WMG News

New Loqski glass fibre ski lock to keep your skis safe this season

- With winter being the ski season many skiers will be off on holiday, possibly taking their own expensive skis

- When leaving your skis for a break from the slopes they’re at risk of being taken intentionally or unintentionally from the racks, however Loqski have come up with a solution made and manufactured in the UK

- Loqski is a pocketable device locking skis and poles together, WMG at the University of Warwick have helped them manufacture the locks affordably and sustainably

- Loqski’s new and improved lock is available to buy now

On a ski resort, after spending time on the slopes skiers will often head inside for a break in a restaurant or bar leaving their skis with everyone else’s on a rack outside. For this reason avid skier James Pittard decided not to buy himself expensive skis for fear that they would go missing, whether intentionally or unintentionally.

On a ski resort, after spending time on the slopes skiers will often head inside for a break in a restaurant or bar leaving their skis with everyone else’s on a rack outside. For this reason avid skier James Pittard decided not to buy himself expensive skis for fear that they would go missing, whether intentionally or unintentionally.

This led him to think about an easy to use, pocketable device that could lock both skis and poles simply together. Taking his idea to a design agency, the Loqski ski lock, with its high security combination lock that can be operated even with ski gloves on, was launched in a zinc-based material.

However, as sales were taking off the zinc-based material used couldn’t be manufactured quick enough to keep up with demand, until they discovered GV-5H, a glass fibre reinforced thermoplastic material that is often used in the automotive industry as it’s incredibly tough yet lightweight.

James then approached WMG, at the University of Warwick for help on a number of aspects of this looking into Grivory GV-5H, including testing the material, assessing the strength of the redesigned components in the assembly and giving advice on ways in which costs can be reduced during the manufacturing process.

Whilst it’s not possible to 3D print in Grivory GV-5H, researchers from WMG printed the prototype parts in strong engineering plastic with a carbon fibre infill using Markforged Mark 2 FDM printer that would reflect the strength of this material. These prints proved the suitability of Grivory GV-5H for this product.

They also assessed whether a redesigned barrel design component would fit into the assembly as changing just this one part would help reduce costs. They produced many 3D prints of the barrel component; these parts were then thoroughly tested not only for form and function but also to assess that it would fit with the other components in this existing assembly.

Being able to fully test the fitment of the new barrel design enabled Loqski to compare the cost of having to tool a completely redesigned product, which would be an excess of £50,000, or spending £7,000 for tooling just this barrel component and using it in the existing assembly.

“Loqski are now in a position where they are able to streamline manufacture. With less components to assemble, the assembly time has sped up and so manufacturing costs have been reduced. Loqski always had an ambition of keeping manufacture in the UK and by reducing manufacturing costs, we are pleased that we could assist them in doing that. We are thrilled to see them take their new and improved lock to the market, and hope that skiers this season will invest to keep their skis safe.” says Neil Jeffree, Innovation Manager at WMG, University of Warwick.

By reducing manufacturing costs Loqski is now able to produce a more cost-effective end product in higher volumes, which will put the company in better stead to work with distributors and have the product stocked by retailers worldwide. It has also led James to consider expanding the product’s reach even further.

“One of the things we’d now like to push is getting the new product into the ski rental market, where it can be hired out when skiers rent their skis. This is something we would never have considered with the zinc-based product as it was just too expensive.” says James Pittard, founder of Loqski.

ENDS

18 JANUARY 2022

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january_2022/img_2601.jpg

Caption: The Loqski Lock

Credit: Loqski

https://warwick.ac.uk/services/communications/medialibrary/images/january_2022/img_2612.jpg

Caption: The Loqski Lock

Credit: Loqski

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Challenges of transport electrification skills to be addressed by Universities of Warwick and Newcastle

Two leading universities in the field of electrification – WMG at the University of Warwick and Newcastle University – are coming together to ensure the UK workforce has the skills necessary to meet the challenges of the transition to fully electric production.

Two leading universities in the field of electrification – WMG at the University of Warwick and Newcastle University – are coming together to ensure the UK workforce has the skills necessary to meet the challenges of the transition to fully electric production.

As anchor higher education institutions with exceptional research and innovation programmes operating in regions at the forefront of the UK’s electric revolution, the universities intend the collaboration will enable the growth of a talent pipeline of graduates and postgraduates into UK business. Led by WMG at the University of Warwick and Zero Carbon Futures at Newcastle University part of the school of engineering, the effort will identify the people, skills and facilities needed across a range of academic disciplines and levels in order to deliver new curriculums to meet growing industry demand.

The UK’s move to fully electric vehicle production and domestic battery manufacturing represents the largest shift in industrial skills for the UK in a generation, leaving competency gaps at all job levels, particularly in engineering and manufacturing roles which will need to be filled with specific education and training. The Faraday Institution estimates that to meet automotive production demand by 2040, an additional 70,000 skilled employees will be needed for battery manufacture and in the associated material supply chain.

“In light of COP26, which stressed the need for electrification to help us combat climate change and reach Net Zero goals, it is imperative that researchers and industry work together to bridge the gaps and create a smooth transition to electrification,” commented Dr Benjamin Silverstone from WMG, University of Warwick. “We are delighted to be working with Newcastle University and believe that together we can define what and who needs upskilling, reskilling and new-skilling.”

and industry work together to bridge the gaps and create a smooth transition to electrification,” commented Dr Benjamin Silverstone from WMG, University of Warwick. “We are delighted to be working with Newcastle University and believe that together we can define what and who needs upskilling, reskilling and new-skilling.”

Professor Colin Herron CBE, Zero Carbon Futures at Newcastle University and Faraday Institution North East regional liaison said, “The bringing together of the two leading universities in electrification, located in the two regions leading on transport electrification is an exciting prospect, and one which should deliver the skills required for massive challenges ahead.”

“We fully support this collaboration between two powerhouse institutions working at the forefront of electrification,” said Professor Pam Thomas, CEO, The Faraday Institution. “Such innovative partnerships will enable the UK to anticipate and deliver the skills needed to fully electrify transport, grow new talent for battery production, and support green growth and economic development."

Another key objective of the collaboration is to help shape national and regional skills strategies and in so doing support national and regional economic development. The call for a collaborative approach to re-skilling, up-skilling and new-skilling the workforce for the electric revolution was published in a report by WMG, University of Warwick, the Faraday Institution and the High Value Manufacturing Catapult ‘The Opportunity for a National Electrification Skills Framework and Forum’ in September 2021.

ENDS

14 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wmg_ukbic-33.jpg

Caption: A battery pouch made at WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/d2807-27.jpg

Caption: A battery production line at WMG, University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wmg_ukbic-49.jpg

Caption: A battery production line at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Festive outreach gifts for young engineers

The WMG Outreach team has been making special Christmas deliveries to children across the West Midlands and Warwickshire.

A total of 45 festive STEM parcels have been delivered to young engineers at primary schools, community groups, Coventry’s Hospital Education Service, Coventry Transport Museum and IntoUniversity.

IntoUniversity.

Each parcel contained printed templates of Christmas-themed decorations on a flat sheet of card, along with instructions and a link to a video tutorial.

Phil Jemmett, WMG Outreach Project Officer, explained: “The activity teaches young people how 3D objects can be made from flat materials. This is often how real-world items are made and stocked in shops because it takes up so much less space. We’re all used to the idea of ‘flat-pack’ now – it's time to show young people why it’s so common.

“To cement the learning for our young audience, there is a final challenge! This is a creative activity where students design and make their own 3D item from paper or materials. The children then bring all their creations together around a central stand to make a festive display.”

Sophie Meeson, Brown Owl at Berkswell Brownies Brown Owl said: “Berkswell Brownies were thrilled to use the Christmas-in-a- box resource. The children enjoyed seeing their hard work become a 3D final product, and it was a great way of combining reading comprehension skills with fine motor skills and problem solving to ensure they had made the necessary cuts and folds for their final piece to fit together. Being able to tie it into our Christmas craft evening was a bonus for the leaders too, fitting the theme perfectly. Our thanks go to the outreach team at WMG.”

Professor Margaret Low, WMG’s Director of Outreach and Widening Participation added: “These boxes are only possible thanks to the support of our staff designing the items in the boxes, packing and delivering boxes to their local schools, as well as the support of WMG and the High Value Manufacturing Catapult. The contributions of our entire team, during a busy festive period, show our commitment as a department to inspiring the next generation of engineers.”

All of the resources are also available online for free here: www.warwick.ac.uk/wmgoutreach/resources/flatpack

Heritage locomotive project picks up steam thanks to WMG

WMG’s SME Team has been supporting 3D Heritage and The A1 Steam Locomotive Trust (A1SLT) in their quest to revive steam rail travel.

3D Heritage and The A1 Steam Locomotive Trust’s (A1SLT) plan was to build a brand new Gresley class P2 steam locomotive, No. 2007 Prince of Wales at its Darlington Locomotive Works (DLW). The original class P2s were designed by Sir Nigel Gresley to haul trains on the arduous Edinburgh to Aberdeen route, however sadly the design was never fully developed to its full potential.

its Darlington Locomotive Works (DLW). The original class P2s were designed by Sir Nigel Gresley to haul trains on the arduous Edinburgh to Aberdeen route, however sadly the design was never fully developed to its full potential.

With new technology and expertise, they decided to resurrect the class P2s and bring their dream to life. However, there were some design and materials challenges, specifically with the original Lentz valve gear and cambox, that needed to be resolved.

WMG’s Innovation Manager, Dr Paul Lansdell, worked with the 3D Heritage and the Trust to create a CAD model that could be tested and amended. He also recommended the use of 3D printing in ABS plastic to create a one-third scale model of the cambox for the team to see if any changes were required before committing to manufacture. The box also featured a series of windows that enabled the engineering team to see what was happening with the valve mechanism on the inside.

Following the creation of the model, Dr Lansdell went on to explore the material grades, surface coatings and heat treatment which previously caused issues. This work has been extremely transformative, giving the project huge advantage for making reliable and durable valve gear. He has gone on to explore the use of 3D printing to create sand moulds to manufacture various parts of the locomotive. Developing patterns for sand casted metal parts can be extremely expensive and if there is an issue with the casting of the part it can be costly to start the process again.

Martin Shepherd, Director of 3D Heritage said: “WMG’s support on this project has been invaluable. The advice we have received from Dr Lansdell has enabled us to look at options that we never would have considered before that have the potential to save the project tens of thousands of pounds.”

Martin Shepherd, Director of 3D Heritage said: “WMG’s support on this project has been invaluable. The advice we have received from Dr Lansdell has enabled us to look at options that we never would have considered before that have the potential to save the project tens of thousands of pounds.”

Dr Paul Lansdell, explained: “I have been honoured to work on this prestigious project which has allowed us to apply leading edge research and new techniques on a real-world business case.”

To find out more about the project contact Paul Lansdell: wmgsme@warwick.ac.uk

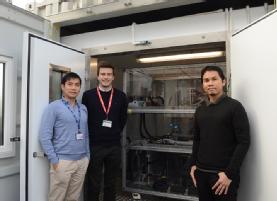

WMG unveils the world’s first EV Thermal Management Testbed

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

The Testbed, which is a world-first, was funded by the High Value Manufacturing Catapult, and is located at the University of Warwick’s Wellesbourne campus. It is designed specifically to develop and evaluate efficient thermal management systems for electric vehicles; including cabin climate control; thermal management of energy storage and electric machines; and the impact on the overall performance of the vehicle.

Truong Quang Dinh, Associate Professor of Energy System Management and Control at WMG, explains: “Effective heating and cooling of vehicle sub-systems is indispensable to ensure safety, reliability and comfort. Our unique thermal management testbed integrates a highly flexible HVAC rig and a hybrid physical-virtual powertrain for the holistic investigation of thermal management systems and other vehicle sub-systems under real-world conditions. This enables real-time tests from vehicle components, sub-systems, to entire systems at lowest time, cost and effort.”

One project that will be exploring the capabilities of the new Thermal Testbed is Cit-E-Van, - a collaboration between WMG, CoolVan and GAH, funded by Innovate UK. Cit-E-Van will look to develop an energy efficient electric refrigerated vehicle with an optimised electric transport refrigeration unit and retrofit the electric propulsion system with advanced thermal-energy management features.

In the coming months WMG experts will be working with more industry partners to develop HVAC solutions.

For further information about the testbed or HVAC solutions in general contact Truong Quang Dinh at: t.dinh@warwick.ac.uk

CO2 consuming concrete technology showcased at COP26 to be tested at University of Warwick

- Concrete contributes to 8% of global CO2e emissions, however Concrete4Change are on a mission to make concrete CO2 sinks rather than producers

- The CO2 sequestrating technology is being developed with the help of the School of Engineering and WMG SME group at the University of Warwick

- Researchers will help by testing the concrete which could revolutionise the concrete industry

- Concrete4Change won the award for Achieving Net Zero category at the UN Climate Change Cup last night at COP26

Technology developed by Concrete4Change that can make concrete a carbon sink rather than carbon producer will be trialled and tested by researchers from the University of Warwick. The technology which could revolutionise the concrete industry on a global scale, has been showcased and won an award at COP26.

Technology developed by Concrete4Change that can make concrete a carbon sink rather than carbon producer will be trialled and tested by researchers from the University of Warwick. The technology which could revolutionise the concrete industry on a global scale, has been showcased and won an award at COP26.

After water concrete is the most consumed material in the world, and accounts for 8% of global CO2e emissions. However, Concrete4Change Ltd. (C4C) are on a mission is to enable the concrete industry to transition from CO2 emitters to CO2 sinks, by developing a technology capable of removing significant amounts of CO2 from the atmosphere and absorbing it into concrete.

In fact, it was announced last night at COP26 that Concrete4Change have been announced as the winner of the Achieving Net Zero category of the 2021 UN Climate Change Challenge Awards.

The sequestration of CO2 results in the strength enhancement of concrete; therefore, reducing the amount of cement required to produce equivalent-strength concrete. Both CO2 sequestration and cement reduction can contribute to the reduction of concrete’s CO2 footprint. This technology has the potential to mitigate 2 billion tonnes of CO2e emissions, the equivalent of 4% of global CO2e emissions.

The School of Engineering and WMG centre High Value Manufacturing Catapult at the University of Warwick are proud to be supporting Concrete4Change, by undertaking essential testing for the company with the help of funding through Innovate UK and the DI4M programme.

Dr Reyes Garcia from the School of Engineering comments:

“As the world strives to reach zero-carbon goals, the construction industry and we civil engineers have a huge role to play to make concrete more sustainable. The cement we use to produce concrete contributes massively to CO2 emissions, and therefore we need to take drastic action now if the construction sector is to achieve its CO2 reduction goals. Here, at the School of Engineering, we are incredibly excited to support Concrete4Change by performing concrete technology and durability tests, which are critical to prove that the technology can be safely adopted by designers, contractors and concrete producers”.

Dave Myers from the WMG SME group at the University of Warwick comments:

“In order to make sure the concrete made by this innovative technology is as good, as if not better than previous standards we will be assisting Concrete4Change by completing testing and microscopical examination.

“Once testing has been completed the partnerships that C4C have made can help bring this technology to market and reinvent the concrete industry into a more sustainable and eco-friendlier one.”

Concrete4Change has built partnerships with other leading academic institutions as well as with some of the largest concrete producers in the world including Hanson Heidelberg, Kier, SIG, Morgan Sindall and Skanska.

Dr Sid Pourfalah, Founder and CEO of Concrete4Change comments:

“We are delighted to have the help to bring our unique technology to the market with help with the University of Warwick, not only are we showcasing our technology at COP26, but we have also been selected by Brazilian Ideiagov as one of the top 10 companies to tackle Latin America’s Net-Zero Challenge, bringing us hope that our technology is transferrable worldwide, and can help us shape tomorrow for future generations.”

C4C has also been selected by British Precast Federation as one of the top 3 most innovative companies and as one of the top 5 companies for Knowledge Transfer Network (KTN) Transforming Foundation Industries (TFI).

ENDS

11 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/img_20211109_132635.jpg

Caption: From left to right, CTO Dr Michael Wise and Dr Sid Pourfalah, Founder and CEO of Concrete4Change at COP26

Credit: Conrete4Change

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/img_20211109_125514_003.jpg

Caption: COP26 flowers

Credit: Concrete4Change

Find out more about Concrete4Change here: https://www.concrete4change.com/

C4C selected for the prestigious Climate Challenge Cup (10th of November): https://lnkd.in/gfdmtWzZ

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG staff recognised by Ventilator Challenge UK

A group of WMG staff have been presented with personalised certificates of appreciation from the Ventilator Challenge UK in recognition of their hard work during the Covid19 pandemic.

A group of WMG staff have been presented with personalised certificates of appreciation from the Ventilator Challenge UK in recognition of their hard work during the Covid19 pandemic.

In summer 2020, WMG was part of a consortium that helped to produce a total of 13,437 Penlon ESO 2 and Smiths paraPAC ventilator devices for the NHS.

WMG staff operated a quality control facility in an automotive parts warehouse in Solihull with colleagues from other High Value Manufacturing Catapult centres - the National Composites Centre (NCC) and the Manufacturing Technology Centre (MTC). Together they worked around the clock tirelessly inspecting over eight million parts.

Dr Mark Swift, Head of WMG SME Group, said: “It’s once again great to see WMG involved in such a nationally important project. The team have done a fantastic job of showcasing our continuous ability to collaborate and support business. This recognition is well deserved and is a testament to our capabilities.”

The 12 strong team included Dave Cooper, Paul Charlton, Ricky Nestor, Lee Oldham, Divyesh Mistry, Max Raybone, Joe Ward, Luke Millage, Myles Vale, Simon Fox, Steve Leemoon and Mark Swift.

Read more about the WMG SME Group here: WMG SME Group | How can we help you? (warwick.ac.uk)

Inspiring young engineers with STEM masterclasses

The WMG Outreach Team has successfully completed another series of Royal Institution Engineering Masterclasses.

This series was a little different to those in years gone by with the Masterclasses forced online by the Covid 19 pandemic.

Professor Margaret Low, WMG’s Director of Outreach and Widening Participation said: “WMG has supported the Ri with masterclasses, since 2013, with workshops and activities that put our cutting-edge engineering research into context for young people. Our masterclasses have been run in person each year since 2013 so we were determined not to miss a year for 2021, finding a way to deliver the activities online instead.

“These experiences allow students to see how their school learning applies to complicated and world-changing technologies. Through our outreach programmes we hope to inspire young people to pursue careers in STEM, widen participation in Higher Education and make the STEM workforce more diverse.”

The project was run virtually, by WMG staff and students, for two local schools; Nicholas Chamberlaine in Bedworth, and Northleigh House in Warwick, with a special focus on intelligent vehicles.

The WMG team used Kitronik project boxes to introduce the ideas of intelligent vehicles, calibrating components, coding, algorithms, and to explore how design technology is used to balance the pros and cons of any creation.

explore how design technology is used to balance the pros and cons of any creation.

The children were tasked with making, testing and then improving a car that a computer can control.

The teacher said: “The students were really engaged and got so much out of it. Considering it was video link and the first event they've been able to do like that in ages.”

Rachel Dorris, Masterclass Programme Manager at the Royal Institution added: “The Royal Institution (Ri) has been collaborating with Warwick University for many years to bring hands-on workshops to school students, and we are very pleased to be working with Northleigh and Nicholas Chamberlaine schools this year. Ri Masterclasses offer students an engaging, collaborative taste of STEM subjects involving mathematics, engineering and technology. We aim for Masterclasses to increase interest and confidence in STEM subjects, creating a sense of engagement to last throughout students’ school careers and beyond.”

Find out more about the WMG 2021 Ri Engineering Masterclasses here: Ri Engineering Masterclasses 2021 (warwick.ac.uk)

WMG experts to present at key EV battery conference

WMG’s Professor James Marco, Dr Ben Silverstone and Dr Anwar Sattar will be sharing their expertise at the IMechE’s International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles next month.

WMG’s Professor James Marco, Dr Ben Silverstone and Dr Anwar Sattar will be sharing their expertise at the IMechE’s International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles next month.

The two-day event which takes place on 9-10 November at Kia Oval, London, explores the latest developments in battery design, testing, thermal management, charging and integration right across the lifecycle of the battery with the aim of creating more resilient and cost-effective systems.

On day one, Professor James Marco, WMG’s energy storage expert will present ‘Smart battery development for improved EV safety characterisation,’ and Ben Silverstone, WMG’s UK Electrification Skills Framework Programme Lead, will explain more about the 'National Battery Skills Framework: Collaborating to Elevate UK Industry.’

characterisation,’ and Ben Silverstone, WMG’s UK Electrification Skills Framework Programme Lead, will explain more about the 'National Battery Skills Framework: Collaborating to Elevate UK Industry.’

On the final day, Lead Engineer in Battery Recycling, Anwar Sattar will be presenting ‘Establishing a lithium-ion battery recycling industry in the UK,’ discussing types of waste material found along the supply chain, recycling processes required to deal with material streams, and explaining more about the RECOVAS research project.

Find out more about the conference and book your place here: International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles | London | CMP7333 (imeche.org)

Joint European effort boosts automated driving

- L3Pilot, Europe’s first comprehensive pilot test of automated driving on public roads demonstrates automated systems for cars in Hamburg, Germany, in conjunction with ITS World Congress 2021

- SAE Level 3 and 4 automated driving systems have been tested on ordinary roads in seven European countries, including cross-border activities, thanks to pan-European testing environments and methodologies that have been developed with help from WMG, University of Warwick

- A “Code of Practice” has been created to speed up and harmonise the development of automated driving systems as well as a framework for collection, storage and evaluation of large amounts of data

- Increased safety identified as main benefit of SAE Level 3 automated driving systems

From 11 to 15 October the European research project L3Pilot, which WMG at the University of WarwickLink opens in a new window has worked on, led by Volkswagen AG and co-funded by the European Commission, showcases automated driving functions in the City of Hamburg and on motorways nearby. The four-year project will now come to its successful end with performing its Final Event in conjunction with the ITS World Congress in Hamburg 2021.

Running from 2017 to 2021, the project consortium brought together stakeholders from the whole value chain, including car manufacturers, suppliers, academia, research institutes, infrastructure and governmental agencies, user groups and the insurance sector.

Running from 2017 to 2021, the project consortium brought together stakeholders from the whole value chain, including car manufacturers, suppliers, academia, research institutes, infrastructure and governmental agencies, user groups and the insurance sector.

The experience of the partners in large-scale testing intelligent vehicle technologies made it possible to create a pan-European testing environment. The Code of Practice for the Development of Automated Driving Functions (CoP-ADF) is one of the major achievements of L3Pilot. It provides comprehensive guidelines for supporting the design, development, verification and validation of automated driving technologies.

Fourteen partners focused on testing automated driving functions in normal motorway driving, traffic jams, urban driving and parking. The pilots, running from April 2019 until February 2021, involved seven countries: Belgium, Germany, France, Italy, Luxemburg, Sweden and the United Kingdom and included two cross-border activities between Germany and Luxemburg as well as Germany, Belgium and the United Kingdom.

WMG, at the University of Warwick focussed on the development of a proof-of-concept prototype and a real-world demonstration of a cutting-edge technology for cooperative perception, using WMG’s state-of-the-art Open Innovation Vehicle Platform and mobile roadside units.

Aiming to enable safe automated driving at complex driving scenarios, such as roundabouts and T-junctions, the equipment was funded by the WMG Centre High Value Manufacturing (HVM) Catapult.Link opens in a new window Specialising in innovation aimed at making transport cleaner, safer and more efficient, the CentreLink opens in a new window works with UK manufacturing partners to develop automated, connected, electric and shared mobility for a sustainable future.

However WMG also contributed to a variety of key project activities including: Cyber Security Analysis of highly automated driving functions in highway environments, known as highway chauffeur, and the development of a Consolidated Database (CDB) to store large datasets acquired in the project during the experimental phase, which also included designing and implementing a web-based User Interface (UI) to provide access to CDB for L3pilot users, for example, partners and data analysts.

Prof. Mehrdad Dianati, from WMG at the University of Warwick comments:

“A major challenge for the safety of automated vehicles is how they will navigate through complex road segments, a part of our role in L3Pilot was to demonstrate how this challenge can be addressed using state-of-the-art cooperative automated driving technology we have developed at WMG.

L3Pilot Coordinator Aria Etemad, Volkswagen AG comments:

“Automated driving has a huge potential to make mobility safer, more efficient and more comfortable. The L3Pilot partners made great efforts to pursue piloting and met the project goals – despite the tremendous pandemic crisis. This shows the outstanding commitment of our Europe-wide partner network. One of our major achievements is a Code of Practice for the Development of Automated Driving Functions. It provides guidelines that will support the development of safe and reliable automated driving systems.”

The project equipped 70 vehicles and the test fleet comprised 13 different vehicle brands, from a passenger car to a SUV. More than 400,000 kilometres were driven on motorways including 200,000 km in an automated mode and 200,000 km in a manual mode as a baseline for comparison of the user experience and evaluation of the impacts. More than 24,000 km were travelled in the automated mode in urban traffic. With the aim to put the focus on the user experience of automated driving functions, over 1,000 persons participated in piloting and complementary virtual environment tests.

The project equipped 70 vehicles and the test fleet comprised 13 different vehicle brands, from a passenger car to a SUV. More than 400,000 kilometres were driven on motorways including 200,000 km in an automated mode and 200,000 km in a manual mode as a baseline for comparison of the user experience and evaluation of the impacts. More than 24,000 km were travelled in the automated mode in urban traffic. With the aim to put the focus on the user experience of automated driving functions, over 1,000 persons participated in piloting and complementary virtual environment tests.

The project focused on SAE Level 3 automated driving functions on motorways and in urban traffic, while SAE Level 4 functions targeted exclusively parking and close-distance scenarios. The SAE Level 3 features Conditional Automation which requires the driver to respond appropriately to a request to take-over the vehicle control for manual driving. In case the driver is not responding properly to a take-over request, the vehicle performs an automatic minimum risk manoeuvre to safely stop the vehicle.

Moreover, L3Pilot carried out extensive supplementary tests to also research user experiences that were difficult to address in large-scale piloting due to safety requirements and legal issues. Therefore, supplementary studies were performed in addition to the on-road piloting to be able to study system usage and other relevant user experiences with ordinary, non-professional drivers in safe and virtual environments. The extensive studies comprised some 600 subjects.

Research evaluation results have shown that increased safety is the main benefit of SAE Level 3 automated driving systems. They also show that an automated driving system consisting of motorway, urban and parking functions for robust hands-off driving will generate a social benefit that is higher than the social costs of installing it.

L3Pilot paved the way for scaled-up driving tests with automated series vehicles in real-life traffic. This underscores the leadership of Europe's automotive industry in developing reliable, thoroughly tested and user-friendly technology.

ENDS

12 OCTOBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/microsoftteams-image_5.png

Caption: WMG, at the University of Warwick demonstrating their technical achievement at ITS World Congress.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/microsoftteams-image_7.png

Caption: WMG, at the University of Warwick demonstrating their technical achievement at ITS World Congress.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/microsoftteams-image_8.png

Caption: WMG, at the University of Warwick demonstrating their technical achievement at ITS World Congress.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/microsoftteams-image_9.png

Caption: WMG, at the University of Warwick demonstrating their technical achievement at ITS World Congress.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/microsoftteams-image_10.png

Caption: WMG, at the University of Warwick demonstrating their technical achievement at ITS World Congress.

Credit: WMG, University of Warwick

Video available to view at:

https://www.youtube.com/watch?v=eJnzMGcr9Fc

Credit: WMG, University of Warwick

L3Pilot is an Innovation Action, co-funded by the European Union under the Horizon 2020 programme with the contract number 723051. Thirty four organisations have committed to scientifically test and assess the impact of automated driving systems on driver comfort, safety and traffic efficiency as part of the project.

www.l3pilot.eu

Twitter _L3Pilot_

LinkedIn: L3Pilot

Duration: 50 months, 1 September 2017 – 31 October 2021

Total cost: €68 million

EC contribution: €36 million

Coordinator: Volkswagen AG

Partners:

Automotive manufacturers: Volkswagen AG, AUDI AG, BMW Group, Stellantis | Centro Ricerche Fiat SCPA, Ford, Honda R&D Europe, Jaguar Land Rover, Mercedes-Benz AG, Adam Opel AG, Stellantis, Renault, Toyota Motor Europe, Volvo Car Corporation

Suppliers: Aptiv, FEV GmbH, Veoneer Sweden

Research: German Aerospace Center DLR; ika RWTH Aachen University; VTT Technical Research Centre of Finland; Chalmers tekniska hoegskola; SNF – Centre for Applied Research at NHH; University of Leeds; Institute of Communication and Computer Systems ICCS; Würzburg Institute for Traffic Sciences WIVW; University of Genoa; TNO – Netherlands Organisation for Applied Scientific Research; WMG, University of Warwick; European Center for Information and Communication Technologies – EICT GmbH

Authorities: Federal Highway Research Institute BASt; The Netherlands Vehicle Authority RDW

User Groups: Federation Internationale de l’Automobile FIA

Insurers: AZT Automotive GmbH, Swiss Reinsurance Company

SMEs: ADAS Management Consulting,

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk