicle production. As one of the UK’s biggest academic institutions working in the area of battery and electric vehicle innovation, this is great news for all 250 of our researchers – we will now see the results of our work used in UK based industries and benefiting UK taxpayers rather than being exploited by competitors abroad.

“This is the culmination six years work here at Warwick Manufacturing Group - we helped the UK government set up the Faraday Battery Challenge which was a key part of the then Government’s industrial strategy. That investment has now borne fruit. Clearly, we now need to define our future vision and strategy as the global industrial landscape evolves at breakneck speed.

“This means the Prime Minister has realised he must provide sufficient investment to ensure the country is a competitive runner in the global race to dominate the markets created by the massive green transition needed to avert climate catastrophe.”

Battery recycling

Researchers at the University of Warwick estimate that by 2040 339,000 tonnes of batteries are expected to reach the end of their life in the UK alone.

Prof David Greenwood adds: “While we are busy building all these electric cars, we also need to think about what happens at the end of their useful life. Batteries contain significant quantities of materials which are costly to extract and refine and which could be hazardous to the environment if improperly disposed of. Investment is needed to create suitable recycling facilities in the UK within the next few years, and beyond that further research is needed to allow economic recovery of much greater proportions of the battery material. In doing so we will protect the environment, secure valuable raw materials, and reduce the cost of transport.”

Gigafactory FAQs

What is a gigafactory?

A gigafactory is a large factory that produces large numbers of batteries for electric vehicles. Tesla has pioneered the concept in the US, with six factories so far to produce batteries for their cars.

Why do we need one?

In order to a compete internationally and help preserve the UK automotive industry battery production needs to be scaled up rapidly across both the UK and Europe. This situation is exacerbated by tariffs due to be imposed across the UK and EU unless a certain proportion of a car is produced in one of those jurisdictions.

As an EV battery makes up around half of a vehicle’s weight it is crucial the UK vastly scales up battery production. Gigafactories are the most efficient way to do this.

How are electric car batteries made?

EV batteries come in lots of different shapes and sizes but are all made up of many battery cells put together to form a battery pack.

To make a battery, we take electrochemically active materials, like graphite, nickel manganese, cobalt and lithium, and make powders from them. These powders are mixed with solvents and adhesives, then coated onto metal (aluminium or copper) foils which are then packaged together inside cells.

This is a very precise process – otherwise the quality of the battery is impacted. At WMG, around 20 battery cells per day can be produced. At a gigafactory, production would be closer to 20 cells per second.

How are batteries recycled?

To recycle batteries, fire is used to recover most of the metals. Water can then be used to get further metals that can’t be reached using heat alone. There are still difficulties however in recycling lithium or graphite, which make up a large percentage of the metals in the batteries themselves.

With 11 million tonnes of lithium-ion batteries expected to need recycling by 2030, the need to build domestic capacity to recycle them is greater than ever.

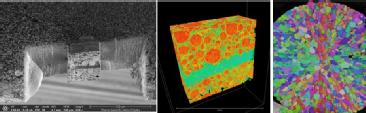

£1.5m funding secured to advance the investigation of microstructures in battery materials

Researchers at WMG, University of Warwick’s Forensics & Advanced Characterisation of Batteries Group, have secured £1.5m funding for materials analysis in multiple format batteries.

The funding, from the University of Warwick’s Academic Equipment Fund and the High Value Manufacturing Catapult, will be used to purchase a Plasma Focused Ion Beam (PFIB) microscope. The microscope is key to the accelerated development of new battery chemistries, providing unique access to the critical interfaces within battery cells that dictate best performance. This will be instrumental in developing new materials for better batteries, regardless of their end use application.

Focused Ion Beam (PFIB) microscope. The microscope is key to the accelerated development of new battery chemistries, providing unique access to the critical interfaces within battery cells that dictate best performance. This will be instrumental in developing new materials for better batteries, regardless of their end use application.

This PFIB will be the first specifically configured microscope dedicated to battery research in the world, allowing researchers at WMG to inform battery manufacturing, answer key scientific questions and link with industry and growing supply chains.

There is increased recognition in the battery community that the integration of new chemistries needed for the UK Government’s 2030 electric vehicle battery targets will require integrating new manufacturing processes with advanced microscopic characterisation. The PFIB has been specifically designed to address the critical challenges of studying alkali-based battery systems and will provide unique insights needed for the development of next generation batteries.

The performance of battery materials is dictated by the stability, efficiency and functionality of the interfaces, i.e. the solid electrolyte interphase (SEI) at the anode and oxygen-induced cathode-electrolyte interface (CEI) at the cathode. Attempts to analyse these interfaces, in order to determine structure and chemistry, is seriously compromised using conventional techniques by the extreme air-sensitivity, beam sensitivity and the high volatility of certain species present. The specially configured PFIB microscope will address these issues.

The performance of battery materials is dictated by the stability, efficiency and functionality of the interfaces, i.e. the solid electrolyte interphase (SEI) at the anode and oxygen-induced cathode-electrolyte interface (CEI) at the cathode. Attempts to analyse these interfaces, in order to determine structure and chemistry, is seriously compromised using conventional techniques by the extreme air-sensitivity, beam sensitivity and the high volatility of certain species present. The specially configured PFIB microscope will address these issues.

WMG is one of seven HVM Catapult centres in the UK and is the lead centre for transport electrification. Investment in this PFIB is part of a range of equipment investments by the HVM Catapult and the University of Warwick to maintain WMG’s leading position in battery technology.

The PFIB has already secured interest from the Faraday Institution and from the Royal Academy of Engineering’s Lord Bhattacharyya Education Programme. Starting in the Autumn, a student will use this for a project entitled “The development of a new multi-modal capability for investigating the performance-controlling interfaces and microstructures that underpin operation of battery materials.”

The Lord Bhattacharyya Education Programme provides up to 90 bursaries annually for local students from lower socio-economic backgrounds. The objectives for the scheme include encouraging a greater number of young people from a more diverse range of backgrounds, raising their aspirations and skill levels. Moreover, it supports the growth of a science and engineering skills base for the UK.

The project will make extensive use of the new system to develop strategies for studying the degradation of buried interfaces and structure dynamics in state-of-the-art high Ni NMC cathodes as a function of cycle ageing i.e., the evolution of the cathode-electrolyte interphases. The platform provides some unique opportunities for developing powerful new ways to characterise these controlling interfaces and will form the basis for the project. Preliminary research will commence in October 2023. The project will be advertised online for interested applicants to apply – the studentships page, Jobs.ac.uk, FindAPhD.com and the Doctoral College website.

Find out more about WMG’s electrochemical research here: Electrochemical Materials (warwick.ac.uk)

The new PFIB microscope will be based in WMG’s Advanced Material Manufacturing Centre (AMMC).

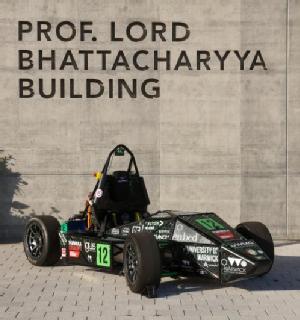

Warwick University's Formula Student Team Unveils Cutting-Edge Race Car for 2023 Season

The University of Warwick student team at Warwick Racing (WR), has unveiled its 2023 racing cars that will compete in the Formula Student competition at Silverstone just two weeks after the British Grand Prix.

Silverstone just two weeks after the British Grand Prix.

The cars will be judged on speed, acceleration and endurance at the Formula Student competition – the largest student motorsport competition in the world.

With a legacy of engineering excellence and a passion for motorsport innovation, Warwick Racing is a team made up of over 100 talented and dedicated students from diverse backgrounds and disciplines, who work collaboratively to design, build, and race high-performance vehicles that compete against university teams from around the world.

This year, the team have built their first electric autonomous race car, Wrai and the WRe2 – a battery electric race car. The cars were unveiled on 29th June 2023, at the National Automotive Innovation Centre.

The cars include use of cutting-edge technology, such as torque vectoring which enhances performance, while the autonomous car applies advanced software and artificial intelligence (ai) to an electric racing car to enable driverless racing.

The Formula Student competition, run by the Institute of Mechanical Engineering, serves as a launchpad for the next generation of engineers and allows participants to showcase their technical expertise, creativity, and teamwork. Warwick University's team, known for their commitment to excellence, has achieved some remarkable results in previous years including second place for business performance in 2022, and winning ‘most reliable EV’ in 2021. This year Warwick Racing are entering all three classes at the competition: Formula Student, AI, and Concept. Team Principle and MEng Mechanical Engineering student, Prem Singh Gill said "We are incredibly proud to present the WRe2 and WRai to the world. Our team has poured their hearts and souls into this project, and we are confident that our cars will make a strong impact in the upcoming Formula Student competition at Silverstone. We invite everyone to join us in celebrating the culmination of our hard work and dedication. We are incredibly grateful to the University, WMG, High-Value Manufacturing Catapult, and our main sponsor Optimas."

Team Principle and MEng Mechanical Engineering student, Prem Singh Gill said "We are incredibly proud to present the WRe2 and WRai to the world. Our team has poured their hearts and souls into this project, and we are confident that our cars will make a strong impact in the upcoming Formula Student competition at Silverstone. We invite everyone to join us in celebrating the culmination of our hard work and dedication. We are incredibly grateful to the University, WMG, High-Value Manufacturing Catapult, and our main sponsor Optimas."

Student Projects Manager Dr James Meredith said: “The cars look fantastic, they represent a culmination of a huge effort from students and staff at WMG, University of Warwick and we are really proud to see them launched. We very much look forward to seeing them compete at Silverstone.”

Ends

Notes to editors

For media inquiries and interview requests, please contact:

Bron Mills, Bron.mills@warwick.ac.uk, +447824540720

About Warwick University Formula Student Team:

The Warwick University Formula Student team is an interdisciplinary group of students passionate about automotive engineering and motorsports. With a legacy of success and innovation, the team aims to design, build, and race high-performance vehicles that compete in the Formula Student competition. The team represents Warwick University on a global stage, showcasing their technical expertise and pushing the boundaries of automotive engineering.

£220m boost to Midlands economy through WMG support programme

WMG at the University of Warwick is celebrating the completion of a major funded programme this week which has helped to add £220m to the Midlands economy.

Over the last five years, WMG’s Digital Innovation for Manufacturing (DI4M) has helped create 660 jobs and digitise 370 businesses – supporting hundreds of small and medium sized manufacturers across the Midlands.

New products have been taken to market through the programme including a novel electric charging point that attaches to lampposts, ultra-high speed 3D printer, and a wall climbing robot to undertake important maintenance work on tall buildings.

DI4M has been a five year, £10m programme supporting SME manufacturers to implement digital innovation. Delivered across the six Local Enterprise Partnership (LEP) areas of Coventry and Warwickshire, Greater Birmingham and Solihull, the Black Country, South East Midlands, Leicester and Leicestershire and Worcestershire, it has been led by the SME Group within Warwick Manufacturing Group, part of the University of Warwick. The programme was funded by European Regional Development Fund (ERDF) and the WMG centre High Value Manufacturing Catapult.

Companies that have benefited include Jaltek Systems who were helped to set up a new factory layout using digital twin technology and who also accessed a funded internship to get two major production lines up and running.

Companies that have benefited include Jaltek Systems who were helped to set up a new factory layout using digital twin technology and who also accessed a funded internship to get two major production lines up and running.

Gordon Ellis & Co was also a recipient of the funded programme and they were able to implement sensors and data collection devices around the factory to boost productivity and reduce waste.

Although this project has reached its endpoint, WMG’s SME group are continuing to support manufacturing SMEs through the High Value Manufacturing Catapult, Made Smarter West Midlands and through new schemes such as its Net Zero Innovation Programme and Business Energy Advice Toolkit which helps businesses reduce energy and costs with low-cost technology solutions.

Dr Mark Swift, Director of SME Engagement said: “The DI4M programme has been an important anchor for Midlands SME businesses through a period of unprecedented challenge and disruption. The programme has been a constant effective enabler for introducing new ideas, new technology to boost productivity as well as acting as a springboard to Net Zero and business energy efficiency. The economic impact speaks for itself – adding £220m, or £22 for every £1 invested, to our region is something we are all immensely proud of. We now look forward to further successes from a range of new energy efficiency, digital and productivity programmes.”

Find out more about WMG here https://warwick.ac.uk/fac/sci/wmg/

New Director of Business Development appointed at WMG

Dyrr Ardash has been appointed as the new Director of Business Development for WMG, at the University of Warwick.

Dyrr Ardash has been appointed as the new Director of Business Development for WMG, at the University of Warwick.

Dyrr will engage with education and research communities focusing on growing services to industry. He will lead business development across WMG, within professional education programmes and across all research areas - whether it be collaborative or industry funded opportunities. He will be engaging with a variety of customers from SMEs to large multi-nationals, within the UK and across the globe.

Dyrr is an automotive engineering graduate with more than 25 years’ experience in mobility and transportation, and a breadth of technical, commercial and strategic experience.

He started his career in powertrain development at Ford Motor Company, before joining DENSO where he developed electronic powertrain control and fuel systems for several European manufacturers. Dyrr held both Chief Engineer and senior commercial roles at Ricardo before joining WAE.

He has delivered projects globally in a variety of technical areas across products, from two-wheel mobility solutions, passenger cars, through to construction equipment and marine applications. At WAE he was responsible for strategic partnerships, collaborating closely with industry and academia, in addition to leading several de-carbonisation initiatives.

Dyrr explains: "I have long admired the impact that WMG has had on UK industry and its reach across the world. WMG capability is very relevant for the needs of today, but also the transformation of industry to one that will meet the sustainability requirements of mobility, transportation and beyond. I am very excited to be able to work with our current and potential partners to meet their sustainability goals and have a lasting impact on the world we live in.”

Professor David Greenwood, the CEO of the WMG centre High Value Manufacturing Catapult and Director for Industrial Engagement at WMG, University of Warwick, comments: “Dyrr joins WMG at an exciting time, as our primary research areas of electrification; sustainable materials; sustainable manufacturing; and sustainable transport are at the top of the agenda for government and much of industry.

“We look forward to broadening the impact of our research by working with an increasing number and type of businesses to deliver innovation into a wide range of market sectors.”

Find out more about the High Value Manufacturing Catapult centres here: https://hvm.catapult.org.uk/

To contact Dyrr about working with WMG, please email: wmgbusiness@warwick.ac.uk

You can also connect with Dyrr on LinkedIn

WMG marks fifth anniversary of its Graduate Development Programme

WMG, at the University of Warwick, is celebrating the fifth anniversary of its Graduate Development Programme.

In the past five years, WMG has seen a total of 23 graduates complete the two-year scheme, with a further 24 part of the current programme.

Of those 23, 14 are working at WMG in engineering roles, and a further nine are employed by industry.

The programme provides graduates with an opportunity to accelerate their careers by undertaking a series of placements in different teams across the department.

Graduates complete up to three different project rotations in year one, followed by a more in-depth project in year two. It provides the perfect opportunity for self-discovery and valuable work experience, whilst earning a competitive graduate salary.

The scheme has grown in size since it was first launched, and graduates are now offered four distinct pathways of Energy Innovation; Smart, Connected & Autonomous Vehicles; Materials & Manufacturing, or Catapult Projects.

Friya Tailor, who completed the Energy Innovation pathway, and is now a Project Engineer at WMG, commented: “I became aware of the WMG Graduate Development Programme during my MSc project at the University of Nottingham.

“My research involved the development of lithium-sulfur cells for a range of applications. This closely linked to the everyday activities performed at WMG, which was my motivation for applying to the programme. The graduate scheme allowed me to translate the knowledge and skills obtained during my degree and use it in world-class projects with automotive industry partners. The rotational programme encompasses various placements that pushed me to work proactively and develop vital skills required in any working environment.”

Shivam Mishra, joined in 2021 after completing a B.Eng in Mechanical Engineering and a MSc in Sustainable Automotive Electrification. He commented: “I have worked in various domains ranging from automotive powertrains to aerospace motor manufacturing, learning both technical as well as professional skills. Working closely with industrial partners has given me the opportunity to enhance my commercial awareness in this ever-changing sustainable industry. I have improved my CAD and modelling skills along with learning niche hands-on manufacturing skills. I have also developed technical report writing skills allowing me to publish my first conference paper with my team.”

Harry Boyce, who is now a Project Engineer in the Automation Systems Group at WMG, commented: “The WMG graduate scheme is ideal for anyone who is keen to both develop their technical and personal skills. You have the flexibility to choose the direction for your projects and learn from an experienced supervisor.

“In my opinion the scheme is a great stepping-stone into research and industry from university. The strongest aspect of the scheme is the focus on development for the graduate. The Project Management module in the first year is a great example, this provides a certification in project management from the APM, and provided me with many useful skills I could apply to my projects.”

The opportunity to work on projects that have a real impact on society is a key driver for many applicants. Anima Rahman studied Electronic and Electrical Engineering, and is currently in the second year of the scheme. She commented: “A career in research is working with tomorrow’s technology. It is a chance to gain an insight into current challenges in the industry and play an active role in overcoming them.”

Jet Feng, who completed the scheme and is now a Lead Engineer at WMG added: "I think one of the most important aspects of the graduate scheme is the people I met. They have shaped who I am both professionally and personally, and taught me valuable life lessons that I will keep forever."

For some graduates the scheme has also opened up the opportunity for further study, with two of the 2021 cohort now studying for a PhD at WMG.

The scheme is part-funded by the High Value Manufacturing Catapult, under the theme of Workforce Development. The UK has a shortage of skilled workers in the engineering sector, and it was recognised, by the Catapult that initiating and supporting a scheme that could upskill STEM graduates would be valuable to all – WMG as an organisation, the graduates themselves, and industry partners. In addition, WMG is keen to promote a diverse workforce in the STEM sector, in particular, encouraging applications from females and from BAME communities. Graduates on the scheme have generally studied engineering at university, although some have studied other STEM subjects

The scheme provides an opportunity to gain experience in different fields, without having to commit completely to one specific area. By rotating around a variety of placements, the graduates are able to build their confidence and skills, as well as learning what sort of work they enjoy and may wish to pursue.

In October 2023 a new intake of graduates will begin the scheme. Find out more about the programme here :https://warwick.ac.uk/fac/sci/wmg/careers/gs/

WMG inspires young engineers at Engineering Industry Day

On Tuesday 25th April, the Outreach Team at WMG, University of Warwick hosted an Engineering Industry Day.

The Team welcomed 200, year 9 and 10, students who were identified by their teachers as students, from groups under-represented in engineering and STEM careers, with an interest and a potential to do well in those subjects.

STEM careers, with an interest and a potential to do well in those subjects.

The students came from schools across the region including Eden Girls School Coventry; WMG Academy for Young Engineers in Coventry and Solihull; Colmers School and Sixth Form College; Nicholas Chamberlaine School; Lyndon School; Harris Church of England Academy; Barr’s Hill School and Community College; and KEVI Northfield School for Girls.

The group was welcomed by Professor David Greenwood, the CEO of the High Value Manufacturing Catapult and Director for Industrial Engagement at WMG, before being taken on a tour of the STEM facilities on campus.

Along with their teachers, they met academics and students, and heard about the research being carried out by the High Value Manufacturing Catapult; WMG and the School of Engineering. WMG Technical Services and the apprentices demonstrated their skills, and the Student Project teams - Warwick Racing and Warwick Mobile Robotics - showcased their work and shared their experience of studying engineering.

Participants also met with local companies including Jaguar Land Rover; Tata Motors; Aston Martin; National Grid ESO; Balfour Beatty; Wates; Willmott Dixon; National Grid; Tarmac and 3P Innovation, who provided them with advice and guidance about the skills and knowledge required to become an engineer.

They also received information about a range of support available from the Degree Apprenticeship Team; Student Funding; the Warwick Scholars Access Programme; the Sutton Trust Pathways to Engineering; the Royal Academy of Engineering’s Educational Programme and the Engineering Development Trust Programme.

WMG’s Outreach Project Officer, Marie Diebolt, who organised the event, explained: “With these types of events, and across our outreach activities, we work with our partners to close the engineering skills gap and inspire young people to pursue careers in STEM. We purposely timed the event to coincide with students selecting their GCSE subjects to enable them to make an informed choice and inspire them to consider a range of careers in engineering.”

Professor David Greenwood added: “We know that the UK manufacturing sector has a big skills gap – which WMG is keen to fill. Events like these help to shine a spotlight on the exciting career prospects in manufacturing – thanks to advances in digitalisation, automation and sustainability. The opportunity to speak to potential future engineers was a privilege, and the event was a great success.”

Professor David Greenwood added: “We know that the UK manufacturing sector has a big skills gap – which WMG is keen to fill. Events like these help to shine a spotlight on the exciting career prospects in manufacturing – thanks to advances in digitalisation, automation and sustainability. The opportunity to speak to potential future engineers was a privilege, and the event was a great success.”

Find out more about WMG’s Outreach programme here: Public engagement and Outreach (warwick.ac.uk)

WMG announces new partnership with global engineering company

WMG, at the University of Warwick, has announced a new two year research partnership focusing on sustainable high-performance sealing materials.

Researchers at WMG’s Link opens in a new windowInternational Institute for Nanocomposites Manufacturing (IINM), led by Dr Chaoying Wan, will be working with experts at James Walker to develop the next generation of sealing compounds which will be compliant with future per- and poly- fluoroAlkyl substances (PFAS) regulations.

In February 2023, the European Chemicals Agency announced a proposal for the European Economic Area that will effectively lead to a ban on all PFAS materials, due to their persistence in the environment.

This research project will use high quantity techniques to develop and identify novel elastomer compounds that comply with proposed PFAS regulations, for use in critical industrial applications drawing on WMG’s expertise in elastomer and polymer technology.

The new technologies developed will have a high impact on a wide range of industries from transportation, oil/gas, semiconductor to hydrogen storage and wind turbines.

and wind turbines.

Conventional high performance sealing compounds rely on PFAS, as these materials are resistant to extremes of temperature and aggressive chemicals. PFAS are essential to the semi-conductor, aerospace, petrochemical, defence and nuclear industries for example, and there are currently no suitable replacement materials available. Alternative sealing materials are urgently needed to substitute PFAS.

Dr Mike Eason, Technical and Quality Director at James Walker commented: "Industrial dependence on PFAS elastomers is a global issue with supply chain impact already seen. I am delighted that we will work with Dr Wan and her team to identify and develop materials which will help industry be compliant with the proposed regulations. This partnership will accelerate James Walker’s development of seal materials for critical industry. WMG has small scale, advanced, mixing capability, with knowhow regarding nanofillers and polymer science that will allow James Walker to rapidly design, manufacture and screen bench-scale test formulations.

“I believe the combination of James Walker’s history and expertise in critical industrial sealing together with WMG’s state of the art capabilities will enable rapid development and commercialisation of materials. James Walker is committed to developing solutions to the PFAS regulations faced by global industry."

Dr Chaoying WanLink opens in a new window, Reader of Functional Polymers and Nanocomposites at WMG, University of Warwick explains: "Collaborating with James Walker to develop alternatives for PFAS seals is an important and exciting opportunity. Our elastomer research facility is supported by High Value Manufacturing Catapult CentreLink opens in a new window (HVMC), equipped with the latest technology, including a rubber process analyser (RPA) with wide temperature range - it is the only one in the UK, and one of only a few in the world with the capability to simulate dynamic elastomer performance at very low temperature.

“This function is extremely useful to compare differences in formulation design for applications such as high pressure or low temperature sealing. I am very much looking forward to working with the James Walker team on the development of new material options for high performance sealing applications and advancing our knowledge of polymer formulation and performance."

Find out more about WMG’s Nanocomposites research here: Nanocomposites (warwick.ac.uk)

WMG celebrates a decade of Engineering Masterclasses

The Outreach Team, at WMG at the University of Warwick, is proud to have completed a decade of Royal Institution Engineering Masterclasses.

Over the past 10 years staff and students, from WMG, have supported 250 pupils from 45 schools across Warwickshire and the West Midlands. The Masterclasses have opened the eyes of young people to the excitement and value of engineering and, have in turn, inspired the next generation of scientists, mathematicians and engineers.

A special celebration event was held to mark the occasion with 2023 masterclass students and their families and teachers. At the event, University of Warwick alumna and award-winning engineer, Yewande Akinola delivered a key note before presenting certificates in a mini graduation ceremony.

Professor Margaret Low, WMG’s Director of Outreach and Widening Participation said: “WMG has supported the Ri with the masterclasses, since 2013, with workshops and activities that put our cutting-edge engineering research into context for young people. We even found a way to deliver the activities online during the pandemic.

Professor Margaret Low, WMG’s Director of Outreach and Widening Participation said: “WMG has supported the Ri with the masterclasses, since 2013, with workshops and activities that put our cutting-edge engineering research into context for young people. We even found a way to deliver the activities online during the pandemic.

“These experiences allow students to see how their school learning applies to complicated and world-changing technologies. Through our outreach programmes we hope to inspire young people to pursue careers in STEM, widen participation in higher education and make the STEM workforce more diverse.”

Mujthaba Ahtamad (Mosh), Senior Teaching Fellow at WMG, who worked alongside Professor Margaret Low on some of the original masterclass sessions, said: “With Margaret’s enthusiasm and motivation, she really brought everything together, including inspiring the teaching team. It was really evident that the attendees were very excited to attend the Masterclasses, (perhaps more so than attending school!).”

Dr Phil Jemmett, Widening Participation Co-ordinator at WMG added: “The Royal Institution is a prestigious organisation with a long history of being at the forefront of teaching science. Partnerships between universities in the local community, and the fact that these famous, royal-chartered groups are housed only a stone’s throw from Buckingham Palace, adds so much value to the student experience.

forefront of teaching science. Partnerships between universities in the local community, and the fact that these famous, royal-chartered groups are housed only a stone’s throw from Buckingham Palace, adds so much value to the student experience.

“This is not just an extra lesson that happens to be on a Saturday, this is an experience of just how far these students can go with their engineering talents. We hope that the students felt every bit of the prestige of both WMG and the Royal Institution.

“We would also like to thank the High Value Manufacturing Catapult who have supported these activities since 2019.”

Rachel Dorris, Clothworkers’ Fellow of Mathematics at the Royal Institution, said: “On behalf of the Royal Institution and the Masterclass team, I would like to congratulate you for successfully shepherding the Engineering Masterclasses at WMG to its 10th anniversary.

“We appreciate your hard work as an Ri collaborator - inspiring future generations within your community in the world of engineering.”

Find out more about WMG’s Outreach Programme here: Public engagement and Outreach (warwick.ac.uk)