Success Story

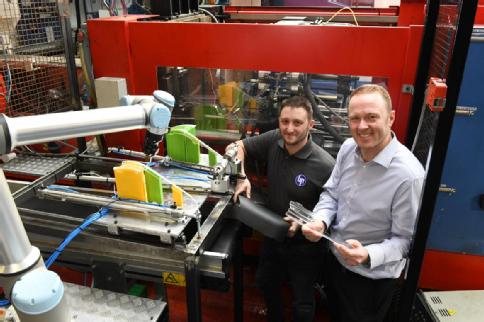

Developing the next generation of manufacturing talent with Data Image Group

Data Image Group, a large-scale print production house based in the East Midlands, has been working with global brands for over forty years.

With a vision to become an industry leader in innovation, the company partnered with WMG to access funding, engage in knowledge exchange programmes, and collaborate with talented graduates, turning their ambition into action via internships.

From manual to modern: how WMG helped drive Darvick’s growth journey

Based in the Black Country, Darvick is a leading manufacturer of bespoke testing machines that push high-tech components to their limits.

Founded by husband and wife Darren and Vicki Wilkes, the company works with clients across aerospace, nuclear engineering, transport and more, designing machines capable of testing new materials and components under extreme conditions.

As the team grew and workload increased, outdated processes and data systems became a major bottleneck. To overcome this, Darvick partnered with WMG’s SME Group through Made Smarter West Midlands, to upgrade their lab management system to fly closer to its sky-high growth ambitions.

From start-up to scale-up: how WMG helped The Muzzle Movement cut lead times by 80%

Founded in 2022 by CEO Clara Hewson, The Muzzle Movement is an East Midlands-based manufacturer creating well-designed and comfortable muzzles for dogs.

The company exists not only to shake up an outdated muzzle market, but to shift public perceptions; demonstrating that muzzled dogs aren’t ‘scary’, but friendly, supported, and approachable.

To support their ambitions for growth, The Muzzle Movement partnered with WMG’s SME Group to scale-up production, improve business processes and expand their customer base.

From 2.5 days to 40 minutes: how WMG helped power Wright Rubber’s growth

Challenge: Traditional processes in need of digital transformation

Led by Managing Director Laura Hill, Wright Rubber’s team of six supplies gaskets, hoses, extrusions and rubber mouldings to their customers across the UK and Europe.

To secure the future of the business, Laura wanted to modernise operations and introduce digital processes to make their manufacturing faster and more efficient.

WMG Winding Centre of Excellence validates key stator impregnation processes, advancing Safran’s ENGINeUS electrical machine development.

WMG’s Winding Centre of Excellence has worked with Safran Electrical and Power to validate advanced stator impregnation processes, helping to overcome key manufacturing challenges in developing the ENGINeUS electric propulsion engines. As aviation moves rapidly towards cleaner, quieter and more efficient electric and hybrid flight, this collaboration is laying the foundations for scalable, automated production of next generation electrical machines.

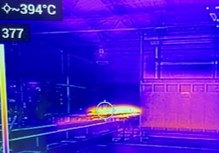

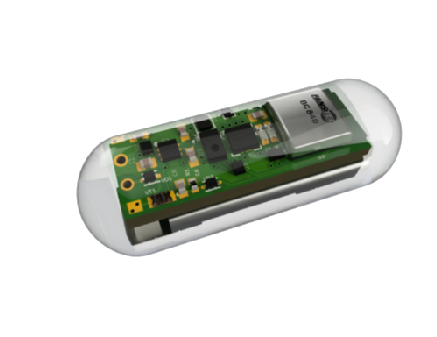

Inside the Cell: Internal thermal sensing for eVTOL battery performance

At the heart of eVTOL technology lies the battery system, crucial to the aircraft’s safety, performance and cost-efficiency. During take-off and landing, batteries endure high power demands, which drive requirements for high temperature operation and wide operational current windows. Cylindrical cells are commonly used, in eVTOL applications, due to their standardised shape and built-in safety features such as Current Interruption Devices (CID).

Building a future-ready factory: Samuel Heath’s digital transformation journey

“Working in collaboration with Made Smarter and WMG meant we were dealing with people who really take the time to understand." Find out more about how WMG's SME Group helped manufacturer Samuel Heath to futureproof its factory.

Flexibility, Precision and Speed: Transforming Electrical Machine Manufacturing

The aerospace sector is increasingly focused on enhancing sustainability and efficiency to support a net-zero future. To achieve this, it is exploring various solutions, including the advancement of aero engine and component manufacturing.

Securing UK devices through a new cybersecurity test lab

The Internet of Things (IoT) presents vast and exciting opportunities for innovation for businesses. However, as more businesses are increasingly reliant on connected devices, they expose themselves to increasing security risks.

On track for success: WMG’s role in the future of transport

WMG at the University of Warwick is driving the future of sustainable transport with its leading role in Coventry Very Light Rail (CVLR). This world-first, battery-powered tram system uses innovative track and vehicle technologies to cut costs, reduce emissions, and minimise disruption; delivering light rail at just £10m per kilometre. Developed in partnership with Coventry City Council, CVLR showcases WMG’s expertise in low-carbon mobility, advanced manufacturing, and transport innovation, with global interest already growing.

Breaking the mould: Fixit Medical partners with WMG to deliver a safer, smarter medical device

Fixit Medical is transforming healthcare with innovative medical devices that prioritise patient safety, comfort, and usability.

The first device to feature their groundbreaking force dissipation mechanism is Cingo: a next-generation percutaneous drainage catheter securement device. To bring Cingo to life, Fixit Medical collaborated with experts at WMG to refine the design and optimise it for efficient, scalable manufacturing.

How WMG helped ProtectaPet claw its way to international success

ProtectaPet, founded by Eve and Simon Davies, is a Staffordshire-based company that designs and manufactures innovative cat fence barriers, enclosures and ‘catios’, helping cats safely enjoy being outside.

Driven by a mission to deliver world-class, revolutionary feline care, the company earned the King’s Award for Enterprise in Innovation in 2023, recognising their commitment to pet safety and product excellence.

50% reduction in boiler energy use: how WMG brought Eco Smart Systems’ idea to life

Eco Smart Systems specialises in providing innovative and eco-friendly heating solutions for their customers. Through advanced renewable technologies, they help homes achieve greater energy efficiency while reducing environmental impact.

Sonotu transforms affordable hearing aid production with WMG

Sonotu is dedicated to improving the quality of life for people with hearing loss in low to middle income countries such as India. Established as a spin out from the University of Warwick by Professor Nigel Stocks, Sonotu works with top experts in UK academia and clinicians in Nepal, to successfully re-engineer, manufacture and supply affordable high-quality hearing aids to those who may not have access to them otherwise.

What's next for manufacturing leadership - event recap

Our event, hosted by WMG, offered a taster session of our newly developed manufacturing leadership course, showcasing key learnings, and exploring how we can shape the future of leadership in SME manufacturing businesses, together.

Shaping the future of manufacturing with WMG's leadership programme

How WMG’s new programme is shaping the next generation of manufacturing leaders. With so many challenges facing manufacturers today, from energy hikes to understanding AI, it’s easy to be distracted from what can make or break a manufacturing business: strong leadership at all levels of the organisation.

Dover Clean Ferry Power: Finding the Route to Electrification

The Port of Dover (PoD) plays a critical role in the UK’s economy, handling a staggering £144 billion of trade annually. There is the potential to facilitate an increase of up to £173bn per annum as part of its ‘Port of Dover 2050: Empower Exchange’ initiative that aims to deliver long-term smart, seamless and sustainable trade and travel.

Stainless steel industry develops leaders of the future with WMG

A cohort approach to solving succession challenges in the stainless-steel industry is underway at the British Stainless-Steel Association as WMG sign up to deliver a second leadership programme for members.

Background and Challenge

Manufacturers consistently recognise the critical importance of enhancing leadership and management skills to bridge existing and anticipated skills gaps and to tackle the major challenges facing the industry. The British Stainless Steel Association members are no different and the association has seen a surge in interest from member firms wanting to develop staff to boost growth and innovation.

Adam Bradley, Director of Corrosion Resistant Materials and Vice Chair of the BSSA said:

“Leadership is not something that is taught. What we find at BSSA is that employees that are good at their job and have worked for a long time in a manufacturing firm are generally made leaders. This type of succession activity does not necessarily translate into success, because a distinct set of skills are required to lead, and you must spend time to learn and embed them. Businesses are finding it difficult to help those employees with that transition and are not investing in training because they don’t know where to go.”

Solution

To help their members thrive and move forward, BSSA and WMG worked together to create a leadership programme crafted specifically for the needs of their members. BSSA realised that the membership base would benefit from a taster of what was available in terms of leadership and development training before investing fully. The BSSA Talent Development Programme consists of two modules helping attendees understand their own leadership qualities and behaviours as well as how to lead a team to success. The programme also provides coaching and an opportunity to work on a cohort project to benefit the businesses as well as the association.

The successful pilot that ran earlier this year resulted in the cohort working together on a directory and support materials to help members better understand the food and drink and interiors sectors where stainless steel has enormous potential and application.

Impacts

As a result of the pilot programme BSSA have committed to offering members the opportunity to join a second Talent Development Programme.

Individuals will benefit from:

- A leadership certificate from the University of Warwick

- Expanding knowledge of products and services within the industry

- The opportunity to network with likeminded individuals

- Additional skills in areas such as presenting, marketing, social media, project management, as well as a boost in confidence

Benefits to the companies involved include:

- The opportunity to promote their brand

- The opportunity to boost their training and development credentials, which will ultimately boost productivity and attract new skills to the sector

James Sweeney, Production Manager at Birmingham based Anopol Group participated in the pilot programme after being promoted to manage a new team. David Cass, Managing Director at the firm said:

“It has been a pleasure observing James’s growth through the BSSA Talent Development Programme. Our team at Anopol are benefitting from his leadership training and networking interaction development. James has clearly grown in confidence and is demonstrating excellent communication skills, attentive process driven approaches to conflicting situations, and mature self-awareness. He thoroughly enjoyed spending time with the programme lecturers and delegates whilst experiencing new business environments. Our next delegate is ready to go!”

Liz McArdle, Innovation Manager at WMG who delivers the programme alongside colleague Steven Norgrove said:

“We are delighted that Adam and the team have decided to invest in this valuable programme for the second time off the back of the successful pilot. WMG is on a mission to equip the leaders of the future with the skills to navigate changes and opportunities in the manufacturing sector. We thoroughly enjoyed collaborating with the participants and seeing them flourish and grow in confidence. We look forward to meeting the next cohort in October.”

Adam Bradley added:

“Our hope is that schemes like this will help to retain and attract talent to the sector which is vitally important for the association and companies across the board. We are excited to witness the journeys that our next set of leaders will go on through the programme.”

For more information about membership at the BSSA and joining the programme which starts in October visit:

BSSA Talent Development ProgrammeLink opens in a new window

For more information about WMG’s leadership programmes for manufacturing SMEs contact: wmgsme@warwick.ac.uk

A turnover and wellbeing boost at Wrekin Sheetmetal through Made Smarter support

“Working with Made Smarter and having the new system in place has been invaluable for us. It has dramatically improved our production line process and has not only made staff happier but has made it easier for us to onboard new colleagues and products thanks to the system’s ease-of-use.”

Claire Robinson, Managing Director, Wrekin Sheetmetal Ltd

Wrekin SheetmetalLink opens in a new window, based in Telford, manufactures and shapes a wide variety of steel parts and components for a range of sectors, including healthcare, automotive, aerospace, and retail.

Challenge

Although the company were thriving in some areas, there were issues with productivity and data visibility on the shopfloor. They were still printing technical drawings on paper and there were often bottlenecks as one department waited on information from another. The company were not optimised to take on new client products due to a lack of time to develop new processes. This was hindering their ability to grow.

Solution

Managing Director Claire Robinson got in touch with the Made Smarter West Midlands programme, who linked Claire with WMG Engineer, Manikanta Ravi. Mani, with the help of Intern Ravikishore Karuppuswamy, undertook a value stream mapping of Wrekin Sheetmetal’s complete manufacturing process from start to finish, to assess improvement opportunities. He recommended they install a suitable dashboarding solution integrated with current Enterprise Resource Planning (ERP) software MIE Track, using a network of tablets on every machine and in every department to monitor data. Together with WMG’s Denis PelychLink opens in a new window, Made Smarter assisted Wrekin Sheetmetal to access a match-funded grant of £20,000 towards the cost of the new system which reduced the risk associated with the investment.

Impacts

- The new system has allowed Wrekin Sheetmetal to devote more time to new product development which will open new growth areas for the business and will help them meet its targets to double turnover by next year

- With the new system in place, Wrekin Sheetmetal are expected to grow capacity by between 10-15% and create seven new jobs

- Wrekin Sheetmetal is now a paperless operation and is using data to drive decision making

- Staff are highly motivated as they now have visibility of their activity, there is reduced time wastage, and they feel bought into the whole manufacturing process. Existing roles will benefit from upskilling going forward

WMG's Manikanta Ravi said:

“Key data such as machine uptime and downtime, technical drawings, and order information is now instantly accessible to every member of the team, with information constantly updated in real time.

The new system has meant the waste identified in our value stream mapping exercise, such as the time taken for the engineering team to pass on drawings to the shop floor team, has been virtually eliminated.”

For the full case study visit:

made-smarter-case-study-wrekin-sheetmetal.pdf (madesmarter.uk)

If you are a manufacturing organisation wanting to work with WMG’s SME team visit:

WMG SME Group Engagement Form (office.com)

Championing the importance of digital in manufacturing, Bridge Cheese picks up two business awards.

Telford based Bridge Cheese has gained two prestigious awards for the way it has harnessed digital technology to grow turnover to £30m in five years. Working with WMG through Made Smarter West Midlands, they have implemented a series of recommendations that have improved efficiency and enabled growth.

Background

Bridge CheeseLink opens in a new window, based in Telford, supplies a variety of cheese and dairy products to the wholesale market, with many of its customers working in the food service industry or food manufacturing. Since its inception in 2018, it has grown rapidly, achieving double-digit growth year-on-year.

Challenge

Bridge Cheese had a mission to double its turnover from £30 million to £60 million in three years. However, to mitigate the pressures of rising costs and to maximise profitability, the two directors Michael Harte and Martin Bowden knew they had to tackle the efficiency of their processes. They were also keen to address issues with stock control and production management.

Michael Harte said:

“We realised that for us to grow further, the analysis of our production processes and costs needed to be a lot better. We had previously relied on spreadsheets and paper records to monitor much of our business’s performance.”

They were aiming to create a smart paperless factory with some automation that would enable them to grow without too much additional labour.

Solution

Telford and Wrekin Council referred the duo to the Made Smarter West Midlands scheme and Made Smarter digital expert Martyn Mangan recommended WMG come in to undertake a thorough audit. This included a “Digital Roadmap” highlighting the steps needed to digitise the business and boost productivity.

WMG's Denis PelychLink opens in a new window worked with Bridge to understand their requirements and what was impeding their growth potential. He suggested a new Enterprise Resource Planning (ERP) system would help improve real time data and visibility to better manage processes. He reviewed various solutions and providers before recommending a specialist food industry package with proven integration to Sage 200, which they were currently using.

The software and services cost was £70k but through Made Smarter, Bridge was able to access a £20k grant. During 2023 using a phased approach, the company implemented the new system which included customised KPI/status dashboards for factory visibility and decision-support.

Impacts

Now up and running, the new system handles everything from tracking orders, stock taking, monitoring machine uptime and downtime, and producing instant quality control reports. Key expected benefits include:

· 20-30% year-on-year growth expected, from £30m to £60m+ revenue in 3 years, including increasing export sales from 2% to 20%+

· 100% reduction in ‘on-time delivery failures’ of orders, plus a saving of the time wasted resolving production issues due to stock issues

· 15-20% improvement in current process efficiency, from process automation across order processing, planning, and production execution

· 10-15% additional efficiency improvement through shop floor digitisation of food safety compliance data capture and management

· 50% reduction in stock days which is around £1.5million of cash freed up to support investment

The outstanding results led to Bridge Cheese being crowned as overall winner of the Made Smarter Adoption Award for the West Midlands region in Birmingham as well as in their own area of the Marches. They represented the West Midlands at the national Made Smarter Awards on 27th June.

Testimonials

“For SMEs like us, support from a scheme like Made Smarter is so important. As part of this journey, Denis’s role became akin to a “non-executive director” advising us in all matters IT related. We are now taking the next steps towards a digital future for our business, and we would encourage others in our position to do the same.”

Michael Harte, Director, Bridge Cheese Ltd

“Bridge Cheese were a delight to work with and are highly motivated to build on their already excellent reputation for service quality. The new system will enable them to achieve their growth ambition without any risk to delivering on client expectations. There are many additional areas that they can focus on with digital going forward such as further automation which is very exciting.”

Denis Pelych, Digital Manufacturing Advisor, WMG, University of Warwick

To find out more about working with WMG on digitising your business contact WMG's SME TeamLink opens in a new window

For further information on Bridge Cheese visit: Welcome to our World of Cheese - Bridge CheeseLink opens in a new window

To read the full story and watch the video about Bridge Cheese’s journey on Made Smarter visit: Case Study - Bridge Cheese | Made SmarterLink opens in a new window

Machine learning project automates complex tooling job at Expert Technologies Group

A two-year Knowledge Transfer Partnership (KTP) between WMG, University of Warwick and expert industrial automation specialist Expert Technologies GroupLink opens in a new window has introduced machine learning into a range of engineering settings that were previously thought too complex to implement. KTP Associate Mateusz Ogrodnik reduced the time of designing new mechanical fixture plans* from weeks to minutes.

Challenge

Historically the job of creating mechanical fixture plans was deemed too complex to automate. Despite involving repetitive tasks, the processes were too nuanced for simple automations to handle, and tooling designers were still an essential component.

However Expert Technologies were keen to devise and implement a novel approach to this unsolved problem, so that designers’ time could be better utilised on higher value, strategic tasks in the business.

The key challenge was the sheer computational complexity of this process. A typical fixture plan has around 40 elements which would mean that around 250 parameters had to be implemented into an automated solution.

As part of this project, Expert wanted to create and embed a systematic approach to solving complex engineering problems for the future. With the use of machine learning on an upward curve, this project would pave the way for them to continue to use this kind of technology for other hugely complex problems.

Solution

With the support of WMG, they opted to apply for an Innovate UK funded Knowledge Transfer Partnership (KTP). KTPs link forward thinking businesses with a knowledge base to deliver on an innovative project led by inspired graduates.

Initially, Knowledge Transfer Associate (KTA), Cesar Reyes, was appointed. His work laid strong foundations and a year later, a second KTA, Mateusz Ogrodnik joined the team. His approach, thanks to experience in optimisation and software development, along with support from WMG's Professor Pasquale FranciosaLink opens in a new window, led to the development of a completely novel set of algorithms that reduced the computational complexity.

Mateusz arranged meetings with senior engineers at Expert to understand how an experienced designer would approach the problem which helped to speed up the time it took for the automated system to create a design. This was followed by building a prototype app, where multiple case studies could automatically be tested. As the number of bespoke algorithms grew, and time left to create a solution decreased, Mateusz spent time working directly with the engineers to undertake further beta testing to arrive at the final prototypes. Mateusz also attended the Association for the Advancement of Artificial Intelligence conference in Canada, where he was able to gather further insights for this project as well as other opportunities to take forward at Expert.

Impacts

· A final prototype tool was created which reduced the time of developing mechanical fixture plans from weeks to hours which will lead to significant cost savings for the business.

· Mateusz has been hired by Expert as a Senior Software Development Engineer.

· Expert has put new software development approaches into practice which will de-risk other software-based projects.

· The project opened up a number of ideas for other Expert employees to build, develop and share within the company.

· New software projects, including complex machine learning tasks have been brought forward and de-risked thanks to this project.

· Expert has now applied for a further Accelerated Knowledge Transfer grant to work on a similar project.

Ian Snape, Engineering Director at Expert Technologies Group said:

“To witness the ground-breaking final prototype demonstration was a realisation of an unrealistic idea four years ago. Not accepting the ‘norm’ and embracing development failure as an opportunity to dissect and optimise, is the heartbeat of this achievement. We celebrate the powerful new fusion of engineering and data science within this Expert / WMG collaboration and look forward to the next set of limitations we rip up.”

WMG Reader and academic supervisor on this project Pasquale Franciosa said:

“The work with Expert Technologies Group through the Knowledge Transfer Partnership root is great evidence of transferring academic research outputs into industrial operation. The project nicely bridged engineering design with digital technologies and proved that this is the way forward to support business growth, whilst releasing capacity and maximising productivity.”

For more information on working with WMG on KTP projects contact wmgsme@warwick.ac.uk

For more information on Expert Technologies Group visit:

Expert Technologies Group | Industrial Automation Technology

*A fixture is a device for locating, holding and supporting a workpiece during a manufacturing operation. Fixtures are essential elements of production processes as they are required in most automated manufacturing, inspection, and assembly operations.

Flux Aviation flying high as business transitions to the next level

A WMG internship to embed 3D scanning technology into the business leads to big efficiency gains and the opportunity to transform the aviation industry on its pathway to electrification.

Background

Flux Aviation is an innovative start-up on a mission to accelerate the transition of aviation towards electric power. Its technologies will enable zero emission aviation from two-seat trainer aircraft and up to 50-seat regional airliners. Its core innovations focus on electric motors and battery modules that have been designed from the ground up specifically for aviation applications. The team were recently propelled into the limelight as overall winners of the Manufacturing Start-up Award at the Made in the Midlands Insider Awards.

Challenge

Flux Aviation develops complete systems that include electric motors, batteries, and control electronics all in one package designed to be retrofitted into a range of existing aircrafts to replace combustion engines (e.g. traditional ROTAX engines).

The company is targeting direct compatibility with 80% of aircrafts on the market, enabling aircraft manufacturers to offer electric variants of their products with minimal re-design effort. The current process of building a design library of compatible aircrafts is very manual and time consuming. It requires moving the aircraft to Flux Aviation premises and taking measurements manually. Founders Radovan Gallo and Neofytos Dimitriou decided to invest in 3D scanning technology to improve the process but were unsure how best to embed it in the business and did not have the expertise to do all the necessary tests to prove its efficacy.

Solution

Already engaging with WMG through the Natwest funded Clean Transport Accelerator programme, the duo were made aware of WMG’s internship programme. They took on Design Engineer Intern, Aryan Bharmani with supervision from WMG’s Manikanta Ravi to create a series of processes and workflows that would maximise the benefit and accelerate the speed of implementing scanning technologies in the business.

Ultimately the process had to be customised to Flux’s needs and fully documented and tested. Aryan worked on configuring the scanner for optimal performance, testing it on engine bays, fuel tanks, fuselage, and mountings all at different resolutions. He designed an appropriate workflow from pre-processing all the way to post-processing scan data, including looking at ways to export scan data as stereolithography (STL) files by reducing size and without compromising quality to carry out design work in CAD software for conversion into solid bodies. Additional evaluation and verification work was carried out, as well as the creation of Standard Operating Procedures.

Impacts

· As a result of the internship project, Flux Aviation is now able to measure and design aircraft engine mount parameters using scanning technology with a deviation of less than 1%;

· The standard workflows produced by Aryan have given Flux the confidence to use scanning technology in the aircraft electrification process, eliminating the need to move the client aircraft from its owner’s hangar for retrofitting;

· The new scanning technology has reduced aircraft measuring time from four weeks to just two hours (a reduction of 99.7%) increasing the company bandwidth to deliver more client projects, accelerating the transition of aviation to zero-emission electric power;

· This new capability will enable Flux Aviation to conduct the aircraft electrification process outside the UK, opening up opportunities to sell in European markets;

· The project led to new quotations for projects worth £300k and the company are hoping to convert those as well as grow the order book by a further £300k in the next three months.

Testimonials

“The WMG internship programme has been incredibly helpful. We identified a gap in our capabilities and with the help of WMG experts and a highly skilled intern we were able to address it in a quick and cost-effective way. The programme requires minimum additional overhead for recruitment and ongoing management. It is an incredible resource for an SME like us and we would be delighted to use this programme again in the future.”

Radovan Gallo, CEO, Flux Aviation Ltd

“This internship provided valuable hands-on experience in cutting-edge technologies for electrifying aircraft, improved my technical skills, and contributed to my employability in the engineering field, particularly in areas related to design, scanning, and workflow optimisation.”

Aryan Bharmani, Design Engineer Intern

“WMG's Internship programme helped Flux Aviation identify the right talent to address its skill gap and accelerate their vision. It also helped Aryan to initiate his professional journey in the manufacturing world under an expert’s supervision, thereby contributing to the development of a skilled workforce in the UK.”

Manikanta Ravi, Engineer, Business Transformation, WMG

Notes

*Flux Aviation's most recent accolades are:

- Most promising solution by Innovation Zero

- Manufacturing Start-up by Made in the Midlands

- Cleantech Startup of the Year by the Midlands Startup Awards

For more information on Flux Aviation’s work and mission visit: Flux Aviation

For more information on working with WMG's SME team and internships email wmgsme@warwick.ac.uk

A sustainable edge leads to transformative changes at Alpha Anodising

“The work undertaken in this project has so far exceeded our expectations, we are looking forward to getting the new system up and running in the business and continuing our productivity push through sustainability measures.”

Leslie Sharp, Managing Director, Alpha Anodising Ltd

Background

Alpha Anodising was formed in 1972 to fulfil a requirement for quality black anodising of equipment for the motion picture industry. Anodising is an electrochemical process that develops an aluminium oxide coat on the surface of a part or product. This protects the product from wear and tear as well as enhancing the overall look.

Challenge and Drivers

Alpha Anodising were on a mission to develop their sustainability credentials and reduce the costs of running their energy intensive shop floor, which houses a swathe of large bubbling tanks preparing anodising treatments ready for products including high end consumer electronics, and industrial process equipment.

Another key driver was that more and more of their clients were requesting information about their Environmental, Sustainability and Governance (ESG) targets.

To get an edge in this area, they wanted to energy monitor key equipment including three electrically powered 240V heaters heating a 1 1000L boil tank used during the anodisation process, which were responsible for 37% of the entire site’s energy consumption.

They also wished to improve the current method of managing their equipment across the factory more generally. In the current state, employees were coming in early to manually turn on heaters to get the boil tanks up to temperature ready for production. This was not ideal when arranging weekend or shift work and when the clocks changed, as it involved having to manually reprogram heater timers on up to 50 tanks.

Solution

Tap into a network and get to grips with baseline data

The company joined WMG’s Net Zero Innovation Network and were one of the first companies to benefit from a tailored manufacturing energy toolkit to better understand energy hotpots in the business.

We measured the electrical energy consumption over a six-week period, looking at the consumption of energy, the cost and carbon equivalencies, as well as testing some insulative lids to compare energy consumption before and after. As a result, a full report with a range of energy saving recommendations was presented including heater upgrades, timers, and the introduction of a dashboard to increase visibility of energy usage in the factory.

Access funding to make a difference

Following this initial project, Alpha secured a grant through the Innovate UK Business Growth programme to develop a solution that would network, centralise and simplify the process of managing the temperature of the boil tanks in the business in order to increase efficiencies and optimise energy usage.

WMG’s Julian Swiestowski, identified that there was an opportunity to use IoT (Internet of Things) technology and connectivity to make this happen.

Julian explored a range of off the shelf solutions for Alpha, that were competitively priced, easily programmable, and possible to retrofit beyond this project to other equipment. He settled on some factory automation software from the Siemens logo series. It provides a compact controller that links directly to the cloud so that the company can set and adjust the temperature for the tanks away from the shop floor, in the office or on tablets and mobile devices at home.

With this solution there is now the opportunity to monitor data over time to understand energy usage, system performance, and productivity and make changes accordingly. The tanks would also be set with thermostats.

Impacts

Whilst initially Alpha Anodising started work with WMG to enhance its ESG activity, the collaboration and IoT project will lead to a number of transformational benefits:

· The new IoT system will save Alpha thousands of pounds a year in energy costs through automation and better insight into usage;

· The new system will allow for higher levels of productivity in the business and enhanced quality as there will now be a whole range of data that can be used to tweak production parameters;

· The system will free up staff to work on other activities which will increase efficiencies and there will also be opportunities for the upskilling of staff to use the new digital systems;

· There are now a range of sustainability-led ideas developing within the firm such as insulation on tanks and the introduction of a two-stage counter current rinse system to reduce water consumption by 40-50% They have also invested significantly in Solar Energy Panels and new equipment such as a top of the range Timesaver linishing machine and additional bead blasting cabinets. Link opens in a new window

Link opens in a new window

For more information on working with WMG's SME group contact wmgsme@warwick.ac.uk

For more information on Alpha Anodising visit: https://www.alphaanodising.co.uk

PAVE UK’s first outreach event at Somerscience 2024

A week has now passed since PAVE UK’s first outreach event at Somerscience 2024. The annual Somerscience Festival brings together families and organisations for a day of fun and exciting STEM-based activities, with the science fair taking place at Haynes Motor Museum. There were over five thousand visitors attending the events across Somerset this year. This week, we’ve had the opportunity to reflect on the many conversations and discussions that were held, and we are now able to share them with you. In this blog entry, we’ll be discussing a few of our thoughts and observations from the event, as well as our next steps as we look towards future events.

PAVE UK aims to engage the general public in conversations about automated vehicles, allowing future users to play a role in informing the safe technological development of such systems. The Somerscience Festival was a fantastic opportunity to directly speak with the public, allowing us to understand some of the current perspectives surrounding automated vehicles and to spark discussions on their safety, accessibility, use, and impact on people’s daily lives. Additionally, it facilitated engagement with school aged children by getting them involved in the conversation and enabling them to start exploring the technologies behind automated vehicles, therefore developing the skills and knowledge of the next generation.

As this was PAVE UK’s first outreach event, the main goal was to foster discussion with members of the public and discover their thoughts on self-driving vehicles. To this end, a few activities were set up as part of the PAVE UK stand—a remote-controlled vehicle, a demo of road scenario creation using WMG’s SafetyPool™ Studio, and a post-it board to capture the perceived benefits and challenges of self-driving vehicles—all of which were designed to spark conversations with people of all ages.

When asked “If we had a self-driving vehicle here today, would you get in it?”, everyone had their own response. Most people were very willing to get into a self-driving vehicle on a closed test track, with no external traffic, but fewer were happy to test one on the real roads straight away—instead, they indicated that they would be confident to move to higher-speed roads with other vehicles once they had a better understanding of the technology and its safety. Attendees were optimistic about the possibilities of self-driving vehicles, with many people hoping that they could be used to restore mobility to some of the more vulnerable members of society, such as people with visual impairments, or older drivers with less confidence on the road. However, a few visitors also mentioned that they would only trust the vehicles personally once they had been running safely for several years first. Considering another angle, some people also voiced doubts as to whether insurers would be willing to cover fully autonomous vehicles.

On a level closer to home, a lot of people who had driven to the event said that their cars had some level of driving assistance, varying from adaptive cruise control to automated lane keeping systems. There were also different levels of trust in these systems, with most people confident to use them on a motorway. However, a few drivers described existing performance issues in more nuanced scenarios, such as on rural roads with unreliable road markings. One thing that these discussions illustrate is the importance of educating the public on the difference between cars with high levels of driver assistance, and fully self-driving vehicles. In general, people were optimistic, but curious about a range of areas regarding safety, practicality, human factors, and administration.

The next outreach event on PAVE UK’s radar is MotoFest 2024, in Coventry. Unlike the Somerscience Festival, which is primarily aimed at families with children, MotoFest 2024 caters to those with a

particular interest in driving and vehicles more generally—as such, it will be exciting to see how opinions differ between the two events.

Overall, the Somerscience Festival was a highly successful initial outreach event for PAVE UK, fostering discussion across all ages and sparking curiosity in future generations. With the new insights gained from this, we hope to improve our educational offerings going forwards, and reach many people in the events to come. We look forward to seeing you next time!

Advances in Laser Welding Using Beam Shaping Bolster Green Transport Future

WMG, in collaboration with Lumentum, a San Jose-based market-leading designer and manufacturer of innovative optical and photonic products, has developed an innovative beam-shaped laser welding technique to dramatically increase the reliability of welded joints between dissimilar metals. In a bid to meet the growing demand for lightweight and environmentally friendly vehicles, this process will allow manufacturers to join mixed materials in an efficient way that does not limit performance.

Flexing their operational muscles – Goodflex Rubber Ltd set to expand with new ERP system

“Our involvement with the Made Smarter programme gave us the confidence to move forward with one of biggest changes to the company in its 22-year history. This investment will not only allow us to improve our efficiencies but also provide us with the security to continue to grow in the future, aiding us to deliver even better products and services to our customers and ensure we remain a leader in the industry.”

Natalie Benwell, Commercial Manager, Goodflex Rubber Ltd

Warwickshire based Goodflex Rubber Ltd are world renowned manufacturers of high quality, bespoke-design silicone hoses, serving a range of industries including automotive, pharmaceutical, renewable energy, and food.

Challenge

Goodflex had plans to double their turnover over the next three years but were concerned that their Factory Management System was holding them back from achieving this growth. They had been using their current bespoke ERP system since the business was started and it had evolved over time to be used for multiple areas within the business, including material resource planning, accounts, stock management, work order management, invoicing, and delivery notes.

But they needed to move to software which would enable their day-to-day operations to be more efficient, allow them to respond more quickly to their customers and futureproof their processes.

Solution

Commercial manager Natalie Benwell got in touch with the Made Smarter West Midlands programme and was introduced to WMG’s Denis Pelych who quickly set about understanding the company’s specific requirements. It was clear that Goodflex needed an enhanced, futureproof, digital system to drive efficiencies and maintain control of some of their more complex product builds, but they were unsure what specific system to invest in.

Denis conducted a two-stage MRP and ERP* vendor selection process, with Made Smarter support and helped Goodflex select an ERP system that offered the capability they needed today, with a degree of futureproofing. The investment required was approximately £100k but Goodflex were able to access £20k with the help of a Made Smarter grant.

Natalie said:

“Denis understood and identified our needs better than we understood them ourselves and then successfully translated them into an RFP (Request for Proposal) that was such a true reflection of our business. His knowledge in the industry, not only opened our eyes to what was possible, but also took us down a route we never knew existed.”

Impacts

- The new system will help Goodflex increase the speed of response to their customers

- The new system will help Goodflex double their revenue to £10m in three years, with the potential to reach £15-20m in five years, whilst maintaining margins and investment

- The system will lead to a 20-30% efficiency improvement from the automation of business processes

- The company expect to see a 15-20% improvement in material supply and stock efficiencies

- Efficiencies gained through the system will lead to higher levels of profitability

- The new system provides better management information with the ability to set KPIs and have greater operational insight in order to make data driven business decisions

- The new system will also improve Goodflex’s business development strategy enabled by greater insight into costs and opportunities

- The new system has improved workplace motivation and will help to retain and develop highly skilled staff

*ERP vs MRP: What’s The Difference? – Forbes Advisor

Read the full story on the Made Smarter website here.Link opens in a new window

Heating up for expansion with Eskimo Products

“WMG have been great to work with, they digested the brief, stuck to it, and delivered a great factory optimisation project. I was really impressed with the level of detail within the report and really enjoyed working alongside their engineers.”

Phil Ward, Managing Director, Eskimo Products Ltd

Background

Luxury radiator and towel rail design firm, Eskimo ProductsLink opens in a new window designs and manufactures a range of top end products with a focus on creating beautiful aesthetics within homes as well as being highly energy efficient. With a design office in Bristol and manufacturing space in Birmingham close to the international airport, the firm were setting their sights on growth and expansion.

Challenge

The company had plans to move into a new factory in 2025 to scale up production following an increase in demand. They were looking for support to maximise the productivity potential of the layout in the new space and in the existing facility. They also needed support to digitise their manufacturing process.

Solution

Phil Ward, founder of the firm worked with WMG SME group’s Manikanta Ravi and Gun Gokmen to set up a project using Innovate UK Business GrowthLink opens in a new window (previously Innovate UK EDGE) funding with objectives to:

- Measure the current state of the factory to understand what was inhibiting target productivity

- Recommend improvements to increase capacity and reduce wastes on two key product lines (Column and Gordon) using lean methods and automation

The project would allow for a seamless transition and the opportunity to scope any new investments and potential changes before the move - essentially minimising any risks and to avoid any downtime.

Mani and Gun compared current capacity against the required capacity to meet the forecasted demand and identified that there was a shortfall. They performed bottleneck analysis for the overall process flow from customer order to raw materials, and manufacturing to customer delivery.

The extensive study allowed them to identify bottlenecks and areas for lean improvement, as well as make recommendations for where capacity could be enhanced such as an additional spindle tool to reduce CNC Machine setup time, standardising the setup of the powder coating process, improving lighting to reduce the number of re-works, introducing a new cell for assembling, testing and packing, adopting 5S workplace organisation methods and more advanced techniques such as automated welding with a suggested cycle time to meet demand. They recommended a phased approach for improving different areas overall, including welding, machining, and treatment.

Impacts

- Once implemented, WMG’s recommendations will reduce current bottleneck times by 72% per product on the Column product line and 43% on the Gordon line. So, for every 100 units made, 33 hours can be saved on the Column product line and 20 hours on the Gordon;

- As a result of the project, with the addition of robot welding and a pre-treatment plant, production capacity for the Column line will increase by 360% and for the Gordon line 37%;

- The improvements suggested will lead to estimated additional turnover of up to £365k per year;

- The company is now in a more informed position to make the move to the new space with automation and factory layout proposals that will help them meet capacity and grow the business.

Eskimo are currently working with other WMG colleagues through the Made Smarter West Midlands programme to implement the robotic welding process and will benefit from a grant to make this a reality. They are also embarking on a new WMG project for advice on the best manufacturing techniques and layout to take a new thermal energy storage product to market.

“It was great to work with the team at Eskimo to help them realise some of their growth ambitions through an improved factory layout. With the added digital capabilities proposed through Made Smarter West Midlands, there are even more opportunities for expansion. Innovate UK's Edge programme (Innovate UK Business Growth) helps businesses connect with the right expertise at whatever stage of growth they are at. We are excited to see where Eskimo goes next.”

Engineer Manikanta RaviLink opens in a new window and Industrial Engineer Gun GokmenLink opens in a new window, WMG University of Warwick

Armac Martin reignite sustainability drive with second collaborative project

“Working with WMG again has been really beneficial for us. This project will enable us to lower our carbon emissions, something critical for us from both a CSR perspective and in combating rising energy costs to remain competitive.”

Steven West, Head of Operations, Armac Martin Ltd

Background

In 2021, following the introduction of the UK Government’s Net Zero strategy, luxury brass hardware manufacturer, Armac Martin was one of the first companies to join WMG’s Net Zero Innovation (NZIN) Progamme. They collaborated with us to implement sustainable packaging for key product lines in their business. After exploring recyclable, compostable, and returnable options, a cost effective and biodegradable paper-based material was selected which reduced packing time significantly, leading to productivity gains in the business.

Challenge

With renewed drive to reduce emissions by 50% by 2025 and reach Net Zero by 2041, Armac Martin wanted to work with WMG again to see where they could best focus their attentions to achieve these goals. They joined the NZIN programme on a second cohort alongside Brandauer, Sarginsons, Modpods and McGeoch.

Solution

WMG examined how the company could reduce emissions across Scope 1,2 and 3[i] in the business, through a Greenhouse Gas Accounting project. We highlighted a range of opportunities for them to take onboard as part of a five-year roadmap for sustainable change aligned with business visions and priorities through a NZIN roadmap. Representatives from the company also participated in several workshops hosted by WMG.

Impacts

· The company now have a clear vision of how they are going to reach their 2025 and 2041 targets with an action plan to reduce energy costs in the business, including using data to optimise energy usage, as well as voltage optimisation, insulation, and variable speed drives of machinery,

· They plan to install Solar PV Panels to reduce energy related emissions and susceptibility to grid price fluctuations

· They have the opportunity to access grant funding to install the Solar Panels of up to £100,000,

· They now have a robust sustainability strategy which they communicate to both internal and external stakeholders.

“Armac Martin are a company committed to sustainability and it was great to work with them on a second project looking at energy usage in the business. They are a shining example of how businesses can work towards Net Zero targets while adding value to their clients’ customer experience.”

Archit Tamboli, Technology Transfer Engineer, WMG, University of Warwick

For more info on Armac Martin’s sustainability strategy visit:

https://www.armacmartin.co.uk/

[i] *Scope 1 emissions are the Green House Gas (GHG) emissions that a company makes directly — for example while running its boilers and vehicles.

Scope 2 emissions are the emissions it makes indirectly – like the electricity or energy it buys for heating and cooling buildings, which is being produced on its behalf.

Scope 3 emissions are all the emissions associated, not with the company itself, but those that the organisation is indirectly responsible for, up and down its value chain. For example, from buying products from its suppliers, and from its products when customers use them.

Reaping the rewards of collaboration – further impact for Jaltek Systems as partnership with WMG goes from strength to strength.

Automation project leads to productivity gains and new opportunities to upskill valuable teams.

Background

Founded in 1988, Jaltek Systems are a contract electronics manufacturer with full electronics design capability. They first worked with WMG in 2022 when we helped them with an expansion and new factory layout for new premises. Two years later, having landed new business worth almost £3 million and taken on Nayan the intern that helped them implement production line changes, they contacted WMG again for support with automation.

Challenge

Jaltek has grown significantly in recent years with further ambitious plans, and they were looking to adopt digital technology, particularly in robotics and automation to facilitate this growth. Steve Blythe, at Jaltek had visited the Advanced Metal Research Centre in Wales and other SME businesses who had started using collaborative robots (cobots) and had identified that automation could:

· Provide productivity enhancement with the need to recruit less

· Offer extended working hours – machines could operate outside regular working hours

· Help with issues such as the UK’s restrictions on labour movement, which were making it difficult to find new employees with the right skills

· Provide the opportunity for skilled employees to do more interesting, higher value tasks

Already using machines for the surface mount placement process, Steve identified that cobots could also be implemented for post surface mount assembly activity and labelling.

Solution

Following the success of previous WMG internships at Jaltek, they decided that taking on another intern would help them direct the resource needed on this project while saving valuable management time. With WMG supervision, intern Kesava Viknesh was appointed. He initially undertook an automation feasibility study for the complete set of processes in the business, quantifying the benefits of automation for each one. He then conducted a comparison study of different automation solutions, resulting in a list of the top three opportunities. After creating and presenting the business case to the board of directors, Kesava then went on to create a simulation of the automated labelling process to de-risk the investment. Jaltek also benefitted from a pilot trial of automation to assemble one of their products using WMG’s UR5e cobot before investing in their first cobot.

Impact

The internship project led to a range of impacts including:

· Identifying significant productivity improvements;

· A new full-time position for Kesava as an automation engineer;

· The upskilling of existing staff to fulfil higher value skilled jobs now that the cobots can undertake other tasks;

· A change in proposition for new employees, with a focus on highlighting the business’s values;

· Improved precision and uniformity which in turn supports the sustainability credentials for Jaltek as there is less waste;

· The opportunity for extended operations (as robots can work outside regular working hours);

· The ability for Jaltek to keep pace with technological advancements;

· An additional Accelerated Knowledge Transfer (AKT) grant to enable another young engineer to join the firm on a 16-week project to continue with the integration of robotics technology into their processes.

Steve Blythe, at Jaltek Systems said:

“We are continually looking to improve productivity through training, improved processes, and automation. We saw good practice using cobots in other businesses and reached out to WMG to support our plans. We are very happy with the results of the second internship, and we are only at the beginning of this journey.”

Jack Davis, Technology Transfer Engineer at WMG who supervised Kesava said:

“This internship project enabled Jaltek to trial the use of cobots on one of their key processes before taking the plunge to invest themselves, reducing risk and ensuring that they got the exact technological solution for their requirements. Kesava did a fantastic job, so much so that he has now secured a position with Jaltek.”

WMG supports Goodfish on its sustainability journey

Goodfish Group have benefited from WMG’s Net Zero Innovation Network with a tailored project focused on helping them achieve their Net Zero goals.

Background

Goodfish Group is the UK’s leading privately-owned contract manufacturer of plastic and composite components. Its expertise in injection-moulding, extrusion, vacuum-forming, and tooling has been developed through successive acquisitions of leading companies in each discipline.

The group has partnered with WMG at the University of Warwick over the last ten years to work on new product and process development and most recently were one of the first companies to benefit from a new Net Zero Innovation Network which was set up to support SME manufacturers achieve their Net Zero goals.

Challenge

Goodfish were keen to map their current waste streams to identify opportunities where they could reduce emissions and increase their environmental, financial, and social sustainability. They recognised that the St Asaph site was the least mature in terms of sustainability, therefore asked the WMG team to focus on this site initially.

Solution

WMG undertook a Factory walk at St Asaph to identify the waste streams on site in terms of internal waste generation (extrusion and injection moulding) as well as external. They examined waste across Scope 1, 2 and 3 emissions*. Recommendations were then made via the 5R model which helps companies see where they can reduce waste, recycle, reuse, recover or ultimately refuse or prevent the waste happening in the first place.

Goodfish were advised to start making cultural changes within the organisation to encourage better monitoring of wasteful practices and to understand which machines were most energy intensive. WMG suggested using reusable packaging, finding more local recycling facilities, and reusing waste material for new products. They also suggested implementing thermal insulation jackets on injection moulding machines which on a 500T clamp force machine for example could offer a 13% energy saving over a 13-hour shift.

Impact

- Since joining the WMG cohort, Goodfish have taken significant strides forward with their waste reduction activities.

- They have invested approximately £70k in monitoring equipment to enable visibility of energy usage of all machinery across all three sites. With such granularity, they can make changes and updates to machines for optimal energy usage.

- They implemented the insulation jackets on 70 injection moulding machines which has saved 20% on monthly energy consumption

- They are now able to attribute the carbon footprint or CO2 equivalent for each product/part made, which has boosted their sustainability credentials with their clients

- They are now implementing total preventative maintenance and staff training programmes across the group to make even more savings

Guy McDonald, Director and Business Transformation Manager at Goodfish said:

“The NZIN programme was useful to meet other business leaders on similar journeys and to understand the Net Zero requirements from an OEM’s perspective, in this case Polestar.

At Goodfish, data is the bedrock of all that do we in terms of energy efficiency. We pretty much know where all the energy hotspots are in the business now and can therefore make targeted changes to boost our Net Zero credentials going forward.”

WMG’s Net Zero Approach

WMG’s Net Zero Innovation programme brings businesses together to gain knowledge about sustainable manufacturing processes, implement change and grow. As well as offering events, workshops, and a best practice visit to a company already implementing sustainable approaches, participating companies also benefit from a tailored project, Net Zero assessment and roadmap report.

For more information about joining a cohort email: wmgsme@warwick.ac.uk

*Scope 1 emissions are the Green House Gas (GHG) emissions that a company makes directly — for example while running its boilers and vehicles.

Scope 2 emissions are the emissions it makes indirectly – like the electricity or energy it buys for heating and cooling buildings, which is being produced on its behalf.

Scope 3 emissions are all the emissions associated, not with the company itself, but those that the organisation is indirectly responsible for, up and down its value chain. For example, from buying products from its suppliers, and from its products when customers use them.

Investing in Digital leads to Brighter Future for ECAM Engineering

“Business has been amazing and last year we had our best year ever. Turnover was up 20% on the previous year.”

Phil Arme, Managing Director, ECAM Engineering Ltd

Background

ECAM Engineering began life in 1968 based on the Derbyshire/ Staffordshire border before moving to Cheadle in the Staffordshire Moorlands, near Stoke on Trent.They specialise in laser cutting, metal fabrication, CNC machining, welding, and painting. They worked with WMG recently through the Made Smarter West Midlands programme.

Challenge

Phil Arme, Managing Director at ECAM Engineering has been investing in the company’s digital transformation since he bought it ten years ago. Having already implemented one robotic welder in the business he wanted to explore automation further to increase productivity and to allow staff to develop skills in other areas.

“We recognised we needed to go down the road of having a second robot. I had read about the Made Smarter programme, and I thought it could help us make a decision about which robot would be best for us since we are not experts in that field.”

Solution

Through Tim Kirby at Made Smarter West Midlands, ECAM were introduced to WMG’s Ioan Lutas who set out a digital roadmap for ECAM with advice about how best to set in place a new Panasonic welding robot to help produce parts for key clients such as JCB.

Impacts

The benefits of the second robot were noted immediately.

Overtime is no longer needed to complete jobs and the level of productivity is up

The robot has sped up processes and shift patterns have been changed to reflect this with staff now able to diversify their skills and work on other activities

ECAM went on to invest even further in digital technologies including a fully automated laser cutting machine

To read the full story visit:

https://www.madesmarter.uk/media/u0ahxjlt/made-smarter-case-study-ecam-engineering.pdf

And to see the video case study visit:

https://www.youtube.com/watch?v=4qdf4-GxnS4&t=2sLink opens in a new window

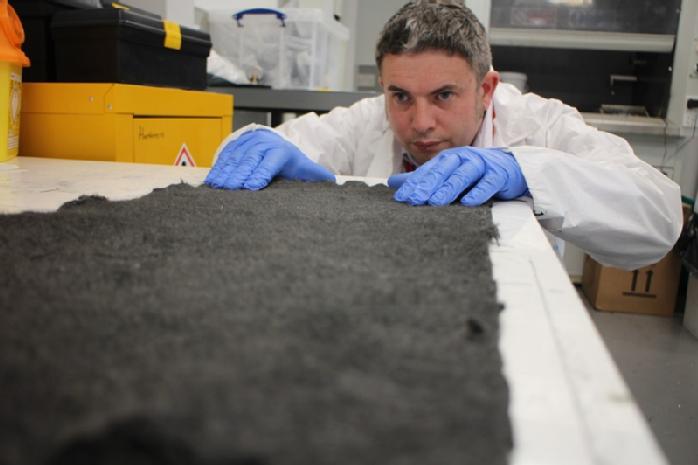

Expressing steely determination to innovate

Working with partners in the steel industry, WMG has been accelerating the development and optimisation process for steel products.

WMG Announce Take Off for the New eVTOL Battery Diagnostic Algorithm

Background

The world is witnessing a paradigm shift in aviation, with electrified aircraft presenting a promising solution to reduce environmental impact through lower emissions of noise and pollutants. Within this transformative landscape, electric Vertical Take-Off and Landing (eVTOL) aircraft have emerged as one of the most innovative designs, offering quieter, safer, and low-cost possibilities for urban air mobility and sustainable transportation. However, the successful integration of eVTOL technology hinges on addressing critical concerns surrounding battery safety, a challenge that Warwick Manufacturing Group (WMG) took on with unparalleled determination and expertise.

Vertical Aerospace Ltd (VA) is a British technology aerospace that is pioneering electric aviation and was set up by entrepreneur Stephen Fitzpatrick in 2016. Based in Bristol, Vertical is working with world-leading suppliers and partners to decarbonise air travel using the best technologies from across the aviation, energy, and automotive industries with the aim to provide faster, quieter, greener, and smarter ways for people to travel around cities and regions.

As the eVTOL sector continues to gain momentum, lithium-ion batteries have become the primary choice for meeting the power and energy density demands of these aircraft. However, organisations express apprehension about battery safety, especially in the aerospace domain where the consequences of failure could be catastrophic.

Challenge

Vertical Aerospace are a pioneering and best in class management company with a technical team hand-picked from the aerospace and advanced automotive sectors and 300+ in-house engineers. The challenge for Vertical Aerospace for certifying batteries is that there was no battery diagnostic system capable of detecting potential faults in eVTOL battery packs before take-off.

With this challenge in mind, Vertical Aerospace approached WMG and set out to help fill this crucial gap in the industry. The diagnostic system was to be an innovative blend of cutting-edge electro-chemical methods, ensuring the seamless integration of advanced technology into aircraft systems.

In response to this pressing need, WMG embarked on a pioneering project to develop a revolutionary smart-diagnostic charge device for eVTOL aircraft batteries. This device aimed to enhance in-flight performance, safety, and, most importantly, enable fit-to-fly certification of the battery pack before every flight.

Image courtesy Vertical Aerospace

Solution

As part of a £2.3m project funded by ATI (Aerospace Technology Institute) through Innovate UK, a collaborative project was launched with VA. WMG's diagnostic algorithm demonstrated its capability to detect potential battery faults with unmatched accuracy. The algorithm capitalises on the battery data collected by the battery management system (BMS) during charging. The system underwent rigorous testing and validation using battery modules provided by VA. This crucial feature enabled VA to implement the diagnostic procedure for fit-to-fly certification of their battery packs before every flight, bolstering aviation safety and instilling confidence among passengers and industry stakeholders.

The device's exceptional performance and reliability not only met the project's objectives but also exceeded expectations, marking a remarkable milestone in aerospace technology.

Image courtesy Vertical Aerospace

“Battery systems including charge and diagnostics testing are well-known in academia and industry; having undergone years of development and research for the automotive market.

“An aerospace application provides a fantastic opportunity to utilise methods, designs, models, and algorithms that were not financially, volumetrically, or technically feasible before. Using these novel approaches, we plan to significantly improve the safety, range, and capability of our battery system.”

Limhi Somerville, Head of Energy Storage at Vertical Aerospace

Impact

The impact of WMG's eVTOL diagnostic technology reverberated far beyond the confines of the project. The successful outcome of this groundbreaking initiative opened doors to a broader consortium collaboration with AMEC, demonstrating the industry's recognition of WMG's ability and capabilities. AMEC (Advanced Mobility Ecosystem Consortium is aiming to demonstrate the commercial and operational viability of Advanced Aerial Mobility (AAM) in the UK, has been awarded a £9.5m grant by the UK Government’s Future Flight Challenge to develop the essential building blocks of a viable AAM ecosystem that has the potential to be progressed into full commercial operations. The algorithm for this is being further developed to extend its capability to work with new battery technologies.

Additionally, WMG's trailblazing work in aerospace electrification played a crucial role in securing funding for future projects like ZEST (Zero Emissions for Sustainable Transport). This has reaffirmed their position as pioneers in sustainable aviation research on battery safety evaluation through experimental research and creation of new models to prediction LIB failure modes appropriate to aerospace. It includes the use of novel in-cell instrumentation to measure failure and system level strategies to mitigate propagation.

The collaborative partnership with VA resulted in a mutually beneficial knowledge exchange. WMG shared invaluable expertise, code, and battery parameterisation insights with VA engineers, empowering the industrial partner with essential capabilities they lacked in-house. Furthermore, WMG provided unwavering support to VA in data factory generation, further enhancing their ability to optimise battery pack performance.

The smart charger will be used for Vertical's recently unveiled passenger model, VA-1X. Capable of carrying a pilot and four passengers for up to 100 miles at speeds of 150mph. They aim to certify in early 2026.

“The successful integration and management of battery systems within future electric aircraft represents a significant research challenge and one that WMG is excited to be working on in partnership with Vertical Aerospace.

“This project has allowed us to expand our capabilities in battery characterisation, battery system modelling and novel methods of fault diagnosis and prognosis. All within a sector that is strategically important for the UK as it move towards its zero emissions transport targets.”

Professor James Marco, University of Warwick

Notably, the development of the eVTOL diagnostic device revolutionised aerospace battery technology. The technology's uniqueness and pioneering nature can potentially increase battery pack usage in various aircraft and promote second-life applications. By extending battery life and repurposing used packs, the project aligns with sustainability goals, reducing the environmental impact associated with battery manufacturing.

Conclusion

WMG's commitment to innovation and excellence in aerospace technology has borne fruit through the development of the eVTOL diagnostic device. This project produced a prototype smart-diagnostic algorithm for the eVTOL aircraft battery. It will use innovative and cutting-edge electro-chemical methods and allow improved in-flight performance, safety, and assist in future certification of battery systems.

The prototype smart-diagnostic charge device is poised to redefine the future of eVTOL aircraft, enabling greener and safer flights, and paving the way for a sustainable aviation industry.

As the world continues to embrace electrified aviation, WMG's expertise stands ready to shape the future of aerospace technology. Their portfolio of success stories and invaluable contributions to the industry is a testament to their dedication for progress and sustainability. Companies and organisations in the aerospace sector can find a reliable partner in WMG, poised to propel them into a new era of innovation and success.

Find out how WMG can help you start your own success story in aerospace electrification. Contact us at wmgbusiness@warwick.ac.uk and embark on your journey towards innovation and sustainable aviation solutions.

Manufacturing Energy Toolkit in Action Alucast cuts energy costs by £78,000 with clever machine monitoring

“In the current energy crisis, the Manufacturing Energy Toolkit (MET) has been beneficial to Alucast, as we are a high energy user with three aluminium foundries. The team at WMG has helped the company reduce our energy usage, lower carbon emissions, and save waste.”

Tony Sartorius, Chairman, Alucast Ltd

Challenge – How to reduce energy usage in busy machine shop

Alucast is an aluminium foundry in Wednesbury, (West Midlands), and a very high energy user. Like other manufacturers, Alucast were struggling with increased energy prices. Their fixed rate was coming to an end, with prices going from £0.14 per kWh to £0.44 per kWh - a 300% increase in energy costs. They needed to reduce their consumption drastically and identify energy wastes.

One key area to focus on was to investigate the energy consumption of their machine shop and to see whether there was scope to minimise energy usage there.

Solution – Make use of WMG’s Manufacturing Energy Toolkit

Alucast heard about WMG’s Manufacturing Energy Toolkit which was launched at the height of the energy crisis to help manufacturers identify practical ways to reduce energy usage and quickly got onboard. Sustainable manufacturing specialists Laura Downey and Veer Angadi at WMG suggested that Alucast should implement shut down periods over the weekends rather than leaving machines idle. A common myth with manufacturers is that by fully shutting down machines, there will be issues with restarting them again. However, this is an easy quick win to begin making savings.

They then kick started a project to identify the potential savings and de-risk the process of shutting down machines both over the weekend and during the working week. Using a series of monitoring devices, they measured consumption of four different types of machines (17 machines in total) when left idle compared to being switched off. Essentially by managing machine uptime more effectively to ensure energy is only used when processing parts, it eliminates idle time energy use to create substantial CO2 reductions, whilst at the same time reducing KWhs used.

capture the heat.

Impact – Big cost and CO2 savings

Through their analysis, Laura and Veer discovered that over a two-year period Alucast could save 95,107 kWh in energy usage, which equates to £78,225 and 19,971 kg in CO2 equivalent. To put this into perspective, 19,971 kgCO2 is equal to 19.9 tonnes. This is the equivalent of driving 65,670 miles in an average car or driving around the world in a diesel car 2.86 times.

And this is for just two years, the savings will be more and more over time.

The percentage energy consumption saving over the weekend is 100% but over a working week this will save an average of 19%.

“This is a great example of our Manufacturing Energy Toolkit in action. The programme is really ramping up now, helping many manufacturing businesses both save energy and increase profitability while also supporting the UK with its net zero targets.

Dr Mark Swift, Director of SME Engagement, WMG, University of Warwick

For more information on working with WMG, please email wmgsme at warwick dot ac dot uk

Aerospace components supplier uses automation for in-process quality control

Summary: SKF Limited is a leading supplier of parts and components for the aerospace industry, including precision-made bearings. WMG and SKF developed a non-contact, in-process vision system which can measure individual component dimensions and dynamically adjust the downstream assembly process, reducing assembly issues and therefore rework. This has led to reduced costs across the assembly line, increased productivity, and an increase in quality.

Background

SKF Limited is a world leading supplier of a range of parts and components for the aerospace industry, including supplying Original Equipment Manufacturers (OEM) and Maintenance Repair Overhaul (MRO) companies. The aerospace industry requires sub-components to be made with a high level of precision, meaning quality control during manufacturing is of the utmost importance.

Challenge

The parameters of the bearing assembly process are determined by assuming nominal dimensions of all the subcomponents. However, small variations in the dimensions of each subcomponent can result in a mismatch in the assembled subcomponent sizes, which causes inconsistent product performance and requires rework to correct. This causes a significant cost increase and prevents SKF from entering the higher volume/lower cost markets.

Solution

To address this, SKF worked with the Automation Systems Group (ASG) at WMG, University of Warwick to develop a high-accuracy, non-contact in process measurement system which allows SKF to use the dimension information collected to dynamically customise the downstream assembly process. This allows SKF to work towards a ‘right first time’ manufacturing methodology, reducing rework costs, and assists in the adoption of automated quality control/inspection functions that are currently completed manually.

This solution utilised a static 3D stereoscopic camera to measure the dimensions of each component while it is rotated on a bespoke platform. This had major benefits over other solutions such as rotary laser line scanners, including lower cost, lower computational power required, and better metrology data produced. The only disadvantage was the greater automation burden to rotate the component to measure all sides.

Initially a proof of concept was developed, which was trialled using representative SKF parts. This was then put through a qualification test to compare this new system with traditional techniques and the results found that the new automated system was faster with similar accuracy compared to traditional measurement methods