WMG News

The University of Warwick supports RIFT Technology with a greener cost-effective electric motor

A cheaper and more environmentally friendly electric motor for electric vehicles is a step closer to market with the support of WMG at the University of Warwick.

WMG has provided valuable knowledge and expertise in developing a UK focused, cost-effective production and supply chain for RIFT (Reduced  Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

The aim of the project was to help RIFT Technology; an R&D company bringing a product to market for the first time, advance RIFT-10 to a higher manufacturing readiness level (MRL 7), to get the motor closer to production, by rooting the supply chain in the UK, rather than abroad (given the disruption to supply caused by the pandemic) and supporting production of trial units.

WMG, is committed to delivering UK economic impact and achieving net-zero by supporting industry in accelerating new concepts to commercial reality. This supports the University of Warwick’s approach to sustainability - the Way to Sustainable – which focuses on the real-life implications of creating a sustainable future and the practical challenges of getting there - prioritising research expertise, sustainability in the curriculum, and developing solutions for the benefit of industry and society.

The team of experts at the University has facilitated the RIFT-10 project to deliver on creating revenue, jobs, CO2 reduction, and supply chain growth in the UK.

RIFT Technology has developed the RIFT 10-30 kW motor (RIFT-10) by taking an exciting innovation from their sister business (RIFT Actuators) and working with APC and the Niche Vehicle Network to get the motor to working prototype stage (installed on a G-Whiz). The novel electric motor configuration is proven to generate 10-30kW of power, torque from 0-400Nm and up to 10,000RPM as demonstrated with a prototype vehicle.

The RIFT 10 motor demonstrated unique advantages over conventional EV motors:

Environmental benefits of the project:

· The low sales cost and attractive features of RIFT-10 enable greater/earlier market adoption of EUV’s, resulting in a reduction of CO2 production over ICE vehicles.

· A RIFT-10 weight saving and efficiency over competing EV motor designs increase vehicle range, resulting in less energy usage over alternatives.

· With RIFT-10, equivalent power output is achieved using fewer raw materials (i.e., 85% reduced copper weight and ~85% reduced magnet volume), resulting in less earth material usage as well as fewer material costs.

· Less materials usage results in an estimated 75% reduction in CO2 produced during manufacture. Planned production efficiencies also lead to further CO2 reductions. An estimated 612,000 Tonnes of CO2 would be saved by year 5.

· Development of an EV motors supply chain in the UK for a UK and EU market reduces international shipping of components thus reduces related CO2 production.

Social benefits of the project:

· RIFT-10 creates/safe-guards 50+ much needed and good-quality manufacturing, sales, administration and R&D jobs in the Malvern area with an estimated X14 more UK jobs across the supply chain (over 5-years).

· Growth of RIFT-10 addresses the government’s priority area of ‘Smart Cities’ by allowing smart monitoring of vehicle fleets efficiency performance, usage and other data points. The use of the Internet of Things and resulting analysis can only be as strong as the data input. Traditional alternatives offer no smart functionality.

James Black, WMG Innovation Manager at the University of Warwick said, “The Covid-19 pandemic has been particularly difficult for SMEs and R&D-focused organisations that have previously relied on face-to-face networking events to find new partners, investors, and customers.

“WMG’s network means we’re in a great position to connect UK companies together to help them accelerate their product to the market, and we’re delighted that RIFT Technology has benefited from our extensive background for practical supply chain solutions that have delivered economic and societal value to the project.”

James O’Donnell, Technical Manager from RIFT Technology said, “As a research and development company bringing a product to market for the first time, RIFT Technology needed to bridge the gap between prototype and small-scale production. We had to answer difficult questions such as what to make and what to buy, high level questions such as how to develop a supply chain strategy and practical questions such as how best to select suppliers.

“With a unique blend of academic expertise and industrial experience from the University of Warwick, WMG’s Supply Chain and Operations Group were able to support us in our journey.”

The project took place during the pandemic, meaning several online workshops were carried out targeting topics such as strategic management, supplier selection and decision-making, and end-of-life strategies.

For further stories, click here.

ENDS

4 April 2022

Partnership between WMG and The Blair Project to deliver electrification skills training in the north

WMG has partnered with The Blair Project, a social enterprise based in Manchester, to deliver the Emerging Skills Project in the north, a programme funded by the Department for Education (DfE).

The Emerging Skills Project will create a highly skilled workforce that will enable industries including automotive, energy and food and drink, to take advantage of electrification and hydrogen-power to deliver Net Zero.

The course provided by The Blair Project will specifically address technologies related to electric vehicles. This will include the assembly and maintenance of battery modules and packs, recycling and second life, the manufacturing and installation of motors, drives and power electronics and the designing and testing of vehicle and software systems.

Developed in conjunction with businesses who were invited to a series of workshops with DfE, the course will directly respond to the demand for wider adoption and deployment of transport electrification technologies.

The course will be held at the new Manchester Innovation Activities Hub (MIAH) – launching in Spring 2022. Dedicated to the rapid upskilling, reskilling and retraining of more than 5,000 local residents over the next five years, MIAH is set to become a centre of excellence in Greater Manchester and a hub for electrification skills training in the north.

Ben Silverstone, Associate Professor and Head of WMG Skills Centre, said:

“As important as it is to train up the younger workforce in green tech, there is a significant workforce primed for reskilling now. It’s the combination of both that will ensure we are well-equipped to meet the UK’s ambitious Net Zero targets.

“We are pleased to partner with an organisation like The Blair Project to deliver the Emerging Skills Project, meeting the UK-wide demand for electrification skills and giving people in the region the opportunity to upskill or reskill in this area.”

Nile Henry, Founder and CEO of The Blair Project, said:

“The UK is facing a huge skills gap in green tech, particularly electrification, and this is only set to increase as we power towards Net Zero and the demand for a highly skilled workforce grows. Partnering with WMG to become a delivery partner for the Emerging Skills Project is a huge milestone for The Blair Project, and it’s brilliant to see this focus from Government on upskilling adults in green tech.”

WMG welcomes Victoria Prentis MP, Minister of State at the Department for Environment, Food and Rural Affairs (DEFRA)

WMG was pleased to welcome Farming Minister Victoria Prentis yesterday (Thursday 20th January).

The Minister was welcomed by WMG Executive Chair, Margot James, and given a tour of the Innovate UK-funded Natural Light Growing Centre and DEFRA-funded vegetable gene bank research centre, run by the School of Life Sciences, at the University of Warwick’s Wellesbourne campus.

DEFRA-funded vegetable gene bank research centre, run by the School of Life Sciences, at the University of Warwick’s Wellesbourne campus.

The delegation then headed to WMG, on the University of Warwick campus, where they were given a presentation from Professor Robert Harrison on horticultural robotics and how they can support on a range of agricultural tasks. They then met with Professor Kerry Kirwan, who explained more about water treatment using recycled carbon fibre sheets.

Finally Dr Mark Swift, Head of SME Programmes, explained more about the SME support programme where WMG has helped the food and drink sector apply digital manufacturing techniques.

Margot James, executive Chair at WMG, University of Warwick said: "It was a pleasure to have Minister Victoria Prentis to visit us today, we were delighted to share the cutting edge research we are doing in collaboration with the agriculture and horticulture industries.

“These are vital sectors to the UK economy but there is vast potential to improve using automation, AI and digital manufacturing, as well as new growing practices being researched by our Life Sciences department."

Farming Minister Victoria Prentis, added: “It was great to visit the University of Warwick, which is making significant strides to ensure agri-robotics can be a reality for farmers and growers in the UK.

reality for farmers and growers in the UK.

“We know how important it is for the industry to maximise productivity and yields. We are putting in place a series of initiatives – from the Farming Investment Fund, to the Farming Innovation Programme – to support the development and uptake of technology which can boost food production, productivity and the environment.”

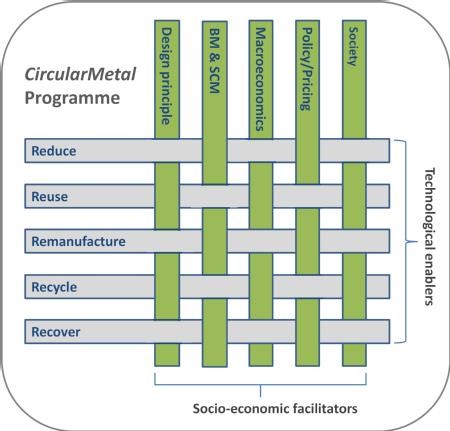

UK aims to be the first Country in the world to circulate steel and aluminium fully, supported by the CircularMetal programme

§ The UKRI National Interdisciplinary Circular Economy Research Programme aims to create a sustainable circular economy for lots of different industries, including metals

§ Metals and metal products create 10-20% of all the world’s harmful impacts, such as greenhouse gas emissions and pollution and energy consumption; we cannot do without goods made from metals; so we must learn how to make their use circular, i.e. extend their lifetimes and increase their repair, re-use and recycling

§ The Interdisciplinary Centre for Circular Metals aims to accelerate the transition from the current largely take-make-waste linear economy to full metal circulation by conducting high quality research and innovation through a systems approach. Its ambition is to make the UK the first country to realise full metal circulation (at least for the high-volume metals – steel and aluminium) by 2050. This will form an integral part of the government’s efforts to achieve Net Zero by 2050

§ To deliver the CircularMetal research programme, WMG at the University of Warwick will conduct inter-disciplinary research on steel production, recycling technologies, remanufacturing of steel components, and artificial intelligence in scrap separation

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The UKRI has established five Interdisciplinary Circular Economy Centres in the UK, coordinated by the Circular Economy Hub (CE-Hub), which together form the NICER Programme, a £30 million investment on research aimed at developing a circular economy in the UK, One of these CECs is CircularMetal, the Interdisciplinary Centre for Circular Metals, led by Brunel University London, with partners from WMG, University of Warwick, University College London and Loughborough University.

The ultimate aim of the group is to make the UK fully circulate all their steel and aluminium, thereby minimising or eliminating the extraction of raw materials and the production of waste.

WMG, at the University of Warwick, will specifically research steel, including opportunities for reuse and the technologies for scrap sorting to increase recyclability, working with partners in the project on business model supply chains and the economy and policy surrounding them.

The Interdisciplinary Centre for Circular Metals is a four-year project, which started in January 2021 thanks to £4.2m funding from UKRI. Discussions within the team on strategies to reuse / recycling / reduce / remanufacture / recovery and the technological barriers are on-going with input being provided to government groups.

Professor Claire Davis, from WMG, University of Warwick comments:

“To be part of the Interdisciplinary Centre for Circular Metals is incredibly exciting, especially in light of COP26, as the potential that a circular economy for metals could have towards meeting goals of sustainability and furthermore preventing climate change.

“At WMG, University of Warwick we hope to research how technology can help us to reuse and recycle steels, for example, understanding the end of life condition of steel components to determine whether and how they can be used, and using artificial intelligence to increase scrap recyclability.

“If metals can be fully recycled and reused the need to extract raw materials to make them in the first place could be eliminated, and the current workforce in the metals industry could be reskilled to work in recycling and repurposing metals.”

Professor Brian Cantor, Deputy Director, The UKRI Interdisciplinary Centre for Circular Metals BCAST, from Brunel University comments:

“Metallic materials are the backbone of manufacturing and the fuel for economic growth. They underpin the competitive position of almost every industrial sector and, including metal manufacture and downstream product processing, they collectively contribute 15-20% of all greenhouse gas emissions, pollution and energy consumption. Transformation of the metals industries from the current largely linear economy to a circular economy will, therefore, play a critical role in delivering the government’s industrial strategy for clean growth, doubling of resource productivity and reaching net zero carbon emissions in 2050.

“CircularMetal is focused on helping the UK become the first country to realise full metal circulation, concentrating on the two main bulk metals aluminium and steel, and the three main industrial sectors of transport, construction and packaging.”

ENDS

22 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture1.jpg

Caption: A graphic of the factors considered in the CircularMetal programme

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture2.jpg

Caption: The building the Warwick arm of the CircularMetal project are based in at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

New city climate change commission to drive forward low carbon targets

Senior leaders from organisations across Coventry met today to help shape and move forward actions to reduce the impact of climate change.

Senior leaders from organisations across Coventry met today to help shape and move forward actions to reduce the impact of climate change.

A new Coventry Climate Change Board will meet regularly to share policies, plans, good practice and work together collaboratively in an effort to keep the city on track for a zero carbon future.

The Board is chaired by Margot James, the former minister for culture, communications and creative industries and Executive Chair for WMG at the University of Warwick.

Senior representatives from businesses located in the city, public service providers and community organisations will work together on plans for the future of the city.

Margot James, Executive Chair at WMG, University of Warwick said:

“I want to be involved in the Board because I believe organisations must collaborate if we are to reduce our carbon footprint. This applies to the public sector and the commercial sector, charities and voluntary groups of all sizes.

“At WMG we are working with industry to develop solutions that will have a long-term impact on climate change, including electrification of transport from passenger cars to very light rail vehicles, and developing sustainable manufacturing processes.

“I want this Board to make a difference and cut through any blockages preventing action within and between the organisations we represent to develop collaborative solutions to sometimes complex issues.”

“Ultimately, we need to set out actions and win hearts and minds. We also want to communicate how residents of all ages can be involved. It’s about the wellbeing of future generations in the city.

“I expect more organisations will be invited to join the Board in the coming months.”

Cllr Jim O’Boyle, Cabinet Member for Jobs, Regeneration and Climate Change at the Council, added: “As a local authority we are applying innovative approaches and technologies but no one organisation can work alone to address a low carbon future.

Cllr Jim O’Boyle, Cabinet Member for Jobs, Regeneration and Climate Change at the Council, added: “As a local authority we are applying innovative approaches and technologies but no one organisation can work alone to address a low carbon future.

“I hope that as a Board and a combined group of organisations we can come together to identify new ways of working together.

“I’m sure that we will be able to deliver a range of cost-effective schemes to invest in a more sustainable future for the city.”

§ Last week Coventry held a COP26 Regional Roadshow highlighting a Transport Expo which was funded by the UK Government to celebrate and showcase the city’s innovative work in addressing climate change and decarbonising transport in the city.

§ Coventry has an A-rated CDP energy performance rating which is a national standard that is independently verified.

§ It has the highest number of electric charging points per head of population outside of London and will be the first city with an all-electric bus fleet from 2025.

The Council is investing in 5,000 solar panels on 41 Coventry buildings with public funding and there are many other schemes that city partners are supporting.

ENDS

17 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_36.jpg

Caption: Front, Cllr O’Boyle with Margot James and partners from organisations across Coventry congregating outside the Prof. Lord Bhattacharyya building home to NAIC the National Automotive Innovation Centre at WMG, University of Warwick

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_29.jpg

Caption: The board congregating at WMG, University of Warwick

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_08.jpg

Caption: Margot James, Executive Chair of WMG, University of Warwick talking to the board

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_03.jpg

Caption: Cllr Jim O’Boyle talking to the board

Credit: Mark Radford Photography

For further information contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Coventry schools to build future cities from recycled household items

· TeenTech is a national charity working with school children to help them consider a future in digital, science technology and engineering.

· Their TeenTech City of Tomorrow initiative is working with nine Coventry schools with the help of WMG, University of Warwick

· Experts from WMG will deliver advice to children on sustainable materials, and inspire them as they design and build their city of the future out of recyclable household items

· A few Cities will then be exhibited at The Coventry Transport Museum

TeenTech City of Tomorrow will see Coventry school children make a city of recyclable household items, with help from researchers at WMG, University of Warwick who will teach them all about sustainability. A select few ideas – buildings and technology- will then be exhibited at the Coventry Transport Museum.

TeenTech is a national charity engaging children and teenagers in Digital, Science, Engineering and Technology and their latest initiative has launched today, the 11th November, in Coventry, which will see nine schools in Coventry build a futuristic sustainable city out of recyclable household items.

As it’s ‘Cities, Regions and Built Environment’ day at the COP26 summit in Glasgow, researchers from WMG at the University of Warwick are helping children understand sustainability and its importance, by delivering an online session about sustainable materials and why it’s important we use them more for a greener future, thanks to funding from the University’s Innovative Manufacturing and Future Materials GRP.

The children will then have two weeks to build their cities from recyclable household items. Three researchers from WMG, University of Warwick will run workshops, educating the children in using natural products for sustainable solutions and how to dispose of products.

On the 25th November the researchers from will then provide feedback, before selecting a few of the buildings and ideas to be exhibited at the Coventry Transport Museum from the end of the month.

Dr Stuart Coles from WMG, University of Warwick comments:

“Having spent my career researching how to reduce, reuse and recycle materials I am honoured to be a part of the TeenTech City of Tomorrow initiative, and look forward to seeing how creative the children can be in making a futuristic and environmentally friendly city.

“It is our children that will suffer from the damage we have caused and are causing to the planet, therefore it is imperative that we educate them from young age about sustainability and how they can create a cleaner and greener future for themselves and future generations, whilst we work out how we can change our ways to further prevent the climate crisis.”

Maggie Philbin, CEO of TeenTech comments:

“We want young people in Coventry to understand they can shape the future with their ideas. Young people think boldly, differently and inclusively and this is the thinking we need for a sustainable future. Tomorrow is very much a two-way event – experts will be sharing their knowledge, but we know that it will be the children who surprise everyone with their creativity, honesty and who will be the ones to challenge outdated thinking.

“Their buildings may be constructed from cardboard boxes but their ideas will be sophisticated and ones which should be seriously considered. They really are the architects, the engineers and the designers of the future. Let’s listen to them.”

Mrs Kaur, Class Teacher at Courthouse Green primary school comments:

"TeenTech is a great project to engage and enthuse the children and encourages them to consider how to be responsible about improving their environment. It has given the children the opportunity to think big about their world. their future and their role within it.

"The children are learning life skills, teamwork and are thinking outside the box to design and create cities that could effect change. The project is amazing! If I could give up a whole week to work on this, I would...it's real-life skills in the classroom."

Two children from year 5 at Courthouse Green Primary school have said:

"I love the project because it will help the future. It has made me think about climate change and how it is affecting our cities. In Coventry I see lots of litter and it gives our city a bad reputation. My team, Team Queen Tech are designing a treehouse from recycled materials that filters wastewater to use again." - Bhavika age 9

"We have designed a hotel for homeless people which is made from sustainable materials like bamboo." Sanjot Age 9

CO2 consuming concrete technology showcased at COP26 to be tested at University of Warwick

- Concrete contributes to 8% of global CO2e emissions, however Concrete4Change are on a mission to make concrete CO2 sinks rather than producers

- The CO2 sequestrating technology is being developed with the help of the School of Engineering and WMG SME group at the University of Warwick

- Researchers will help by testing the concrete which could revolutionise the concrete industry

- Concrete4Change won the award for Achieving Net Zero category at the UN Climate Change Cup last night at COP26

Technology developed by Concrete4Change that can make concrete a carbon sink rather than carbon producer will be trialled and tested by researchers from the University of Warwick. The technology which could revolutionise the concrete industry on a global scale, has been showcased and won an award at COP26.

Technology developed by Concrete4Change that can make concrete a carbon sink rather than carbon producer will be trialled and tested by researchers from the University of Warwick. The technology which could revolutionise the concrete industry on a global scale, has been showcased and won an award at COP26.

After water concrete is the most consumed material in the world, and accounts for 8% of global CO2e emissions. However, Concrete4Change Ltd. (C4C) are on a mission is to enable the concrete industry to transition from CO2 emitters to CO2 sinks, by developing a technology capable of removing significant amounts of CO2 from the atmosphere and absorbing it into concrete.

In fact, it was announced last night at COP26 that Concrete4Change have been announced as the winner of the Achieving Net Zero category of the 2021 UN Climate Change Challenge Awards.

The sequestration of CO2 results in the strength enhancement of concrete; therefore, reducing the amount of cement required to produce equivalent-strength concrete. Both CO2 sequestration and cement reduction can contribute to the reduction of concrete’s CO2 footprint. This technology has the potential to mitigate 2 billion tonnes of CO2e emissions, the equivalent of 4% of global CO2e emissions.

The School of Engineering and WMG centre High Value Manufacturing Catapult at the University of Warwick are proud to be supporting Concrete4Change, by undertaking essential testing for the company with the help of funding through Innovate UK and the DI4M programme.

Dr Reyes Garcia from the School of Engineering comments:

“As the world strives to reach zero-carbon goals, the construction industry and we civil engineers have a huge role to play to make concrete more sustainable. The cement we use to produce concrete contributes massively to CO2 emissions, and therefore we need to take drastic action now if the construction sector is to achieve its CO2 reduction goals. Here, at the School of Engineering, we are incredibly excited to support Concrete4Change by performing concrete technology and durability tests, which are critical to prove that the technology can be safely adopted by designers, contractors and concrete producers”.

Dave Myers from the WMG SME group at the University of Warwick comments:

“In order to make sure the concrete made by this innovative technology is as good, as if not better than previous standards we will be assisting Concrete4Change by completing testing and microscopical examination.

“Once testing has been completed the partnerships that C4C have made can help bring this technology to market and reinvent the concrete industry into a more sustainable and eco-friendlier one.”

Concrete4Change has built partnerships with other leading academic institutions as well as with some of the largest concrete producers in the world including Hanson Heidelberg, Kier, SIG, Morgan Sindall and Skanska.

Dr Sid Pourfalah, Founder and CEO of Concrete4Change comments:

“We are delighted to have the help to bring our unique technology to the market with help with the University of Warwick, not only are we showcasing our technology at COP26, but we have also been selected by Brazilian Ideiagov as one of the top 10 companies to tackle Latin America’s Net-Zero Challenge, bringing us hope that our technology is transferrable worldwide, and can help us shape tomorrow for future generations.”

C4C has also been selected by British Precast Federation as one of the top 3 most innovative companies and as one of the top 5 companies for Knowledge Transfer Network (KTN) Transforming Foundation Industries (TFI).

ENDS

11 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/img_20211109_132635.jpg

Caption: From left to right, CTO Dr Michael Wise and Dr Sid Pourfalah, Founder and CEO of Concrete4Change at COP26

Credit: Conrete4Change

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/img_20211109_125514_003.jpg

Caption: COP26 flowers

Credit: Concrete4Change

Find out more about Concrete4Change here: https://www.concrete4change.com/

C4C selected for the prestigious Climate Challenge Cup (10th of November): https://lnkd.in/gfdmtWzZ

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Electric vehicles could be powered by Hydrogen harvested from sewage

Hydrogen is valuable as it is a renewable source, and could be sold to the chemicals and plastics industry or used in hydrogen fuel cells for energy storage or electric vehicles

Hydrogen is valuable as it is a renewable source, and could be sold to the chemicals and plastics industry or used in hydrogen fuel cells for energy storage or electric vehicles- The ability to take hydrogen from waste water provides a new economic and environmental opportunity, however until now it has been incredibly expensive to suffice

- Using a recycled carbon fibre mat, researchers from WMG, University of Warwick, have been able to produce Hydrogen from wastewater for Severn Trent

Wastewater treatment is vital to remove pathogens, but is incredibly energy intensive. The ability to treat it more sustainably is a challenge researchers from WMG, University of Warwick have been able to achieve, using recycled carbon fibre mats to produce hydrogen from waste water.

Treating wastewater is a vital process, as it removes pathogens and protects the environment, however this comes at its own environmental cost, as it is highly energy intensive, using around 3% of energy use in the UK – the equivalent to 13 billion kilowatt hours.

The water and waste company Severn Trent set researchers from WMG, University of Warwick, the challenge of finding a more energy efficient way to treat wastewater, with the team successfully building on research into Microbial Electrolysis Cells.

Microbial Electrolysis Cells involves using electromagnetic microorganisms to break down organic pollutants in waste water, producing clean water and hydrogen gas. The ability to produce Hydrogen gas is valuable in itself as it can be sold to chemical and plastics industry, or for use in hydrogen fuel cells for energy storage or electric vehicles.

Although this all sounds promising it hasn’t been developed on an industrial scale, as the anode materials - which are used in the reaction to breakdown the organic pollutants – are made of graphite or carbon, and cost several hundred pounds per square metre, and produce low rates for Hydrogen.

Dr Stuart Coles and his team therefore took on the challenge of refining the technique by looking at alternative anode materials and processing methods, and successfully identified recycled carbon fibre mats as an alternative anode, which costs only £2 per square metre, making it significantly cheaper than existing anode materials.

After testing the carbon fibre mats on synthetic wastewater and real wastewater, researchers found the bacteria developed on the recycled carbon fibre anode, which had better temperature tolerance and produced more hydrogen than previously used materials.

They then decided to pilot their techniques at Severn Trent’s Minworth waste treatment site, where they successfully processed up to 100 litres of wastewater per day and managed to remove 51% of organic pollutants and up to 100% of suspended solids from the water while producing 18 times more hydrogen (at 100% purity) than the graphite material.

Dr Stuart Coles, from WMG, University of Warwick comments:

Dr Stuart Coles, from WMG, University of Warwick comments:

“We are really excited about this technology. By taking waste from the automotive and aerospace sectors, we have developed a circular solution to a longstanding problem. Instead of just treating the wastewater, we are now able to extract value from it in the form of hydrogen at a lower cost than ever before.

“The next phase of this work is look at optimising the design of the microbial electrolysis cells and further reduce the level of pollutants in the water. This in turn should help produce even more hydrogen!”

Bob Stear, Chief Engineer at Severn Trent adds:

“The performance boost and cost savings demonstrated from this research mean that MEC technology is one step closer to being cost competitive with existing wastewater treatment assets. WMG have also demonstrated that this technology has the potential to create a more circular wastewater treatment process which will be essential to delivering on our long term sustainability goals and Net Zero plans. We’re currently scoping scaling up the technology at our test-bed plant in Redditch.”

ENDS

2 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1054.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1054.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1043.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1058.jpg

Caption: A sample of a roll of graphene

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Margot James, Executive Chair, comments on the Government’s new Net Zero Strategy

Expert comment from Margot James, Executive Chair at WMG, in response to the Government’s Net Zero Strategy.

"The decarbonisation of personal transport, by moving to Electric Vehicles (EVs), will be a major contributor to delivering on this target as EVs become a viable option for the majority of consumers. Viability depends upon EVs being affordable and drivers having access to a reliable network of fast charging in urban and rural networks"

UK Government Net Zero Strategy

Find out more about the new National Skills Framework that has been created by WMG, The Faraday Institution and the High Value Manufacturing Catapult: New National Electrification Skills Framework and Forum could put the UK at the forefront of the green revolution News

WMG experts to present at key EV battery conference

WMG’s Professor James Marco, Dr Ben Silverstone and Dr Anwar Sattar will be sharing their expertise at the IMechE’s International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles next month.

WMG’s Professor James Marco, Dr Ben Silverstone and Dr Anwar Sattar will be sharing their expertise at the IMechE’s International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles next month.

The two-day event which takes place on 9-10 November at Kia Oval, London, explores the latest developments in battery design, testing, thermal management, charging and integration right across the lifecycle of the battery with the aim of creating more resilient and cost-effective systems.

On day one, Professor James Marco, WMG’s energy storage expert will present ‘Smart battery development for improved EV safety characterisation,’ and Ben Silverstone, WMG’s UK Electrification Skills Framework Programme Lead, will explain more about the 'National Battery Skills Framework: Collaborating to Elevate UK Industry.’

characterisation,’ and Ben Silverstone, WMG’s UK Electrification Skills Framework Programme Lead, will explain more about the 'National Battery Skills Framework: Collaborating to Elevate UK Industry.’

On the final day, Lead Engineer in Battery Recycling, Anwar Sattar will be presenting ‘Establishing a lithium-ion battery recycling industry in the UK,’ discussing types of waste material found along the supply chain, recycling processes required to deal with material streams, and explaining more about the RECOVAS research project.

Find out more about the conference and book your place here: International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicles | London | CMP7333 (imeche.org)