Deployment of Industrial Robotics

Deployment of Industrial Robotics

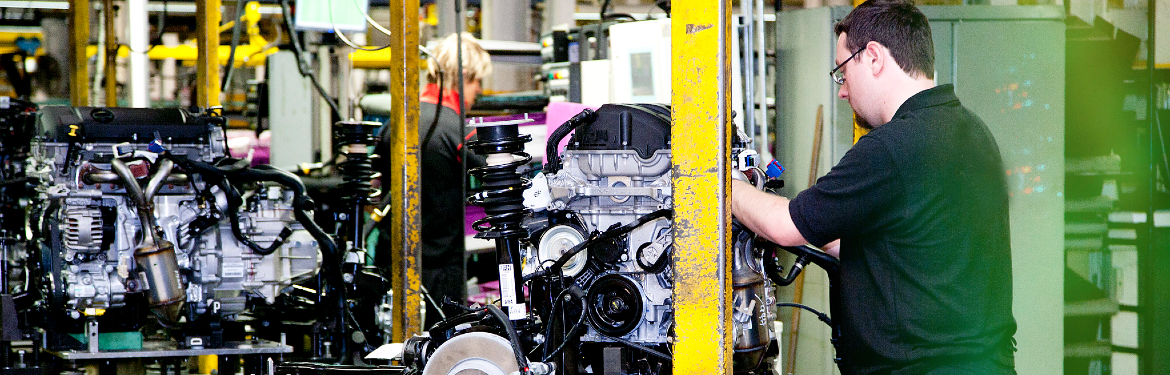

Improving Efficiency and Overcoming Quality Issues in the Automotive Sector

The automotive sector is highly competitive, and exceptional quality is a key decision point for end-consumers. Efficiency in production is also crucial in ensuring costs are kept down so that manufacturers remain profitable.

Professor Robert Harrison and colleagues have developed novel forms of integrated smart manufacturing solutions directly addressing the needs of industry. These knowledge-driven systems have integrated analytics with new forms of automation and robotics to improve efficiency and overcome quality issues and have been adopted by companies in the automotive sector specialising in tyre manufacturing and seat technology.

The challenge

Limited research has considered how automation systems might be effectively configured and supported through their lifecycles and how application modelling, visualisation, and reuse of such systems might be best integrated into manufacturing businesses. Therefore, Professor Harrison and colleagues focused on developing engineering best practice in these key areas, enabling manufactures to achieve an optimal balance of quality and efficiency in their systems and processes.

Our approach

Research by Professor Harrison and colleagues has focused on the following areas:

-

Development of architectures and methods for the design and implementation of configurable manufacturing systems

-

Development of algorithms and machine learning-based image processing tools to characterise material defects in cyber-physical systems

-

Development of integrated automated robotic systems that perform the necessary actions in real-time.

Our impact

Several organisations have benefitted from Professor Harrison’s research, including one multinational tyre manufacturer who wished to accelerate their digital transformation by speeding up adoption of the latest technologies into their production systems. The tyre manufacturer applied Warwick’s machine-learning and systems integration research at key points in their manufacturing systems, to analyse tyre compounds for quality, implement predictive maintenance for mixers, and enable tyre bladder failure prognostics at their plants in Europe and Asia, leading to a 20% reduction in downtime.

Additionally, another large manufacturer of automotive seating has integrated Warwick’s novel algorithms and machine learning-based image processing tools, into its automation systems, providing smart solutions to automate their seat assembly, inspection and rectification processes.

These smart systems have been deployed at production plants in the UK and US, enabling improvements in product quality and reduced operational costs, leading to an annual saving of approximately £2.3 million annually.

What is research impact?

Discover why it matters

More impact stories

Explore other work from Engineering at Warwick