WMG News

Changes to WMG’s leadership team

WMG is pleased to announce the appointment of Professor Robin Clark as its new Dean. In addition, Professor Paul Jennings has been appointed as Director of Research and Professor Dave Greenwood as Director of Industry Engagement. Professor Greenwood will also act as the CEO of the WMG Centre of the High Value Manufacturing (HVM) Catapult following the recent departure of Archie MacPherson.

Professor Clark takes up the role as Dean, having been at WMG since 2017, and most recently as Director of Education. Robin has 14 years’ experience of working in industry both in the nuclear and rail sectors, and has been working in HE since 2003 where his expertise lies in learning and teaching, HE management & leadership, and engineering education research. He is a graduate of UCL (BSc (Eng) and PhD), has an MBA from WCSU and is a National Teaching Fellow.

Professor Clark takes up the role as Dean, having been at WMG since 2017, and most recently as Director of Education. Robin has 14 years’ experience of working in industry both in the nuclear and rail sectors, and has been working in HE since 2003 where his expertise lies in learning and teaching, HE management & leadership, and engineering education research. He is a graduate of UCL (BSc (Eng) and PhD), has an MBA from WCSU and is a National Teaching Fellow.

Professor Jennings is a physicist who has been with WMG for over 25 years. He has built groups in Intelligent Vehicles, Energy Storage and Management, and Experiential Engineering through significant research and capital funding. He currently leads a team of 6 academics, over 25 researchers and engineers, and over 40 doctoral students. He has published over 100 academic papers and has been Principal Investigator on over 30 research grants, from sources including EPSRC, Innovate UK and the EU.

Professor Jennings is a physicist who has been with WMG for over 25 years. He has built groups in Intelligent Vehicles, Energy Storage and Management, and Experiential Engineering through significant research and capital funding. He currently leads a team of 6 academics, over 25 researchers and engineers, and over 40 doctoral students. He has published over 100 academic papers and has been Principal Investigator on over 30 research grants, from sources including EPSRC, Innovate UK and the EU.

Professor Greenwood joined WMG in 2014. Dave leads WMG’s Energy Research, and also holds advisory and board positions for the Advanced Propulsion Centre, Innovate UK (Faraday Challenge) and IDP and the Faraday Institution, and is Head of the Advanced Propulsion Centre's Electrical Energy Storage Spoke.

Professor Greenwood joined WMG in 2014. Dave leads WMG’s Energy Research, and also holds advisory and board positions for the Advanced Propulsion Centre, Innovate UK (Faraday Challenge) and IDP and the Faraday Institution, and is Head of the Advanced Propulsion Centre's Electrical Energy Storage Spoke.

Professor Jennings and Professor Greenwood also provide academic leadership for the development of R&D activities within the National Automotive Innovation Centre.

They form the Executive Team at WMG along with the Executive Chair, Margot James, the Chief Operating Officer, Jane Coleman, and the Chief Finance Officer, Nicola Constant.

WMG's Margot James and Professor David Greenwood respond to the news that Britishvolt will be establishing their UK headquarters and R&D centre in Warwickshire

WMG, at the University of Warwick, welcomes the news that Britishvolt will be establishing their UK headquarters and R&D centre on the MIRA technology park in Warwickshire.

This move underlines the Midlands region's role as the UK's leading innovator in battery technology, building on investments and expertise at WMG and the UKBIC.

WMG’s Executive Chair, Margot James, said: “The West Midlands has a strong position in battery research and innovation, and in the future we aim to take a key role in battery manufacturing. Britishvolt's recent announcement is further affirmation of the region's capability.”

Professor David Greenwood, CEO WMG centre HVM Catapult and Director of Industrial Engagement adds: “The establishment of large scale battery manufacturing in the UK is critical to retaining and growing the UK car industry. With such a facility in place, this opens up opportunities for both upstream and downstream supply chain companies.”

WMG part of new eLV car battery project

WMG, University of Warwick is part of a new project to create a new circular end-of-life supply chain for the electric vehicle industry. The project, led by EMR has won grant support from the UK Government’s Advanced Propulsion Centre.

WMG, University of Warwick is part of a new project to create a new circular end-of-life supply chain for the electric vehicle industry. The project, led by EMR has won grant support from the UK Government’s Advanced Propulsion Centre.

RECOVAS is a partnership between WMG, EMR, three major vehicle manufacturers; Bentley Motors, BMW and Jaguar Land Rover, the Health and Safety Executive, the UK Battery Industrialisation Centre, Autocraft Solutions Group, Connected Energy, which repurpose electric car batteries and uRecycle, which will develop the UK’s first commercial scale recycling facility for automotive battery packs.

Under current EU law and also post Brexit, manufacturers retain responsibility for the safe disposal of electric car batteries. There are already 164,100 pure electric vehicles on Britain’s roads, with that number rising to 373,600[1] when plug-in hybrids are included. This project aims to provide a standardised and reliable route for recycling and repurposing lithium ion car batteries at a scale that can cope with the expected sales of electric vehicles in the UK.

The project will start in January 2021 and will run for 3 years, by which time the partners expect the circular supply chain to be operating commercially.

Remanufacturing is the process of repairing and re-engineering existing batteries so they could potentially be used in new cars. Reuse involves giving batteries a second life in stationary storage to help balance the use of the electricity grid during peak use and optimise the use of renewable energy and other applications. The new supply chain will help all partners to triage batteries when they arrive at approved end-of-life vehicle treatment facilities across the UK for either remanufacturing, reuse or – where this is not possible – recycling.

Professor David Greenwood, CEO of the High Value Manufacturing Catapult, WMG, University of Warwick, said:

“Delivery of end-of-life provision for electric vehicle batteries is a strategic necessity for the UK, and this project will establish its first full scale facility. Without proper provision, end of life batteries could become a major safety and environmental concern.

“This project will implement state-of-the art recycling methods to meet and exceed the requirements of the current regulations. In addition, we will conduct research into new processes which could make the recovery of a much higher proportion of the battery material economically feasible. In doing so we will reduce the need for mining and refining of critical materials and we will reduce the carbon footprint of future electric vehicles. WMG is delighted to be at the core of this project, and we look forward to its delivery.”

Roger Morton, Managing Director for Technology and Innovation at EMR, said: “Our aim is to create a circular supply chain for batteries and, in the process, reduce the cost for end-of-life disposal for the vehicle manufacturer or last owner of the car to zero. By working in partnership with the RECOVAS consortium, electric vehicle manufacturers will develop simple design changes that greatly improve the potential to remanufacture, reuse or recycle their batteries at end of life. This will help to transform the economics of the electric vehicle market.”

Ian Constance, Chief Executive at the APC said: “Recycling of electric vehicle batteries is a principal part of the electric supply chain, so it’s vital that we get it right. The investment in innovative projects like RECOVAS, by EMR Metal Recycling, awarded as part of our APC 16 programme, demonstrates the importance of creativity and engineering excellence in the UK’s bid for a sustainable and commercial net-zero future.”

Developing and managing the infrastructure to process end-of-life electric vehicles and their batteries will generate new economic activity for the UK and create over 550 green jobs in the UK within the consortium members and their supply chain.

As part of the project, leading automotive manufacturers have agreed to share more information about the design and construction of their batteries, allowing the consortium to more effectively and efficiently repurpose or recycle them.

Morton added: “We have a very strong electric vehicle industry in the UK and it is changing fast. RECOVAS is an essential part of the sustainable roll out of electric vehicles.”

The UK Government is supporting RECOVAS as part of a £49m investment in technologies that will help the automotive industry to “go green”.

Minister for Business and Industry, Nadhim Zahawi MP, said the investment showed that the UK “is leading the global battle against climate change”.

He added: “Backed by government funding, these trailblazing projects will help the UK to build back better by creating all-important green jobs, ensuring the sector can make further strides towards an electrified automotive future.”

ENDS

27 NOVEMBER 2020

NOTES TO EDITORS

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Early construction of prototype innovative light rail vehicle for the City of Coventry

The Coventry Very Light Rail (VLR) is an innovative light rail system which will be battery powered, lightweight and rail-based.

In March 2019 a 3D simulation of the vehicle was released, and even with Covid-19 lockdowns, the vehicle build is progressing on schedule at NP Aerospace in Coventry.

On the 25th November Coventry City Councillor Jim O'Boyle, Coventry Cabinet Member for Jobs and Regeneration, took the opportunity to see how the construction of the prototype, developed by engineers at WMG, University of Warwick for the City of Coventry is progressing.

On the 25th November Coventry City Councillor Jim O'Boyle, Coventry Cabinet Member for Jobs and Regeneration, took the opportunity to see how the construction of the prototype, developed by engineers at WMG, University of Warwick for the City of Coventry is progressing.

WMG, University of Warwick have been working with TDI (Transport Design International) to deliver the novel very light rail vehicle, which as demonstrated in the photos is swiftly reaching completion with the driver’s desk and other sub systems now in place. The vehicle is expected to be finished in February 2021 ready for testing at the new rail innovation centre in Dudley.

Dr James Meredith, from WMG at the University of Warwick comments:

“WMG are delighted that the vehicle build is running on plan in spite of Covid-19. The project is an excellent showcase for UK engineering and manufacturing with over 70 % UK content. We look forward to testing the vehicle in 2021 alongside the innovative low cost trackform we are developing in parallel.”

Cllr Jim O’Boyle, Coventry Cabinet Member for Jobs and Regeneration, said:

Cllr Jim O’Boyle, Coventry Cabinet Member for Jobs and Regeneration, said:

“It is very exciting to see the VLR prototype take shape and for the project to take another big step towards becoming a reality.

“VLR will make a massive difference to our city, revolutionising travel and helping the environment. It will help keep our city at the forefront of the new transport industry and help us to attract new firms and jobs to take the city forward. It also helps cement our position at the centre of the green revolution with work such as UK Battery Innovation Centre.

“There has been some amazing work by all the project partners in some very difficult times and I can’t wait to see the next stages and watch it come out of the design rooms and on to our city’s streets.”

Darren Smith, Head of TDI comments:

“TDI are extremely pleased with the progress to date on the project and are looking forward to delivering the vehicle to our client in early 2021, so that it can begin its testing phase at the new VLRIC in Dudley. The teams involved in the delivery process across our full supply chain have worked tremendously hard, under difficult circumstances this year and I would like to thank them all for their efforts.”

James Kempston, CEO NP Aerospace, comments:

“It’s great to see the progress that has been made on the Very Light Rail project at our facility in Coventry at a time when all businesses are feeling the pressure of the pandemic. The platform will offer significant benefits for local people and the wider economy and we are honoured to have been selected to be part of the project. The team have worked very hard to ensure a high level of build quality and we are looking forward to the final release of the vehicle early next year. It is also very encouraging to be part of a development which will have a significant environmental impact.”

ENDS

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Prof. Lord Bhattacharyya Building, at the University of Warwick, wins prestigious Wood Award

The Prof. Lord Bhattacharyya Building, home to the National Automotive Innovation Centre, has won a highly prestigious Wood Award for its structural excellence.

The Prof. Lord Bhattacharyya Building, home to the National Automotive Innovation Centre, has won a highly prestigious Wood Award for its structural excellence.

The Wood Awards are the UK’s premier competition for excellence in architecture and product design in wood. The Awards’ elite independent judging panel, of professional experts and specialists, visited all the shortlisted projects in person, making the Wood Awards as meaningful and rigorous a competition as possible.

Commenting on the building’s outstanding design, the judges said Prof. Lord Bhattacharyya Building was: “No doubt a product of a client with a passion for superb engineering and a skilful architect able to take up the challenge. The visiting panel was unanimous in the view that this was an award-worthy building.”

This award comes just weeks after the Building was recognised as one of the best workplaces in the Midlands and Central England at the annual British Council for Offices (BCO) regional awards; won Building Magazine Project of the Year at the Building Awards 2020; and won AIA Excellence in Design Awards 2020 for sustainability.

This year, the Prof. Lord Bhattacharyya Building has also been shortlisted for a RIBA West Midlands regional awards; FX International Interior Design Award and 2021 Civic Trust Awards Regional Finalist.

Based at the University of Warwick, the Building was officially open in February 2020 by HRH The Prince of Wales. It is a partnership between WMG, University of Warwick, Jaguar Land Rover, and Tata Motors, and is the largest of its kind in Europe and is well timed, arriving when a global mobility revolution is underway, with a new age for transport mobility.

A beacon for automotive research it brings together the brightest minds from industry and academia, to develop future vehicles and mobility solutions. It is home to up to 1,000 staff working across design, engineering and research, as well as future engineers on degree programmes.

Designed by Cullinan Studios the brief for the Centre was for simplicity and strength of purpose, turning a complex assembly of spaces into an immediately legible building.

WMG Assistant Professor joins Micromobility Research Fund

WMG Assistant Professor of Human Factors, Roger Woodman, has been selected to join the Micromobility Research Fund set up by the Ford-owned e-scooter firm Spin.

WMG Assistant Professor of Human Factors, Roger Woodman, has been selected to join the Micromobility Research Fund set up by the Ford-owned e-scooter firm Spin.

Roger is one of only 12 academics selected to join the panel made up of experts from ten leading UK and US universities and industry. Together they will study various safety aspects of e-scooter use as well as rider behaviour, and the challenges and opportunities of the integration within a city’s road systems and existing public transport networks.

Roger Woodman explains: "Ultimately, the point of introducing e-scooter schemes is to advance our society and to bring a greater benefit to all, not just to the e-scooter riders and the service providers but to all who live in our towns and cities. Just as with many new services, this will require ongoing reflection and review from everyone, including the general public and stakeholders and the path may not always be straightforward. I’m confident that building a strong body of independent research will allow policy makers, e-scooter advocates, as well as sceptics, to advance the dialogue and put forward legislation that best supports everyone.”

Josh Johnson, Public Policy Manager at Spin, adds: “The willingness to share independent research and learnings about the adoption of e-scooters with key stakeholders has become less of a priority for operators and this needs to change. Spin is committed to improving and advancing micromobility policy frameworks globally in the markets we operate in. These studies will give everyone fresh and actionable insights. We look forward to sharing best practices with stakeholders in the UK and beyond around how to best integrate e-scooters into local transport networks while maximising safety of all road users and provide communities with a green, fun and socially-distanced way to travel.”

Safe travel behaviour will be at the centre of research topics and will build on Spin's solid research-based policy work developed in the US over the past two years.

Josh adds: “Our top priority has always been rider safety. All operators have a responsibility to their riders to not only exceed vehicle safety standards but provide a platform to educate riders on safety best practices and how to be mindful of pedestrians and other road users.”

Preparation for the first piece of research is under way in Milton Keynes. This study will explore factors that influence road-user safety including:

● Where do e-scooter users ride most often (cycle lane, roadway, pavement) and why?

● How often do safety incidents occur, and what are common factors?

● What factors or conditions (i.e. cycling infrastructure, weather, traffic volume, etc…) impact real or perceived safety of e-scooters for users and for non-users?

The study will be informed by a diverse set of data sources including qualitative and quantitative consumer survey data and on-street AI and IoT sensor data of e-scooter interactions with pedestrians, cyclists and cars captured by Vivacity Lab’s sensors that are installed in the city. The researchers will also have access to anonymised e-scooter movement data (GPS).

Vivacity’s roadside sensors employ machine learning algorithms to detect near-miss incidents and are able to analyse movement patterns of vulnerable road-users such as cyclists and pedestrians, as well as non-connected vehicles. Such data will be invaluable to assess why near-misses may happen and what could be possibly done to minimise them. All data shared by the sensors is anonymised with video feeds discarded at source, enabling safer roads without intruding on privacy.

The research may include outputs such as a mapping of “safe routes” based on riding patterns and user feedback, and recommendations on how local authorities and operators could encourage riders towards a safer use of e-scooters. Recommendations may also include infrastructure improvements or other policy changes to enhance roadway safety for all users.

Find out more about WMG’s Human Factors research here.

New engineering partnership to develop digital marketplace to improve manufacturing supply chain

A research team, including WMG at the University of Warwick, led by Swansea University College of Engineering, are developing a pilot online marketplace designed to optimise manufacturing supply chain networks and create a new industry-wide business model.

This new platform will seek to better connect manufacturers and suppliers, enabling a streamlined product/process sourcing and selection service tailored to industry needs, with the support of the Institute for Innovative Materials, Processing and Numerical Technologies (IMPACT).

The project will initially focus on supporting Welsh manufacturing companies with the aim to create an innovative digital supply chain marketplace (DSCM) template that can be replicated nationally and globally. One of the first companies to trial the new platform will be Swansea-based company MyMaskFit. Their aim is to produce custom fit reusable PPE masks for use during and beyond the COVID-19 pandemic. Customers will send a scanned image of their face to the company via an app designed to record the dimensions needed to create the bespoke product.

A challenge for many companies, like MyMaskFit, is often creating a new supply chain and sourcing the many products and services required to bring regulated products to market.

Unifying shared expertise with industry experts and researchers from WMG, University of Warwick and the Manufacturing Technology Centre, this new partnership will offer companies, like MyMaskFit, access to a more open and dynamic market, with increased opportunity for UK SMEs, and by making markets more efficient and flexible, should raise productivity and open new value chains through wider reach.

Jan Godsell, Professor of Operations and Supply Chain Strategy, WMG, University of Warwick, comments: “Major disruptions such as COVID-19 have challenged the conventional and static design of supply chains. Market places have an important role to play in connecting UK manufacturers with the emerging demand for new products and services. They support the development of new types of business models and dynamic supply chain designs, that will underpin the future of UK manufacturing. Self-assessment tools, roadmaps and blue prints will be made available through the ISCF Supply Chain Innovation Hub, so that these opportunities can be exploited by firms across the UK”.

Jan Godsell, Professor of Operations and Supply Chain Strategy, WMG, University of Warwick, comments: “Major disruptions such as COVID-19 have challenged the conventional and static design of supply chains. Market places have an important role to play in connecting UK manufacturers with the emerging demand for new products and services. They support the development of new types of business models and dynamic supply chain designs, that will underpin the future of UK manufacturing. Self-assessment tools, roadmaps and blue prints will be made available through the ISCF Supply Chain Innovation Hub, so that these opportunities can be exploited by firms across the UK”.

“The challenge of existing marketplaces is that the relevance and quality of data is subjected to manual scrutiny and intervention,” comments project lead, Professor Johann Sienz, Deputy Executive Dean, Faculty of Science and Engineering and IMPACT Director. “This marketplace will be designed to provide visibility and access to supply chain processes and will deliver live validated and relevant data to make decisions. It will be valuable to the supplier through creation of ‘one supplier-to-many customers’ with the additional benefits of reducing administrating expenses, and maximises volume leverage, with less IT integration requirement.”

“This ‘Made Smarter’ testbed will act as a template for other digital supply chain marketplaces to be created to serve other sectors, geographies and verticals, for instance exclusive communities for highly regulated industries, where trust in the access, integrity, and security of information is critical.”

Driven by industry feedback, this new DSCM will offer much-needed features such as accuracy and precision for parts; pricing accuracy; reduced supplier response times from weeks to hours; and provide options with dynamic lead times and quality, cost, certainty – resulting in a quicker and more efficient supply chain process.

Valerie Bednar, MyMaskFit Director, comments: “MyMaskFit is pleased to deliver a programme to the Manufacturing Made Smarter Testbed where we hope to prove the success of sourcing in the regulated digital supply chain marketplace for components of our Reusable and Custom fitted medical grade mask.

As part of this 6-month project, a rapid scale-up of manufacturing operations is planned involving manufacturing partners – including cloud collaboration tools from design and manufacturing software company Autodesk.

Asif Moghal, Senior Industry Manager, Design and Manufacturing at Autodesk comments: “This is another great example of how the industry is coming together and rising to a new challenge. Protecting our key workers is essential and we have an opportunity to bring about new learnings from this rapid development project featuring personalised masks. We are confident this will be a transformative step for the industry, with the potential to scale globally and pass learnings onto other industries.”

The project is funded by the ISCF Manufacturing Made Smarter programme and will conclude in May 2021. Industrial partners also include Plyable, Amplyfi, AI Idea Factory, PXL ICE, Carapace, Cadarn and Industry Wales.

The IMPACT operation is part-funded by the European Regional Development Fund through the Welsh Government and Swansea University.

ENDS

For further information please contact:

Alice Scott

Media Relations Manager - Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG scientists named amongst the best in the world

Congratulations to the five WMG academics who have been named in Stanford University’s global list recognising the top 2% of the world’s leading scientists.

The scientists were classified into 22 scientific fields and 176 sub-fields using Science-Metrix journal classification system. Led by Professor John Ioannidis of Stanford University, the research team has created a database of over 100,000 top scientists of the world based on standardised citation indicators, which include information on citations, an individual’s scientific research output or H-index, co-authorship, and a composite indicator for career-long impact.

The analysis was conducted using citations from Scopus along with data assessing scientists for career-long citation impact till the year 2019 and for citation impact during a single calendar year. The study has been published in PLOS Biology. According to Professor Ioannidis, this is the first classification that systematically ranks all the most-cited scientists in each and every scientific field to a sufficient ranking depth.

The WMG academics featured on the list are:

Darek Ceglarek, Professor of Digital Lifecycle Management, (sub-field: ‘Industrial Engineering and Automation’)

Claire Davis, Professor of Steels Processing, (sub-field: ‘Materials’)

Richard McMahon, Professor of Power Electronics, (sub-field: ‘Electrical and Electronic Engineering’)

Tony McNally, Professor in Nanocomposites, (sub-field: ‘Polymers’)

Ton Peijs, Professor of Polymer Technology, (sub-field: ‘Materials’)

Professor Darek Ceglarek, explained: It is an interesting study which standardised citation indicators across all scientists and scientific disciplines for all scientists who published at least five papers. This was needed as there has been a challenge in interpreting citation indicators due to large differences in numbers of citations between different fields. For example, the differences between fields can range more than three times between engineering and clinical medicine; or even up to nine times between engineering and physics.

Professor Darek Ceglarek, explained: It is an interesting study which standardised citation indicators across all scientists and scientific disciplines for all scientists who published at least five papers. This was needed as there has been a challenge in interpreting citation indicators due to large differences in numbers of citations between different fields. For example, the differences between fields can range more than three times between engineering and clinical medicine; or even up to nine times between engineering and physics.

“This of course depends on a total volume of scientific publications in a given field, but also on the relevance of other aspects of ‘broader impact’ within a field. For example, in engineering broader impact includes not only scientific contributions as measured by citations but also broader economic impact and impact to society. However, we need to take the data with caution as research importance and impact are not easy to measure.”

Margot James, Executive Chair, WMG adds: “I am immensely proud of all of our academics, and want to congratulate the five Professors on being placed in the top 2% globally, they represent the very best of British academia. It’s wonderful that WMG students and industrial partners have direct access to their expertise.”

View the full list here.

Expert comment from Margot James and Professor David Greenwood

WMG's Executive Chair, Margot James, and Professor David Greenwood, CEO of the WMG centre High Value Manufacturing (HVM) Catapult and Director of Innovation respond to the Government’s 10-point climate change plan.

WMG's Executive Chair, Margot James, and Professor David Greenwood, CEO of the WMG centre High Value Manufacturing (HVM) Catapult and Director of Innovation respond to the Government’s 10-point climate change plan.

Margot James comments: “Zero Carbon transport is crucial to protecting our planet, so the government’s timescale for our national shift to electric vehicles is, rightly, ambitious. We should approach this challenge with optimism and enthusiasm.

“At WMG at the University of Warwick, our researchers identify, test, and scale up for manufacture the next generation of batteries, developing batteries that are smaller, more powerful, longer lasting and cheaper to run than ever before, while also ensuring they have a second life to help power homes and factories with clean energy. From lithium-ion to solid-state, much of our future travel will be battery powered, and the government’s announcement of a £500 million investment in the development and production of electric vehicle batteries will help us get there faster.

“Developing the advanced batteries to improve electric vehicle performance and lower cost is just one part of the sustainable transport challenge. To ensure a green recovery, Britain’s Research and Development networks and manufacturing base must work together so the next generation of green automotive jobs are created in Britain.

“To achieve this, we need to build gigafactories in the UK to produce batteries and back our supply chain to build the motors and power electronics, energy management systems and lightweight materials needed for the next generation of electric vehicles, all as we train up the next generation of engineers and business leaders with the skills needed for the UK to lead in Zero Carbon Transport.

“In all of these areas, WMG and Warwick are partners with Britain’s leading businesses. They tell us how important it is to invest now in the supply chain, infrastructure and skills, training and education if the UK is to benefit from the sustainable transport revolution. The Government’s announcement of extra investment will help ensure British transport innovation will lead to green transport jobs across the UK.”

Professor David Greenwood comments: “This 10 point plan really places the UK at the forefront of decarbonisation. This is truly welcomed but we should not underestimate the scale of the challenge. Sustained investment will be needed both by industry and government to bring the cost of electric vehicle technology down, to have the manufacturing capacity to supply the vehicles, to deliver the charging infrastructure required, and to recycle the EVs at the end of their life. In particular, research and development has a huge part to play in delivering this as quickly and as cost effectively as possible. As this has been exactly the focus of WMG’s Energy research activities over the last decade, we look forward to playing our part in this green transport revolution.”

The ultimate conditions to get the most out of high-nickel batteries

It is common knowledge in battery manufacturing that many cathode materials are moisture sensitive. However, as the popularity of high nickel-based battery components increases, researchers from WMG, University of Warwick have found that the drier the conditions that these cathodes are stored and processed in, then significant improvement in performance of the battery is gained.

High-Ni (Nickel) batteries are becoming increasingly popular worldwide, with more automotive companies investigating the use of high-Ni batteries for electric vehicles.  However, high-Ni cathode materials are prone to reactivity and instability is exposed to humidity, therefore how they are stored in order to offer the best performance is crucial.

However, high-Ni cathode materials are prone to reactivity and instability is exposed to humidity, therefore how they are stored in order to offer the best performance is crucial.

In the paper, ‘The effects of Ambient Storage Conditions on the Structural and Electrochemical Properties of NMC-811 Cathodes for Li-ion batteries,’ published in the journal Electrochimica Acta, researchers from WMG, University of Warwick propose the best way to store high-nickel cathodes in order to mitigate premature degradation.

Researchers exposed NMC-811 (high-Ni cathode material) to different temperatures and humidities, then measured the material’s performance and degradation in a battery over a 28 day period, analysing them using a combination of physical, chemical and electrochemical testing. This included high-resolution microscopy to identify the morphological and chemical changes that occurred at the micron and sub-micron scale during the batteries charging and discharging.

The storage conditions included vacuum oven-dried, as exposed (to humidity) and a control measure. Researchers looked for surface impurities, which include carbonates and H2O, and found there were three processes that can be responsible for impurities, including:

1. Residual impurities emanating from unreacted precursors during synthesis

2. Higher equilibrium coverage of surface carbonates/hydroxides (present to stabilise the surface of Ni-rich materials after the synthesis process)

3. Impurities formed during ambient storage time

They found that in all conditions, (oven dried and as-exposed) showed inferior first discharged specific capacity and cycling performance, compared to the control. However the as-exposed measure showed that after 28 days of ambient moisture exposure the H2O and CO2 react with the Li+ ions in the battery cell, resulting in the formation of lithium carbonate and hydroxide species.

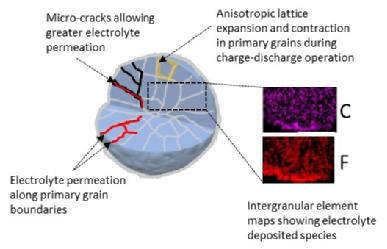

The formation of carbonates and oxides on the surface of NMC-811 contribute to the loss of the electrochemical performance during ageing of the materials, due to the inferior ionic and electronic conductivity, as well as the electrical isolation of the active particles. This means that they can no longer reversibly store lithium ions to convey “charge”. SEM analysis confirmed the inter-granular porosity and micro-cracks on these aggregate particles, following the 28 days of ambient exposure.

The formation of carbonates and oxides on the surface of NMC-811 contribute to the loss of the electrochemical performance during ageing of the materials, due to the inferior ionic and electronic conductivity, as well as the electrical isolation of the active particles. This means that they can no longer reversibly store lithium ions to convey “charge”. SEM analysis confirmed the inter-granular porosity and micro-cracks on these aggregate particles, following the 28 days of ambient exposure.

They can therefore conclude that the driest conditions, at dew points of around -45 oC, are the best for storing AND processing the materials, in order to then produce the best battery performance. Humidity conditions and exposure at junctions along the manufacturing process will cause the materials and components to experience; this results in shorter battery lifespan.

Dr Mel Loveridge from WMG at the University of Warwick comments:

“Whilst moisture is well known to be problematic here, we set about to determine the optimal storage conditions that are required to mitigate unwanted, premature degradation in battery performance. Such measures are critical to improve processing capability, and ultimately maintain performance levels. This is also of relevance to other Ni-rich systems e.g. NCA materials.”

Professor Louis Piper from WMG at the University of Warwick adds:

“Considerable global research effort will continue to focus on these materials, including how to protect their surfaces to eliminate risks of parasitic reactions prior to incorporation into electrodes. In the UK, leading research by the Faraday Institution has a project consortium entirely devoted to unravelling the degradation mechanisms of such industry-relevant materials.”

ENDS

18 NOVEMBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/the_effects_of_ambient_air_storage_on_the_surface_stability_of_nmc-811.jpg

(1) Caption: The effects of ambient air storage on the surface of NMC-811

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/post-mortem_nmc811_particle.jpg

(2) Caption: a-b) Post-mortem NMC811 particle, with no prior exposure to moist air, analysed by FIB-SIMS, targeting Lithium detection. c-d) Post-mortem NMC811 particle, after 28 days exposure to moist air, analysed by FIB-SIMS, targeting Lithium detection.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/schematic.jpg

(3) Caption: Schematic illustration of particle breakdown during charge-discharge of a battery

Credit: WMG, University of Warwick

Paper available to view at: https://www.sciencedirect.com/science/article/pii/S0013468620317515?via%3Dihub